Overview

CNC flame cutting machine is a type of CNC metal cutter that uses fuel gas with oxygen or gasoline with oxygen to cut metal materials, and CNC plasma cutting machine is a type of CNC metal cutting system that uses the heat of a high-temperature plasma arc to melt and evaporate the metal part or part of the incision of the workpiece, and uses the momentum of the high-speed plasma to remove the molten metal to form the incision. The CNC plasma flame cutting machine is to ionize the material to produce a high temperature of 6000 degrees Celsius to 8000 degrees Celsius to quickly melt the object. In the energy center of the plasma arc, the gas can completely form an ion state to reach a high temperature of 15,000 to 30,000 degrees Celsius, and quickly merge metals to achieve rapid cutting. The purpose is to melt the metal through the plasma arc when working, and then use the attached airflow to blow the melted metal away to achieve the purpose of cutting.

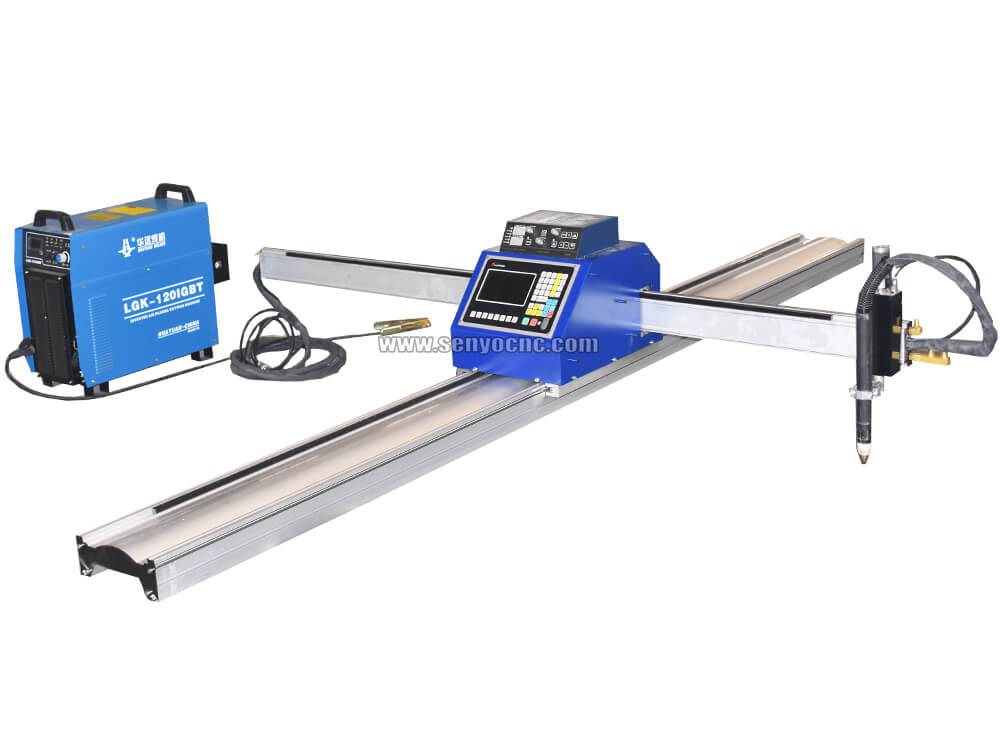

CNC flame cutting machine with plasma torch is a type of portable plasma cutter with CNC controller, which can cut metals up to 200mm. It's also known as CNC oxy-fuel gas and plasma cutting machine, CNC plasma and flame cutting machine, CNC oxy fuel cutting machine, CNC plasma & oxy-fuel cutting machine.

