What is CO2 Laser Cutting Technology?

CO2 laser cutting technology is a gas-based laser system that uses a CO2 mixer as the active laser medium. Electrifying the gas mixture a high-energy beam of light is produced known as the laser. This concentrated laser beam is focused on the object and the laser heats, melts, and vaporizes the material to cut.

Laser-cutting technology offers more efficient machine production, better precision, and accuracy. CNC technology advanced them with a more accurate controlling system.

A laser cutting machine is a part and parcel of many industries now. This technology saves time and offers a higher production rate with minimal wastage, making it a popular choice day by day.

CO2 laser cutters have become the most affordable and best-value cutting tools in the recent years, and can be your good partner to bring your creations, ideas and designs to life with personalized gifts, crafts, arts, decors, signs and logos. With a carbon dioxide laser cutting system, you can easily engrave any graphics and cut any shapes & contours on wood, acrylic, plastic, foam, stone, fabric and leather.

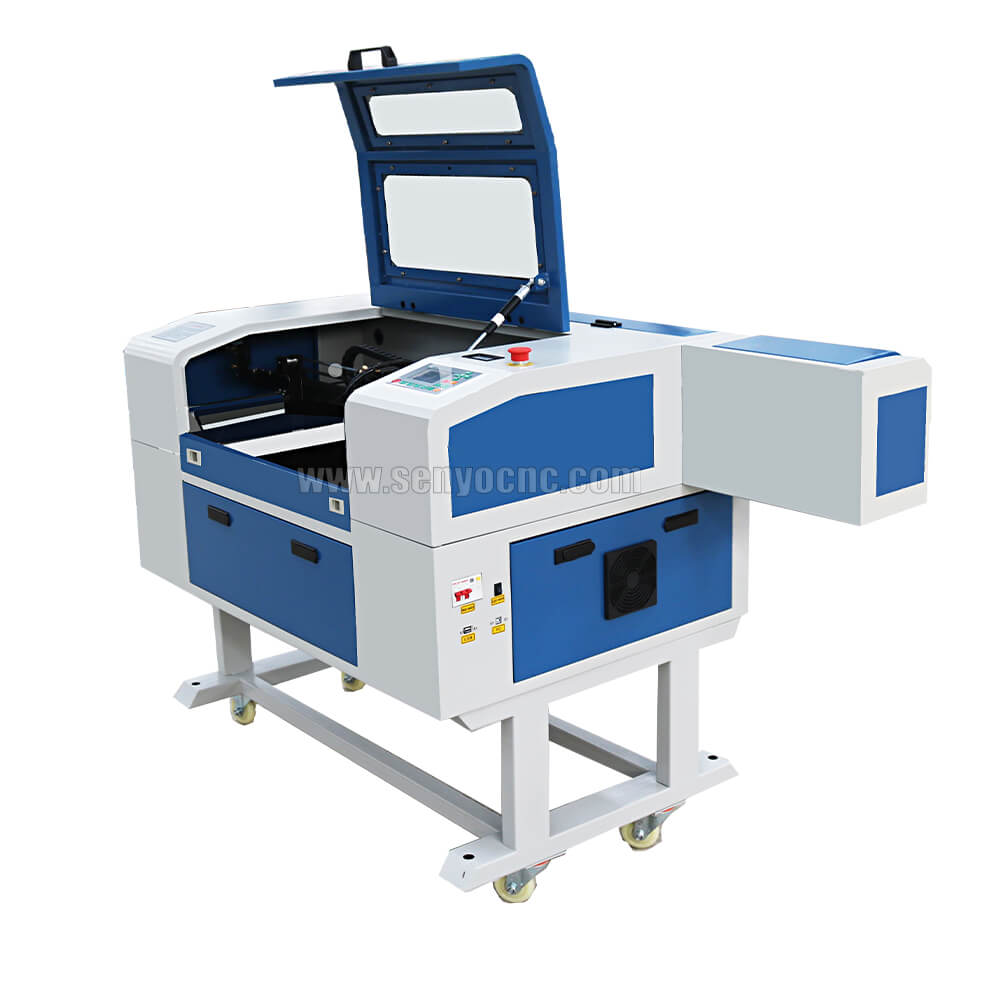

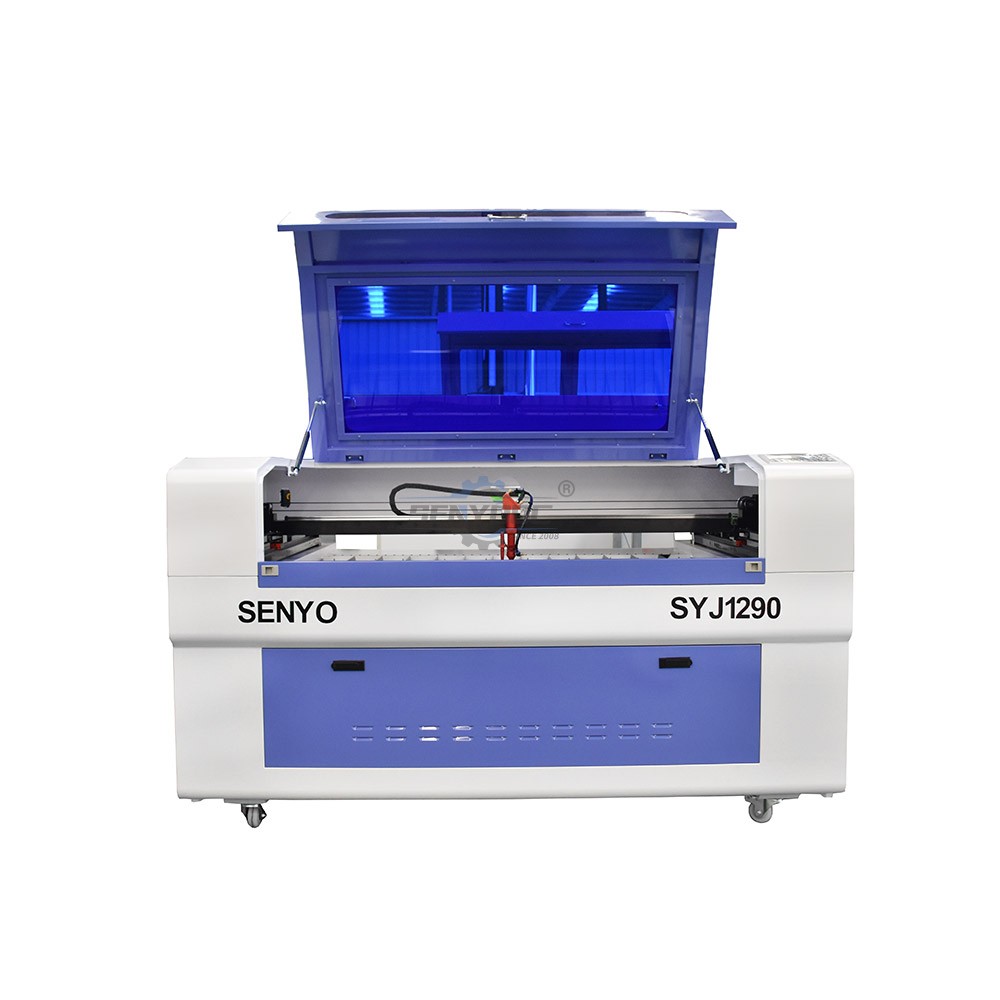

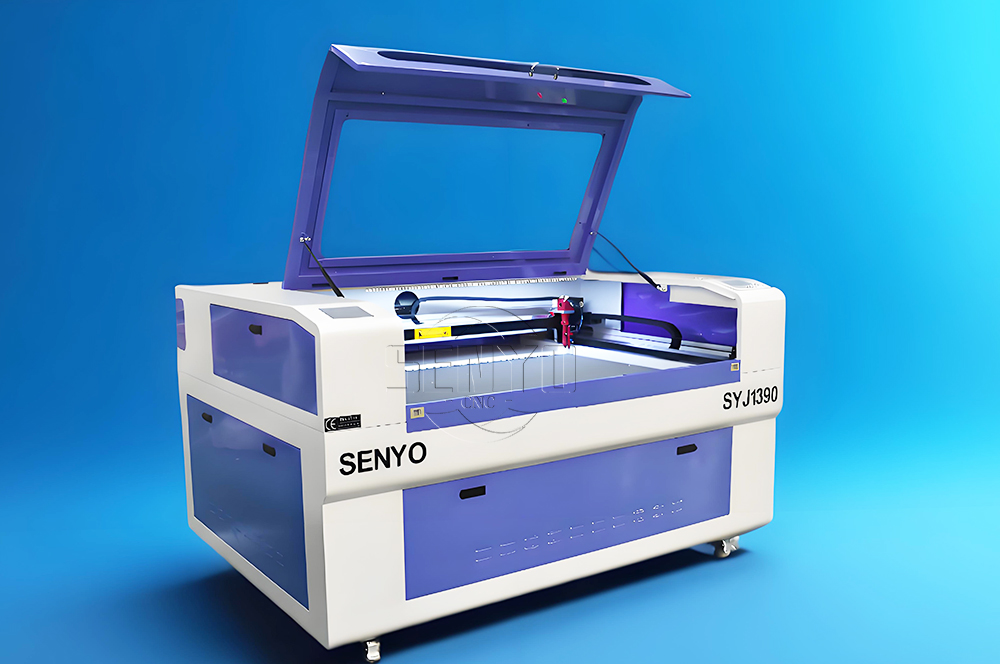

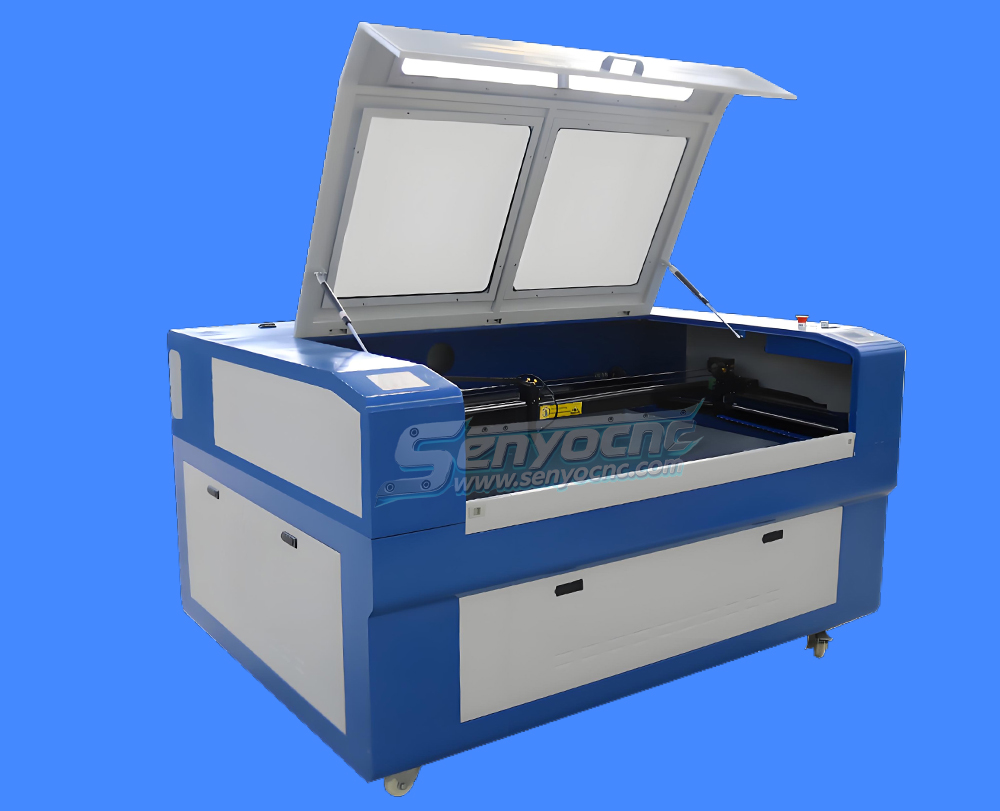

Features & Advantages of Dual Head Entry Level CO2 Laser Cutter for Paper & Cardboard

