CNC foam cutter is a type of automatic computer numerical controlled router machine to cut rigid foam,

soft foam, sponge, and plastic into squares, rectangles, and strips.

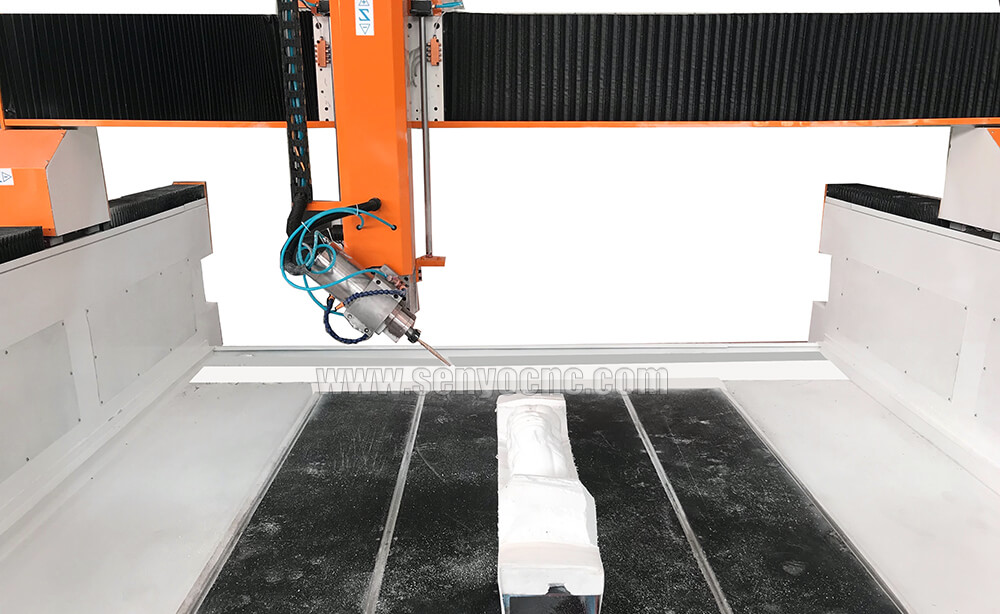

The foam cutting machine is a computer controlled machine that can cut any 3D projects from the extruded and expanded EPS foam.

Through the use of a computer-controlled step motor,

the heating wire is cut in the X, Y and Z directions

which can make the foam material cut quickly and accurately.

The operator can make any graphics with the CNC router software and start cutting with CNC control system,

which has the advantages of high cutting efficiency, accurate

cutting size, and high precision.

The scope of application is suitable for machinery manufacturing, casting, automobiles, ships, industrial design,

mold manufacturing and processing, advertising, architectural decoration and decoration, foam cutting plants, foam manufacturing plants,

foam molding plants, school institutions, advertising production

companies, packaging plants, exhibitions, Model factories,

POP crafts processing and publicity display industries. CNC foam cutters are also known as CNC foam cutting machines,

CNC foam board cutter, CNC foam router and CNC foam cutting kits.

4 Axis CNC Foam Router Cutting Machine Advantages

1. Specialized in making large non-metallic molds, especially automobile foam molds, ship molds, aviation train molds, food molds (such as cake molds), and other molds.