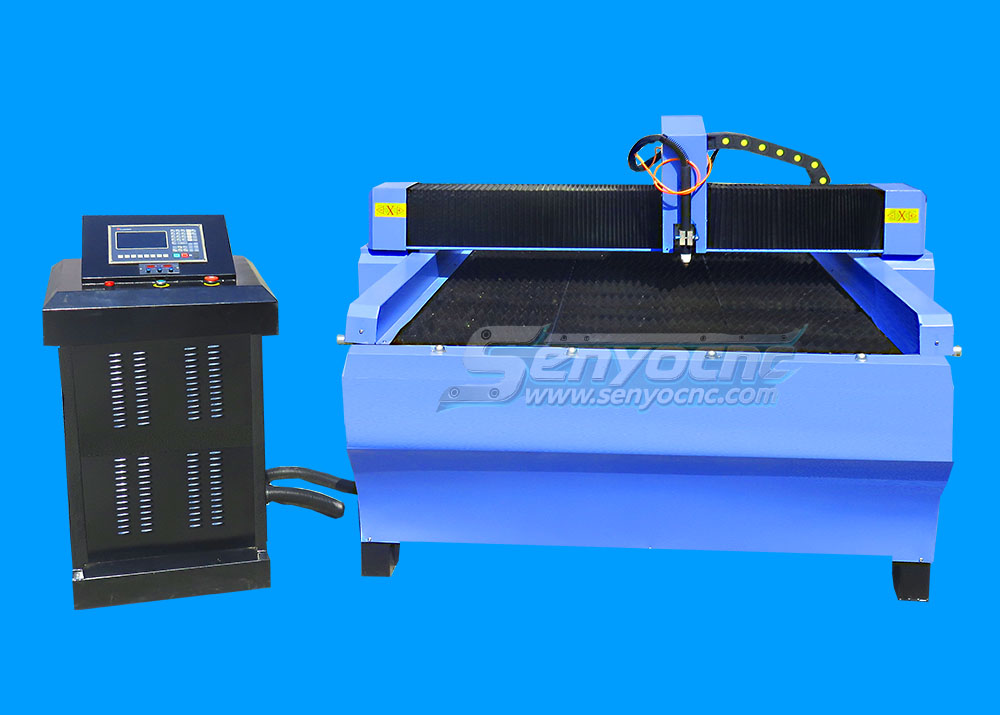

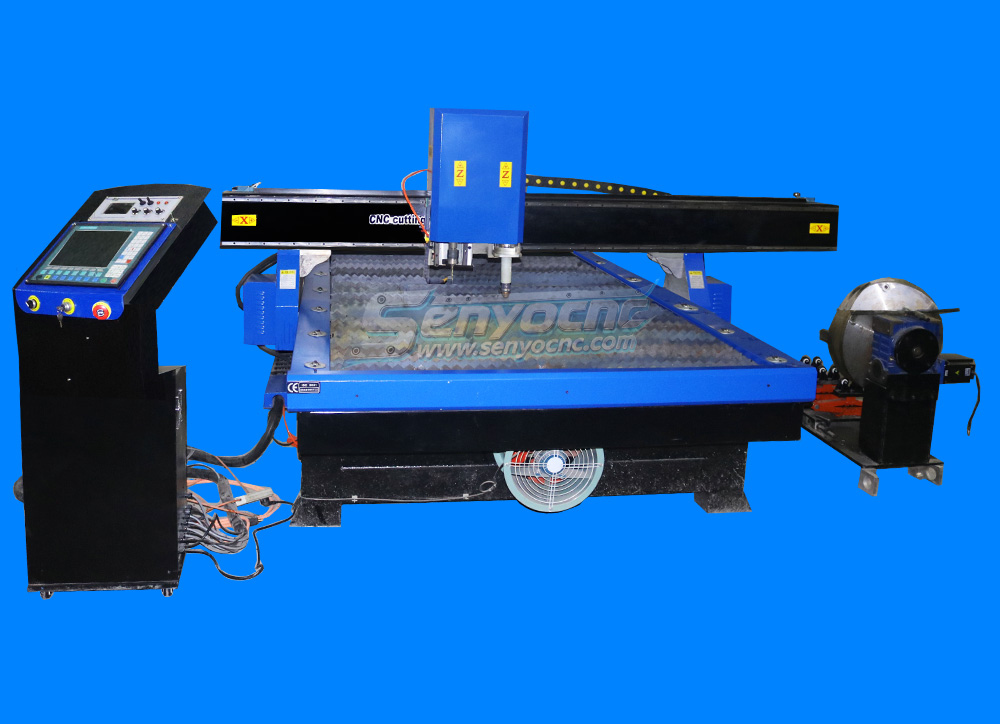

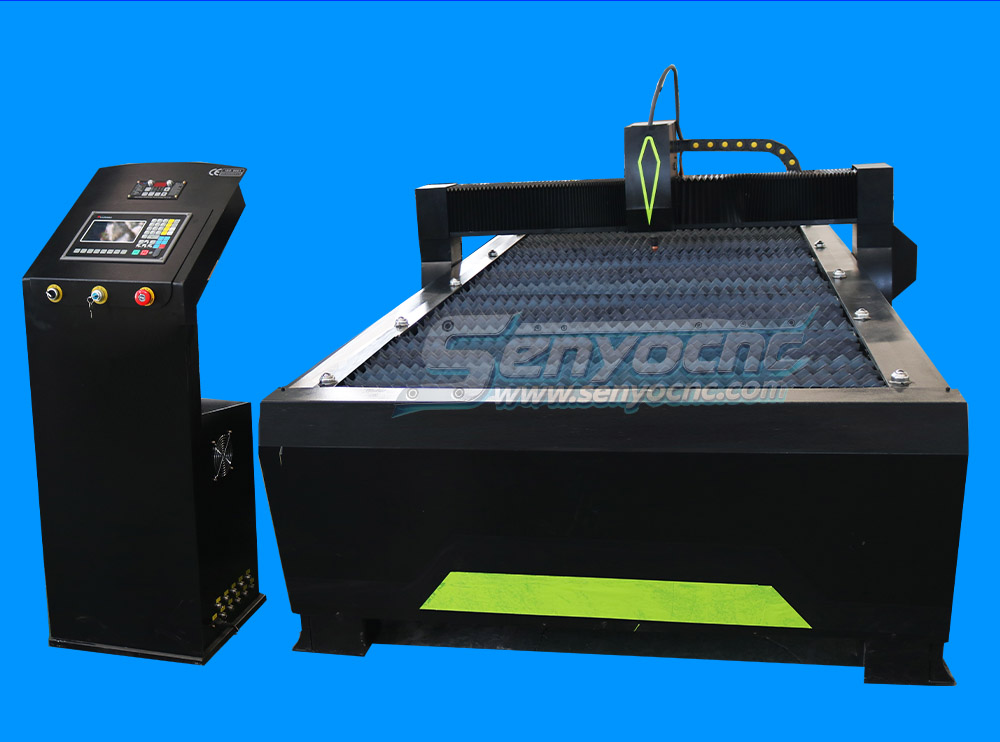

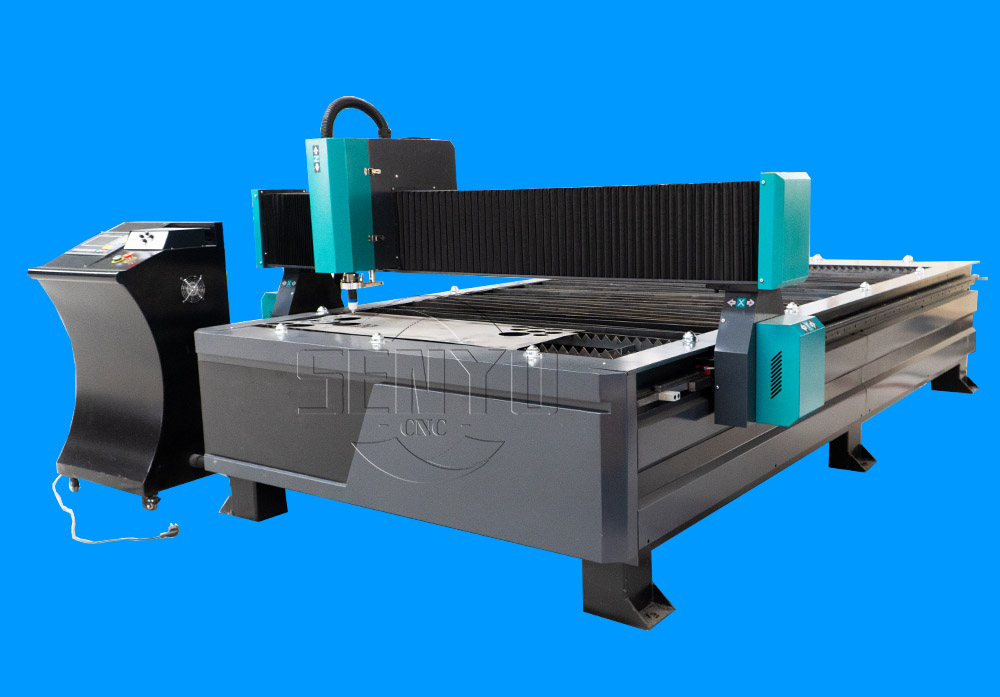

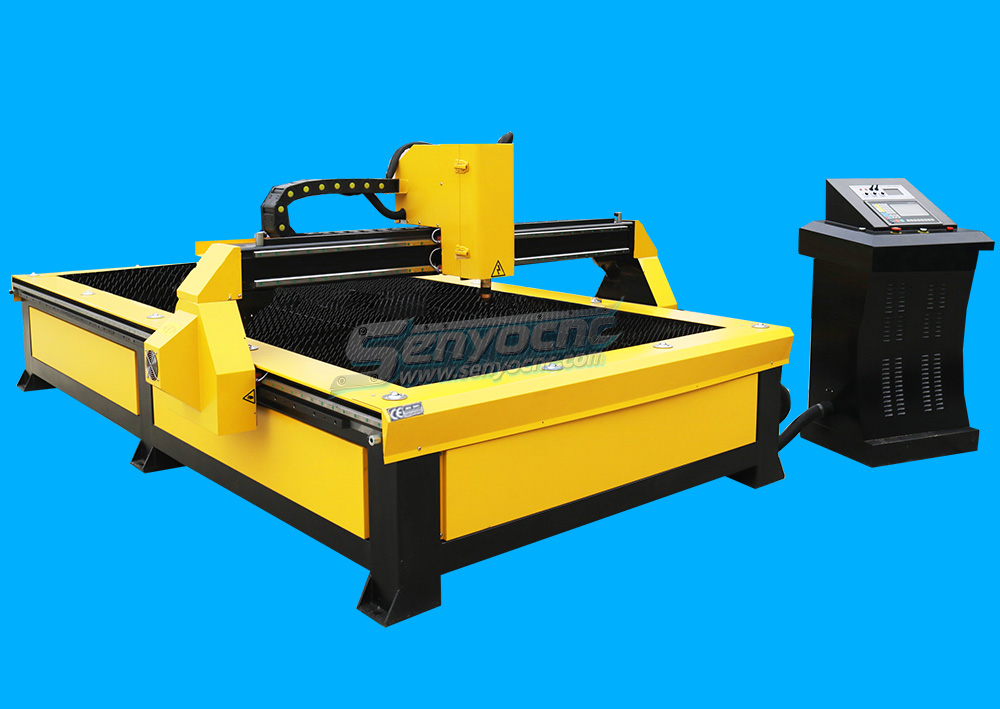

CNC Flame/Plasma Cutting Machine Features

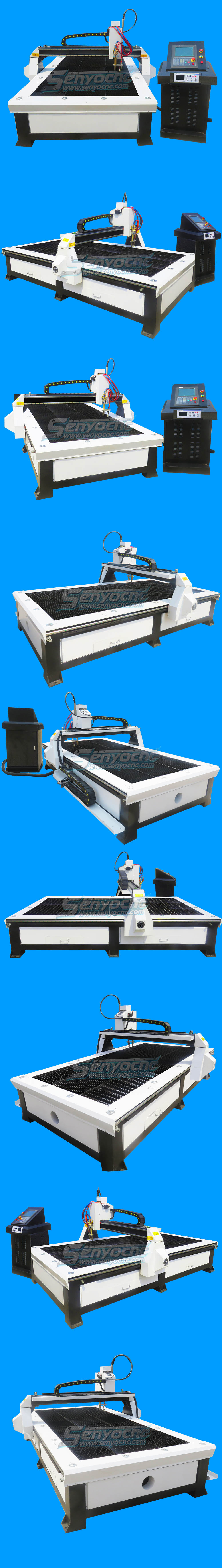

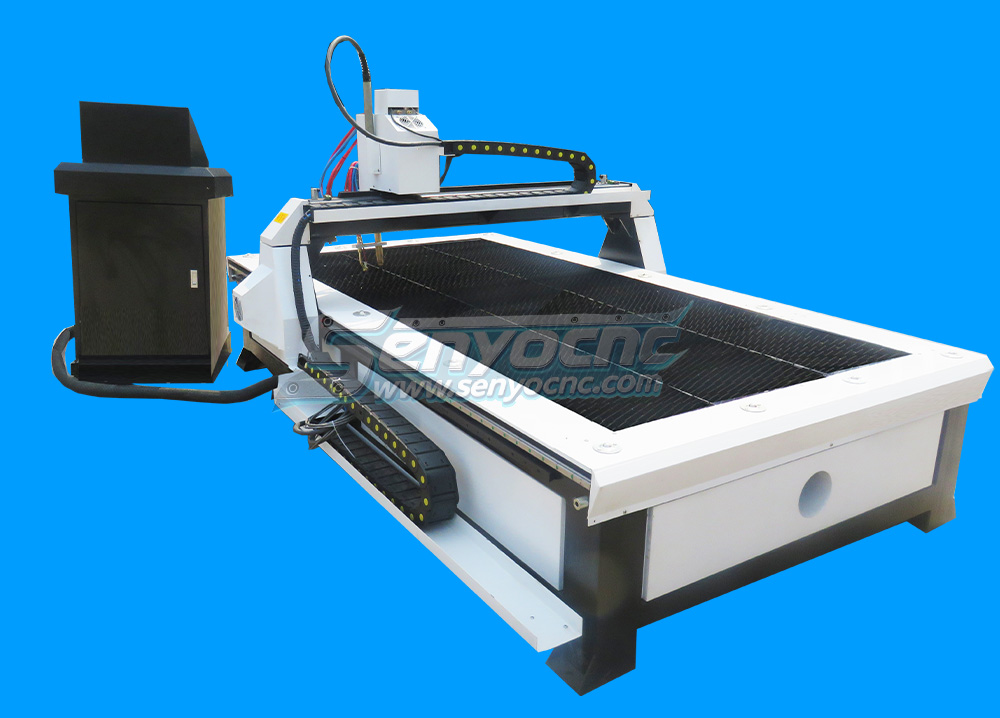

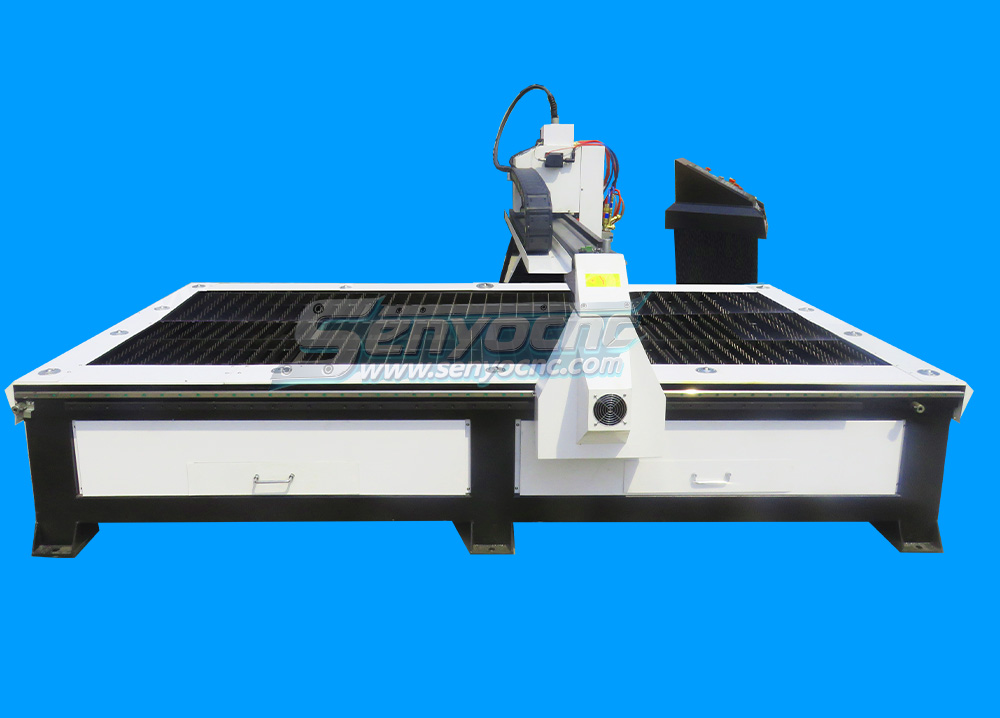

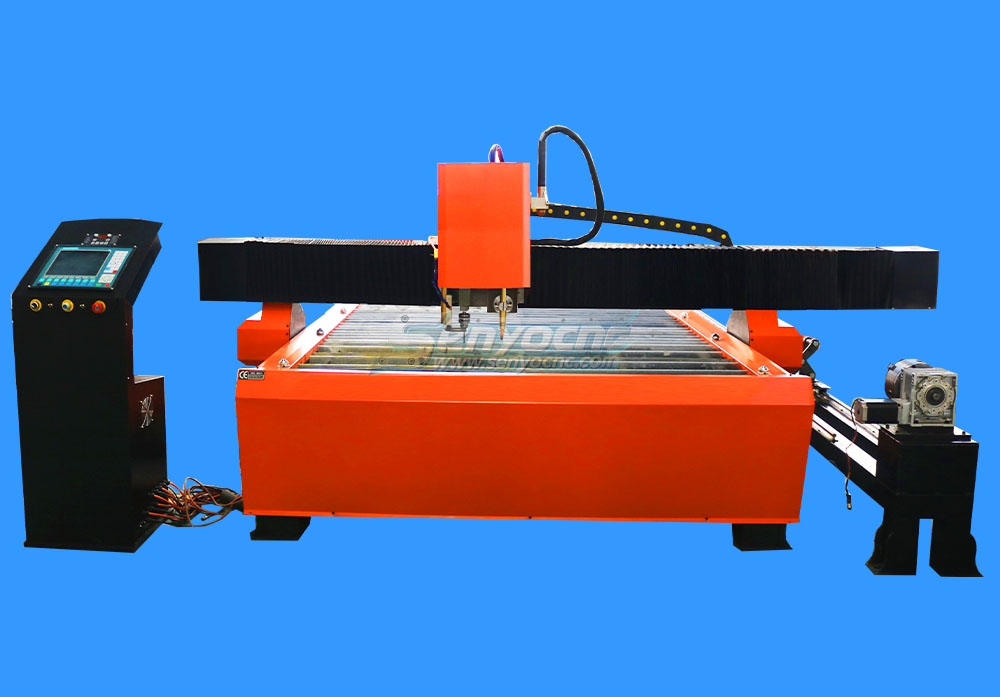

