What is a CNC Metal Milling Machine?

A CNC metal milling machine is a computer-controlled machine tool for shaping and cutting metal materials with high precision.

It works by using CNC(Computer Numerical Control) technology that instructs the movements through a preprogrammed set of commands.

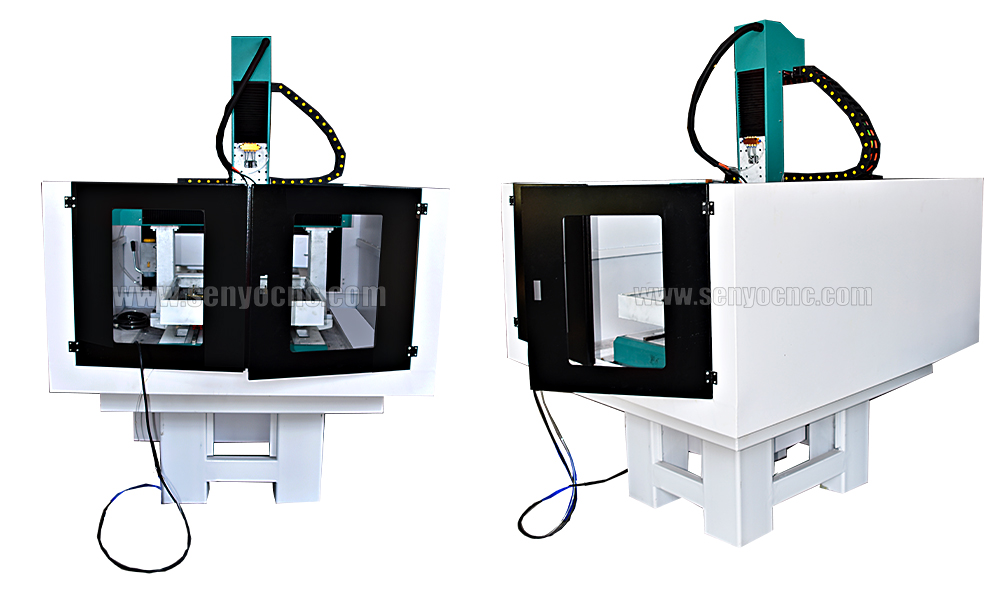

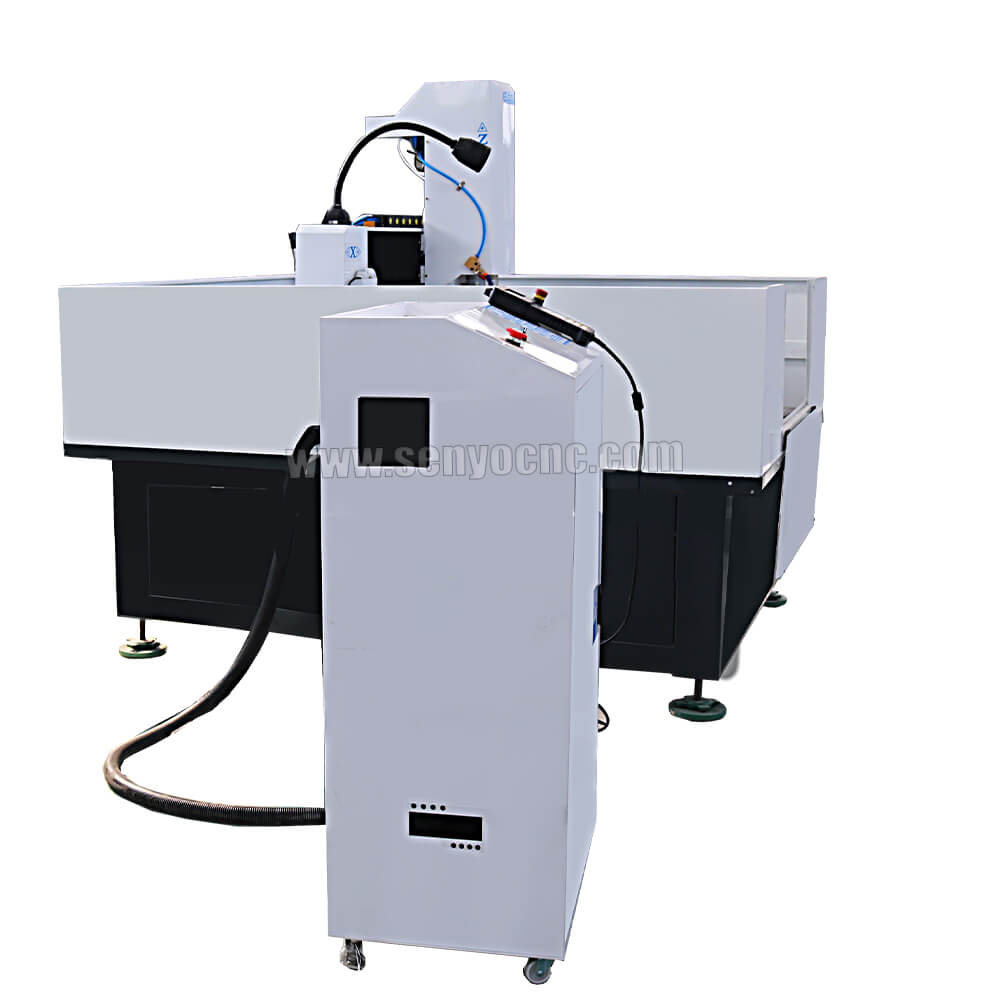

Machine design With DSP Control A1

These machines work at very high levels

of accuracy, moving the rotating cutting tools to remove material and

shape the metal into the desired form.

Applications range from simple cuts to detailed patterns on different types of metals: steel, aluminum, brass, copper, and even titanium.

The CNC metal milling machines are very important in industries dealing with automotive, aerospace,

and manufacturing due to the efficiency they provide in the production of complex parts.

Because machines can be adjusted to different shapes and sizes, they could thus act upon small or large production runs.

Overall, CNC metal milling machines save time, enhance product quality, and repeatable precision,

proving to be a very essential asset when taking on any kind of metalwork.

