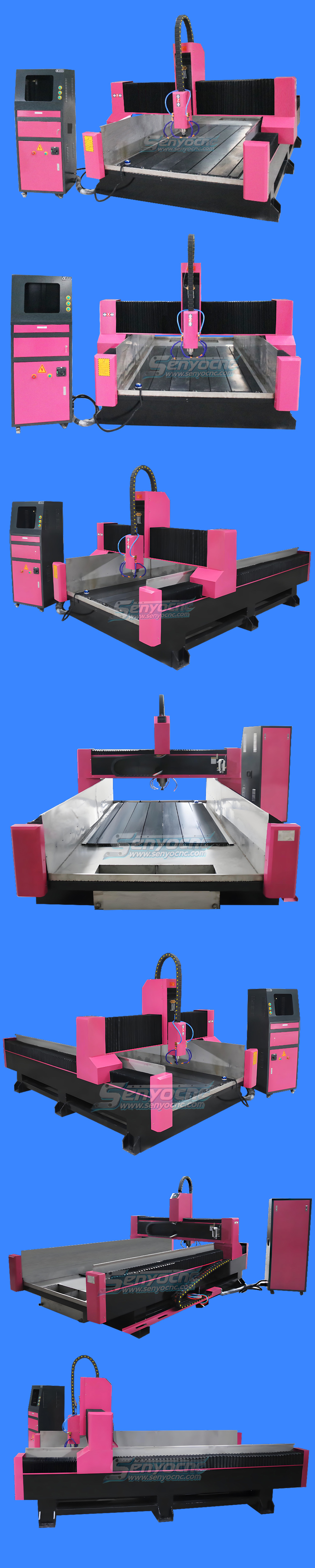

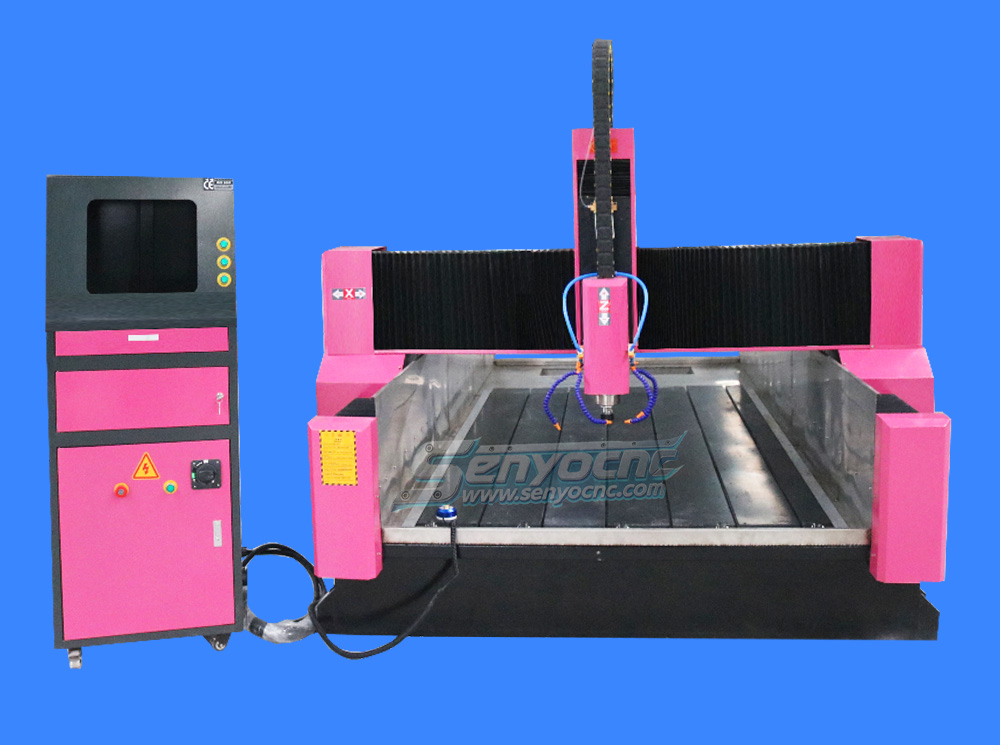

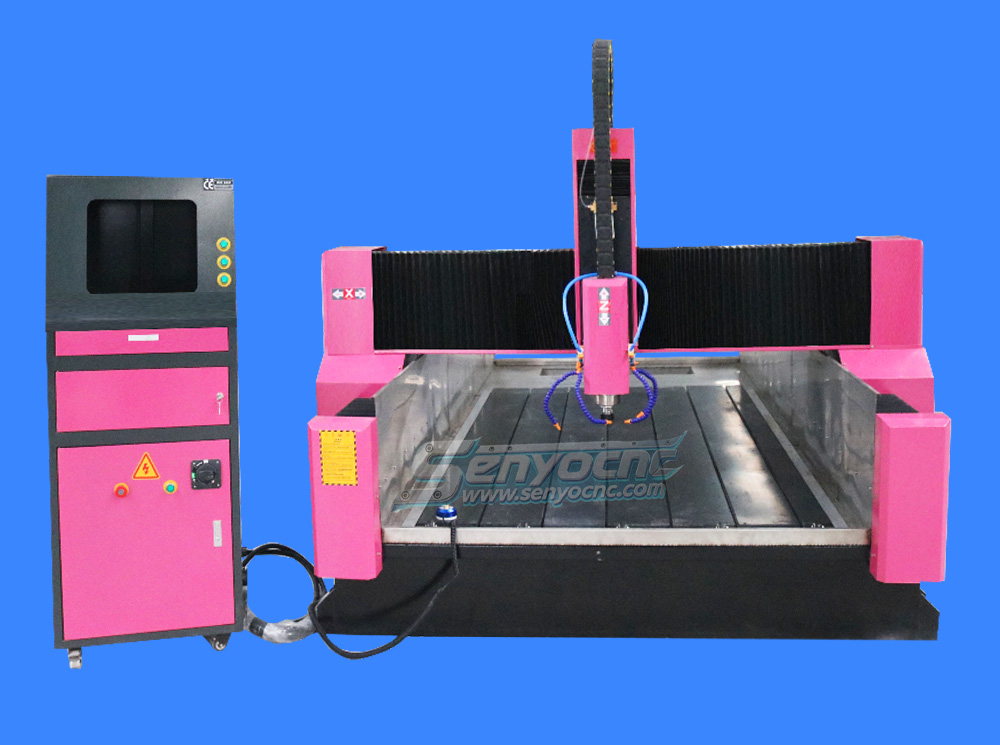

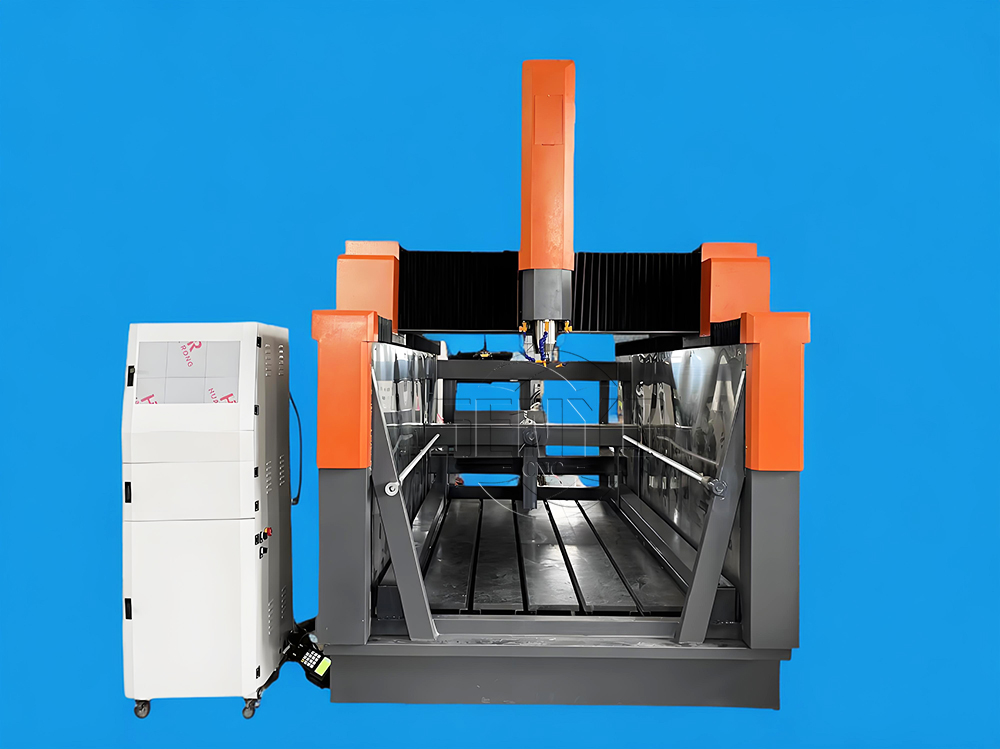

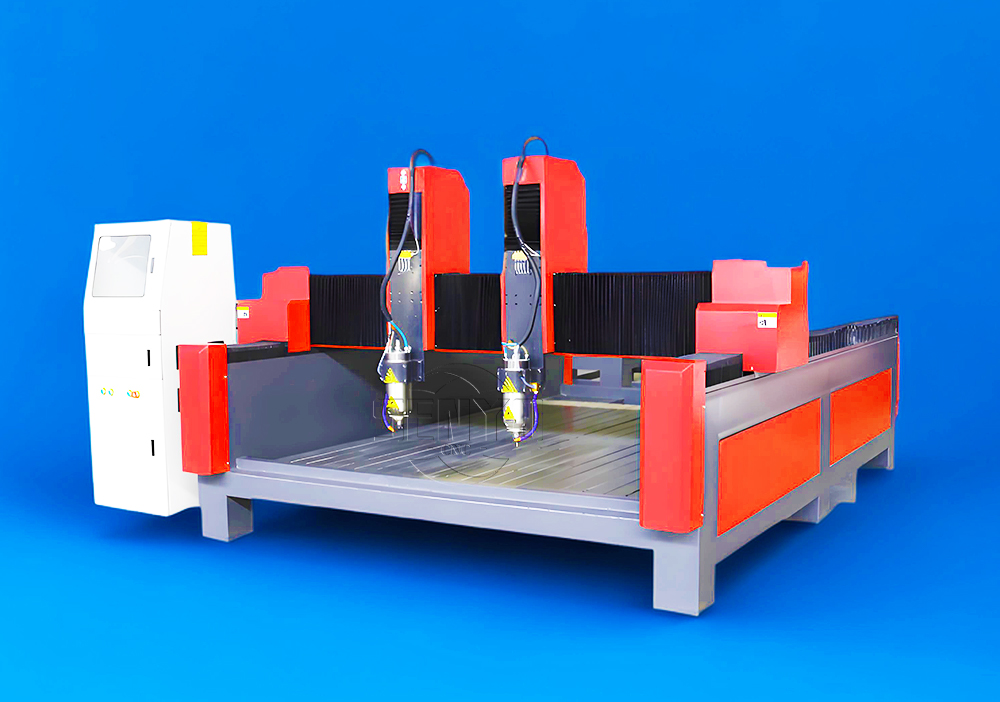

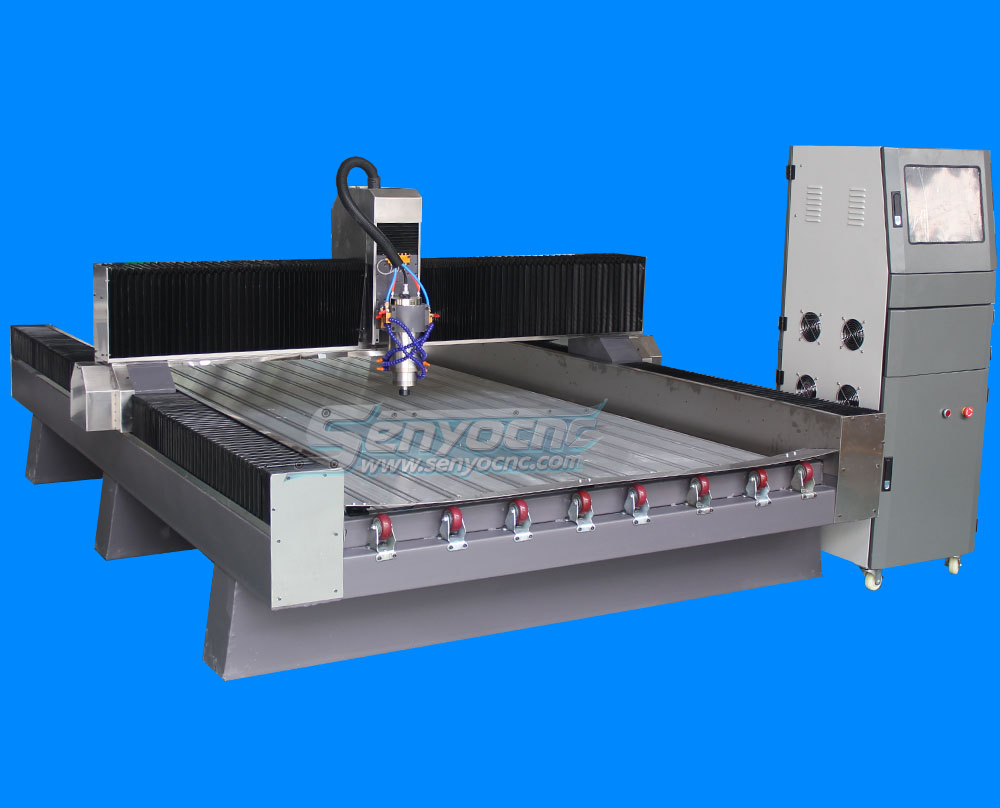

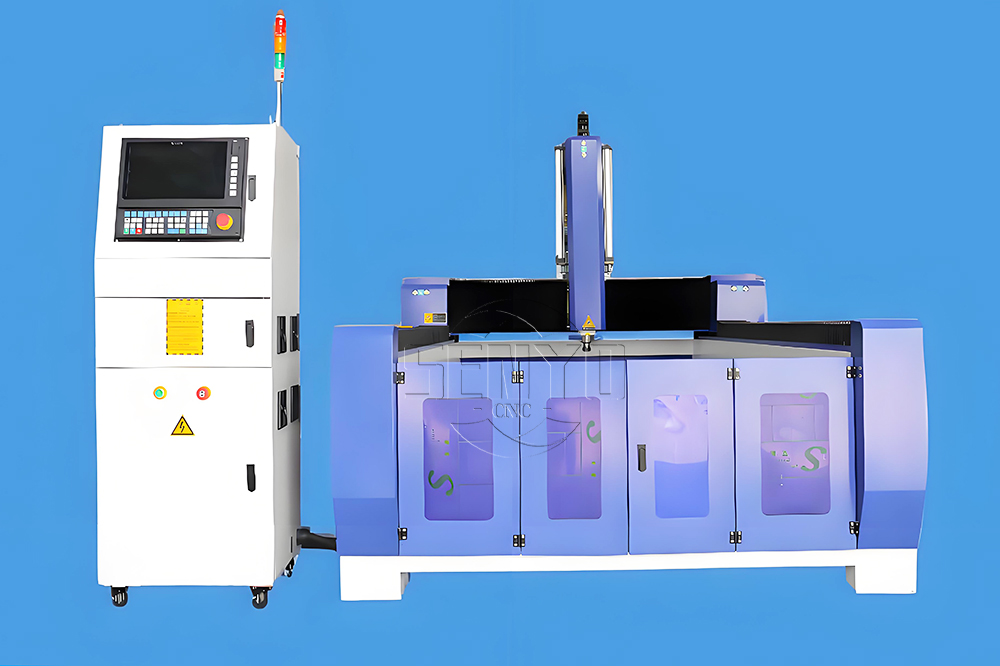

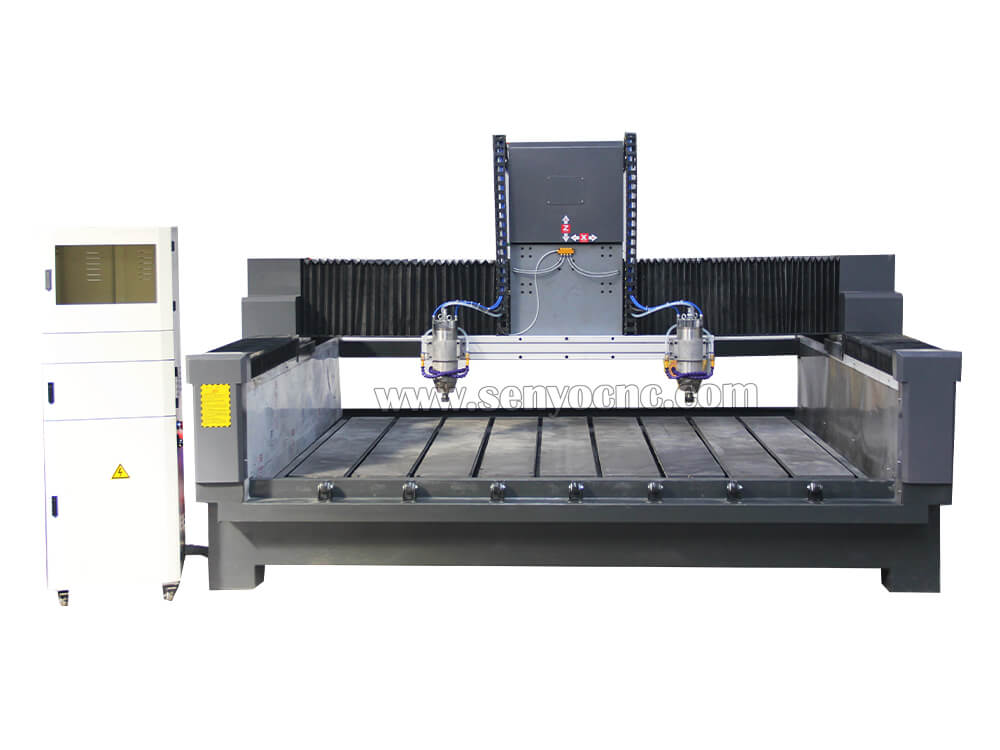

