+86 1525 3141 880

+86 1525 3141 880

Mini Desktop CNC Router for Gifts Making Small Business

Best Granite marble manual polishing machine For Sale

Stone Processing CNC Equipment Automatic Tool Changer CNC Quartz Stone Machining

3020 40W Mini CO2 Laser Engraving Cutting Machine

New Design Mini Stone CNC Machine for Marble, Granite and Quartz

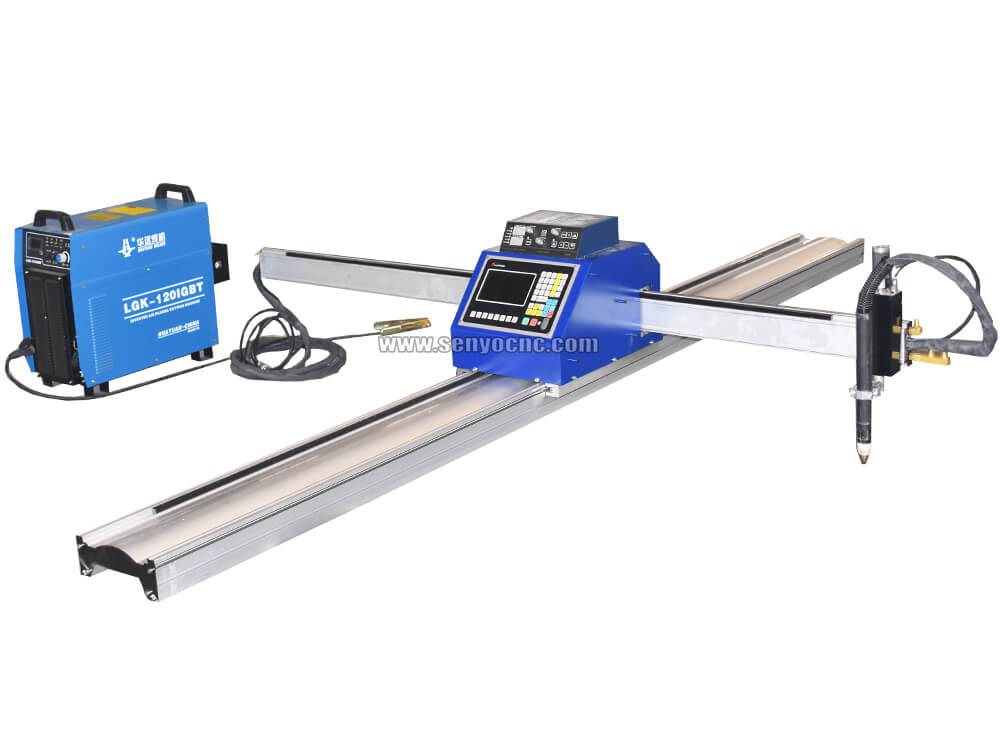