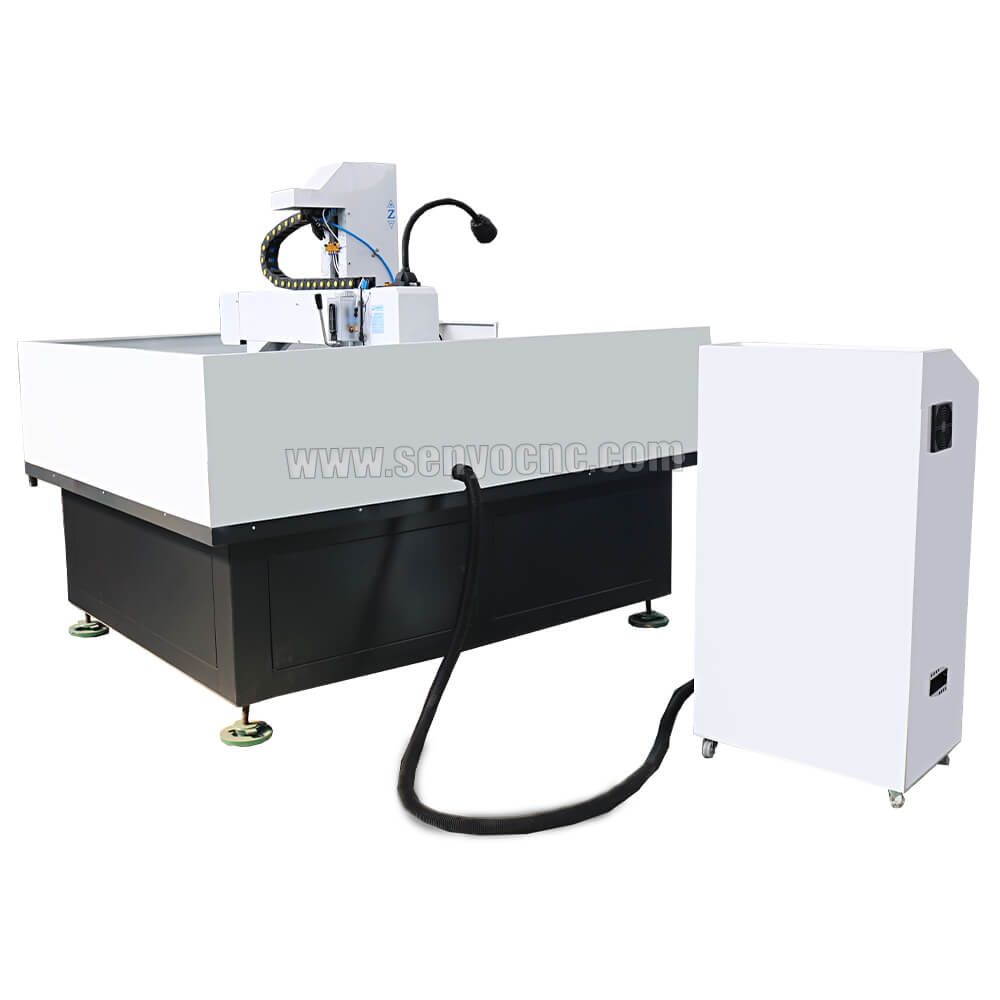

Machine design With Computer A2

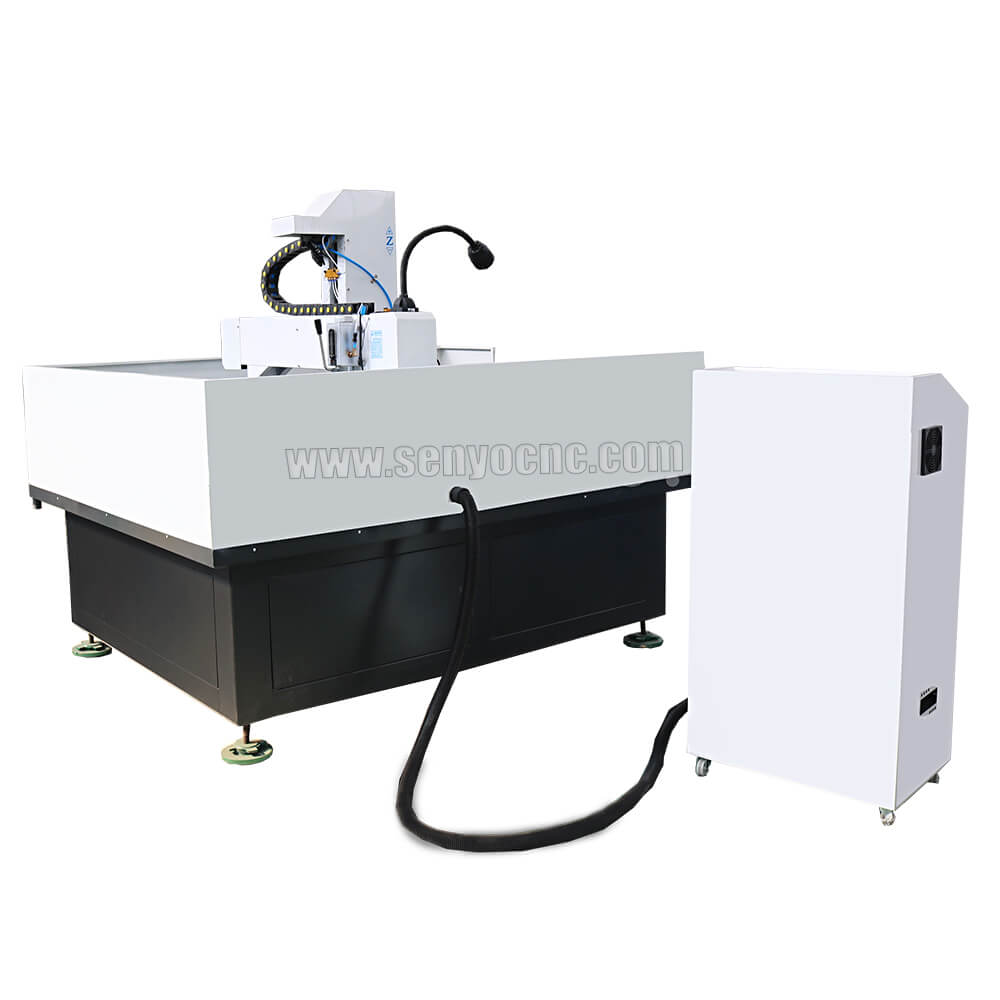

Smaller working size option, or custom make size depend on your work A3

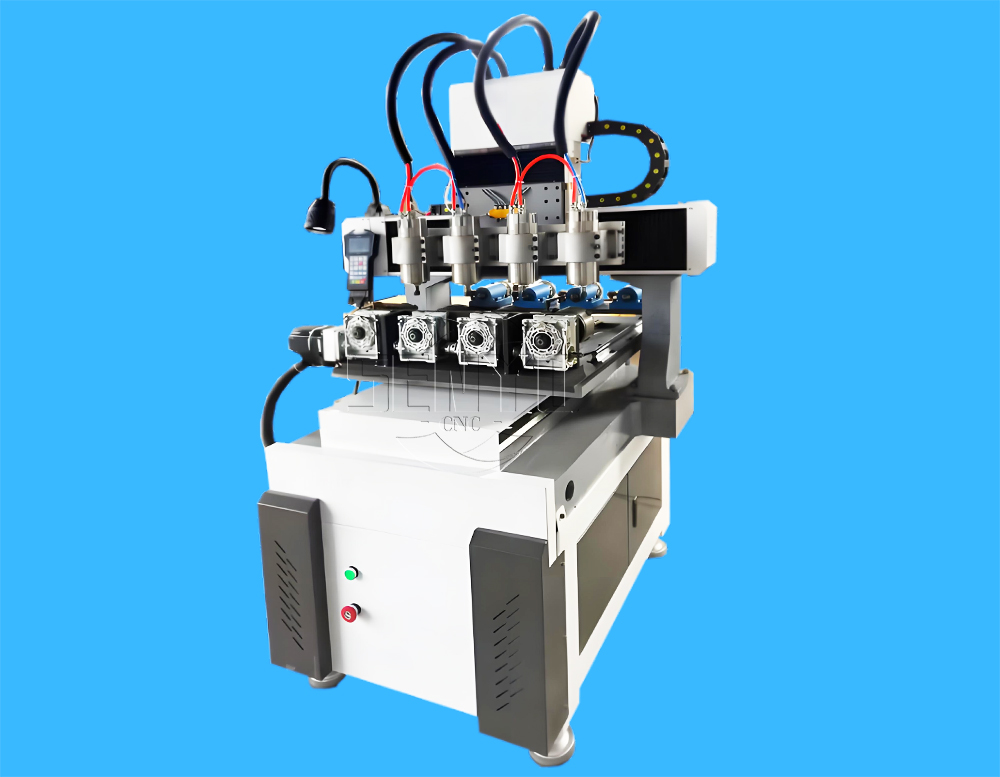