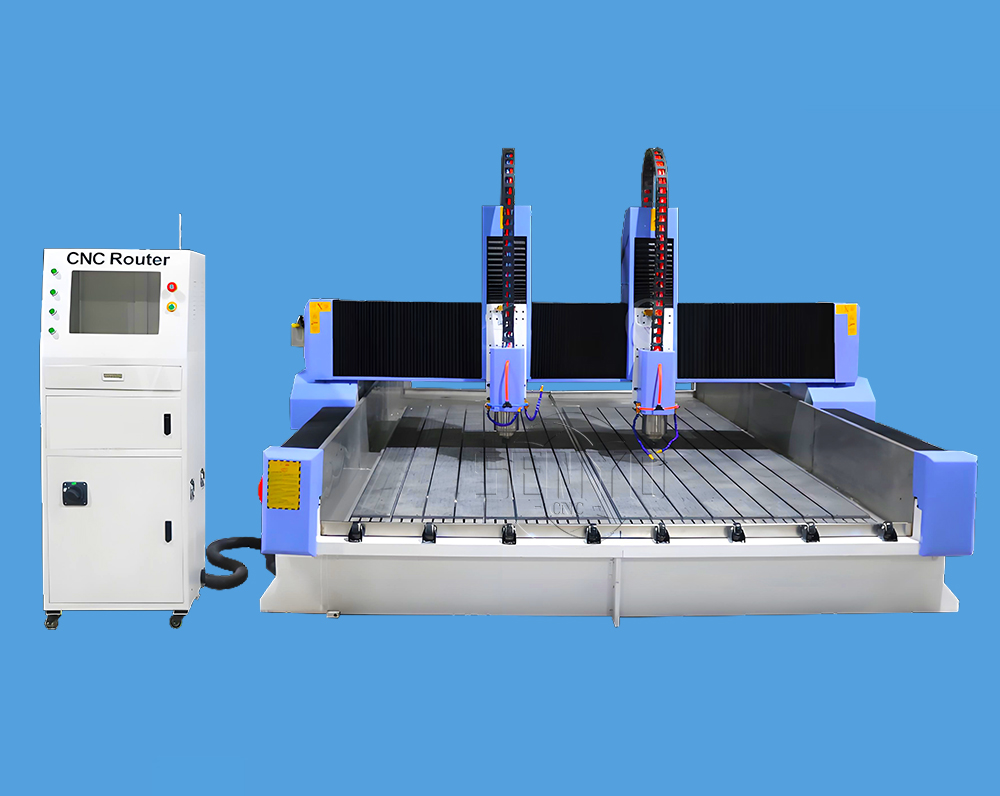

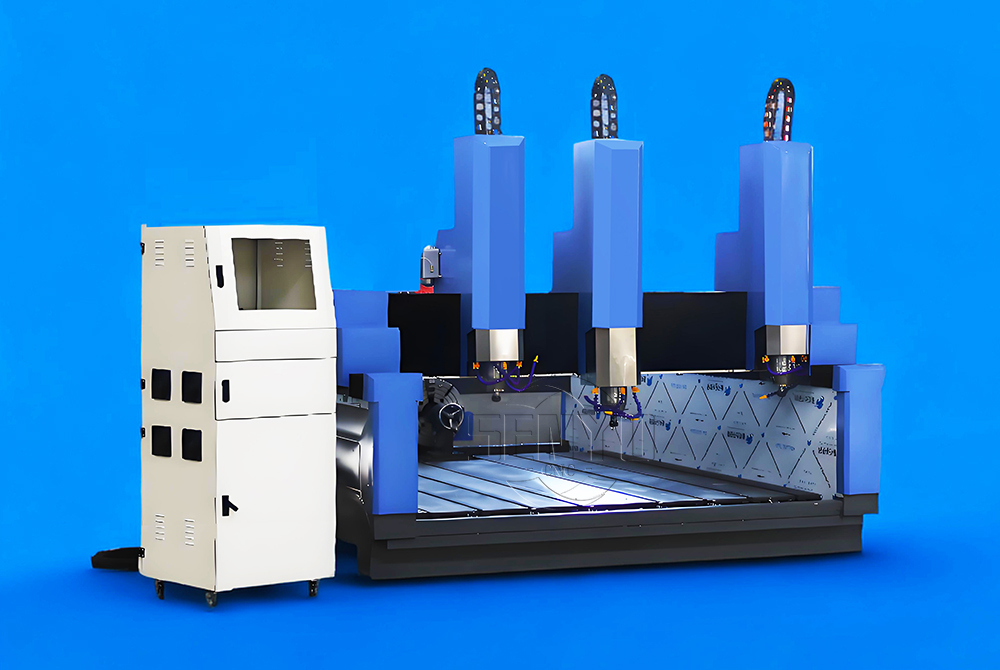

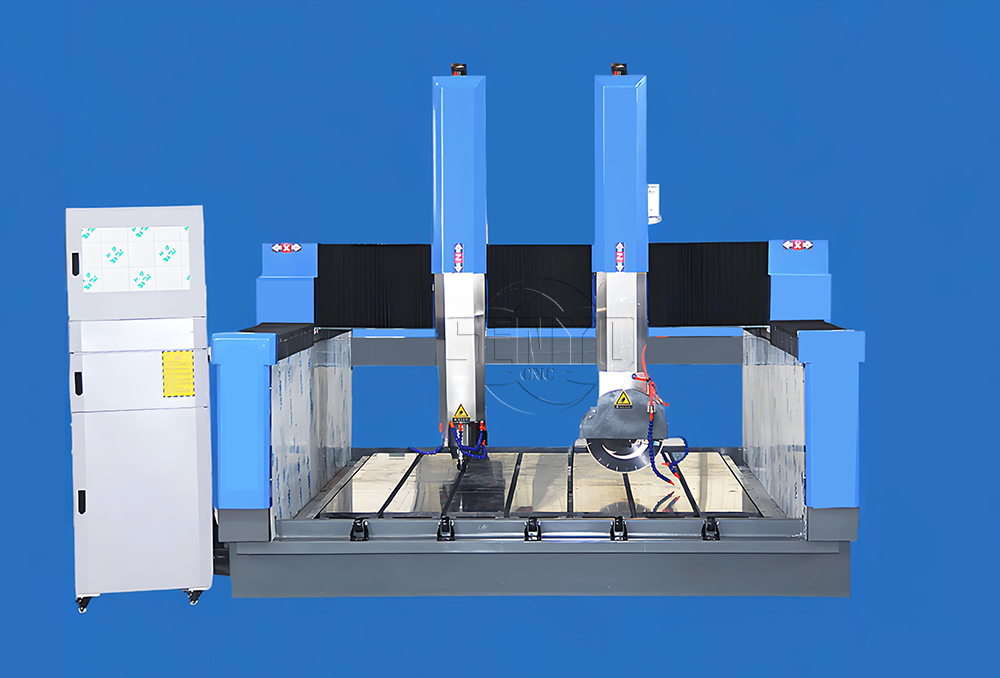

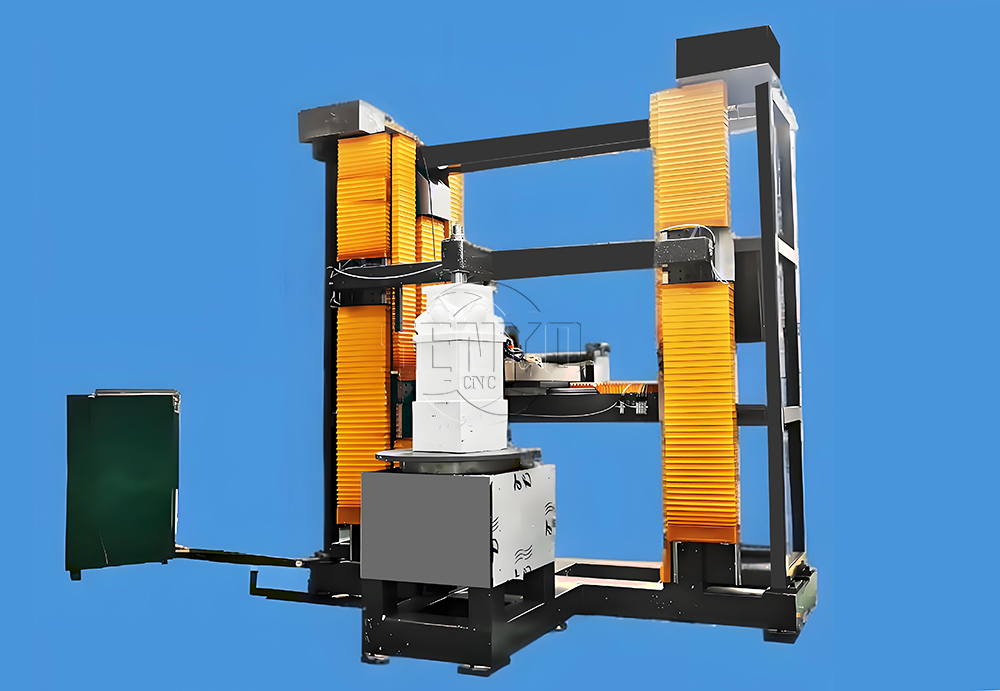

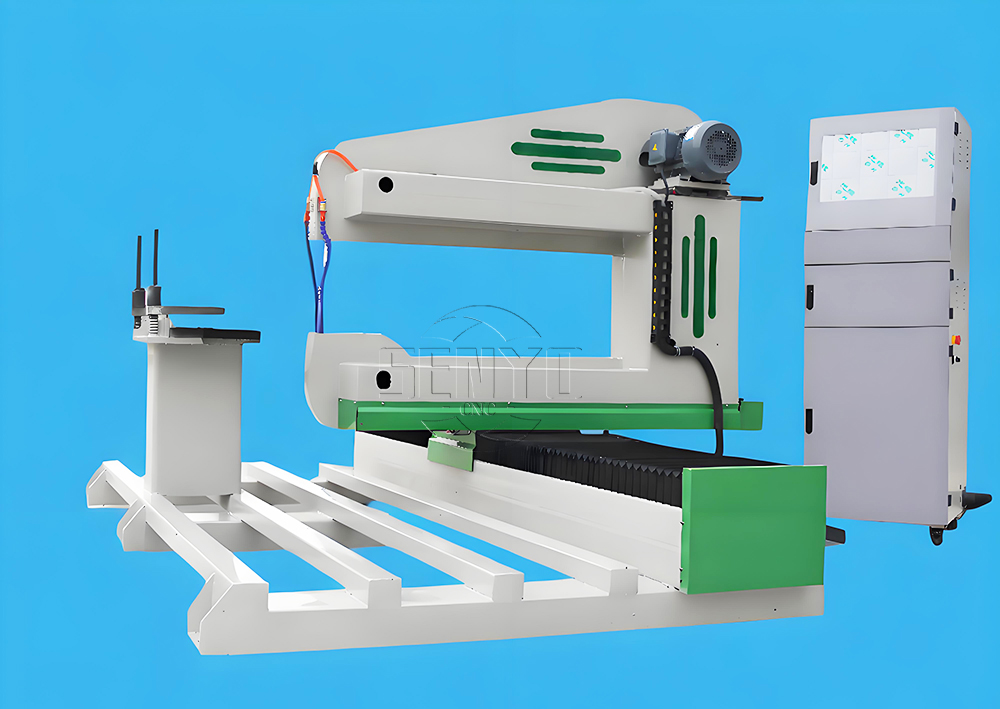

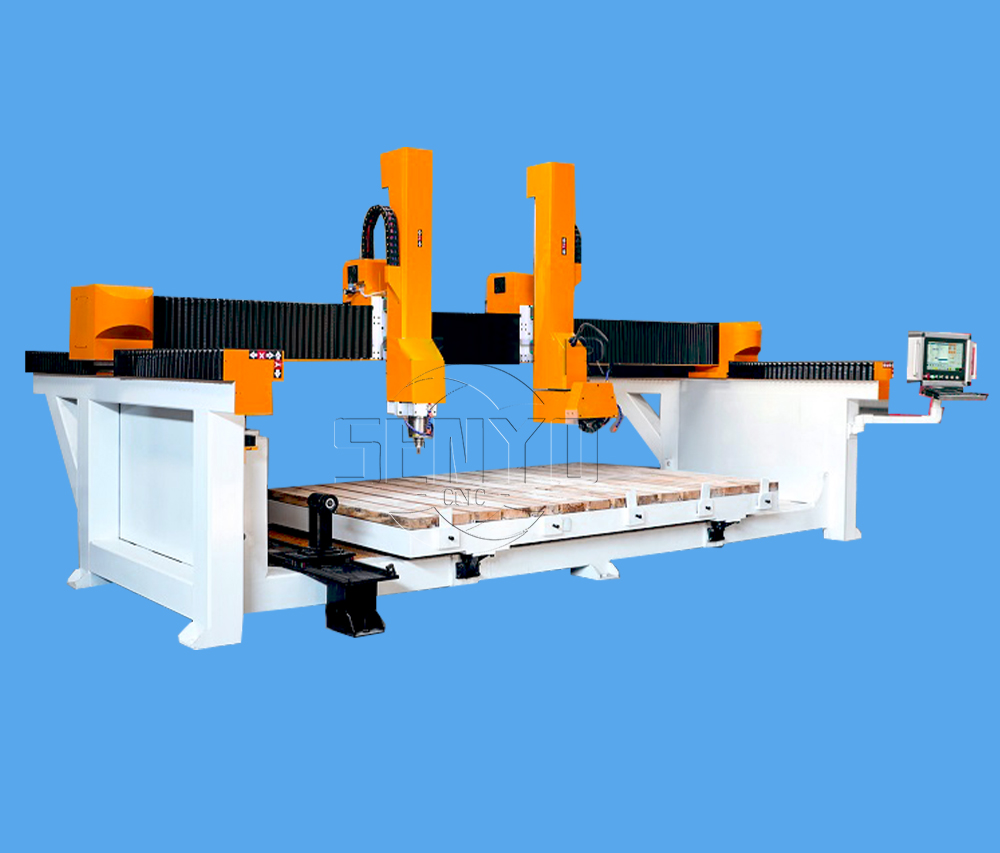

What is a 5x10 CNC Stone Carving Machine?

A 5x10 CNC stone carving machine is a specialized, computer-controlled device that cuts, engraves, and shapes stone. Its extra-large 5x10-foot bed size lets it handle large slabs of stone, ideal for architectural and industrial applications. Such a precision, automated machine can create intricate designs on hard-surface stones like granite, marble, and others.

It involves high-speed routers for engraving, milling, and carving, with the ability to do detailed work. One can program it for multiple tasks to get the same consistency in each project. Software available for its use allows one to have complex patterns and 3D design versatility for both decorative and functional works of stone.

From monuments down to custom countertops, the 5x10 CNC stone carver proves to be highly valuable. It's just what a company needs to take full leverage on its production process in a very effective way regarding efficiency, precision, and consistency.

