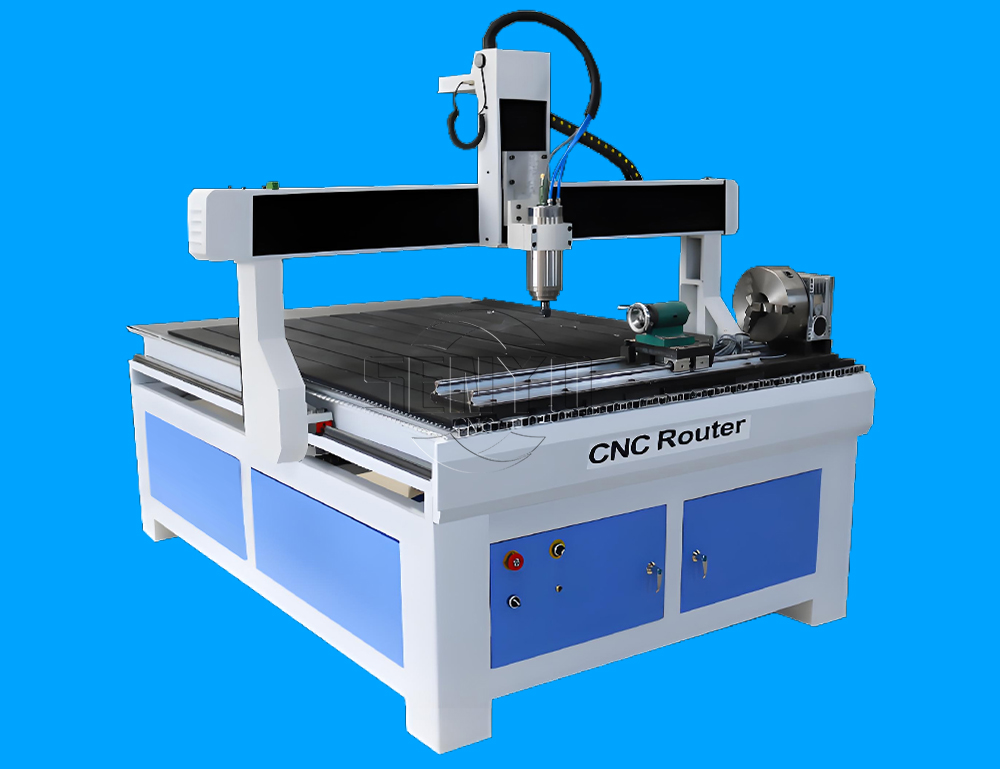

What Is A 4 Axis CNC Router?