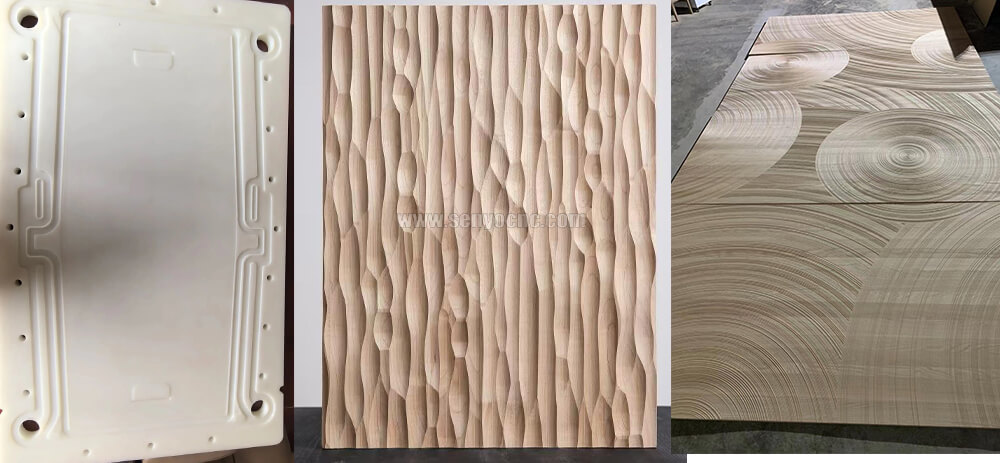

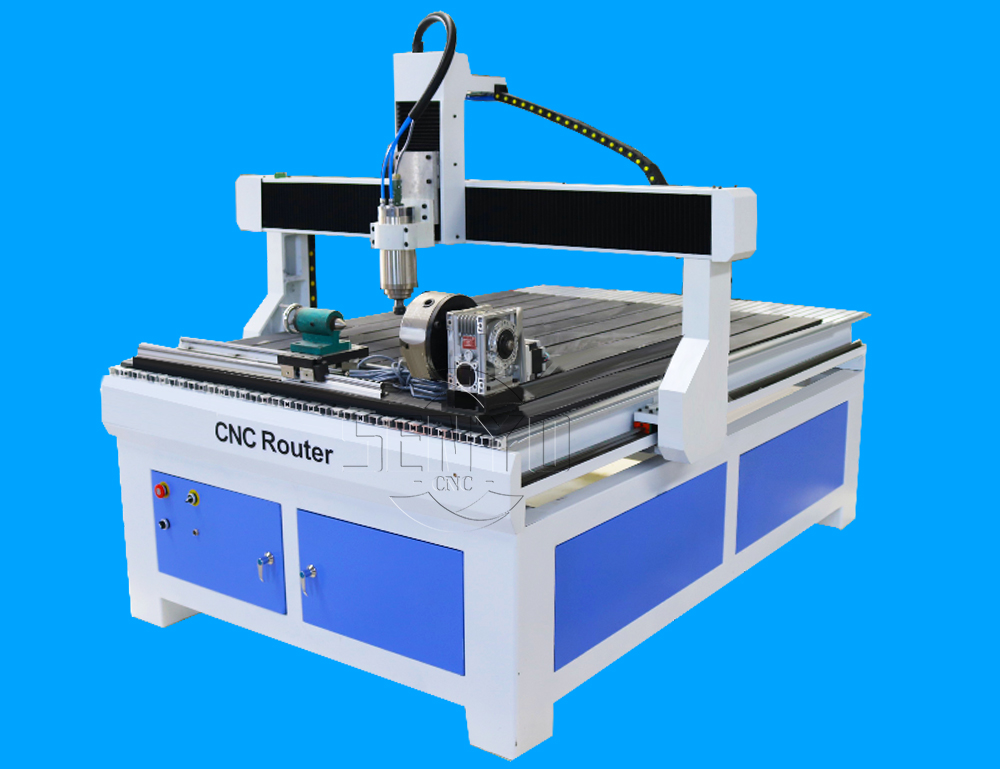

2. The built-in rotating axis is used to process any three-dimensional cylindrical materials for woodworking, advertising, and mold industries.

3. The spindle can rotate 180 degrees and can mill some arched workpieces.

4. The Z axis can be raised to 1000mm, which can perform large-scale three-dimensional curve milling.

4 Axis CNC Foam Router Machine Features

The machine comes with Hiwin high-precision square guide rails, and the X and Y axes adopt gear rack transmission,

which is fast, efficient and low cost. The Z axis adopts German-made ball screws with high precision and long life.

The machine adopts gantry movement and can freely process various materials.

The intelligent processing out-of-bounds protection function can prevent mechanical shock caused by improper design files.

The machine adopts imported ball bearings, widened linear guide rails, and self-lubricating sliders. During processing,

the force in all directions is uniform to ensure accuracy and strength.

The machine features the functions of breakpoint continuation and power-off re-engraving.

The machine has the function of machining time prediction.

The machine works with a diversified control system, which can control the processing speed,

idling speed and cutting speed respectively, greatly improving the processing quality.

The machine bed is welded with thickened square tubes,

and is treated

with high temperature tempering and vibration aging treatment (VSR) to

eliminate residual stress.