Machine with computer and servo motor A4

Automatic CNC Metal Milling Machine Features

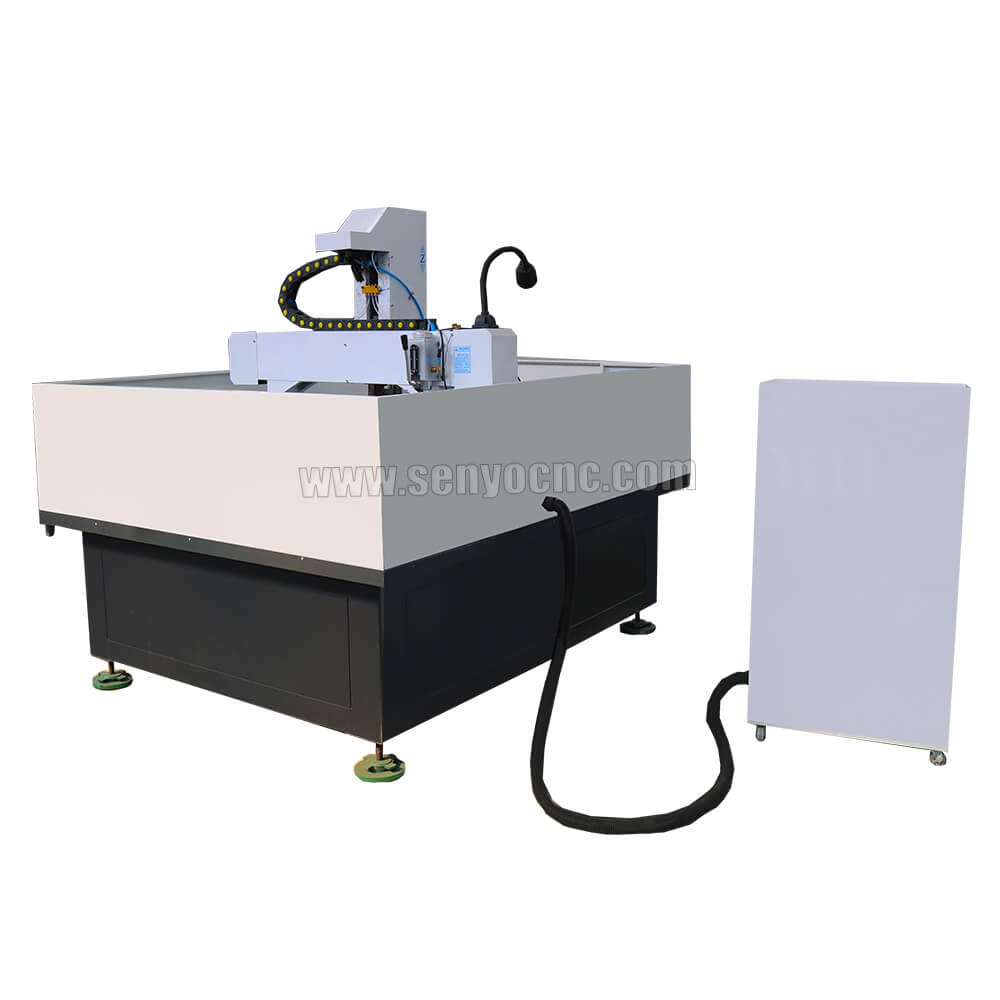

structure after high-temperature tempering, good rigidity and stability.