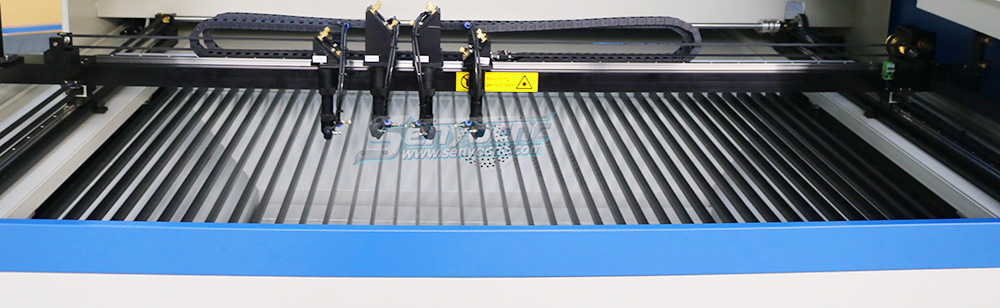

1. Taiwan HIWIN square linear guide rail installed on X Y axis, make sure the works stably and precisely.

2. Professional manufacturers adopt square tube frameworks in China, with more than 40% higher fuselage strength than iron sheet structures. This design prevents the machine from quivering, resonance, and distortion during long-term work.

3. New-style high-efficiency laser tube is adopted. The laser beam is more stable than the traditional type. Usage age is more than 10000 hours.

4. A red dot position system is added to the standard configuration, contributing to a simple and precise working position.

5. Advanced LCD Screen+ USB port+ Offline Control, with professional motion control chip, has the function of consecutively high-speed curve cutting and the shortest path selection, which largely improves your working efficiency.

6. A USB offline control system makes the operation more convenient and faster.

7. An automatic up-down table can be chosen for thick materials and high objects.

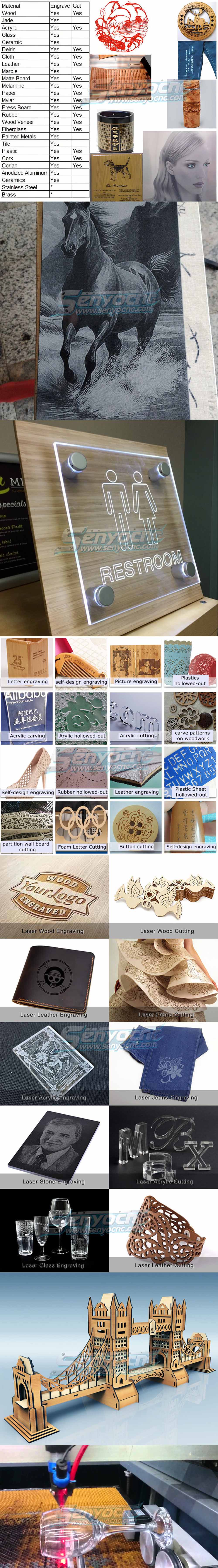

Applications of Dual Head Entry Level CO2 Laser Cutter for Paper & Cardboard

Applicable Industries: Applied to boxes, invitations, cards, sculptures, storages, cloth, toys, computer embroidery, models, arts, and crafts, advertising, building, decorations, packaging and printing, and paper products.

Applicable Materials: Available for engraving and cutting paper, cardboard, cardstock, acrylic, ABS, rubber, plastic, fabric, leather, wool, crystal, glass, ceramic tile, jade, bamboo & wood products.