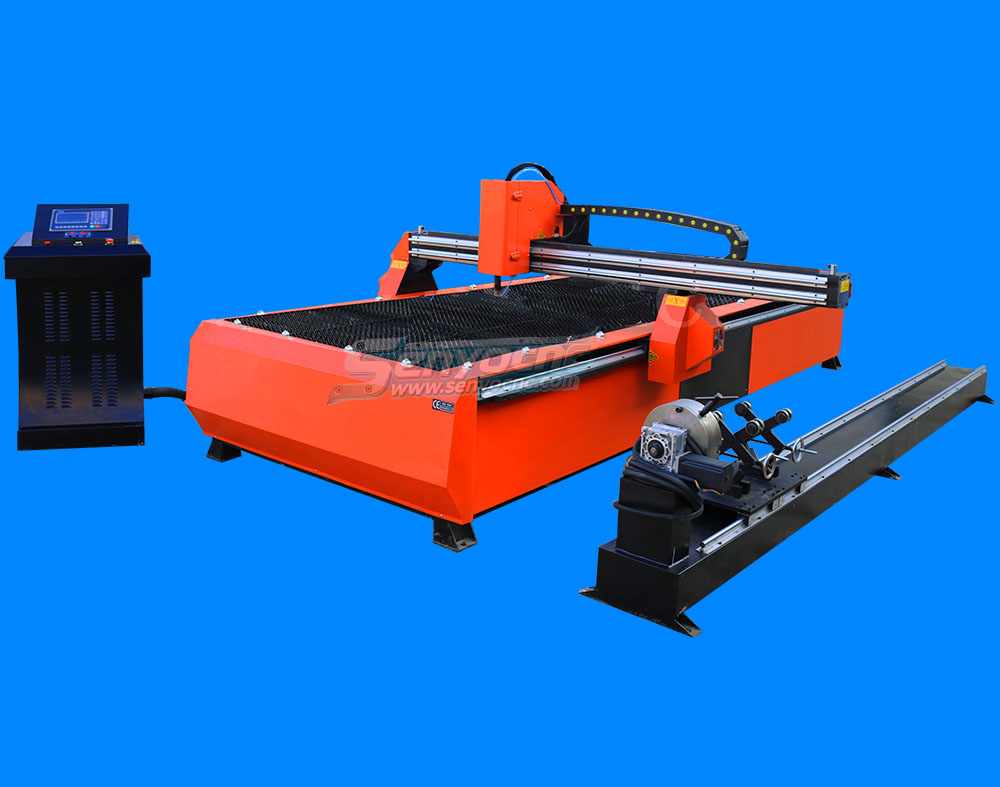

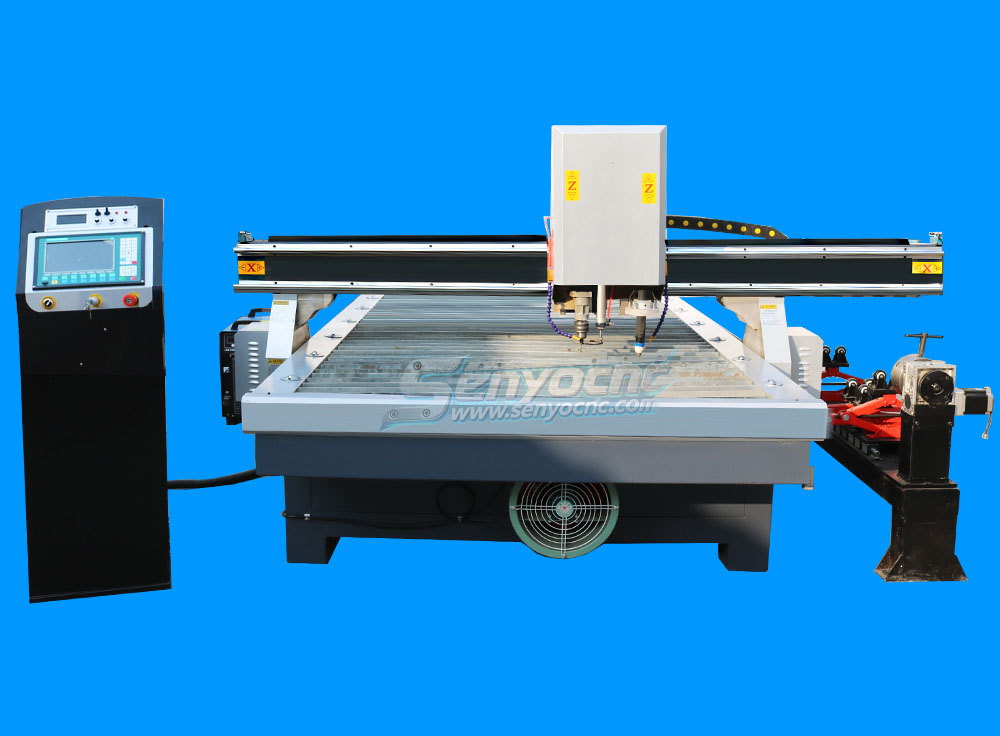

1. The plasma cutter can cut large and small metal parts. The working size is 1000*2000mm and we also can customize the working size according to your requirements, like the Y axis, we can make it up to 8-10m.

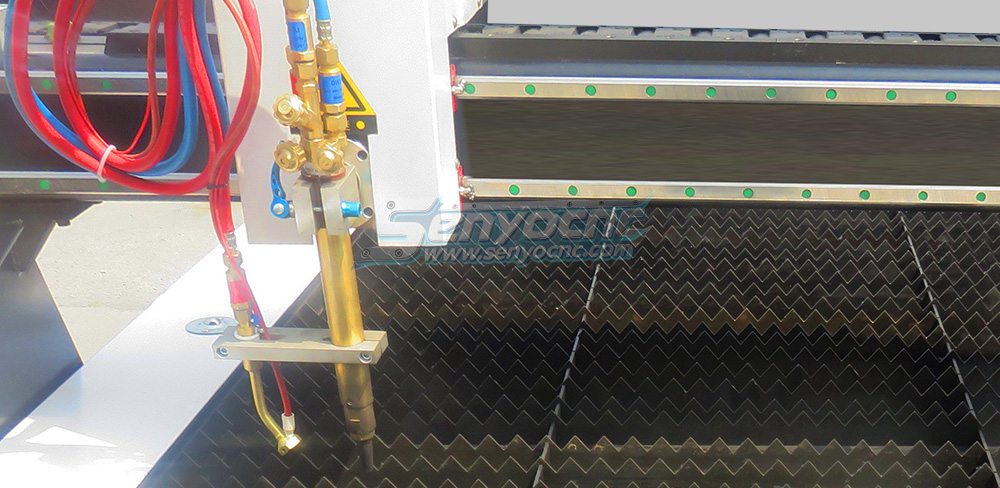

2. The CNC plasma cutter has two cutting head, one of them is Hypertherm plasma cutting head and