Portable CNC Flame Cutting Machine with Plasma Torch for Sale

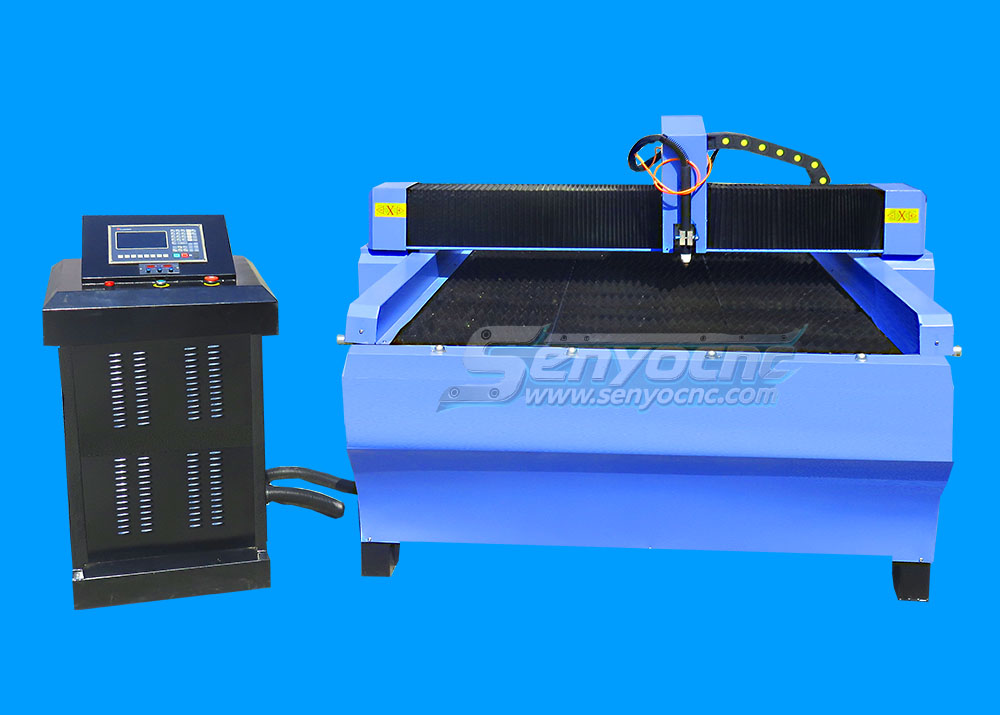

High-Precision Mini Hobby CNC Plasma Cutting Machine for Metal

Mini CNC Plasma Cutter With Rotary

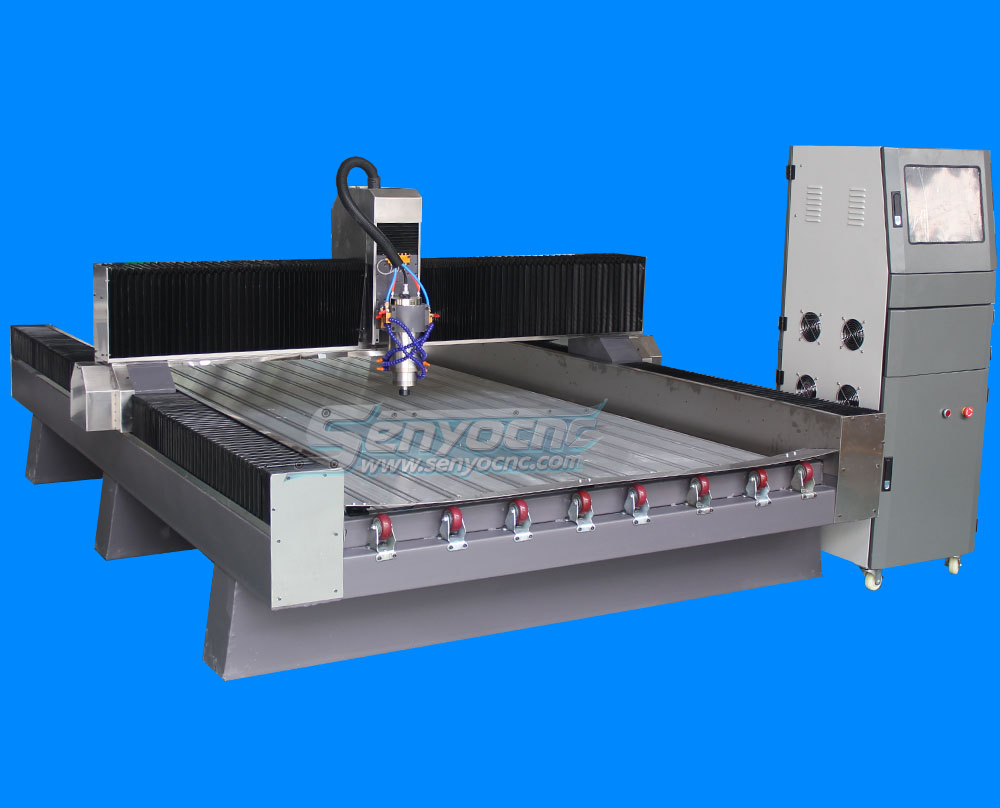

4 Axis 1325 Sculpture Machine Cnc Carving Marble Granite Stone Cnc Router

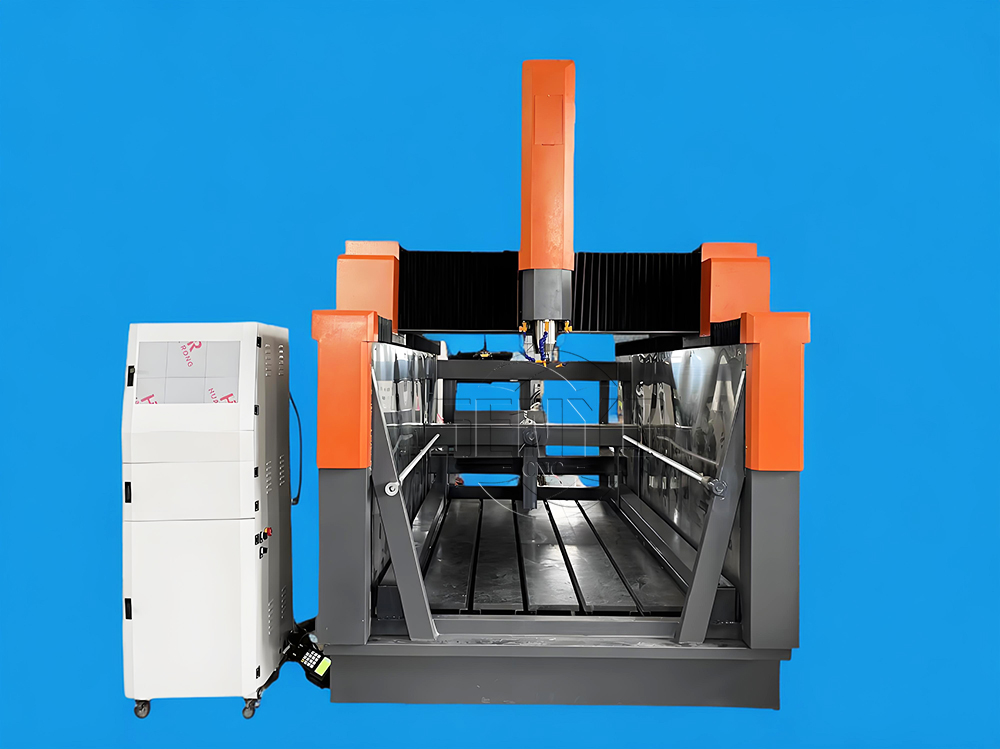

Z Height 1000MM 4-AXIS Stone Engraving CNC Machine Heavy-duty Stone CNC Machine Stone Relief Carving CNC For Sale

4030 portable mini co2 laser carving and desktop rubber stamp laser engraving machine

Stone CNC Router For Kitchen sink tile carving and cutting Marble, Granite and Quartz

Robust CNC Plasma Cutting Machines with Flame Cut Head for Heavy-Duty Industrial Use