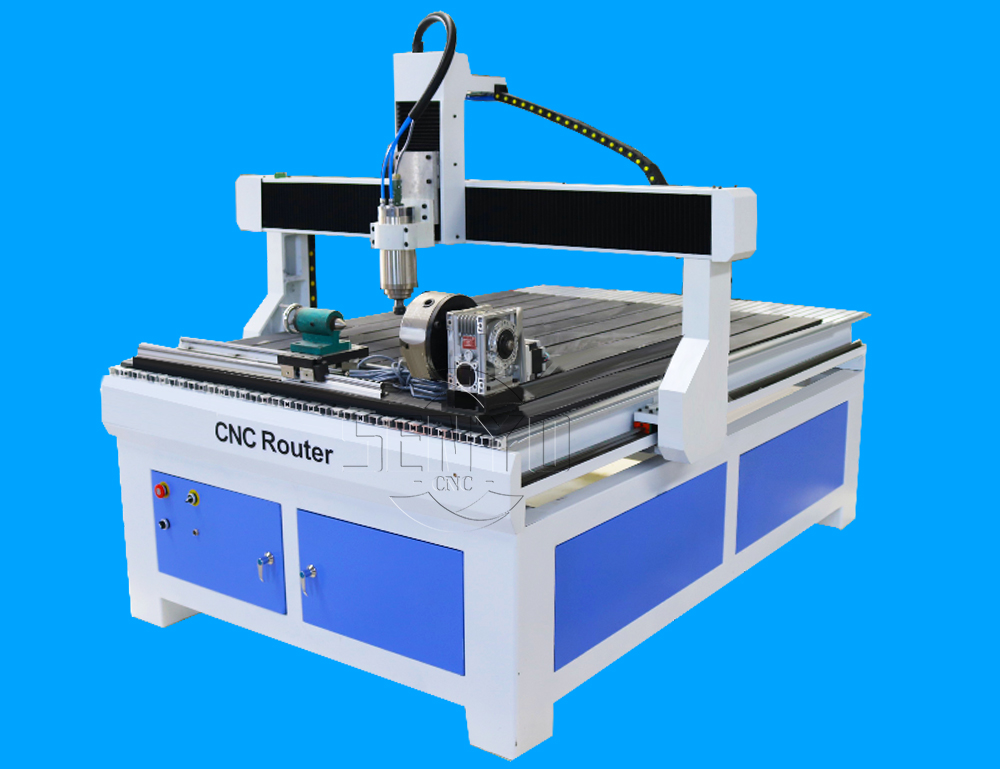

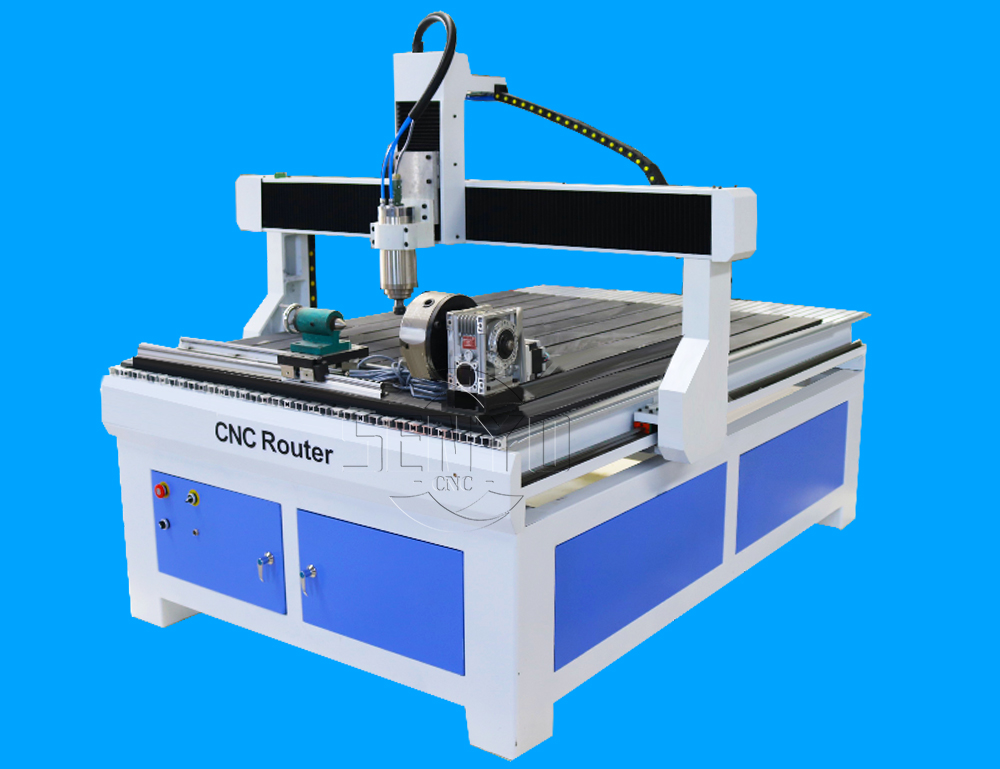

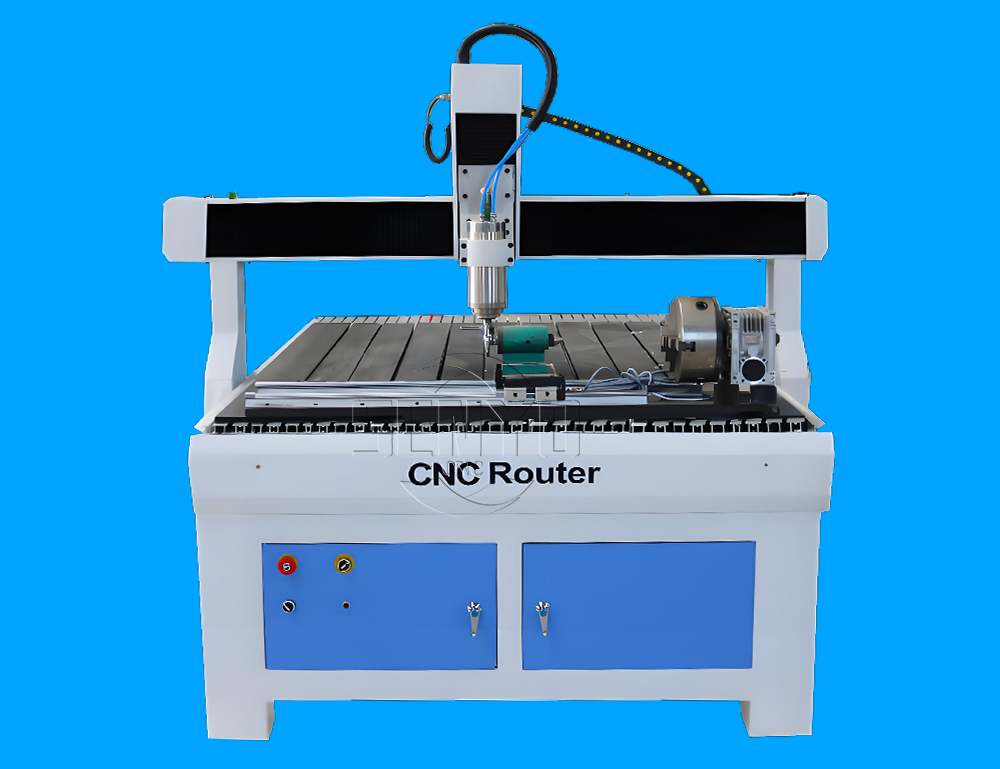

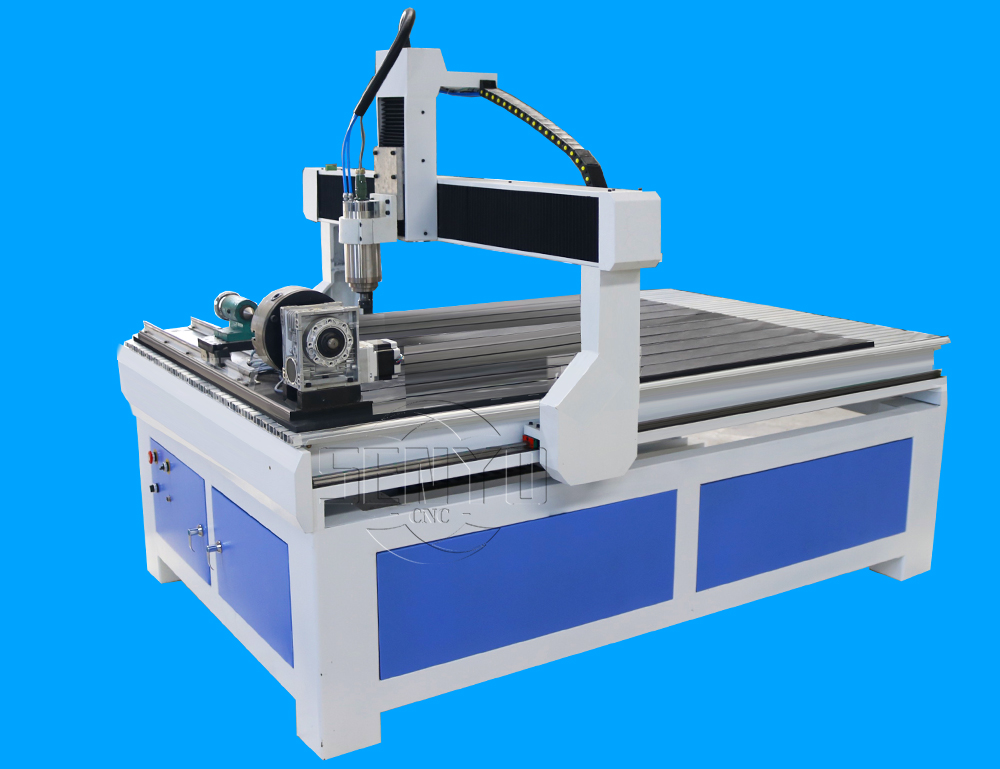

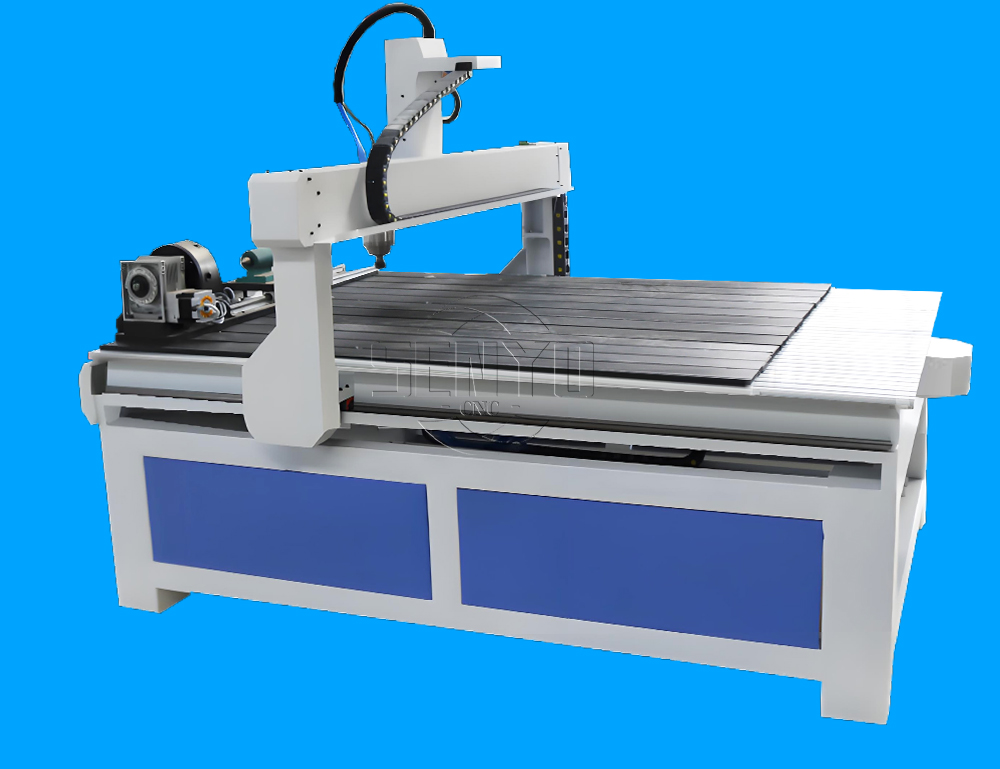

A 4-axis CNC router is a type of basic CNC machine with an X axis, Y axis, and Z axis,With rotary Axis.

It will go along three different axes at the same time. The X-axis will move from left to right, the Y-axis will move from front to back, and the Z-axis will move up and down. 3-axis CNC machines are used primarily for machining flat, 2D, and 2.5D parts. Rotary working 3D.

A 3-axis CNC router is also known as a 3-axis CNC machine, 3-axis CNC cutter, and 3-axis CNC carving machine. The functional software behind any CNC machine is its CAD/CAM software. CAD software allows users to create the designs they wish to engrave. After completing this design, the CAM software converts the design into toolpath code that the machine can understand. The computer then converts this code into a signal that controls the movement of the machine's drive system. The drive system includes a spindle, which is the part that saves the actual machine position. The spindle rotates 8,000 to 50,000 times per minute to cut the material. In short, users create designs and use software to make instructions for the machine.

4th rotary axis hobby CNC router for sign making is the best automatic hobby machine tool for small shop, home business and craftsman. The rotary 4th axis CNC machine is used for custom signs & signage or DIY signs with wood, acrylic, PVC, MDF, plastic, foam, copper, aluminum.

What Is A 4x5 CNC Router?

4x4 CNC router is a type of automatic hobby CNC machine with a 48" x 48" (4x4 feet or 1200x1200 mm) tabletop with a DSP controller for small business, home use, or school education. 4x4 CNC router table is suitable for a variety of materials, including wood, plywood, MDF, foam, plastic, stone, copper, brass, and aluminum.

