The wide belt woodworking sanding machine is to tension the endless belt on several belt wheels to drive the belt for continuous movement.

A tensioning wheel will also make a small amount of warping to make the belt move laterally.

Belt-type woodworking sanders used for surface processing often have fixed or mobile worktables,

while belt-type woodworking sanders used for surface processing will use the flexibility of the sanding belt to perform workpieces under the pressure of the template.

Belt-type woodworking sander has the advantages of high efficiency, guaranteed processing accuracy, easy replacement of sanding belts, etc.

Therefore, it is suitable for sanding furniture panels, decorative panels, front and rear panels of paint, or large man-made panels.

Product Paramenters

This Suitable for PVC, veneer, melamine, plastic, etc materials. (U-shaped can be customized).

There are 9 discs in total, all of which are inverted U-shaped, which can be quickly replaced.

There are 9 longitudinal rolls.Sisal or DuPont silk can be selected for two straight rolls.

The mesh number of abrasive belt is 80-600, which can be selected according to needs.

This machine is suitable for all kinds of plate solid wood furniture. Primer and white stubble can be polished.

The polishing thickness is 10-160 mm.

Machine Paramaters

Model

| 1000-6S

|

Maximum processing width | 1000mm |

Polishing thickness | 5-100mm |

Length of processed plate | ≥350mm |

Polishing roller speed | Variable speed FM |

Belt speed | 5-20m/min |

Diameter of polishing roller | 300mm |

Total motor capacity | 11.65kw |

Straight roller motor | 2.2kw×2 |

Conveying motor | 1.1kw |

Lifting motor | 0.55kw

|

Disc motor | 1.5KW grade 6 |

Disk swing motor | 0.55kw |

Longitudinal roller motor | 1.5KW grade 6 x2 |

Longitudinal roll swing motor | 0.55kw |

Machine Size

| 3100×1600×1700mm |

Shipping size | 3200×1800×1850mm |

Net machine weight | 1200KG |

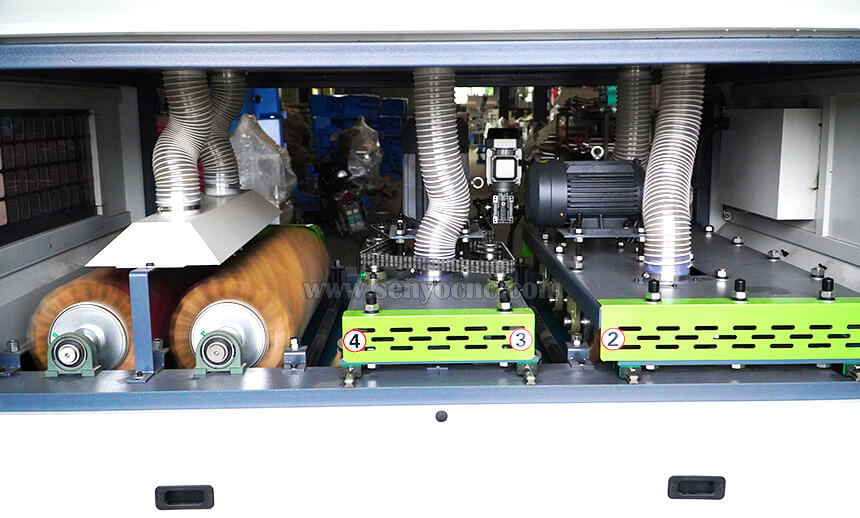

Parts Detials

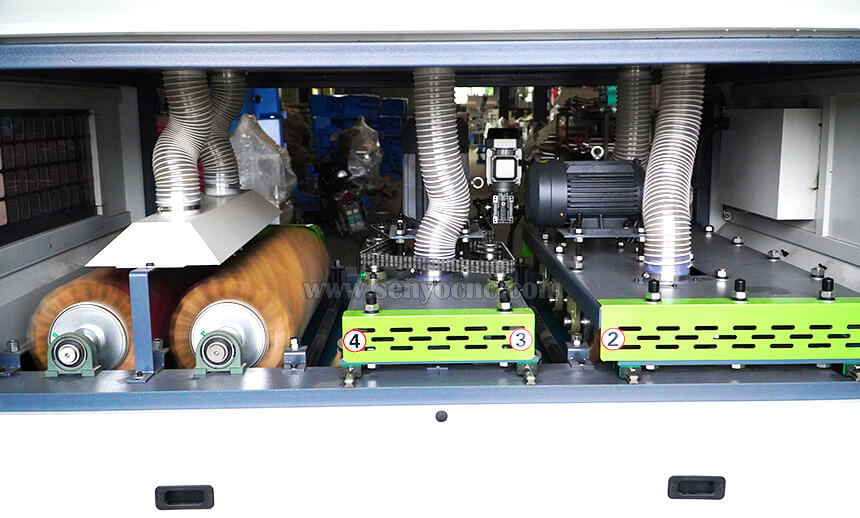

2 rows oscillating brush disc,2 rows of oscillating cross roller, 2

brush rollers.

Each unit can be a separate swing, to eliminate the

grinding wheel in the grinding process generated traces of the plate

surface smoother.