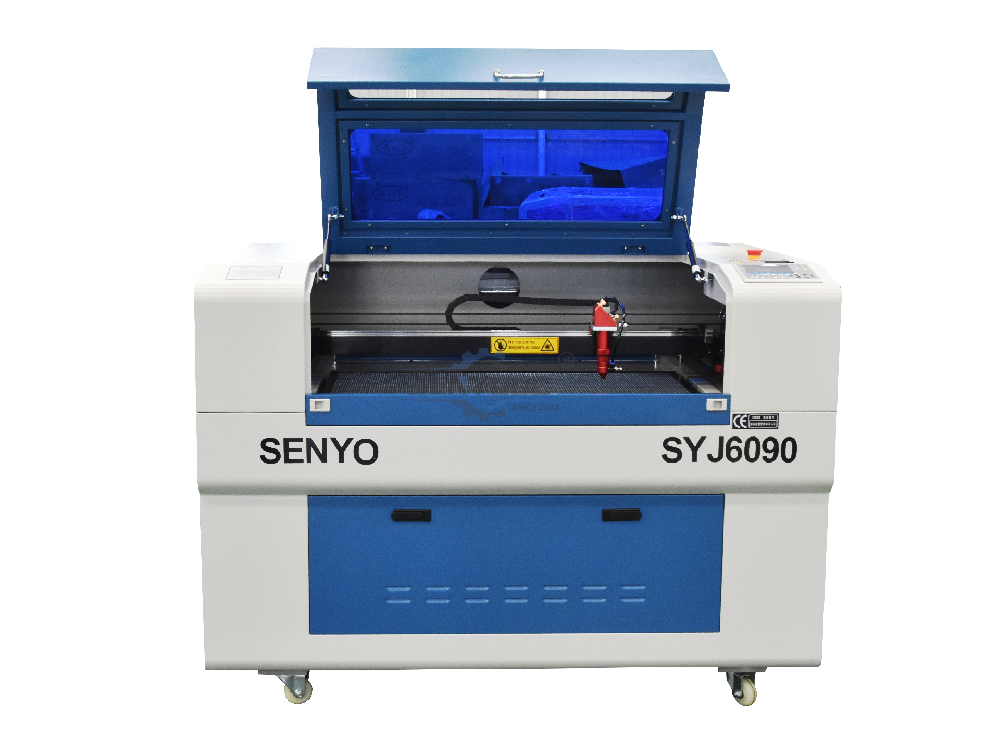

Technical Parameters of Dual Head Entry Level CO2 Laser Cutter for Paper & Cardboard

| Model | SYJ1510-4 |

| Working area | 1500mm*1000mm |

| Laser power | 80W (300W, 220W,150W,130W,100W for option) |

| Laser type | CO2 sealed laser tube, water-cooled |

| Driving system | Stepper motor |

| Transmission | Belt transmission |

| Guideway | Taiwan Hiwin Square guide rails |

| Control system | Ruida control system RD6445 |

| Lens and mirrors | 3pcs mirrors and 1pcs lens from Singapore |

| Working table | Blade table or Honeycomb table for option |

| Water chiller | Included |

| Engraving speed | 0-7500mm/min (According to the materials) |

| Cutting speed | 0-4000mm/min (According to the materials) |

| Power supply | 220V/50HZ , 110V/60HZ |

| Graphic format supported | BMP, PLT, DST, DXF, AI |

| Software supported | CorelDraw, PhotoShop, AutoCAD, TAJIMA |

| Up-down worktable | Optional |

| Autofocus | Optional |

| Red pointer | Yes |

| Optional parts | Rotary device |

| CCD camera |

Working Samples Project

How To Use?

It is very dangerous for a CO2 laser cutter to break down during work. Novices must be trained by professionals before they can operate independently. SENYO experts have summarized 13 easy-to-follow steps for safe work based on experience as follows.

1. Prepare the materials to be cut and fix them on the workbench.

2. Call the corresponding parameters according to the material and thickness.

3. Select the corresponding lens and nozzle according to the cutting parameters, and check whether they are in good condition.