other is independent lift flame cutting head can cutting around 150-200mm metal.

3.Power supply can provide a high and stable power when the portable CNC plasma & oxy-fuel cutting machine working.

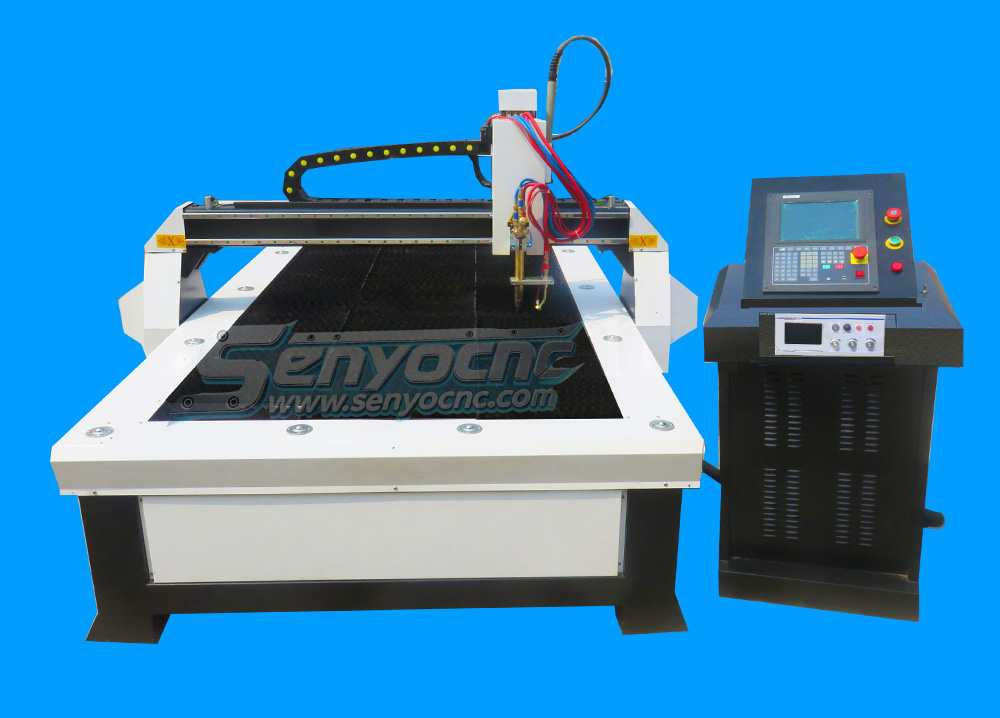

4. STARFIRE control system and with ARC voltage automatic height adjusting device, arcing can protect plasma torch from damage, improve the cutting quality, the success rate is over 99%.

5. Double guide and square rails can keep the portable CNC oxy-fuel gas and plasma cutting table stability.

6. Ultra big torque stepper motor and driver with features of function detecting, high running precision, wide speed range and short speed up time.

7. High-precision HIWIN rail linear guide, smooth movement to ensure that the CNC oxy fuel cutting machine tools with high precision, small cutting gap, no residua.