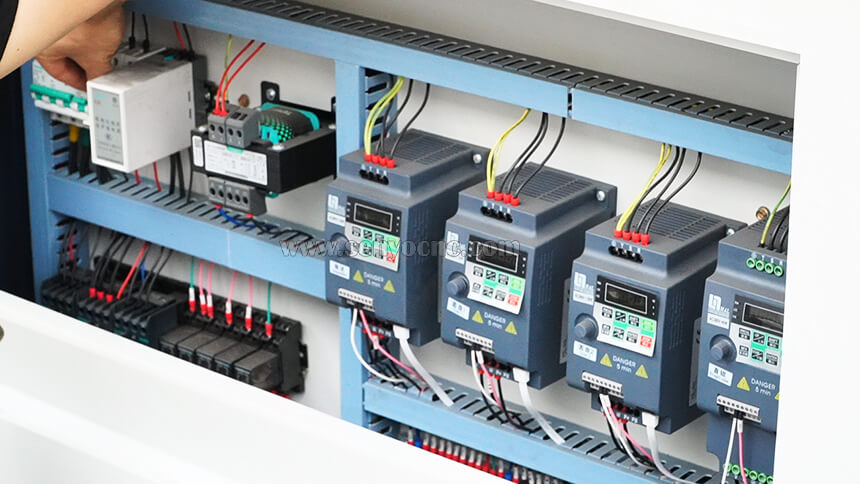

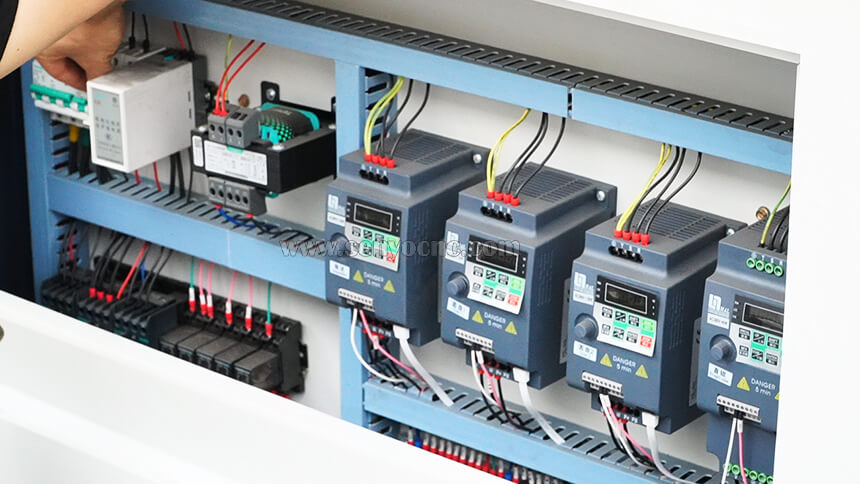

Control Cabinet Simple and clear temperature controller with high control

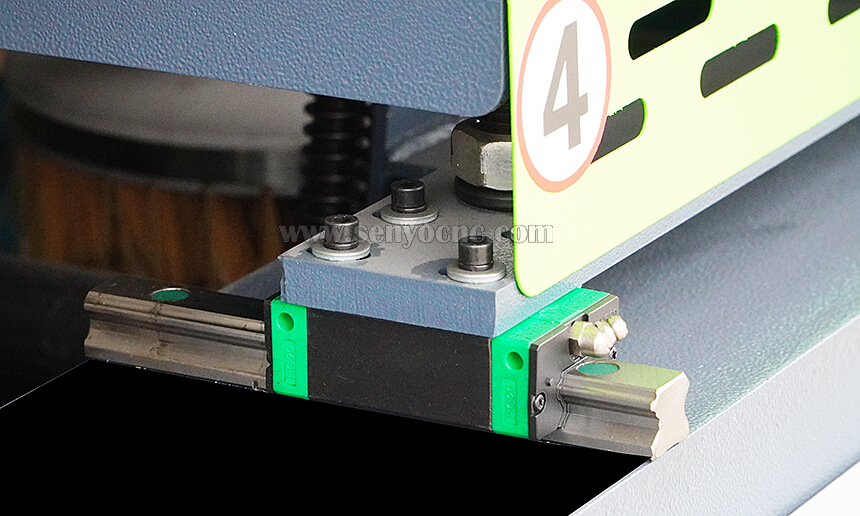

Guide system: each unit can be pushed out and pull in, change of sandpaper strips is more simple

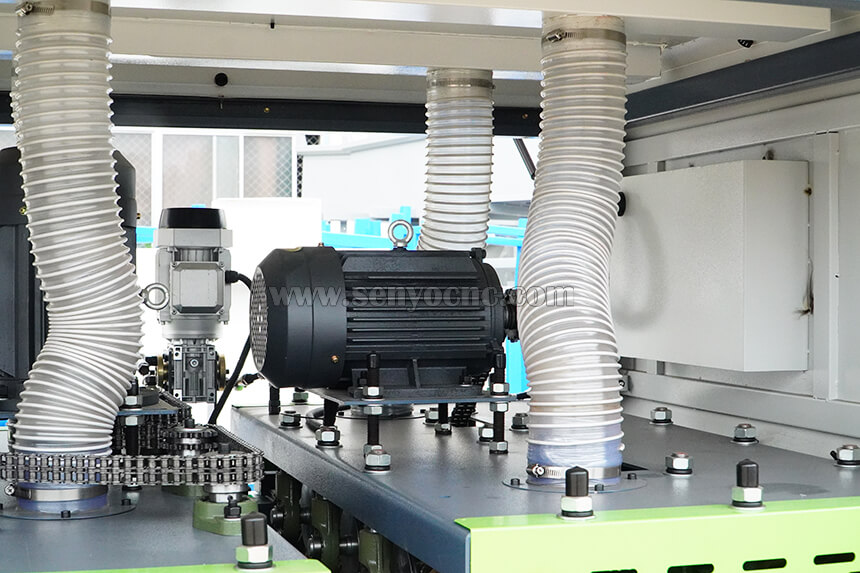

1. Each sanding unit can be adjusted independently, and can be fine-tuned according to the product process