4. Adjust the cutting head to the appropriate focus.

5. Check and adjust the centering of the nozzle.

6. Calibration of cutting head sensor.

7. Check the cutting gas, enter the command to open the auxiliary gas, and observe whether it can be ejected from the nozzle well.

8. Trial cut the material, check the cross-section, and adjust the process parameters until the production requirements are met.

9. Prepare the cutting program according to the drawing required by the workpiece, and import it to the controller.

10. Move the cutting head to the starting point to be cut, and press "Start" to execute the cutting program.

11. The operator is not allowed to leave the machine tool during the cutting process. In case of emergency, quickly press the "Reset" or "Emergency Stop" button to terminate the operation.

12. When cutting the first workpiece, stop cutting to see if it meets the requirements.

13. Pay attention to check the auxiliary gas flow when cutting, and replace it in time when the gas is insufficient.

How To Maintain?

A CO2 laser cutter must be cared for and maintained regularly and regularly, so that it can engrave and cut more accurately and at a higher speed for you, which can also prolong the service life of the machine. We summarizes 13 maintenance tips for everyone as follows.

1. When using the machine, the device should be turned on or off in strict accordance with the correct boot sequence.

2. The machine shell, laser power supply, and computer power supply must be well grounded. Regularly check whether the grounding screw is rusted or loose, and clean and fasten it in time.

3. Before starting work every day, observe whether the focusing lens is polluted, and clean it in time if any. Please be careful not to use too much force when cleaning the reflector, otherwise it will cause the optical path to shift! The maintenance of reflective lenses and focusing lenses at all levels should follow the principle of "cleaning in time if there is pollution". Special lens cleaner must be used for cleaning.

4. Before each machine works, please check whether each limit switch is working normally, so as to ensure that the equipment will not have collisions that affect the accuracy of the equipment during the working process. In addition, please pay attention to adjust the focal length and lock it tightly to ensure that the processing effect will not be affected by the decrease of the focal length, or even mechanical collision will occur.

5. If the moving parts such as trolley pulleys, slideways and linear guide rails are polluted or corroded, it will directly affect the processing effect. They should be cleaned regularly and lubricated on the guide rails to prevent rust.

6. After a long time of use (especially cutting), the honeycomb platform will stick to processing waste and even block the honeycomb holes. It may smoke or even burn when exposed to beam. It should be removed regularly.

7. The cooling water should be kept clean and replaced regularly. During processing, check whether the water level is sufficient and whether the water temperature is too high. It is strictly forbidden to use inferior circulating water. Poor-quality water can seriously affect the laser power and greatly shorten the service life of the laser tube. The damage to the tube caused by the use of poor-quality water by the user is not covered by the warranty. It is recommended to use pure water. The amount of cooling water should not be less than 30 liters, and the submersible pump must be submerged. During the working process of the machine, the water temperature must be checked at any time (the best working water temperature is 25~30°C, the maximum water temperature cannot exceed 35°C, and the minimum water temperature cannot be lower than 5°C). Once the water feels warm, it should be changed immediately. The water change method that does not affect the work is to discharge part of the hot water and then flush with cold water. Every three days, the water tank, water pump (especially the filter sponge of the water pump) and the water inlet and outlet hoses must be cleaned.

8. The laser tube is cooled by circulating water, so some white scale will appear in the tube after long-term use. We can add a small amount of vinegar to the circulating water, then take out the groove and rinse its interior with clean water to keep it in the best working condition and prolong its service life.

9. Pay attention that the smoke exhaust port and the exhaust duct cannot be blocked, and check and remove the obstruction at any time to keep it unblocked.

10. Adjust the light intensity not to exceed 20MA to prevent rapid aging of the laser tube.

11. Before starting work every day, the lens must be cleaned once.

12. Clean the reflector carefully on the machine, otherwise the optical path must be readjusted.

13. The third radiation mirror and focusing mirror must be removed and cleaned. After cleaning, the lens installation must be firm, but not too tight, so as not to break the lens.