Technical Parameters of 5x10 CNC Stone Carving Machine

| Model | SYS1530 |

| Working Area | 1500x3000x300mm |

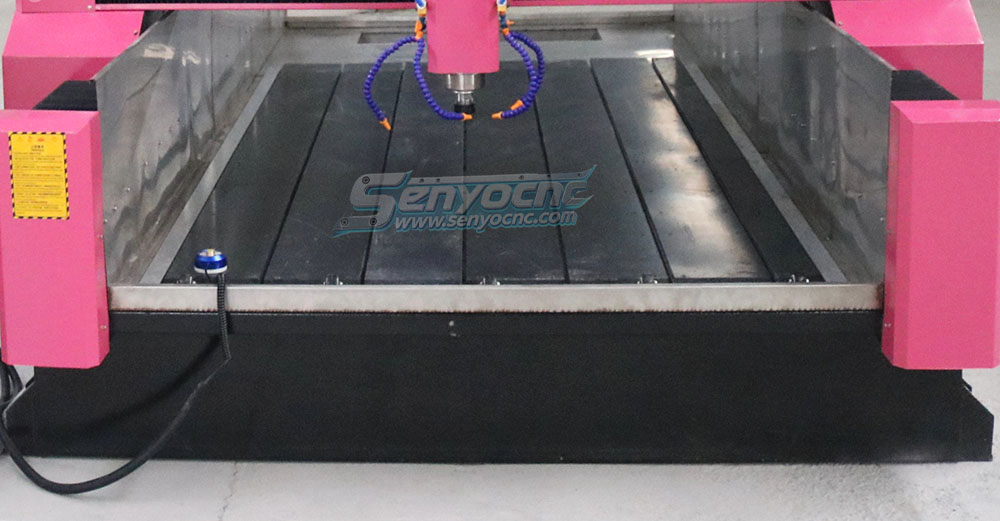

| Table Size | 1560×3340mm |

| Traveling Positioning Accuracy | ±0.03/300mm |

| Repositioning Accuracy | ±0.03mm |

| Frame | Welded Structure |

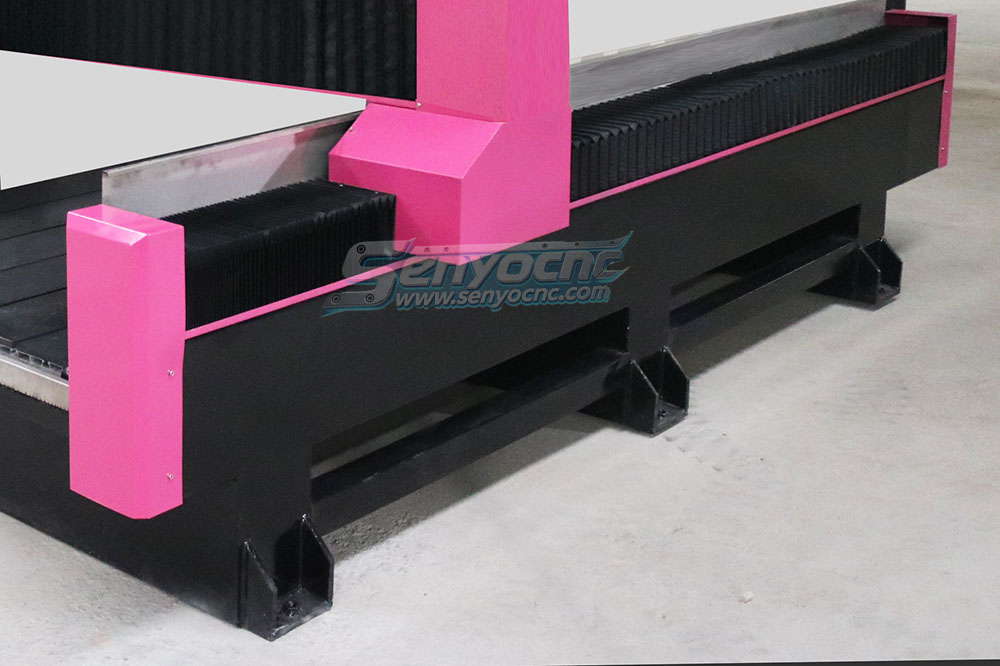

| X, Y Structure | Rack and Pinion Drive, Hiwin Rail Linear Bearings |

| Z Structure | Hiwin Rail Linear Bearings and Ball Screw |

| Max Carving Speed | 3000mm/min |

| Spindle Power | 5.5KW |

| Drive Motors | Yaskwa servo system |

| Working Voltage | AC380V/50/60Hz,3PH (Option: 220V) |

| Command Language | G Code |

| Operating System | NC studio control system |

| Computer Interface | USB |

| Flash Memory | 128M(U Disk) |

| X,Y Resolution | <0.03mm |

| Software Compatibility | Type3/UcancameV9 Software (Option: Artcam software) |

| Running Environment Temperature | 0 - 45 Centigrade |

| Relative Humidity | 30% - 75% |

5x10 CNC Stone Carving Machine Features

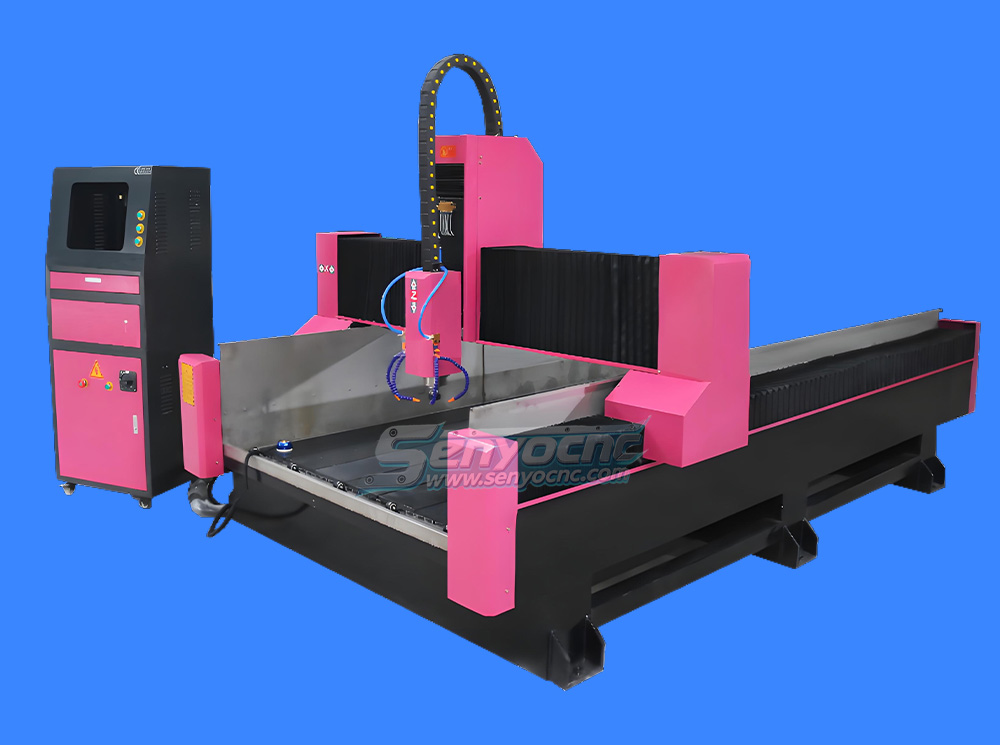

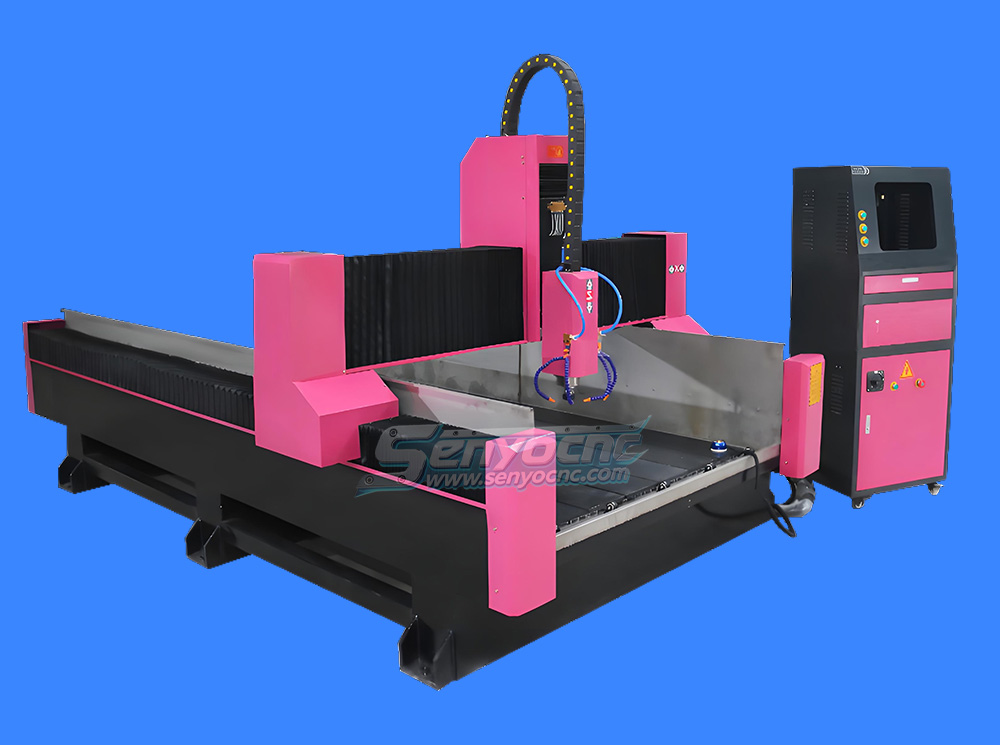

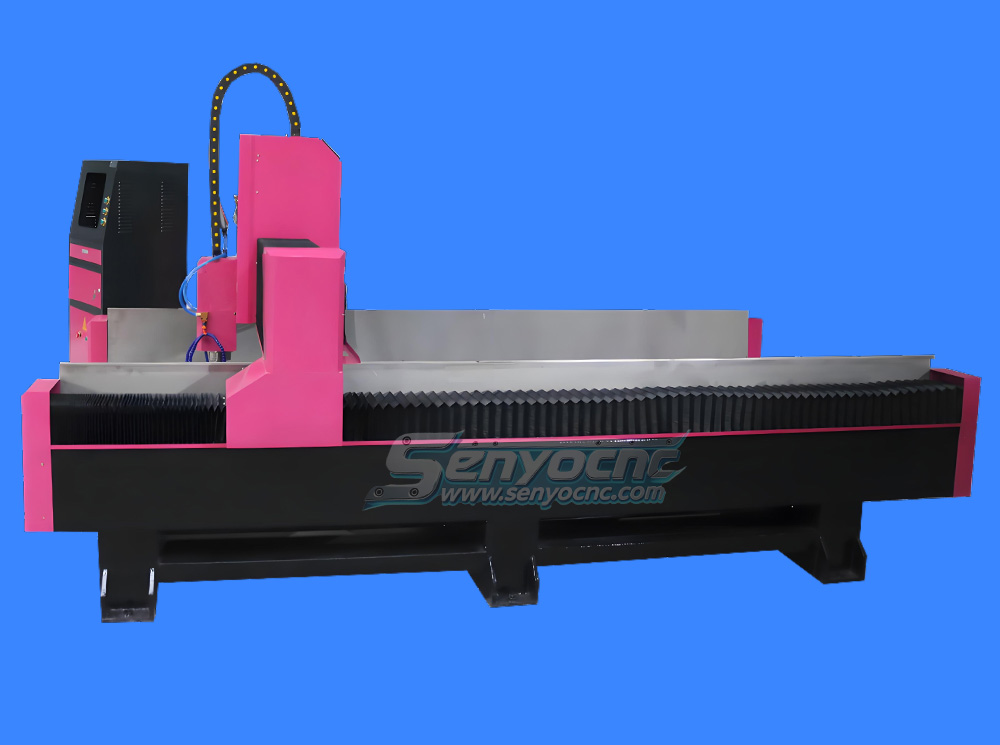

1. The 5x10 CNC stone carving machine bed is welded by the thick wall steel seamless tube, high-temperature tempering treatment, high rigidity, and bearing strength better.

2. The 5x10 CNC stone carving machine adopts a dual Yaskawa servo motor drive for the Y-axis, moving stably with high speed.

3. High-power spindle motor with a direction water-cooling system, strong carving and cutting strength, and high efficiency.

4. Taiwan Hiwin linear square guide way, double row four row slider, high precision, long service life.

5. Dustproof and waterproof design, better to protect the machine driving part.

6. Auto oil lubrication to make the maintenance more easy.

7. Stainless steel water tank for stone carving.

Materials Compatible with the 5x10 CNC Stone Carver

The 5x10 CNC stone carving machine is highly versatile and capable of working with various stone types. Its adaptability to different materials makes it ideal for businesses involved in diverse stone projects.

Granite, Marble, and Quartz

Granite, marble, and quartz probably hold the number one position among stones used in CNC stone carving. These stones are hard and thus give excellent, lasting finishes. With the precision of a CNC, an artist would be able to engrave detailed patterns, cut out custom shapes, or make complex designs without having to sacrifice the integrity of the material.

Limestone, Slate, and Sandstone