to ensure the maximum combination of abrasive and workpiece, which can significantly improve the grinding effect.

Strengthen the independent lifting mechanism to make the grinding process more stable.

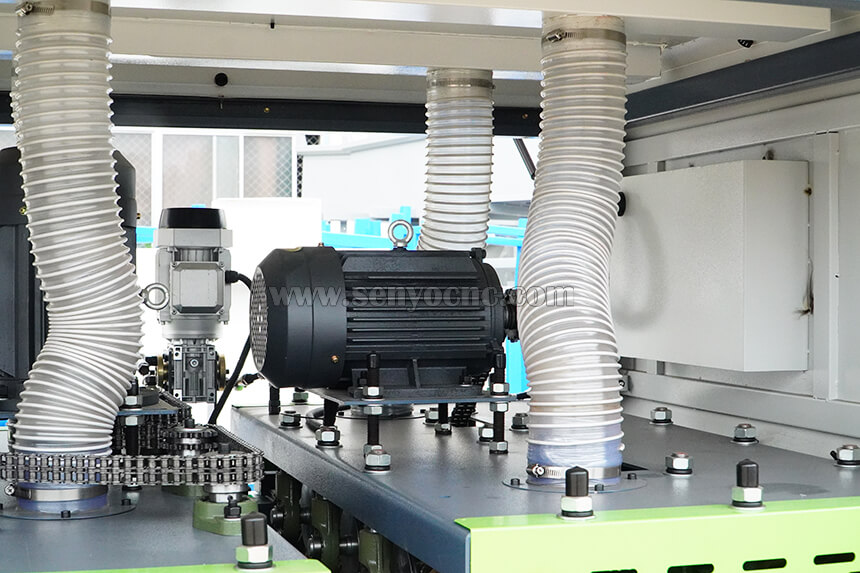

2. Each sanding unit can independently adjust the speed, effectively improve the quality of grinding, prevent damage to the shape and paint leakage.