14. Before each operation, please pay attention to the focal length. Inaccurate focal length will seriously affect the engraving effect.

15. After each operation, the work surface should be cleaned briefly. When cleaning, be careful not to fly dust.

16. Cleaning should be done after each operation. When doing cleaning work, when the power is cut off, you can gently push the beam and trolley, but it is strictly forbidden to push and pull violently.

17. Check the water protection switch regularly (once in half a month) to determine whether it is working normally.

18. Every other week, the guide rails must be cleaned, and lubricating oil should be added to the moving guide rails.

19. Every other week, clean up the peripherals of the machine (such as fans and air pumps).

20. After the machine works every day, it should be cleaned well. In the case of power failure, you can slowly push the focusing lens group and the X-axis guide rail seat, and it is strictly forbidden to push and pull violently. The bed body should be kept clean, especially the two linear guide rails. It is required to clean the oil stains on the guide rails and guide rail seats after work every day; transformer oil must be added to the linear guide rails and sliders before starting work the next day.

For Our Work Steps

1.Before-sale,we will try to know your requirement about our cnc router specification and what kind of work

you will do .then we will offer our best solution for your requirement.

2.During production: we will send photos of machines during making. so you can know more details about

the procession of making your machines.

3.Before shipping,we will take delivery photo and confirm the specification of order to avoid the mistake.

Machine will be adjusted before it is delivered.

4.After shipping: we will sent out the documents for your customs clearance ASAP . and check the

approximate date of arrival.

5.After arrival: we will confirm with you if machine is in good condition.and see if any spare parts missing .

6.About teaching: there are some manual and video about how to use machine , if you have question

about it. we will have professional technicist to help you install and teach how to use through skype ,

calling, video or mail.

Before shipment---Factory technicians will carry out debugging and testing to ensure that there is no problem with the machine before deciding whether to proceed to the next step!

After the shipment is confirmed - the corresponding staff who contacted you will send you pictures and videos of the machine to confirm with you. After confirming that there is no error, will be packed - waiting for delivery instructions.

Package

1. Outside package: Standard plywood package.

2. Inner package:Stretchy film and plastic protective film for humidity.

Warranty of SYJ1510-4 Laser Cutting Machine for Starters

• The whole hobby laser engraving cutting machine: Two year. Laser tube warranty depend on brand

• Laser lens and mirrors: for one month. If the accessories are broken because of quality problems during warranty time, we will change it by free.

• 24 hour technical support online like skype, whatsapp, remote, you can calling us if urgent.

• We offer free training in our factory, and our engineers available to service machinery overseas, but the round-trip air tickets, hotel and meals for the engineers should be paid by our buyer.

We also have hobby fiber laser cutters for metal fabrication:

1. Mini CO2 laser cutter

2. Portable CO2 laser engraver

3. Best mini CO2 laser machine

4. Affordable mini laser cutter

5. Small CO2 laser engraving machine

6. Compact laser cutter for wood and acrylic

7. Desktop CO2 laser engraver

8. Mini laser engraver for metal

9. DIY mini CO2 laser machine

10. Entry-level CO2 laser cutter

11. CO2 laser cutting machine for home use

12. Mini laser engraving machine for beginners

13. Portable CO2 laser for small business

14. Best CO2 laser for crafts and hobbyists

15. Mini laser cutting machine price

16. CO2 laser machine for wood and leather

17. Laser cutter for small projects

18. Compact laser engraving tools

19. High-precision mini laser engraver

• Previous: Portable Co2 9060 Laser Nonmetal Cutting Engraving Machine

• Next: 1400*1000 Co2 Laser Cutting Machine for crafts and hobbyists

Fiber metal Laser Sensor And Its Application

Category: SENYO NEWS 11th Mar, 2021A CNC wood router will use 3D machining in relief carving, the effect is more artistic beauty, but also has a strong sense of three-dimensional 3D, realization of this function is to ...