Limestone, slate, and sandstone are more natural in appearance and softer, thus easier to engrave, than harder stones. This can enable intricate engravings and patterns on such softer stones for more ambitious architectural and decorative projects such as cladding, fireplaces, and sculptures.

Onyx and Travertine

Onyx and travertine have unusually exquisite patterns; hence, they are valued in creating applications requiring high-end values. Gentle and controlled actions by the CNC machine minimize chipping and cracking, retaining the integrity of delicate, translucent stones like onyx. The material application would be intended for high-end projects: inlays, backlit panels, inlaid tables, and decorative wall features.

Soapstone and Bluestone

Soapstone and bluestone are versatile options for intricate designs and carving. While they are soft and easy to shape, they still offer durability and a unique, natural appearance. These materials are popular for countertops, artistic carvings, and specialized architectural features, where the CNC machine allows precise, consistent cuts.

Best 5x10 CNC Stone Carving Machine Applications

Stone Industry: Stone, ink-stone cutting, tombstone, jade, and marble products.

Kitchen Ware Industry: Man-made marble cabinet table surface.

Artwork Decoration Industry: Woodcrafts, gift boxes, jewelry boxes, and other exquisite art crafts.

Woodworking industry: Chair, doors, windows, beds, cabinets, kitchenware, and other furniture; Redwood classical and antique furniture, Exquisite European furniture, decorative products sculpture.

Mold Industry: Engraving copper, aluminum, and other metal molds; Building models, shoes, badges, embossed mold, biscuits, candy, and chocolate mold; Artificial marble, plastic sheeting, PVC, wood, foam, and other non-metallic mold.

Advertising Industry: Billboard, signage, badges, logo, company plate, signs, emblem, badges, display panels, fair signs, building numbers, signs of decoration, literal hole cutting, 3D character cutting, acrylic cutting, LED/neon channel, and lightbox making.

Best 5x10 CNC Stone Carving Machine Projects

How to Maintain a 5x10 CNC Router for Long-Term Performance

Proper maintenance is the key to keeping your 5x10 CNC router running smoothly for years. A well-maintained machine ensures consistent performance, reduces downtime, and prevents costly repairs. Follow these essential tips to extend the lifespan of your CNC router and keep it operating at its best.

Clean the Machine’s Operating Parts and Surface

Regular cleaning removes dust, debris, and metal particles that can build up over time. A clean workspace ensures smooth movements and prevents components from getting clogged or stuck. Neglecting cleaning can impact accuracy and reduce the machine's efficiency.