It has good stability, is not easy to deform, and has the characteristics of good rigidity and strong bearing capacity.

4 Axis CNC Foam Cutting Machine Applications

Applicable Industries

1. Mold making industry: Large sculptures and foam molds.

2. Musical Instrument Industry: 3D musical instruments and silhouettes.

3. Non-Ferrous Metals: Aluminum, brass, copper, alloys, and other light non-ferrous metals.

Applied Materials

1. Timber and wood.Aluminum, brass and copper.

2. EPS as well as any type of foam.

3. Wood, Plastic and acrylic.

4. Wood mdf

4 Axis CNC Foam Router Cutting Machine Technical Parameters

Model | SYS1325-4 axis |

X,Y Working Area | 1300×2500mm |

Z Working Area | 600mm |

Resolution | 0.5mm |

Repositioning Accuracy | 0.5mm |

Lathe Structure | Seamless welded steel structure, better than cast iron one |

X,Y Structure | Rack and pinion transmission, Hiwin square guide rail |

Z Structure | Germany-made rolling ball screw, Hiwin square guide rail |

Max. Idling Speed | 30m/min |

Spindle | 6kw spindle |

Spindle Rotate Speed | 0-24000r/min, variable speed |

Working Voltage | AC380V/50Hz |

Working Mode | Servo motor and diver |

Command | G code (HPGL,U00,mmg,plt) |

Operating System | Nc studio |

Diameter of cutter | φ3.175-φ12.7mm |

Cooling Mode | Water-cooling |

Work-holding | By clamp |

Net Weight | 2000KG |

Software | Type 3, ArtCam, Ucancam |

Maintenance Tips for Your 4-Axis CNC Foam Cutter

Proper maintenance is crucial for ensuring the longevity and efficiency of your 4-axis CNC foam cutter.

Regular care not only reduces downtime but also maintains precision and performance over time.

Follow these essential tips to keep your machine in top condition.

• Clean the Machine Regularly: Foam debris can accumulate on the work table and around the cutting head.

Clean these areas after every session to prevent clogging or misalignment. Use a soft brush or vacuum to remove small particles safely.

• Lubrication of Moving Parts: Smear lubricants on the rails, ball screws, and other moving parts.

This reduces friction, thus preventing damage that may cause inoperability of parts.

Check the recommendations of the manufacturer to apply the right lubricant.

• Check and Fix Components: With time, fittings such as screws and belts are loosened by vibrations.

Check these fittings once in a while and replace them when necessary. It ensures accuracy in operation.

• Check the Cutting Tool: Check the cutting tool for any indication of wear: a dull edge or even any small cracks.

Replace or sharpen the tool to keep the cuts clean and precise. Using worn tools can cause the foam to tear or the machine to be strained.

• Keep an Eye on the Cooling System: If your machinery has a cooling system, then make sure it works effectively.

Never allow blockages in the flow of coolant; in addition, the levels are to be controlled with recommendations.

Proper cooling avoids overheating and prolongs machine life.

• Calibrate the Tests Frequently: Frequently check on the calibration tests so that the movements of the machine will be exact.

For proper calibration, there will be no mistakes in cutting the foams, and the quality of every work will be just the same.

• Update Software and Firmware: The first important thing to be done is to update the software and firmware in such a way

that the machine remains updated with freshly released features and enhancements. Of course, it will take care of bugs and improve the general performance.

Packing & Shipping

1. Outside package: Standard plywood package.

2. Inner package:Stretchy film and plastic protective film for humidity.

3. We can package according to your requirements.

For

standard machines, 7-15 working days after payment

Service & Support

1. Our engineers available to service machinery overseas.

2. 2 years guarantee for the whole machine.

3. Technical support by calling, mail, whatsapp and skype. If you have any problems, we will help you to solve it within 12 hours.

4. You will be get free training advice towards our machine in our factory.

5. If you need any component of the machine, we will provide most affordable price for you.

6. Friendly English version manual and operation video CD disk.

4 axis cnc router, spindle rotation cnc router machine, cnc router,foam cutting cnc machine ,cnc wood router machine

• Previous: CNC Router Lathe Machine with 4th Rotary Axis

• Next: 4 axis mini 6090 small cnc engraving machine router for Sale

Fiber metal Laser Sensor And Its Application

Category: SENYO NEWS 11th Mar, 2021A CNC wood router will use 3D machining in relief carving, the effect is more artistic beauty, but also has a strong sense of three-dimensional 3D, realization of this function is to ...