3.2KW water-cooling spindle could keep working at a low noise level, safeguarding stability for long-time operation.

3. High-quality all-steel linear guide with high precision, ensure machine frame much stability and durability.

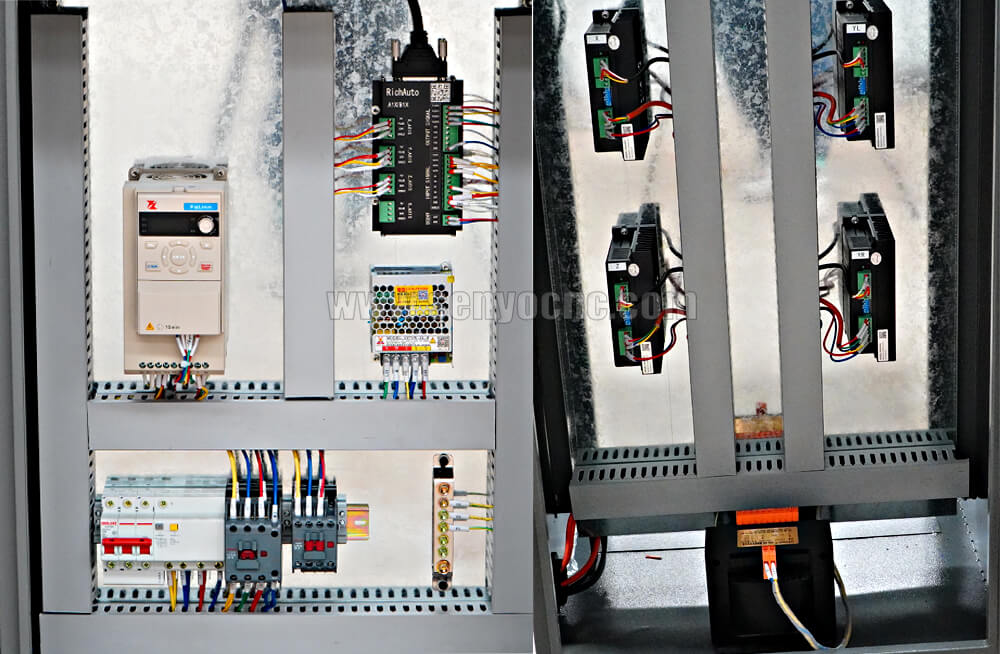

4. The metal milling machine adopts an advanced CNC system (NC studio or DSP control system)

and has a break point memory mode to ensure continuous working after electronic drop or other postponed situations.