Precision Cutting Stents with Fiber Lasers

A CNC wood router will use 3D machining in relief carving, the effect is more artistic beauty, but also has a strong sense of three-dimensional 3D, realization of this function is to ...

How to Laser Cut Copper and Other Reflective Metals

Laser cutting of mild steel and stainless steel has a long history and has been one of the primary applications for CO2lasers. However CO2lasers have not traditionally offered a good solution for cutting highly reflective materials.Fiber lasers have an emission wavelength of around

Laser Cutting Machine Inspection Process For Manufacture

SENYOCNC Have Strict quality monitoring will be carried out when the parts are in the factory.

How Control Costs Use of UV Printers ?

UV flatbed printers are rapidly being used by more and more manufacturers, thanks to its efficient production efficiency, and the control of production costs also needs to arouse our attention.

Why UV flat printing machine is popular in market ?

For the majority of designers, give full play to the creative ability, the design sample can be arbitrarily modified on the computer, the effect on the computer, is the effect after the finished product, customer satisfaction can be directly produced. UV flat printing pattern fine, rich and clear layers, high artistry, strong three-dimensional sense, many high precision equipment can also print photography and painting style patterns.

How does UV ink jet printer save UV ink?

UV inkjet printer use process is an important consumable UV ink, reasonable use of equipment, can save UV ink , it can be said to be the best choice to directly save the cost. In the process of using some skills you need to be familiar with, the following small make up to share with you:1. Try to us

Waterjet Machine delivery and Shipping

Please tell us your max working size and what materials will cutting , also what max cutting thickeness.If you have Working photo sample please also send us , it will be helpful to choose machine with suitable models .

Waterjet Machine finish manufacture 5axis

Waterjet cutting technology is one of the fastest growing major machine tool processes in the world due to its versatility and ease of operation.

Waterjet Machine delivery and Shipping

Waterjet cutting technology is one of the fastest growing major machine tool processes in the world due to its versatility and ease of operation.There are multiple advantages to adding waterjet cutting capabilities to your shop.We are company leading ultrahigh-pressure waterjet system so

How to Create Connected Text – Inkscape for Laser Cutting

Step 1: Create Some TextFirst, we need some text to work with. To create the text, select the Text Tool (keyboard shortcut: T), click somewhere on the canvas, and type your text.You can use the drop-down list on the top left to select your desired font.Step 2: Convert Text to PathNext, we need to tu

Jacob from United States

I am a beginner at CNC, I’ve never used a CNC machine before and with in a day I was carving. An awesome machine for a beginner to learn as hobbyists. I used the manual and the help video. One hour to assemble and test, very friendly and easy to use. It’s a good buy for the money. I would definitely recommend this machine to someone getting into CNCs.

Weinstein from France

I've been using CNC plasma SYP2060-300A and I am very impressed with this unit.

This unit is of higher quality, made in China. Five stars all the way!

2040 from INDIAN

Best 2040 CNC Router Good Price and Quality ! Thank SENYOQC

10w uv laser from American

Best supplier ! I bought 3 machines for laser and router , thank you Aillen ! --Alec

12KW Fiber Cutting - 2000X6000mm -- 이병헌 from Korea

Good machine for metal cut ! Thanks Senyo , Its prefect , I like your business patient kind!

I am a furniture manufacturer, and this machine is very good and fast. thanks Senyoqc Team ! from Bangladesh

Metal ArtWork from Denmark

The plasma cutting machine makes my artistic creation more convenient and precise!! Created more artistic ideas and value! Thank you Aillen team!

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen. from

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen.

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo from

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo

Thank you Senyo for SYJ1290-150W! from

Retired, ex mainframe systems programmer. Now full-time recreational woodworker majoring in puzzles, pens, boxes, Toys and occasional small furniture. Thank you Senyo for SYJ1290-150W!

manager@senyocnc.com

manager@senyocnc.com

SENYOCNC

SENYOCNC

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

2061579344

2061579344