8. Excellent performance on cutting illuminated letters for advertising and channel letters on sheet metal.

9. Perfectly design, equipped with the best machine accessories to minimize the failure rate preferred.

10. The portable CNC flame cutting machine supports G-code files of ARTCAM, Type3 software. It also supports DXF files of AUTOCAD by transfer software. The control system supports U disk file transfer.

Advantage

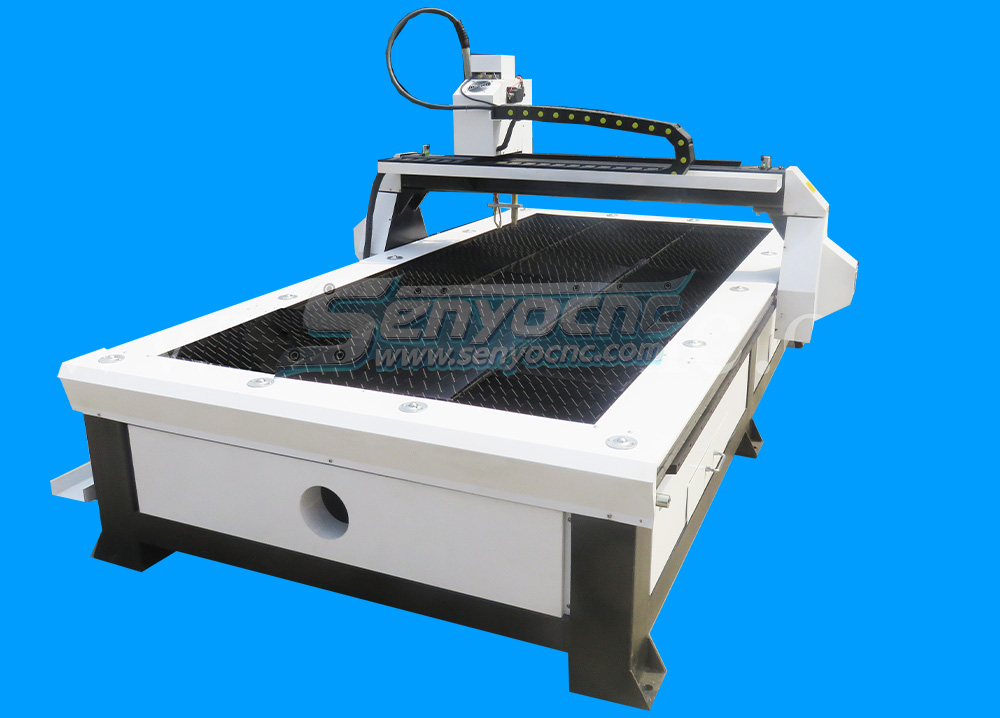

1.Welded lathe bed of thick profiled steel, more solid and stable.

2.Perfect lathe table design, 10mm steel plates fixed on lathe table covered by cast sheath.

The level difference of platform remains in 0-1.5mm.

3.Advanced material inclined discharging design.

4. CNC system configuration high, automatic arc, stable performance, the success rate of 99% arc

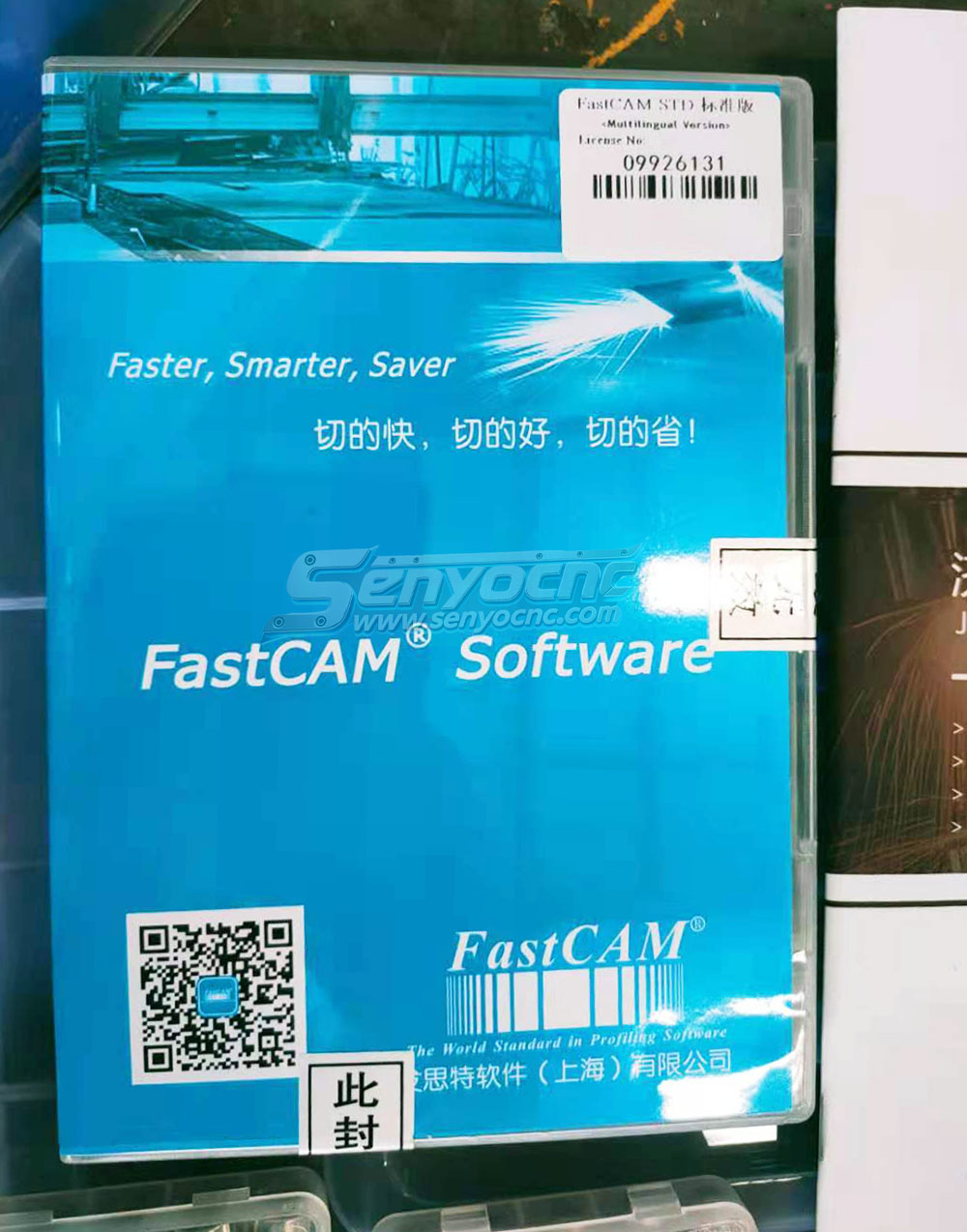

5. Support Fastcam, ARTCAM, Type3 software such as the standard G code path generated file can

also be read by software conversion software such ad AUTOCAD generated DXF formats.