Precision Cutting Stents with Fiber Lasers

A CNC wood router will use 3D machining in relief carving, the effect is more artistic beauty, but also has a strong sense of three-dimensional 3D, realization of this function is to ...

How to Laser Cut Copper and Other Reflective Metals

Laser cutting of mild steel and stainless steel has a long history and has been one of the primary applications for CO2lasers. However CO2lasers have not traditionally offered a good solution for cutting highly reflective materials.Fiber lasers have an emission wavelength of around

Laser Cutting Machine Inspection Process For Manufacture

SENYOCNC Have Strict quality monitoring will be carried out when the parts are in the factory.

How Control Costs Use of UV Printers ?

UV flatbed printers are rapidly being used by more and more manufacturers, thanks to its efficient production efficiency, and the control of production costs also needs to arouse our attention.

Why UV flat printing machine is popular in market ?

For the majority of designers, give full play to the creative ability, the design sample can be arbitrarily modified on the computer, the effect on the computer, is the effect after the finished product, customer satisfaction can be directly produced. UV flat printing pattern fine, rich and clear layers, high artistry, strong three-dimensional sense, many high precision equipment can also print photography and painting style patterns.

How does UV ink jet printer save UV ink?

UV inkjet printer use process is an important consumable UV ink, reasonable use of equipment, can save UV ink , it can be said to be the best choice to directly save the cost. In the process of using some skills you need to be familiar with, the following small make up to share with you:1. Try to us

Waterjet Machine delivery and Shipping

Please tell us your max working size and what materials will cutting , also what max cutting thickeness.If you have Working photo sample please also send us , it will be helpful to choose machine with suitable models .

Waterjet Machine finish manufacture 5axis

Waterjet cutting technology is one of the fastest growing major machine tool processes in the world due to its versatility and ease of operation.

Waterjet Machine delivery and Shipping

Waterjet cutting technology is one of the fastest growing major machine tool processes in the world due to its versatility and ease of operation.There are multiple advantages to adding waterjet cutting capabilities to your shop.We are company leading ultrahigh-pressure waterjet system so

How to Create Connected Text – Inkscape for Laser Cutting

Step 1: Create Some TextFirst, we need some text to work with. To create the text, select the Text Tool (keyboard shortcut: T), click somewhere on the canvas, and type your text.You can use the drop-down list on the top left to select your desired font.Step 2: Convert Text to PathNext, we need to tu

Jacob from United States

I am a beginner at CNC, I’ve never used a CNC machine before and with in a day I was carving. An awesome machine for a beginner to learn as hobbyists. I used the manual and the help video. One hour to assemble and test, very friendly and easy to use. It’s a good buy for the money. I would definitely recommend this machine to someone getting into CNCs.

Weinstein from France

I've been using CNC plasma SYP2060-300A and I am very impressed with this unit.

This unit is of higher quality, made in China. Five stars all the way!

2040 from INDIAN

Best 2040 CNC Router Good Price and Quality ! Thank SENYOQC

10w uv laser from American

Best supplier ! I bought 3 machines for laser and router , thank you Aillen ! --Alec

12KW Fiber Cutting - 2000X6000mm -- 이병헌 from Korea

Good machine for metal cut ! Thanks Senyo , Its prefect , I like your business patient kind!

I am a furniture manufacturer, and this machine is very good and fast. thanks Senyoqc Team ! from Bangladesh

Metal ArtWork from Denmark

The plasma cutting machine makes my artistic creation more convenient and precise!! Created more artistic ideas and value! Thank you Aillen team!

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen. from

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen.

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo from

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo

Thank you Senyo for SYJ1290-150W! from

Retired, ex mainframe systems programmer. Now full-time recreational woodworker majoring in puzzles, pens, boxes, Toys and occasional small furniture. Thank you Senyo for SYJ1290-150W!

manager@senyocnc.com

manager@senyocnc.com

SENYOCNC

SENYOCNC

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

2061579344

2061579344