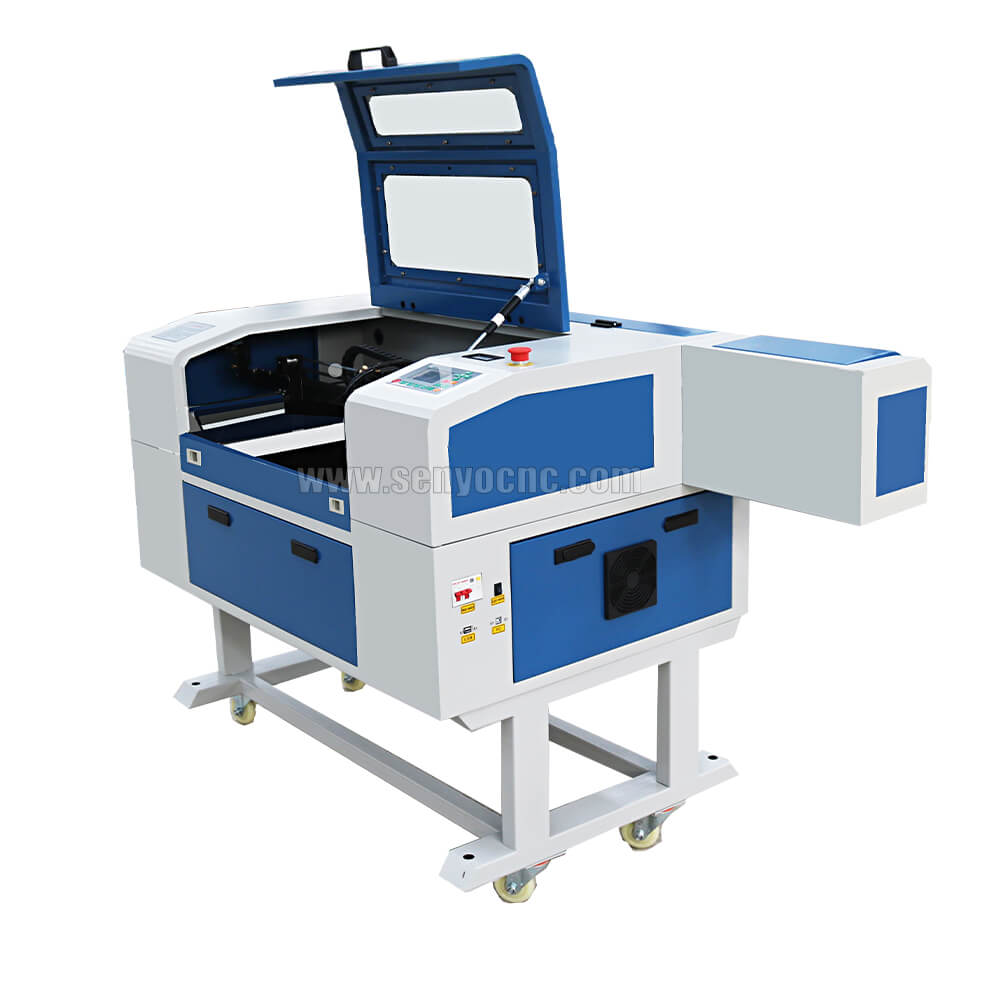

Small Portable CO₂ Laser Cutter Engraving for DIY & Business – Ideal for Wood, Acrylic, Leather