U disk exchange control system processing files, easy to operate.

6. Plasma torch power supply and supporting all famous brands, a number of national patents by the

manufacturers

Technical Parameters

Model name | SYP1020 |

Effective cutting area(X*Y) | 1000×2000mm |

Working material | Iron, steel, sheets, galvanized sheets, titanium plates etc |

Cutting thickness | 50mm /Large thickness cutting 200mm |

Plasma power | Hypertherm or Chinese Power with flame cut head |

Drive Mode | double-axis linear guide rails |

CNC system | Beijing START /Starfire for option |

Plasma cutting speed | 50-6500 mm/min |

Cutting torch lifting distance | 150mm |

Speed setting error | ≤±5% |

Torch height controller accuracy | ≤±1.0mm |

Longitudinal line accuracy | ±0.2mm/m |

Motor and drivers | Stepper |

Gear box | Cast Iron (Better than welded) |

Drive Method | Rack and square rails for X Y Z axis |

Rail Brand | Taiwan HIWN Or PMI |

Moving Precision | 0.01mm per step |

Height controller(plasma) | PHC330-Arc voltage height controller for plasma cutting |

Idling Cutting speed | 0-16000mm/min |

Input voltage | 3 phase 380V |

Power frequent | 50 Hz or 60HZ |

Cooling system | Water chiller |

Gas consumption | Compressed air, oxygen, nitrogen, etc. |

Optional air compressor | 0.8MPa |

General machine accuracy | ±0.05mm |

Models Option

Parameters: | SYP1350 | SYP1530 | SYP2030 |

Working material | Stainless steel/Iron sheets, Aluminum sheets, Galvanized sheets, Titanium Plates | ||

Working Area | 1300x5000mm | 1500x3000mm | 2000*3000mm |

Cutting Thickness | (45A)0.3-8mm | (45A)0.3-8mm | (45A)0.3-8mm |

Brand: LGK/US-Cutmaster/US Hypertherm (optional) | (65A)0.5-12mm | (65A)0.5-12mm | (65A)0.5-12mm |

(85A)0.5-15mm | (85A)0.5-15mm | (85A)0.5-15mm | |

(105A)0.5-18mm | (105A)0.5-18mm | (105A)0.5-18mm | |

(125A)0.5-25mm | (125A)0.5-25mm | (125A)0.5-25mm | |

(200A)0.5-30mm | (200A)0.5-30mm | (200A)0.5-30mm | |

Cutting Speed | 0-6000mm/min | 0-6000mm/min | 0-6000mm/min |

Moving Speed | 0-12000mm/min | 0-12000mm/min | 0-12000mm/min |

Power | 8.5KW-10.5KW | 8.5KW-10.5KW | 8.5KW-10.5KW |

Input Voltage | 3 phase 220/380V | 3 phase 220/380V | 3 phase 220/380V |

Power Frequency | 50/60Hz | 50/60Hz | 50/60Hz |

Files Transfer | USB Interface | USB Interface | USB Interface |

Arc | Untouched Arc Striking | Untouched Arc Striking | Untouched Arc Striking |

Torch Height Controller | Torch Height Controller | Torch Height Controller | |

Working Samples Project

For cutting iron, aluminum, titanium plate, stainless steel plate, galvanized steel, white steel and other

metal materials.

It's widely applied in industries such as machinery, automobile, shipbuilding, petro-chemical,war industry,

metallurgy, aerospace, boiler and pressure vessel, locomotive etc.

Applies in cars, motorcycles, pressure vessels, chemical machinery, nuclear industry, general machinery, engineering machinery,steel structure, hipbuilding and other industries.

Components of a CNC Plasma Cutting Table

Knowing the components and parts of a CNC plasma cutting table is always a firsthand lesson for any beginner. The primary components are,

1. Plasma Torch

2. CNC Controller

3. Cutting Bed

4. Power Source

5. Software

6. Motion Control System

7. Torch Height Control (THC) and

8. Fume Extraction System

Tips for Maximizing Efficiency and Performance

It is important to measure and ensure the maximum efficiency of your cutting table to achieve ultimate profit out of your production.

A few tips can boost your table’s performance in the long run. Additionally, you will find your CNC plasma cutting table a more cost-effective tool in the long run.

⇲ Regular maintenance is a must to ensure all components are in optimal condition.

⇲ Regular calibration is similarly important to maintain accuracy and consistency in cutting.

⇲ Use high-quality consumables such as electrodes, nozzles, and cutting tips.

⇲ Optimize cutting parameters by experimenting with different settings.

⇲ Make sure the material is properly secured before starting the machining.

⇲ Train the operator on nesting software and advanced software features.

⇲ Monitor performance metrics and quality of production routinely.

Pros & Advantages

✔ Consumable parts have the longest life in the industry.

✔ Pilot arc circuit increases pilot arc current precisely when needed, significantly reducing nozzle wear.

✔ The Hypertherm quick-disconnect torch assembly provides easy switching between hand torch and machine torch, and it also features a stress-relief design for durability.

✔ Ease of Use - Easy and convenient gas regulation and current regulation.

✔ Very safe to use When the wearing parts are removed, the interlock device will prevent the machine from starting.

✔ With a special voltage fluctuation compensation device, there is no need to worry about the impact of voltage fluctuations on the machine.

✔ All equipment is equipped with a standard CNC/automatic machine interface, enabling automatic control and quick transfer to machine operation.

✔ New "fan on demand" function minimizes dust inhalation.

✔ Torch lead sheath made of AC chemistry resists jet and cut-through capabilities of molten metal.

✔ Accurate fault alarm indicator light makes it easier for you to operate and maintain.

✔ Auto-voltage™ automatic voltage regulation capability, which can automatically adapt to various input power sources of 200V-600V and three-phase.

✔ Coaxial-assist™ technology increases cutting speed.

✔ The Boost Conditioner™ input voltage compensation circuit compensates for fluctuations in the input voltage, which improves the performance of low-voltage lines, motor generators, and input power (fluctuations).

✔ Design for reliability improves downtime and greatly reduces investment.

✔ CNC interface and Easy Torch Removal (ETR™) are versatile for both handheld and machine use.

Cons

✔ Higher price than ordinary plasma power supply.

✔ Compared with the fiber laser cutting machine, the plasma cutting gap is larger, the cutting end surface is rougher and not smooth enough, and the cutting precision is lower.

Safety Considerations

Safety measurements are very important steps while working with plasma cutters. Plasma cutting involves high-temperature electrical currents which come with significant safety hazards. Proper safety measures are a must to avoid any unwanted exploration.