5. Professional high flexibility anti-bending cable, the number of anti-bending can be up to 70,000 times.

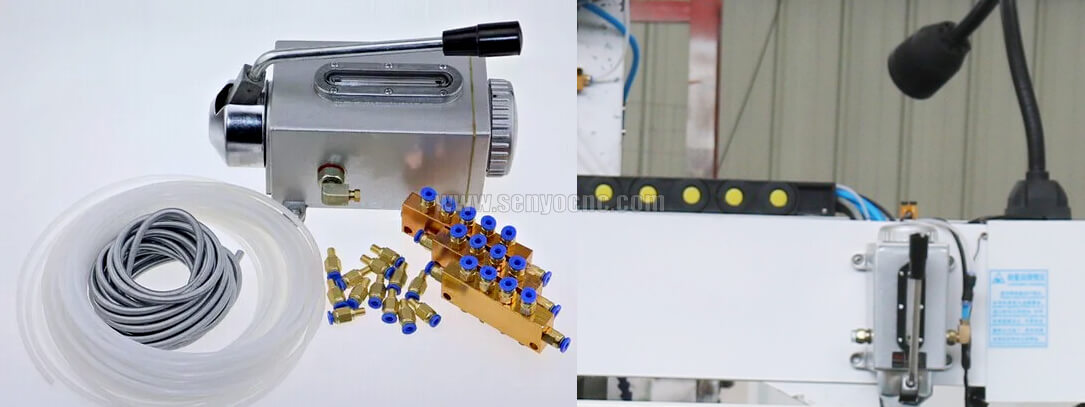

6. The automatic oil lubrication system is easy to operate with one key press,

equipped with dustproof and waterproof for the XY axis, making the maintenance operation easy.

7. Imported high-precision ball screw gap, and smooth movement, to ensure that the machine tools were high-precision.

8. Using well-known domestic brands of a water-cooled brushless spindle, low noise, and strong cutting ability, to ensure the long time working.

9. Good three-axis and dust-proof structure to ensure that the machines have a longer service life.

10. High-performance driven motor to ensure that the machine has high speed and accuracy.

11. The designer perfectly, selects the best machine accessories, to minimize the failure rate preferred.

12. Breakpoint-specific memory, power outages continued carving, processing time forecast, and other functions to ensure accidental processing.

Machine Applications

1. It is suitable for machining compactly all sorts of materials such as brass, steel, iron, copper, aluminum, foam, wood, and plastics.

2. It is widely used in shoe molding, drop molding, automotive, injection molding, ironware molding, and other mold industries.

3. The metal milling machine is specially designed for machining molds, eyeglasses, watches, panels, badges, brands, graphics,

and words of three-dimensional and outside surfaces sleeking of large-size molds.

Technical Parameters

| Model | SYM4040M |

| X,Y,Z Working Area | 400x400x200mm |

| X,Y,Z repositioning Positioning Accuracy | ±0.02mm |

| Frame | Cast iron |

| X, Z Structure | Ball Screw |

| Y Structure | Hiwin Rail Linear Bearings and Ball Screw |

| Max. Rapid Travel Rate | 8000mm/min |

| Spindle Power Motor | 3.2kw water cooling spindle |

| Spindle Speed | 0-24000RPM |

| Drive Motors | Stepper system |

| Working Voltage | AC220V/50/60Hz |

| Command Language | G code |

| Operating System | NC studio control system |

| Flash Memory | 128M(U Disk) |

| X,Y Resolution | <0.01mm |

| Software Compatibility | ArtCAM,UCANCAM,Type3 and other CAD or CAM software |

| Net Weight | 1000KG |

| Gross Weight | 1200KG |

Choosing the Right CNC Metal Milling Machine for You

Finding the right CNC metal milling machine can make a huge difference in productivity and quality.