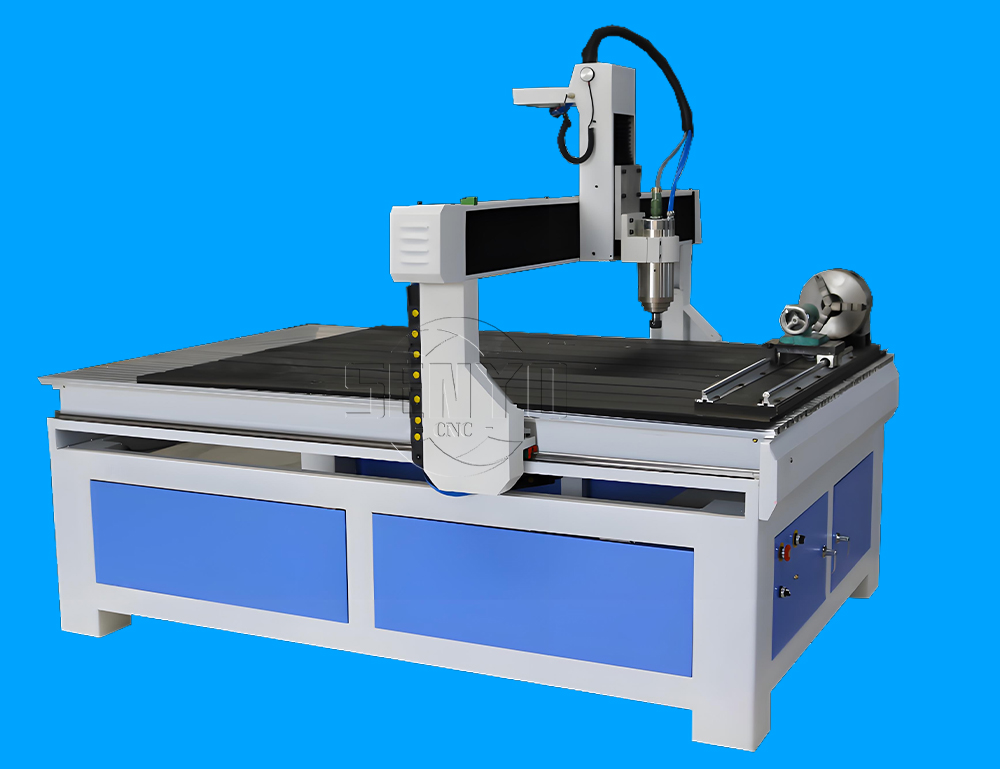

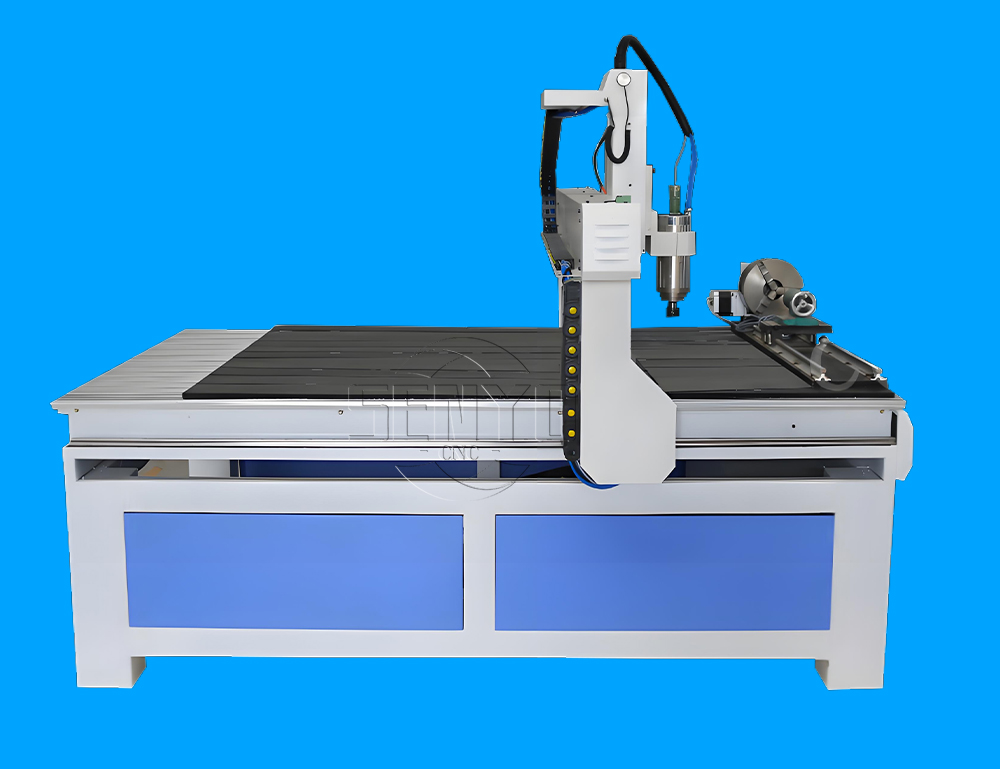

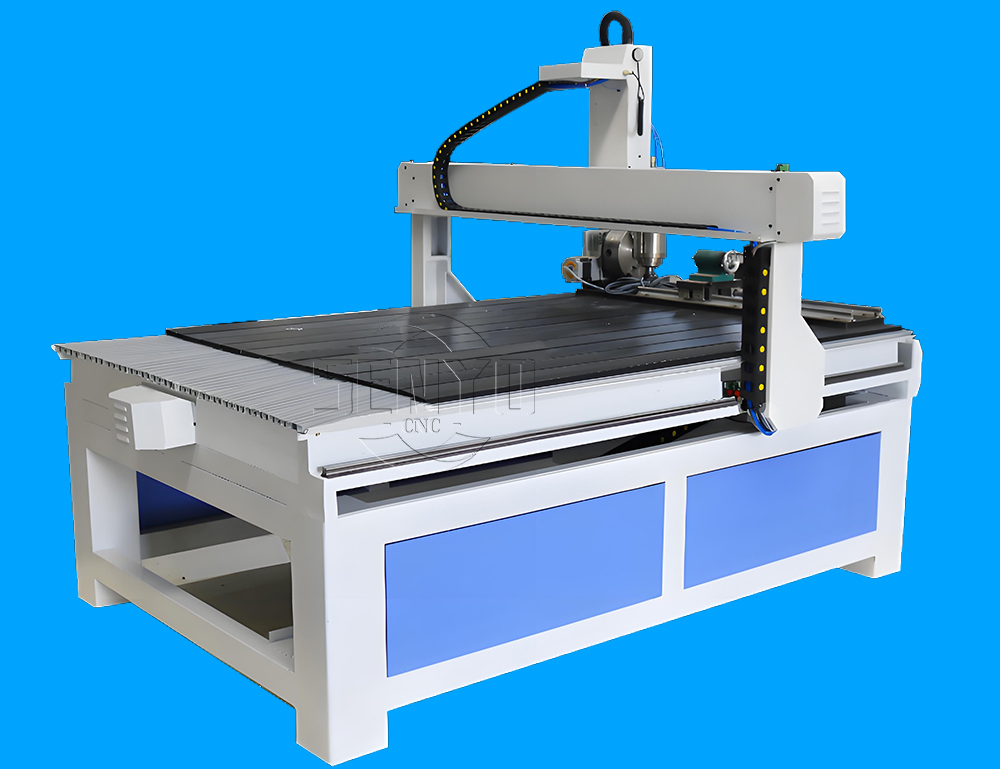

SYG1218 is one 4x5 CNC router table kit with 1200mm x 1800mm table size. Of course, other table sizes can be customized to y

our requirements, like 2x4, 4x8, and 5x10. If you have any 4x6 CNC routing plans or ideas, feel free to tell us.

How Much Does A 4x5 CNC Router Cost?

Several factors are responsible for the wide price range of 4x5 CNC routers. Depending on brands, models, quality, and features prices can reach to maximum. Additional accessories with the kit add more to the expenses.

The average cost to own and operate an entry-level 4x5 CNC router with 3 axeshas soared about 10% since last year to $3,680 due to the rising shipping costs. The prices of professional 4th axis types with 4x6 vacuum table for rotary carving & cutting start from $4000. The high-end 4-axis or 5-axis types for 3D machining are priced anywhere from $10,800 to $78,000.

Considering the usability and performance of the machine an entry-level 4x6 CNC router and table kit might start from $5,000 to $10,000 depending on models and brands.

Mid-range 4x6 CNC routers with better build quality, more advanced motion control systems, and additional features can range from $10,000 to USD 20,000.

High-end or industrial-grade 4x6 CNC routers can cost upwards of USD 20,000 or even more.

Advantages

1. Integral cast iron frame, more durability.

2. Taiwan HIWIN square rails ensure the machine frame has much stability and durability.

3. The 3-axis adopts a high-accuracy ball-screw from Taiwan to ensure the machine working with better precision.

4. DSP handles controlling, not occupying computer resources, one computer can control several pieces of equipment.

5. Be compatible with various CAD/CAM software such as Type3, ArtCAM, Casmate, and Artcut.

Application & Industry

Wood furniture industry | Doors: Cabinets: Tables: Chairs. Wave plate, fine pattern, antique furniture, wooden door, screen, craft sash, composite gates, cupboard doors, interior doors, sofa legs,headboards and so on |

Advertising industry | Signage;