A few probable hazards that can occur due to the lack of safety considerations are,

⇲ Risk of high voltage electric shock

⇲ A densely heated plasma arc can cause fire and eventually potential to burn

⇲ Hazardous gases and fumes can cause severe health issues

⇲ Risk of eye injury from UV radiation

Now the 5x19 Hypertherm Plasma Cutter is equipped with various safety features. To minimize risk and ensure safe operation several features are added. Such as,

⇲ Thermal overload protection

⇲ Emergency stop button

⇲ Machine Guarding

⇲ Voltage monitoring system and

⇲ Safety interlocks

Proper training and availability of safety equipment including PPI and Glasses are recommended before start using the plasma cutter.

Environmental Impact

Like any industrial process plasma cutting can impact the environment to a great extent. It is necessary to consider the environmental impact of plasma cutting to minimize the chances of affecting our environment badly.

Plasma cutting can result in several environmental changes including,

⇲ Air pollution due to excessive fume, smoke, and bi-product

⇲ Uncontrolled usage will affect excessive power consumption

⇲ Off-cuts and scrap materials can be responsible for polluting the environment directly

⇲ Additional water usage as coolant and the chemical bots mixed within water particles can contaminate it to a greater extent

It is a matter of hope that the advanced technology of the Hypertherm plasma cutter utilizes electricity consumption. Implementing strategies to minimize wastage and emissions can help save the environment from pollution. Optimizing the machine parameters will also make a helpful impact on overall environmental detoxification.

Packaging Details

• Outside package: Standard marine export plywood case.

• Inner package: Stretch film and plastic film for humidity.

We can package according to your requests.

Warranty And Service

• 24 months whole machine warranty and maintenance for a lifetime.

• Free installation and testing before shipping and free training for operators

• Advice for the best CNC solutions for customer's requirements.

• Free training and sample making.

• 7/24 free service and support.

1. Metal Fabrication CNC Plasma Cutting

2. Industrial Plasma Cutting

3. Custom Plasma Cutting

4. CNC Plasma Cutting for Automotive

5. CNC Plasma Cutting for Construction

6. Sheet Metal Plasma Cutting

7. Precision CNC Plasma Cutting

8. CNC Plasma Cutting for Stainless Steel

9. CNC Plasma Cutting for Aluminum

• Previous: Best Frame CNC Plasma Cutting Machines for Precise Cuts in Steel, Iron and More metal

• Next: High-Precision Mini Hobby CNC Plasma Cutting Machine for Metal

Fiber metal Laser Sensor And Its Application

Category: SENYO NEWS 11th Mar, 2021A CNC wood router will use 3D machining in relief carving, the effect is more artistic beauty, but also has a strong sense of three-dimensional 3D, realization of this function is to ...

Precision Cutting Stents with Fiber Lasers

A CNC wood router will use 3D machining in relief carving, the effect is more artistic beauty, but also has a strong sense of three-dimensional 3D, realization of this function is to ...

How to Laser Cut Copper and Other Reflective Metals

Laser cutting of mild steel and stainless steel has a long history and has been one of the primary applications for CO2lasers. However CO2lasers have not traditionally offered a good solution for cutting highly reflective materials.Fiber lasers have an emission wavelength of around

Laser Cutting Machine Inspection Process For Manufacture

SENYOCNC Have Strict quality monitoring will be carried out when the parts are in the factory.

How Control Costs Use of UV Printers ?

UV flatbed printers are rapidly being used by more and more manufacturers, thanks to its efficient production efficiency, and the control of production costs also needs to arouse our attention.

Why UV flat printing machine is popular in market ?

For the majority of designers, give full play to the creative ability, the design sample can be arbitrarily modified on the computer, the effect on the computer, is the effect after the finished product, customer satisfaction can be directly produced. UV flat printing pattern fine, rich and clear layers, high artistry, strong three-dimensional sense, many high precision equipment can also print photography and painting style patterns.

How does UV ink jet printer save UV ink?

UV inkjet printer use process is an important consumable UV ink, reasonable use of equipment, can save UV ink , it can be said to be the best choice to directly save the cost. In the process of using some skills you need to be familiar with, the following small make up to share with you:1. Try to us

Waterjet Machine delivery and Shipping

Please tell us your max working size and what materials will cutting , also what max cutting thickeness.If you have Working photo sample please also send us , it will be helpful to choose machine with suitable models .

Waterjet Machine finish manufacture 5axis

Waterjet cutting technology is one of the fastest growing major machine tool processes in the world due to its versatility and ease of operation.

Waterjet Machine delivery and Shipping

Waterjet cutting technology is one of the fastest growing major machine tool processes in the world due to its versatility and ease of operation.There are multiple advantages to adding waterjet cutting capabilities to your shop.We are company leading ultrahigh-pressure waterjet system so

How to Create Connected Text – Inkscape for Laser Cutting

Step 1: Create Some TextFirst, we need some text to work with. To create the text, select the Text Tool (keyboard shortcut: T), click somewhere on the canvas, and type your text.You can use the drop-down list on the top left to select your desired font.Step 2: Convert Text to PathNext, we need to tu

Jacob from United States

I am a beginner at CNC, I’ve never used a CNC machine before and with in a day I was carving. An awesome machine for a beginner to learn as hobbyists. I used the manual and the help video. One hour to assemble and test, very friendly and easy to use. It’s a good buy for the money. I would definitely recommend this machine to someone getting into CNCs.

Weinstein from France

I've been using CNC plasma SYP2060-300A and I am very impressed with this unit.

This unit is of higher quality, made in China. Five stars all the way!

2040 from INDIAN

Best 2040 CNC Router Good Price and Quality ! Thank SENYOQC

10w uv laser from American

Best supplier ! I bought 3 machines for laser and router , thank you Aillen ! --Alec

12KW Fiber Cutting - 2000X6000mm -- 이병헌 from Korea

Good machine for metal cut ! Thanks Senyo , Its prefect , I like your business patient kind!

I am a furniture manufacturer, and this machine is very good and fast. thanks Senyoqc Team ! from Bangladesh

Metal ArtWork from Denmark

The plasma cutting machine makes my artistic creation more convenient and precise!! Created more artistic ideas and value! Thank you Aillen team!

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen. from

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen.

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo from

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo

Thank you Senyo for SYJ1290-150W! from

Retired, ex mainframe systems programmer. Now full-time recreational woodworker majoring in puzzles, pens, boxes, Toys and occasional small furniture. Thank you Senyo for SYJ1290-150W!

manager@senyocnc.com

manager@senyocnc.com

SENYOCNC

SENYOCNC

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

2061579344

2061579344