Lubricate Rails, Bearings, and Lead Screws

Frequent lubrication minimizes friction between moving parts, preventing wear and tear. Smooth operation ensures the machine runs without jerks or interruptions during work. Use the recommended lubricant to protect components and prolong their lifespan.

Inspect and Calibrate the Spindle

Regular inspection helps you detect unusual noises or signs of overheating early. Calibrating the spindle ensures precise cutting depth and avoids inconsistencies in performance. Neglecting the spindle can lead to imprecise cuts and impact product quality.

Check Wiring and Electrical Components

Tight and secure electrical connections reduce the risk of malfunctions or sudden shutdowns. Loose connections can cause operational errors or damage delicate machine parts. Make it a habit to inspect wiring to avoid unnecessary downtime or repairs.

Update Firmware and Software

Software updates from manufacturers often include performance enhancements and bug fixes. Regular updates ensure smooth and efficient operation without unexpected issues. Outdated software can lead to compatibility issues and affect machine functionality.

Monitor Cooling Systems

Cooling systems are essential when cutting aluminum, which generates heat during processing. Proper cooling prevents overheating that can damage components or reduce precision. Check the cooling system regularly to ensure it is functioning correctly for optimal performance.

Packing & Shipping

1. Outside package: Standard marine export plywood case.

Improved package, much more strong and environmental protection.

For Our Work Steps

1.Before-sale,we will try to know your requirement about our cnc router specification and what kind of work

you will do .then we will offer our best solution for your requirement.

2.During production: we will send photos of machines during making. so you can know more details about

the procession of making your machines.

3.Before shipping,we will take delivery photo and confirm the specification of order to avoid the mistake.

Machine will be adjusted before it is delivered.

4.After shipping: we will sent out the documents for your customs clearance ASAP . and check the

approximate date of arrival.

5.After arrival: we will confirm with you if machine is in good condition.and see if any spare parts missing .

6.About teaching: there are some manual and video about how to use machine , if you have question

about it. we will have professional technicist to help you install and teach how to use through skype ,

calling, video or mail.

Service & Support

1. Our engineers available to service machinery overseas.

2. 2 years guarantee for the whole machine.

3. Technical support by calling, mail, whatsapp and skype. If you have any problems, we will help you to solve it within 12 hours.

4. You will be get free training advice towards our machine in our factory.

5. If you need any component of the machine, we will provide most affordable price for you.

6. Friendly English version manual and operation video CD disk.

1. Stone CNC Router

2. CNC Router for Stone

3. Stone Engraving Machine

4. Stone Cutting CNC

5. Stone Carving CNC Router

6. Granite CNC Router

7. Marble CNC Router

• Previous: None

• Next: Industrial 3D Stone CNC Machine with Dual Spindles for Sale at Cost Price

Fiber metal Laser Sensor And Its Application

Category: SENYO NEWS 11th Mar, 2021A CNC wood router will use 3D machining in relief carving, the effect is more artistic beauty, but also has a strong sense of three-dimensional 3D, realization of this function is to ...

Precision Cutting Stents with Fiber Lasers

A CNC wood router will use 3D machining in relief carving, the effect is more artistic beauty, but also has a strong sense of three-dimensional 3D, realization of this function is to ...

How to Laser Cut Copper and Other Reflective Metals

Laser cutting of mild steel and stainless steel has a long history and has been one of the primary applications for CO2lasers. However CO2lasers have not traditionally offered a good solution for cutting highly reflective materials.Fiber lasers have an emission wavelength of around

Laser Cutting Machine Inspection Process For Manufacture

SENYOCNC Have Strict quality monitoring will be carried out when the parts are in the factory.

How Control Costs Use of UV Printers ?

UV flatbed printers are rapidly being used by more and more manufacturers, thanks to its efficient production efficiency, and the control of production costs also needs to arouse our attention.

Why UV flat printing machine is popular in market ?

For the majority of designers, give full play to the creative ability, the design sample can be arbitrarily modified on the computer, the effect on the computer, is the effect after the finished product, customer satisfaction can be directly produced. UV flat printing pattern fine, rich and clear layers, high artistry, strong three-dimensional sense, many high precision equipment can also print photography and painting style patterns.

How does UV ink jet printer save UV ink?

UV inkjet printer use process is an important consumable UV ink, reasonable use of equipment, can save UV ink , it can be said to be the best choice to directly save the cost. In the process of using some skills you need to be familiar with, the following small make up to share with you:1. Try to us

Waterjet Machine delivery and Shipping

Please tell us your max working size and what materials will cutting , also what max cutting thickeness.If you have Working photo sample please also send us , it will be helpful to choose machine with suitable models .

Waterjet Machine finish manufacture 5axis

Waterjet cutting technology is one of the fastest growing major machine tool processes in the world due to its versatility and ease of operation.

Waterjet Machine delivery and Shipping

Waterjet cutting technology is one of the fastest growing major machine tool processes in the world due to its versatility and ease of operation.There are multiple advantages to adding waterjet cutting capabilities to your shop.We are company leading ultrahigh-pressure waterjet system so

How to Create Connected Text – Inkscape for Laser Cutting

Step 1: Create Some TextFirst, we need some text to work with. To create the text, select the Text Tool (keyboard shortcut: T), click somewhere on the canvas, and type your text.You can use the drop-down list on the top left to select your desired font.Step 2: Convert Text to PathNext, we need to tu

Jacob from United States

I am a beginner at CNC, I’ve never used a CNC machine before and with in a day I was carving. An awesome machine for a beginner to learn as hobbyists. I used the manual and the help video. One hour to assemble and test, very friendly and easy to use. It’s a good buy for the money. I would definitely recommend this machine to someone getting into CNCs.

Weinstein from France

I've been using CNC plasma SYP2060-300A and I am very impressed with this unit.

This unit is of higher quality, made in China. Five stars all the way!

2040 from INDIAN

Best 2040 CNC Router Good Price and Quality ! Thank SENYOQC

10w uv laser from American

Best supplier ! I bought 3 machines for laser and router , thank you Aillen ! --Alec

12KW Fiber Cutting - 2000X6000mm -- 이병헌 from Korea

Good machine for metal cut ! Thanks Senyo , Its prefect , I like your business patient kind!

I am a furniture manufacturer, and this machine is very good and fast. thanks Senyoqc Team ! from Bangladesh

Metal ArtWork from Denmark

The plasma cutting machine makes my artistic creation more convenient and precise!! Created more artistic ideas and value! Thank you Aillen team!

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen. from

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen.

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo from

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo

Thank you Senyo for SYJ1290-150W! from

Retired, ex mainframe systems programmer. Now full-time recreational woodworker majoring in puzzles, pens, boxes, Toys and occasional small furniture. Thank you Senyo for SYJ1290-150W!

/5 based on 150 votes/5 based on votes

/5 based on 150 votes/5 based on votes

manager@senyocnc.com

manager@senyocnc.com

SENYOCNC

SENYOCNC

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

2061579344

2061579344