1325 3 Axis 4x8 CNC Stone Router for Sale

Mini CO2 Laser 5030 Cutting Engraving Machine For Sale

Portable CNC Plasma Flame Cutting Machine for Sale at Cost Price

Portable Cnc Plasma Oxyfuel Sheet Metal Cutting Machine for sale

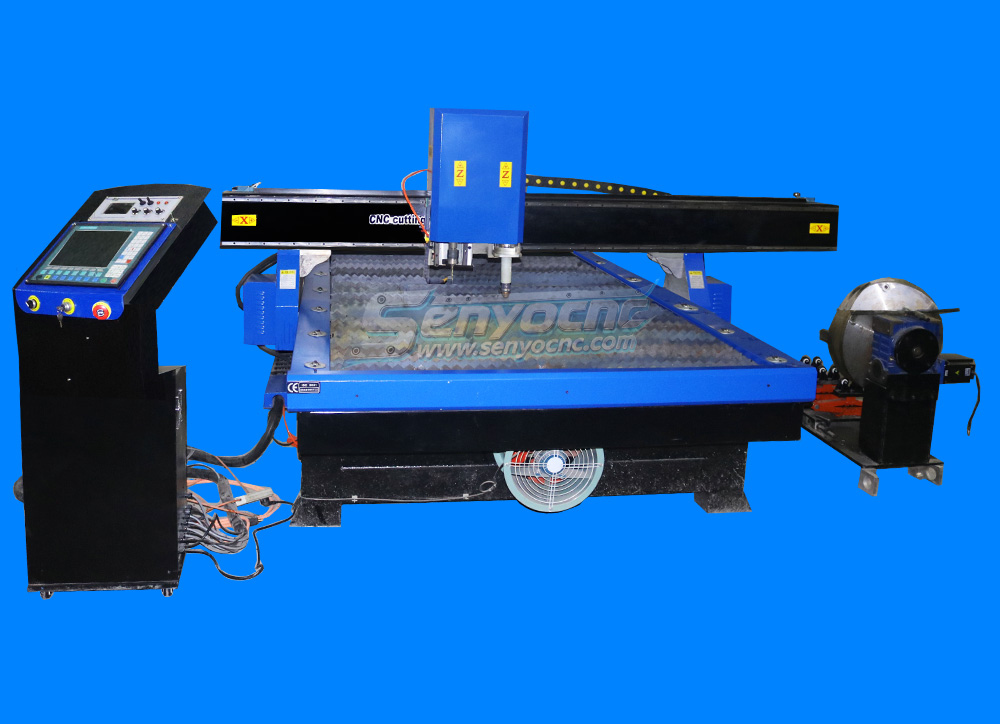

CNC Plasma Cutters for Customized Metalwork –Rotary&Drilling Head

Small Table design 6040 Easy Move CO2 Hobby Laser Cutter Machine for Beginners

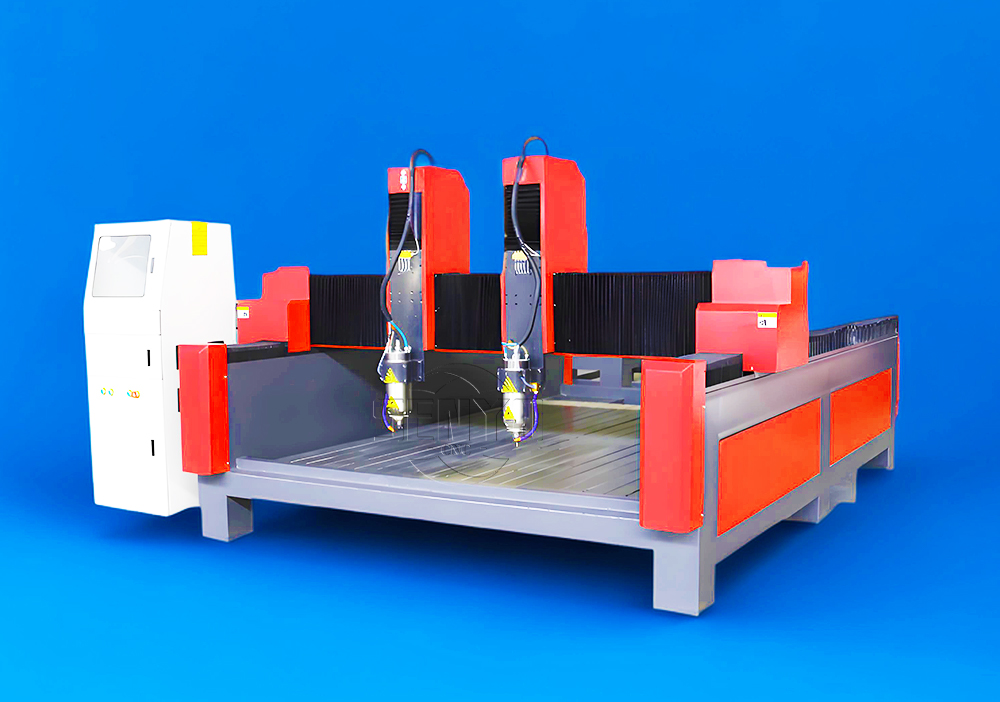

High-Efficiency 2 Heads CNC Machine for Aluminum Stone Marble Engraving & Cutting

Best CNC 2 Spindle 4-AXIS Stone Carving Machine High-precision Stone Carving Stone Countertop Fabrication