Logo; Badges; Display board, Meeting sign board, Billboard Advertising

filed, sign making, acrylic engraving and cutting, crystword making,

blaster molding, and other advertising |

Mold industry | Sculpture

of copper, aluminum, iron and other metal mold as well as artificial

marble, sand, plastic sheeting, PVC pipe and other non-metallic mold |

Artwork and Decoration | Wood crafts, gift box, Jewelry box |

Others | Relief sculpture and 3D engraving and cylindrical obiect |

Project Samples

Techology Paramaters

Model | SYG1218 |

Working area | 1200*1800*200mm |

Body Structure | Stable and Strong Welded Steel |

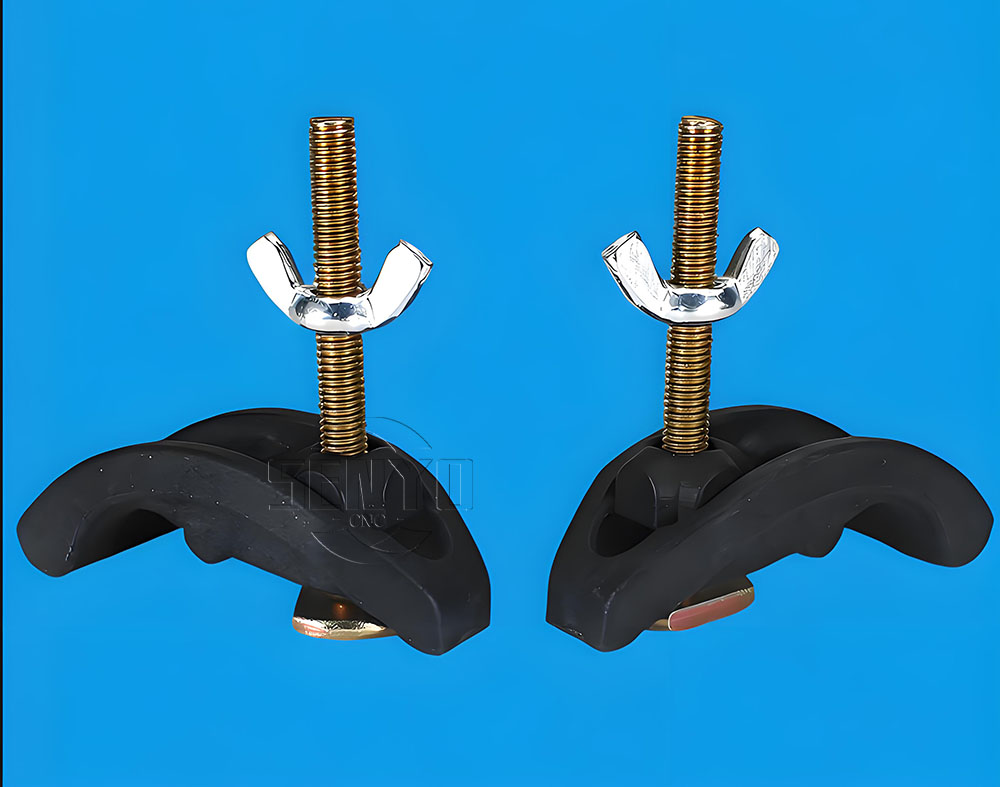

Table style | T slot table |

Guide rail | Hiwin linear square guide rail |

Driving method | Taiwan Original TBI Ball screw; |

Spindle | HQD 2.2KW water cooling spindle |

Motors and drivers | Leadshine Stepper drive and Motors |

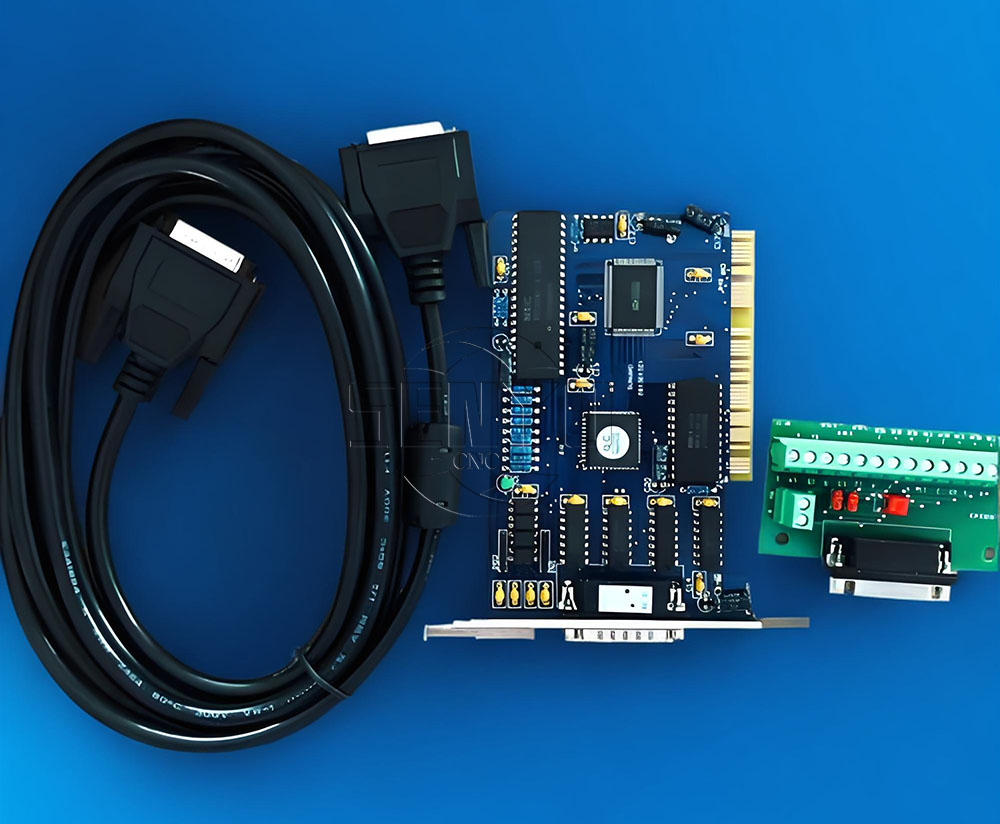

Control system | NC-studio. Mach3, DSP |

Inverter | Fuling /Best Inverter |

Working Accuracy | <0.003/300mm |

Working speed | <10000mm/min |

Traveling speed | 0-10000mm/min |

Instruction formate | G code *.u00 *.mmg *.plt |

Working voltage | AC220V 50Hz/60Hz |

Standard Software | Artcam |

Compatible software | Type3/Castmate/Coreldraw/AutoCADor other CAM/CAD softwares |