3. Each sanding unit cooperates with swing system to make the grinding range wider and more uniform, and effectively avoid scratches caused by long grinding.

4. Each sanding unit is equipped with a human-designed drawing system, which makes it easier to replace consumables.

5. Each group of sanding units with thickness display function, the operation is more intuitive , convenient (Note:This model can choose memory function).

6. Large diameter sanding roller structure , matched with high quality sand paper , mexico sisal, softer and flexible, and it is easier to sand the complex design products.

7. Each sanding unit is removable .This structure is more portable to replace the sanding paper or sanding part and it is easier to sand the complex design products and it is convenient for maintenance.

8. Brush disc adopts the high speed disassembly structure , effectively shortens the replacement time of the sand paper, which is faster and more efficient than the traditional structure

Electric lifting system: height of each unit is electrically controlled due to different processing requirement

Osillating swing system : Each unit can be a separate swing

Eliminate the grinding wheel in the grinding process generated traces of the plate surface

smoother.

Feeding Auxiliary Roller , Equipment Configuration, Carrier roller, Convenient Equipment feed

Working tale is fixed, the top machine body can float up and down

according to work piece thickness, suitable for sanding production line

Conveying motor

Sand roller swing motor

Internal Circuit Safe and stable wire connection of famous brand electrical

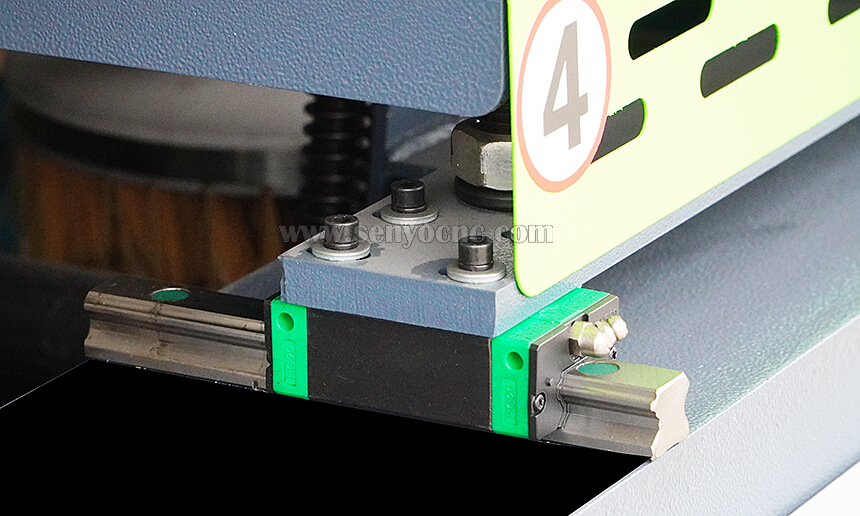

HIWIN Guide Bearing

Square Hiwin Rail Guide

Famous Brand And High work precision

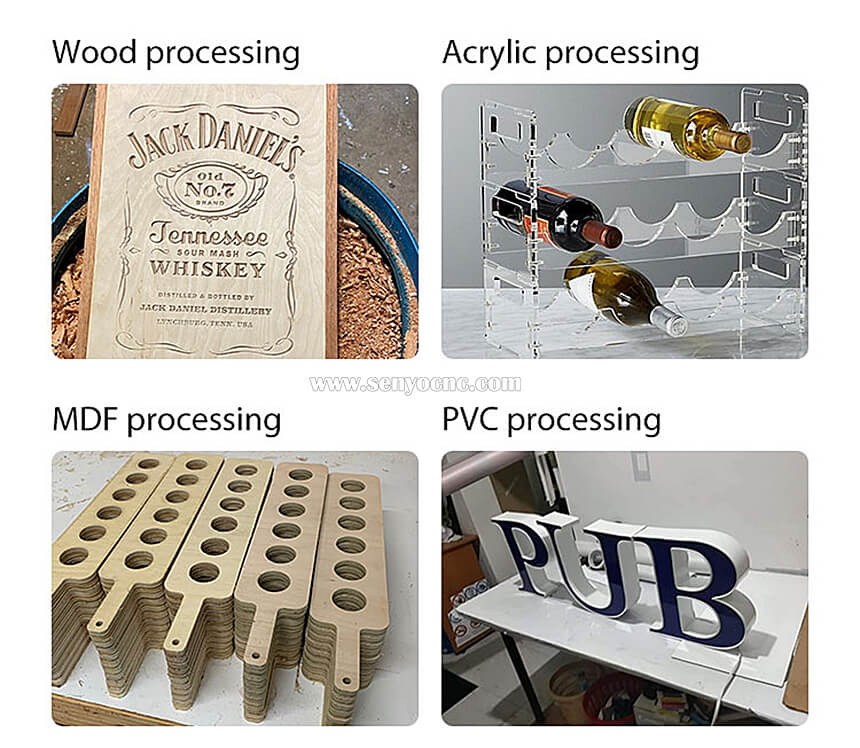

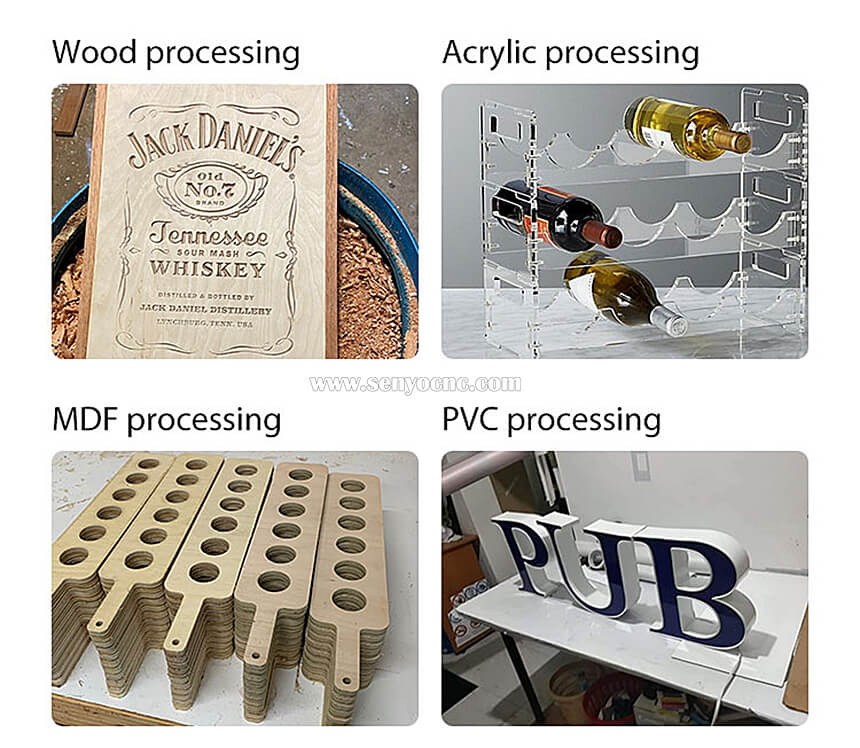

Applicable Materials

1. For finish sanding of louver, shutter, raised panel, doors and frames.

2. For sanding finishing of hard wood, softwood, MDF, Acrylic,PVC,veneer, plywood, and painted panel.

It is suitable for the rough and fine sanding, polishing and polishing of solid wood, density board,

iron sheet and other materials such as linear and L-shaped wood lines and door panels, heterogeneous surfaces,

flat surfaces and curved surfaces. It is an ideal equipment for producing heterosexual polishing of doors, windows, cabinets and furniture.

Package & Shipping

1.Wrapped with plastic film

2.Fumigation free plywood

3.Strong steel pallet

International Shipping

Around the World All the CNC routers can be shipped worldwide by sea, by air or by international express logistics via DHL, FEDEX, UPS.

You are welcome to get a free quotation by filling up the form with name, email, detailed address, product and requirements,

We will shortly contact you with the full information including the most suitable delivery method (fast, secure, discreet) and freight.

/5 based on 200votes/5 based on votes

/5 based on 200votes/5 based on votes

manager@senyocnc.com

manager@senyocnc.com

SENYOCNC

SENYOCNC

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

2061579344

2061579344