Top Rated 2x3 CO2 Hobby Laser Cutting Machine for Sale at Affordable Price

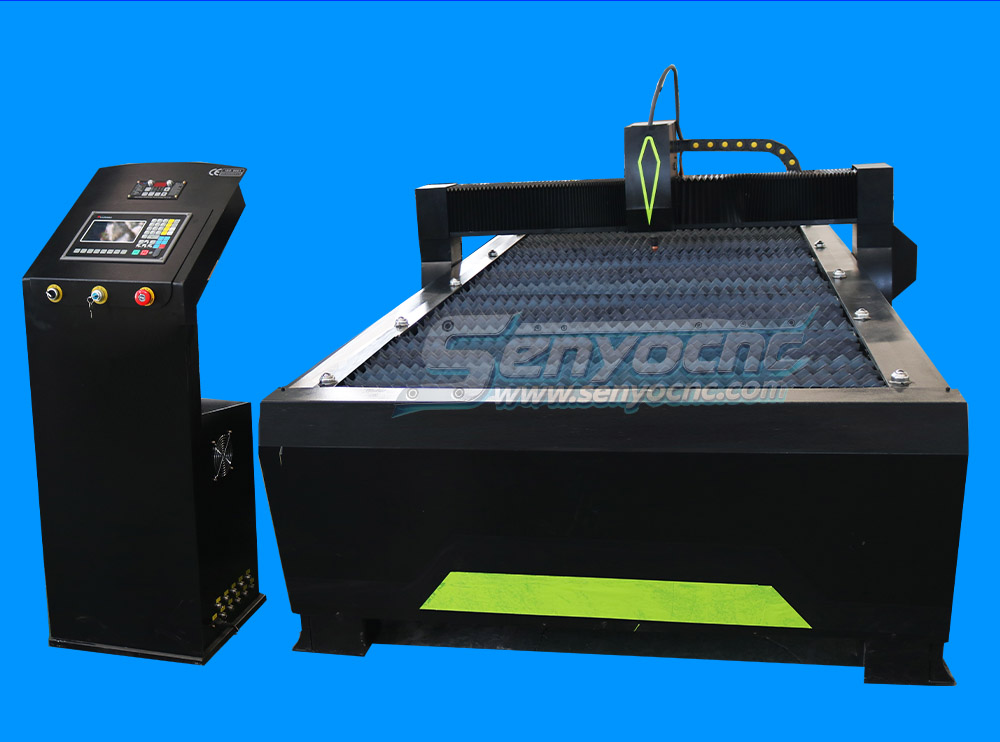

Best 4x8 CNC Plasma Cutter Table for Sale at Affordable Price

Entry Level CO2 Hobby Laser Cutter Machine for Beginners

Top CNC Plasma Cutters for Automotive, Aerospace, and Manufacturing Industries

Precision Stone Engraving Machines for Memorials & Signs

Portable Co2 9060 Laser Nonmetal Cutting Engraving Machine

1090 CO2 Laser Machine with Ruida Controller for Non-metal Glass Acrylic Engraving Cutting

Entry Level 9060 CO2 Hobby Laser Cutter Machine for Beginners

2040 from INDIAN

Best 2040 CNC Router Good Price and Quality ! Thank SENYOQC

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen. from

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen.

CNC Router I love woodworking and the Joy in the Journey! It's a Blessing! from Ricky

CNC Router I love woodworking and the Joy in the Journey! It's a Blessing!

4040 Mini Desktop CNC Router for Small Business from France

Good Machine! Wonderful Service !

Thanks Senyoqc Team for whatsapp Group services , Excellent enginner ! Good work!

SYM1530ATC-A2 from

Thank you Aillen, You are really good person for advice model and service. My furniture work doing very good, thanks

5 axis cnc router machine works very good from UK

We bought An 5 axis cnc router . 5axis CNC routers are popular amongst universities to produce 2D and 3D objects from wood, plastics, foam and many more materials.

Universities and schools across the world have produced many prototypes using their CNC machines. CNC routers are popular in architecture,

woodworking, physics and engineering, for projects and research and development.

Francisco from Portugal

A máquina CNC funciona muito bem.

A fresadora CNC 1325 é uma unidade bem feita e não encontrei problemas com a qualidade de construção ou operação.

Daisuke from Japan

It is still working well since I purchased it.

The Wood working center is really convinient machine for my wood work, I am happy to give the 5 stars to this !

Besnik from Albania

Hi all,

Hopefully you have all seen the results of using my SYM1325 ATC CNC machine to make a Fende replica and I'm very happy with how it came out.

I have started with the neck as this is where most of the work is and the conversion has worked OK for dimensions (I've checked the fret spacing against a calculator)

however there is much more to do and the tasks are roughly as follows:

Convert as many of the curves, which are made up of 100's of short lines into splines or other 360 geometry. I have already done the circles and the upper neck

with fillets and splines for the headstock. The way you can tell is if you hover over a line and the whole curve highlights then it is done.

If it is just a small line amongst hundreds of others then it still needs doing.