Environment temperature | 0-45℃ |

Environment humidity | 30%-75% No coagulate water |

Position cylinder | Yes |

Tool sensor | Yes |

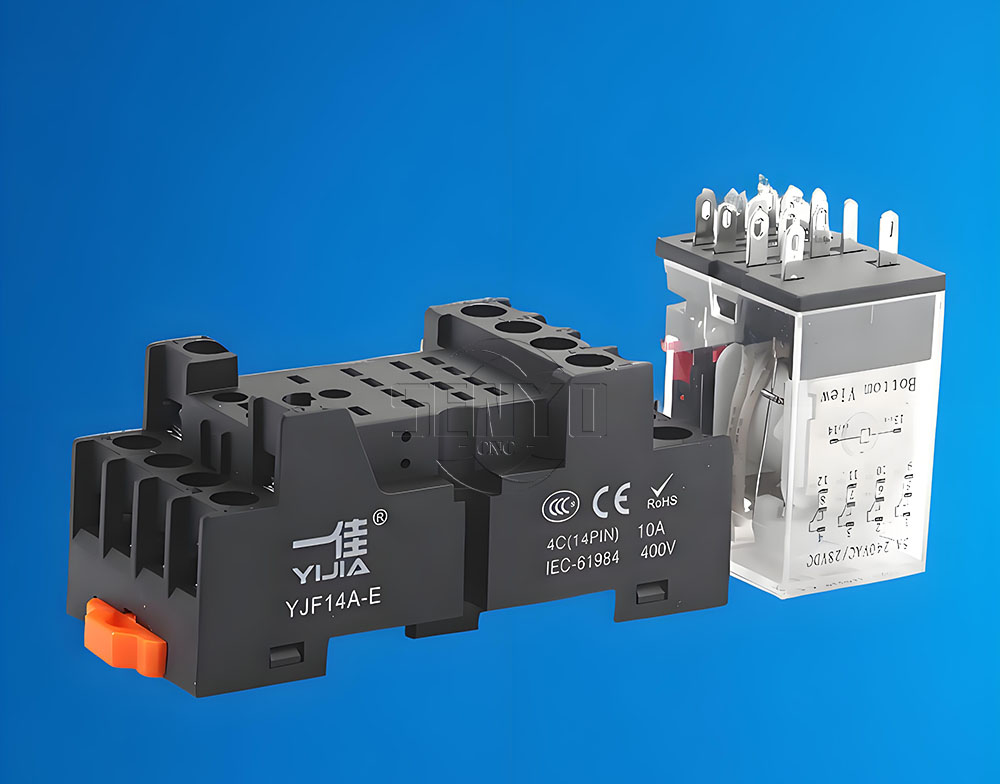

Other | Oiling system; Tool Box,English manuals etc. 2.2KW Single bag dust collector;4 sets tools;Switch and emergency stop: SCHNERDER switch, Omron emergency stop from Japan |

Packaging Details

• Outside package: Standard marine export plywood case.

• Inner package: Stretch film and plastic film for humidity.

We can package according to your requests.Delivery Detail: Shipped in 10 working days after payment.

For Our Work Steps

1.Before-sale,we will try to know your requirement about our cnc router specification and what kind of work

you will do .then we will offer our best solution for your requirement.

2.During production: we will send photos of machines during making. so you can know more details about

the procession of making your machines.

3.Before shipping,we will take delivery photo and confirm the specification of order to avoid the mistake.

Machine will be adjusted before it is delivered.

4.After shipping: we will sent out the documents for your customs clearance ASAP . and check the

approximate date of arrival.

5.After arrival: we will confirm with you if machine is in good condition.and see if any spare parts missing .

6.About teaching: there are some manual and video about how to use machine , if you have question

about it. we will have professional technicist to help you install and teach how to use through skype ,

calling, video or mail.

Before shipment---Factory technicians will carry out debugging and testing to ensure that there is no problem with the machine before deciding whether to proceed to the next step!

After the shipment is confirmed - the corresponding staff who contacted you will send you pictures and videos of the machine to confirm with you. After confirming that there is no error, will be packed - waiting for delivery instructions.

Tips to Maximize 4x5 CNC Router Machine & Table Kit Efficiency

To achieve higher productivity and better efficiency a few tips may work out for most. Our exclusive expert suggestions are given to make sure you get the most out of your tool.

✔ Make sure the material is flat, clean, and securely fastened to prevent errors.

✔ Ensure optimized tool paths using CAM software. This will reduce machining time, and maximize the cutter lifespan.

✔ Do similar projects in batch which will reduce setup time for different projects.

✔ Keep track of the tools using a tool management system.

✔ Experiment with different parameters to gain the best fit for any manufacturing task.

✔ If the router is equipped with a vacuum table setup it with proper sealing and zoning.

✔ Comprehensive training for the operators is as important as others to achieve greater output from your machine.

✔ Last but not least, regular maintenance will ensure better performance of your machine like others.

Buying Considerations

The right CNC machine for your project is going to provide a higher margin on ROI and is a valuable investment for the future.

versatile CNC router is always going to support you financially. Some key factors can assist you in finding the best CNC router model for your business. Have a look at them.

• CNC routers are available for various industries. Therefore, assess your needs according to the type of your projects and materials.

• Keep in mind the volume of your projects as well.

• Balance between cost and features. Consider the long-term value of investment while choosing your model.

• A promising warranty assures a better quality of the machine.

• Look for brands providing training resources and community support.

Trouble shooting

Error 1: After opening the software, the computer prompts "Cannot open the card, query card prompt".

1. Check whether the driver of the board is installed properly, or change the board to a PCI slot.

2. Reinstall the two data cables and check if there is any broken needle.

3. Replace the board.

Error 2: Open the software prompt: Three-axis alarm, initialization error signal.

1. Check whether the two data cables of the computer and the machine are connected properly.

2. Check whether the fuse of the adapter board in the control box is burned out, and replace the fuse.

3. Check whether the power supply is normal.

Mistake 3: The routing is misplaced or the size is wrong.

1. Check whether the path of the routing software is correct or not.

2. Check the gap size of the screw rod and whether the fastening screw of the polished rod is loose.

3. Check whether the software parameters are set correctly.

Error 4: The spindle motor does not rotate or reverse.

1. Check the inverter parameter settings.

2. Check whether the signal wire of the inverter is connected reversely.

Error 5: The phenomenon of smashing the bit occurred.

1. The power of the Z-axis motor is not enough, and the coupling is loose.

2. The current of the Z-axis driver is too small, or the signal wire is connected incorrectly.

Care and Maintenance

⇲ The continuous operation time is less than 10 hours per day to ensure the cleanliness of the cooling water and the normal operation of the water pump. Never cause water shortage in the water spindle motor. Replace the cooling water regularly to prevent excessive water temperature. If the working environment temperature is too low in winter, the water in the water tank can be replaced with antifreeze.

⇲ Every time the machine is used, pay attention to cleaning. Be sure to clean up the dust on the platform and transmission system, and lubricate the transmission system (X, Y, Z axis) regularly (weekly). (Note: The X, Y, and Z three-axis polished rods are maintained with engine oil; the screw part is added with high-speed butter; if the working environment temperature is too low in winter, the screw and polished rods (square rail or round rail) should be washed and cleaned with gasoline first, And then add oil, otherwise it will cause excessive resistance in the transmission part of the machine and cause the machine to misalign.)

⇲ For maintenance and inspection of electrical appliances, the power supply must be cut off, and only after the monitor has no display and the main circuit power indicator light goes out.

When the CNC machine does not work normally, it may be due to a problem with its internal components or other reasons. The following is a general introduction to the frequently occurring problems.

