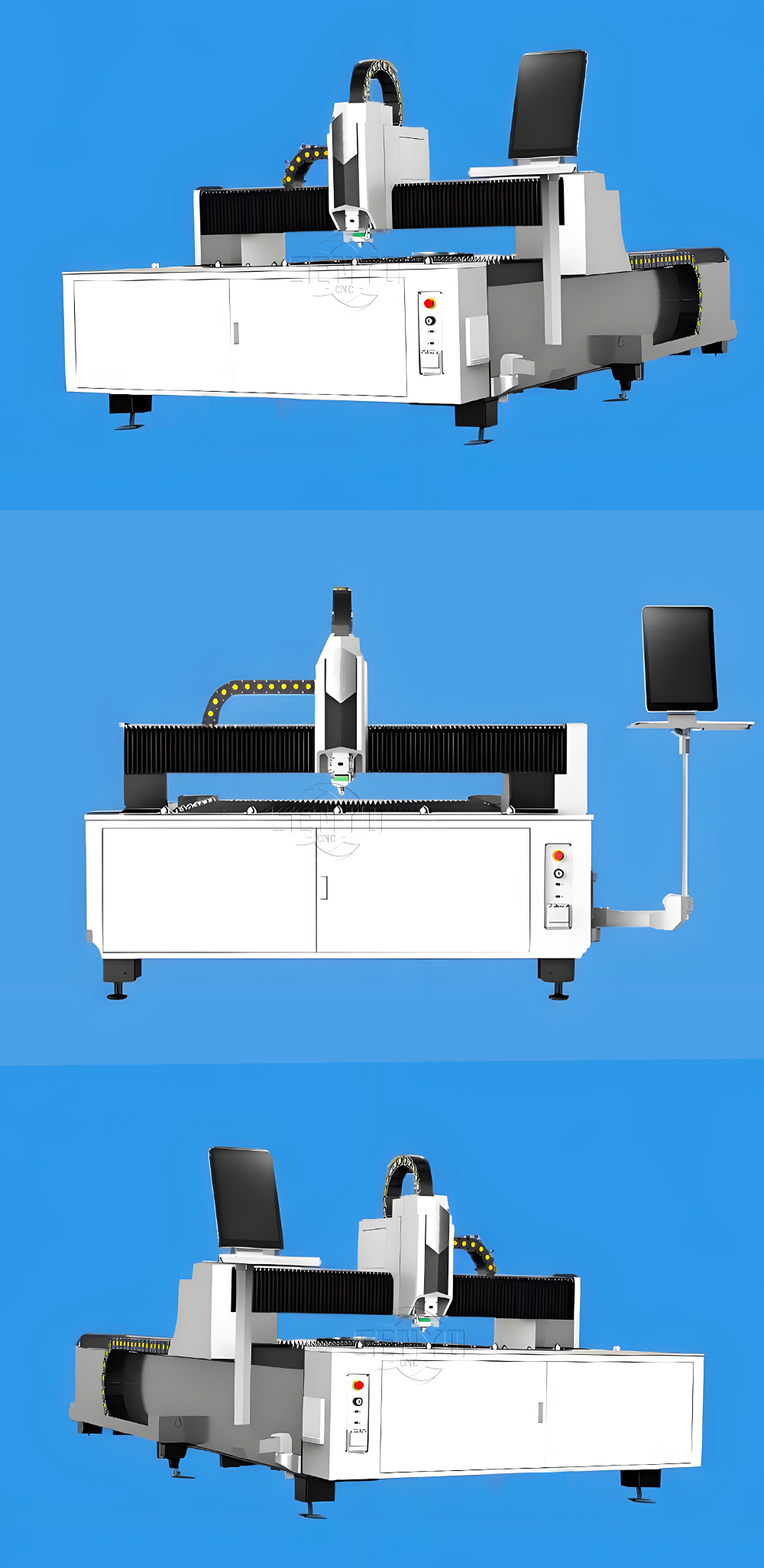

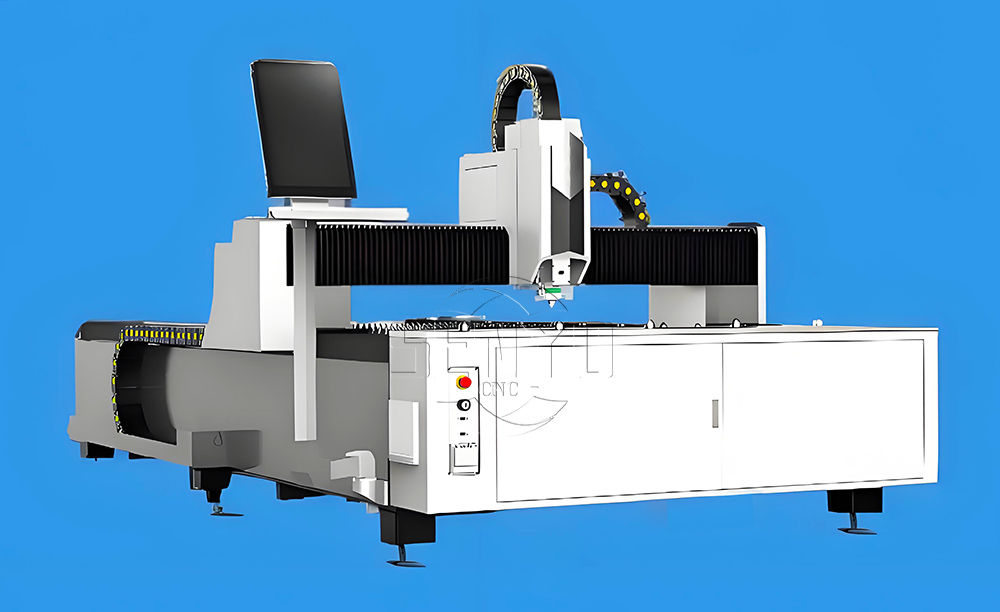

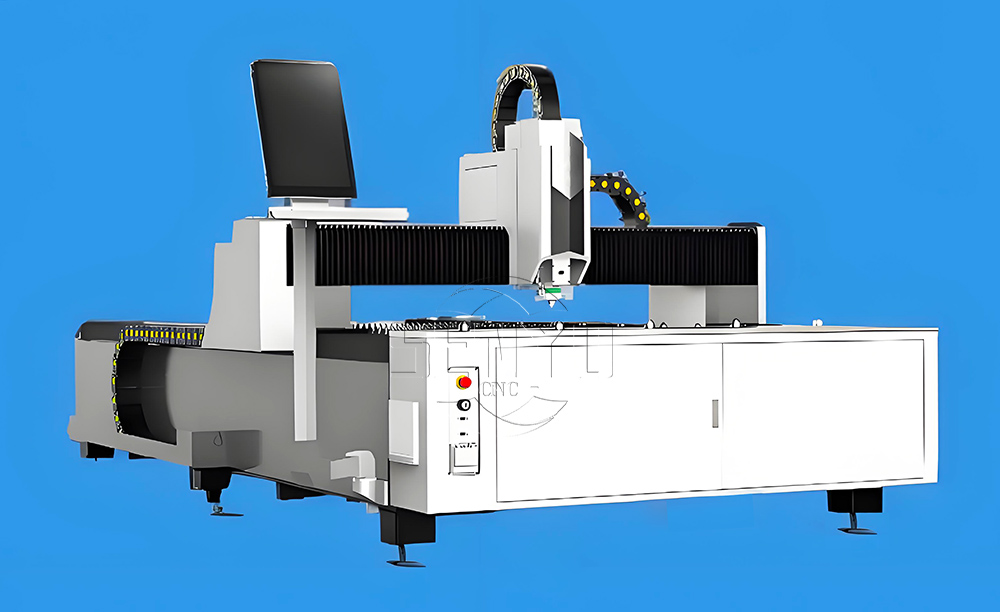

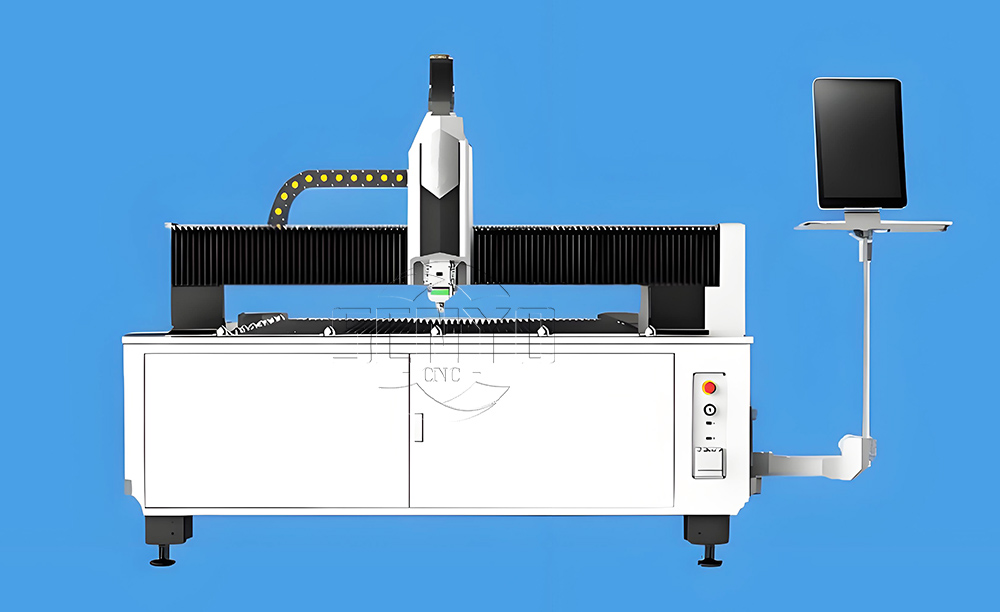

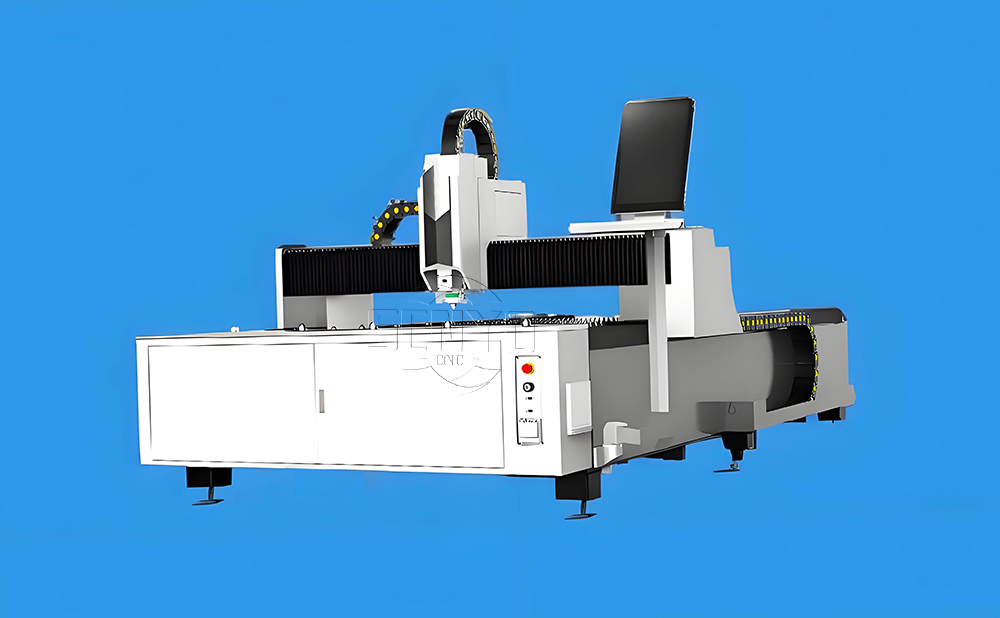

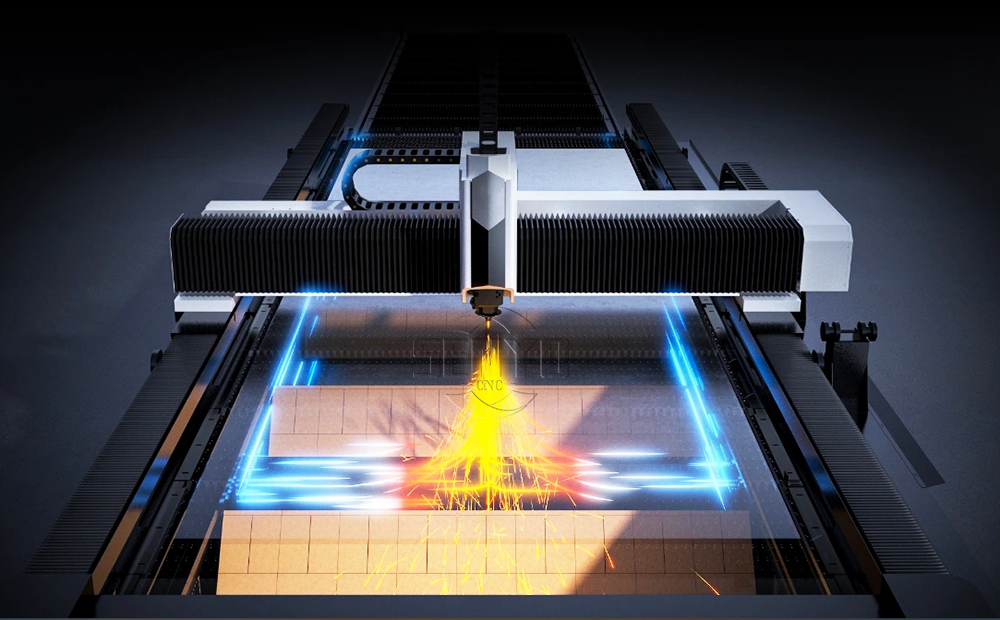

Imagine a machine that can easily combine speed and accuracy, using fiber laser sources from well-known brands in the industry, such as Raycus, IPG or MAX.

But what makes the SYJF3015stand out is its steadfast dedication to new ideas and design that puts the user first. This machine is easy to use and comes with a Swiss Raytools Laser Cutting Head with autofocus. The user-friendly Cypcut Controller Software makes it easy for beginners and professionals to get precise cuts and make even the most complicated designs come to life.

That being said, accuracy is only the start. With its Gear-Rack Transmission System and High Torque Japanese Yaskawa Drive Motors, the SYJF3015 can be used for a wide range of tasks. This machine guarantees that every job is done rapidly and accurately, no matter how complicated the design is or how many structural parts need to be made.