Sort out the truss rod on the side view (top view if you were playing the guitar), so that a standard double action truss rod will fit

(we'll be going for a heel adjuster with a walnut plug at the headstock).

Probably combine or layer the fret slot marks onto the top most plan view so we can extrude and model from that one rather than trying to align extrusions from both.

Extrude the plan view into a solid body and start the process of "carving" the neck profile, fret board etc (going for a solid maple neck as its a lot easier than a cap rosewood ).

Thanks for the kindly and warm saler!

Cheers

Tomaso from Greece

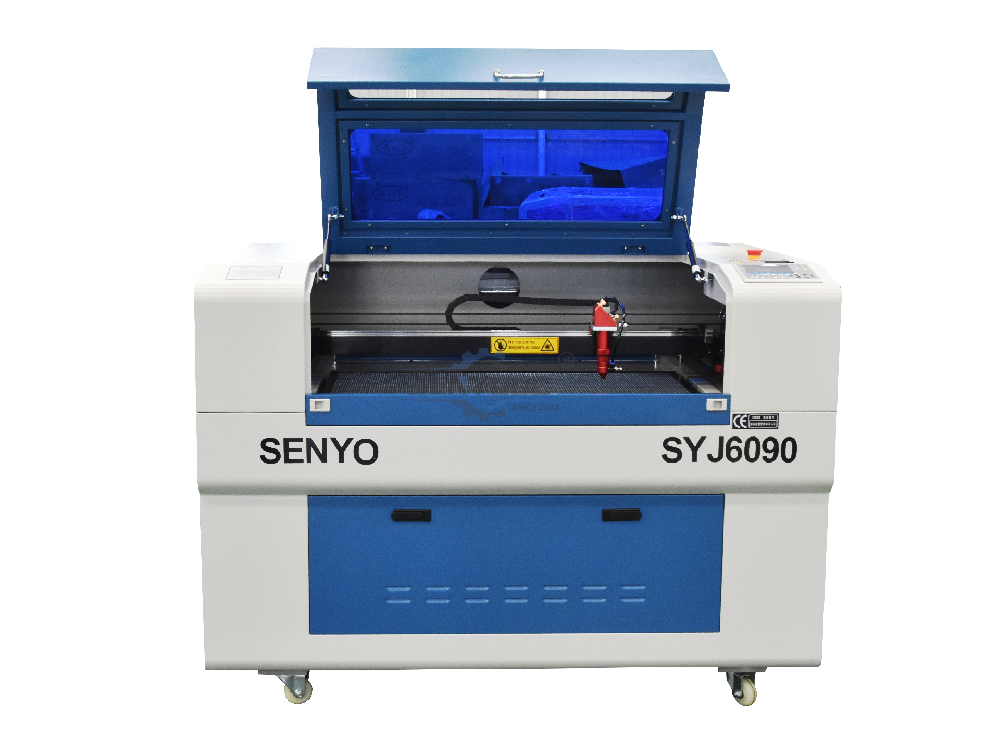

I'm the lucky owner of a SENYO 600x900, and whilst I have barely scratched the surface of what can be done with it, I am beginning to find ways to incorporate it into my work. Whilst I have of course cut signs, v-carved and made boxes with it, my main interest was to use it in furniture making in important but more subtle ways.

Example is this glass and walnut coffee table. The slab of walnut had warped badly and flattening both sides would have left me with less than 15mm of thickness, so I had abandoned it in a corner. However with the CNC I first flattened the top (so much nicer on my CNC with built in dust collection than using an ad-hoc sledge). However then the operation specifically enabled with CNC was to flip the top and machine just two slots where the frame rails could sit. The rest of the underside could remain rough sawn and unfinished. I then added a dovetail housing as well.

The underframe I made conventionally and machined the matching dovetailed rails on the router table till they were a snug fit. Slab tops could then be slid onto dovetails from either side....and top is held perfectly flat and level whilst able to move with seasonal expansion.

I like it so much ! Thanks for senyo !

Mini Desktop CNC Router for Gifts Making Small Business

Best Granite marble manual polishing machine For Sale

Stone Processing CNC Equipment Automatic Tool Changer CNC Quartz Stone Machining