⇲ One of the three axes cannot be moved. At this time, check whether the drive block corresponding to the corresponding axis is damaged. The inspection method can use the replacement method: unplug the aviation plug corresponding to the fixed shaft and plug it into the drive corresponding to the other active shaft.

⇲ If the immovable shaft moves normally after the exchange, it can indicate that the drive block corresponding to the shaft has been damaged and the drive block needs to be replaced. If the shaft does not move, it means that the cable or motor is faulty. Replace the cable or motor. None of the three axes can move. At this time, check whether the three-axis aviation plug has been connected to the control box and whether the power of the control box has been turned on. Whether the data line is well connected with the control box and the control card in the host computer. If the above is normal, please contact the factory.

⇲ The spindle cannot run normally, first, check the error code displayed on the LED display of the inverter.

Warranty And Service

• 24 months whole machine warranty and maintenance for a lifetime.

• Free installation and testing before shipping and free training for operators

• Advice for the best CNC solutions for customer's requirements.

• Free training and sample making.

• 7/24 free service and support.

1. Small CNC router for woodworking

2. Best small CNC router

3. Mini CNC router machine

4. Affordable small CNC router

5. Desktop CNC router

6. Small CNC router for metal

7. Compact CNC router for hobbyists

8. Small CNC router for beginners

9. Precision small CNC router

10. DIY small CNC router

11. Small CNC router with software

12. Entry-level small CNC router

13. Small CNC router for engraving

14. Mini CNC router for 3D carving

15. Portable small CNC router

16. Best small CNC router for home use

17. High-speed small CNC router

18. CNC router for small businesses

19. Affordable CNC router for hobbyists

20. Small CNC router machine for sale

• Next: None

Fiber metal Laser Sensor And Its Application

Category: SENYO NEWS 11th Mar, 2021A CNC wood router will use 3D machining in relief carving, the effect is more artistic beauty, but also has a strong sense of three-dimensional 3D, realization of this function is to ...

Precision Cutting Stents with Fiber Lasers

A CNC wood router will use 3D machining in relief carving, the effect is more artistic beauty, but also has a strong sense of three-dimensional 3D, realization of this function is to ...

How to Laser Cut Copper and Other Reflective Metals

Laser cutting of mild steel and stainless steel has a long history and has been one of the primary applications for CO2lasers. However CO2lasers have not traditionally offered a good solution for cutting highly reflective materials.Fiber lasers have an emission wavelength of around

Laser Cutting Machine Inspection Process For Manufacture

SENYOCNC Have Strict quality monitoring will be carried out when the parts are in the factory.

How Control Costs Use of UV Printers ?

UV flatbed printers are rapidly being used by more and more manufacturers, thanks to its efficient production efficiency, and the control of production costs also needs to arouse our attention.

Why UV flat printing machine is popular in market ?

For the majority of designers, give full play to the creative ability, the design sample can be arbitrarily modified on the computer, the effect on the computer, is the effect after the finished product, customer satisfaction can be directly produced. UV flat printing pattern fine, rich and clear layers, high artistry, strong three-dimensional sense, many high precision equipment can also print photography and painting style patterns.

How does UV ink jet printer save UV ink?

UV inkjet printer use process is an important consumable UV ink, reasonable use of equipment, can save UV ink , it can be said to be the best choice to directly save the cost. In the process of using some skills you need to be familiar with, the following small make up to share with you:1. Try to us

Waterjet Machine delivery and Shipping

Please tell us your max working size and what materials will cutting , also what max cutting thickeness.If you have Working photo sample please also send us , it will be helpful to choose machine with suitable models .

Waterjet Machine finish manufacture 5axis

Waterjet cutting technology is one of the fastest growing major machine tool processes in the world due to its versatility and ease of operation.

Waterjet Machine delivery and Shipping

Waterjet cutting technology is one of the fastest growing major machine tool processes in the world due to its versatility and ease of operation.There are multiple advantages to adding waterjet cutting capabilities to your shop.We are company leading ultrahigh-pressure waterjet system so

How to Create Connected Text – Inkscape for Laser Cutting

Step 1: Create Some TextFirst, we need some text to work with. To create the text, select the Text Tool (keyboard shortcut: T), click somewhere on the canvas, and type your text.You can use the drop-down list on the top left to select your desired font.Step 2: Convert Text to PathNext, we need to tu

Jacob from United States

I am a beginner at CNC, I’ve never used a CNC machine before and with in a day I was carving. An awesome machine for a beginner to learn as hobbyists. I used the manual and the help video. One hour to assemble and test, very friendly and easy to use. It’s a good buy for the money. I would definitely recommend this machine to someone getting into CNCs.

Weinstein from France

I've been using CNC plasma SYP2060-300A and I am very impressed with this unit.

This unit is of higher quality, made in China. Five stars all the way!

2040 from INDIAN

Best 2040 CNC Router Good Price and Quality ! Thank SENYOQC

10w uv laser from American

Best supplier ! I bought 3 machines for laser and router , thank you Aillen ! --Alec

12KW Fiber Cutting - 2000X6000mm -- 이병헌 from Korea

Good machine for metal cut ! Thanks Senyo , Its prefect , I like your business patient kind!

I am a furniture manufacturer, and this machine is very good and fast. thanks Senyoqc Team ! from Bangladesh

Metal ArtWork from Denmark

The plasma cutting machine makes my artistic creation more convenient and precise!! Created more artistic ideas and value! Thank you Aillen team!

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen. from

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen.

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo from

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo

Thank you Senyo for SYJ1290-150W! from

Retired, ex mainframe systems programmer. Now full-time recreational woodworker majoring in puzzles, pens, boxes, Toys and occasional small furniture. Thank you Senyo for SYJ1290-150W!

manager@senyocnc.com

manager@senyocnc.com

SENYOCNC

SENYOCNC

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

2061579344

2061579344