Here are key aspects to consider to ensure you select the best machine for your needs.

Machine Size and Power

The size and power of a CNC milling machine determine its capacity and capabilities.

Small workshops or individual users may prefer compact models that save space while meeting basic metal milling needs.

Larger setups with high production demands will benefit from more powerful models that can handle tougher metals and larger pieces.

Precision and Accuracy

Precision is crucial when working with metal, especially for industries like aerospace and automotive.

Look for machines with high-quality linear guides and stable frames, as these features help maintain accuracy.

High-speed spindles and a reliable control system also contribute to reducing errors and creating precise, repeatable cuts.

Speed and Efficiency

Consider the machine’s speed and the control you have over its operation.

Machines with variable speed settings allow adjustments based on different metals or specific project needs, improving efficiency.

A machine with a faster operation can increase productivity by reducing the time required to complete each job.

Software Compatibility

A CNC machine should be compatible with the CAD or CAM software you use for design and programming.

This compatibility ensures seamless transfer of designs and easy operation.

Most modern CNC milling machines integrate with popular software, but it’s essential to verify to avoid issues later on.

Training and Support

Good training and support can make all the difference in operating a CNC milling machine successfully.

Many reputable brands offer user guides, technical support, and parts availability, which helps minimize downtime.

Knowing that support is available can provide peace of mind, especially for beginners or when upgrading to a more advanced machine.

Benefits of Using an Automatic CNC Milling Machine

Automatic CNC milling machines bring a wide range of benefits, from increased productivity to enhanced precision.

Here’s how these machines can improve operations for many industries.

Increased Automation

Automatic CNC machines operate independently after programming, reducing the need for constant supervision.

This automation allows operators to focus on other tasks, boosting overall productivity.

Continuous operation without breaks also helps meet high production demands efficiently.

Enhanced Precision

With programmable settings, automatic CNC milling machines achieve high levels of accuracy.

This precision is essential for creating identical parts, especially in industries that require strict quality standards.

Minimal variation in each piece ensures consistent quality, reducing waste and improving customer satisfaction.

Improved Safety

Automatic CNC machines minimize direct contact between operators and cutting tools, reducing the risk of accidents.

This safety benefit creates a safer work environment, particularly in high-demand production settings.

Less manual handling of materials also contributes to operator comfort and long-term workplace safety.

Consistent Quality and Repeatability

Automatic CNC milling machines are designed for large-scale production, offering consistent quality across batches.

This repeatability is beneficial when manufacturing parts in bulk, as it ensures each piece meets quality standards.

Reliable and consistent output can also reduce the need for quality inspections and rework.

Cost-Effectiveness

Automated CNC machines help reduce material waste by producing fewer errors and ensuring higher accuracy.

They also cut labor costs since less direct supervision is needed.

Over time, the efficiency and precision of automatic CNC milling machines contribute to lower production costs and faster returns on investment.

Packaging Details:

• Outside package: Standard marine export plywood case.

• Inner package: Stretch film and plastic film for humidity.

We can package according to your requests.

Delivery Detail: Shipped in 10 working days after payment.

Quality Control

• We have a skilled and strict quality inspection team during material procurement and production.

• All finished machines we deliver are 100% strictly tested by our quality control department and engineering department.

OEM Service

• We have rich experience and welcome customized and OEM orders.

• All OEM services are free, customers only need to provide us with your logo image, functional requirements, colors, etc.

• No minimum order quantity required.

• None of your personally identifiable information (such as your name, address, email address, bank information, etc.)

will be disclosed or shared with any third party.

• Contact: All your inquiries, questions or help will be responded within 24 hours, even on holidays,

if you have any urgent questions, please feel free to call us..

Warranty And Service

• 24 months whole machine warranty and maintenance for a lifetime.

• Free installation and testing before shipping and free training for operators

• Advice for the best CNC solutions for customer's requirements.

• Free training and sample making.

• 7/24 free service and support.

Metal cnc router, CNC Router, Mould cnc machine,Aluminum engraving machine,brass cnc router,metal cutting cnc machine

• Previous: Rotary 4th Axis Hobby CNC Router for Sign Making with Wood, MDF, Aluminum

Fiber metal Laser Sensor And Its Application

Category: SENYO NEWS 11th Mar, 2021A CNC wood router will use 3D machining in relief carving, the effect is more artistic beauty, but also has a strong sense of three-dimensional 3D, realization of this function is to ...

Precision Cutting Stents with Fiber Lasers

A CNC wood router will use 3D machining in relief carving, the effect is more artistic beauty, but also has a strong sense of three-dimensional 3D, realization of this function is to ...

How to Laser Cut Copper and Other Reflective Metals

Laser cutting of mild steel and stainless steel has a long history and has been one of the primary applications for CO2lasers. However CO2lasers have not traditionally offered a good solution for cutting highly reflective materials.Fiber lasers have an emission wavelength of around

Laser Cutting Machine Inspection Process For Manufacture

SENYOCNC Have Strict quality monitoring will be carried out when the parts are in the factory.

How Control Costs Use of UV Printers ?

UV flatbed printers are rapidly being used by more and more manufacturers, thanks to its efficient production efficiency, and the control of production costs also needs to arouse our attention.

Why UV flat printing machine is popular in market ?

For the majority of designers, give full play to the creative ability, the design sample can be arbitrarily modified on the computer, the effect on the computer, is the effect after the finished product, customer satisfaction can be directly produced. UV flat printing pattern fine, rich and clear layers, high artistry, strong three-dimensional sense, many high precision equipment can also print photography and painting style patterns.

How does UV ink jet printer save UV ink?

UV inkjet printer use process is an important consumable UV ink, reasonable use of equipment, can save UV ink , it can be said to be the best choice to directly save the cost. In the process of using some skills you need to be familiar with, the following small make up to share with you:1. Try to us

Waterjet Machine delivery and Shipping

Please tell us your max working size and what materials will cutting , also what max cutting thickeness.If you have Working photo sample please also send us , it will be helpful to choose machine with suitable models .

Waterjet Machine finish manufacture 5axis

Waterjet cutting technology is one of the fastest growing major machine tool processes in the world due to its versatility and ease of operation.

Waterjet Machine delivery and Shipping

Waterjet cutting technology is one of the fastest growing major machine tool processes in the world due to its versatility and ease of operation.There are multiple advantages to adding waterjet cutting capabilities to your shop.We are company leading ultrahigh-pressure waterjet system so

How to Create Connected Text – Inkscape for Laser Cutting

Step 1: Create Some TextFirst, we need some text to work with. To create the text, select the Text Tool (keyboard shortcut: T), click somewhere on the canvas, and type your text.You can use the drop-down list on the top left to select your desired font.Step 2: Convert Text to PathNext, we need to tu

Jacob from United States

I am a beginner at CNC, I’ve never used a CNC machine before and with in a day I was carving. An awesome machine for a beginner to learn as hobbyists. I used the manual and the help video. One hour to assemble and test, very friendly and easy to use. It’s a good buy for the money. I would definitely recommend this machine to someone getting into CNCs.

Weinstein from France

I've been using CNC plasma SYP2060-300A and I am very impressed with this unit.

This unit is of higher quality, made in China. Five stars all the way!

2040 from INDIAN

Best 2040 CNC Router Good Price and Quality ! Thank SENYOQC

10w uv laser from American

Best supplier ! I bought 3 machines for laser and router , thank you Aillen ! --Alec

12KW Fiber Cutting - 2000X6000mm -- 이병헌 from Korea

Good machine for metal cut ! Thanks Senyo , Its prefect , I like your business patient kind!

I am a furniture manufacturer, and this machine is very good and fast. thanks Senyoqc Team ! from Bangladesh

Metal ArtWork from Denmark

The plasma cutting machine makes my artistic creation more convenient and precise!! Created more artistic ideas and value! Thank you Aillen team!

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen. from

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen.

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo from

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo

Thank you Senyo for SYJ1290-150W! from

Retired, ex mainframe systems programmer. Now full-time recreational woodworker majoring in puzzles, pens, boxes, Toys and occasional small furniture. Thank you Senyo for SYJ1290-150W!

manager@senyocnc.com

manager@senyocnc.com

SENYOCNC

SENYOCNC

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

2061579344

2061579344