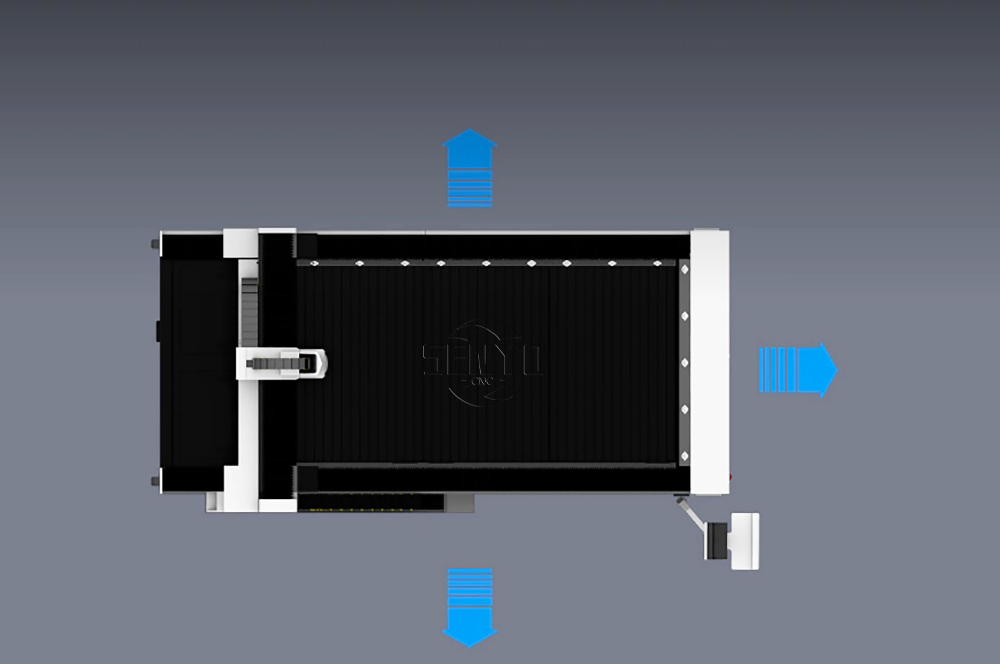

The SYJF3015 lets you be creative and make it your own in a lot of different ways with available upgrades like the Auto Feeding System and Rotary Attachment. This machine lets you be creative and take your metalworking to a whole new level. You can use it to make unique metal signs, decorative panels, and more.

Sheet metal fabrication usually cuts with hand tools, handheld tin snips, electric shears, electric scissors, electric nibblers, wire cutters, plasma cutters, flame cutters, CNC punching machines, CNC shearing machines, water jet cutters, and laser cutters. Various sheet metal cutting tools have their advantages and disadvantages, the accuracy, speed and cost all vary.

What is a Sheet Metal Cutter?

A sheet metal cutter is a type of power tool that cuts metal plates into various shapes with a handheld tin snip, electric shear, scissor, nibbler, laser beam, wire, plasma, oxyacetylene flame, and water jet. Sheet metal cutters can cut cold rolled sheets (SPCC) and hot rolled sheets (SHCC), galvanized steel, copper (true copper), copper, aluminum sheet (6061, 6063, duralumin), aluminum profiles, stainless steel (mirror, brushed, frosted). Although traditional sheet metal cutting tool has their unique advantages, however, whether it is precision, quality, or speed, it is far from modern laser sheet metal cutters.

What is a Sheet Metal Laser Cutter?

A sheet metal laser cutter is a type of automatic precision that cuts metal plates including aluminum, aluminized steel, carbon steel, copper, brass, galvanized steel, galvalume, high strength steel, hot rolled steel, stainless steel, and titanium into various shapes with the fiber laser beam. Compared with hand tools, CNC laser sheet metal cutting features high precision, high quality, high speed, and flexible processing (dieless), and has become the 1st choice to cut metal parts in sheet metal fabrication, construction machinery, saw blade cutting, grain machinery, textile machinery, agricultural machinery, computer case, electrical cabinet, and elevator manufacturing. With a CNC controller, it can do small jobs on sheet metals. With a drill attachment, it can cut holes in metal plates. It is gradually replacing CNC punching, CNC shearing, plasma cutting, flame cutting, and more metal cutting tools.

Laser Sheet Metal Cutter Applicable Industries

Mechanical and electrical equipment, sheet metal fabrication, cabinets, stainless steel products, lamps and lanterns, auto parts, glasses, hardware tools, advertising signs, decorative and other industries.

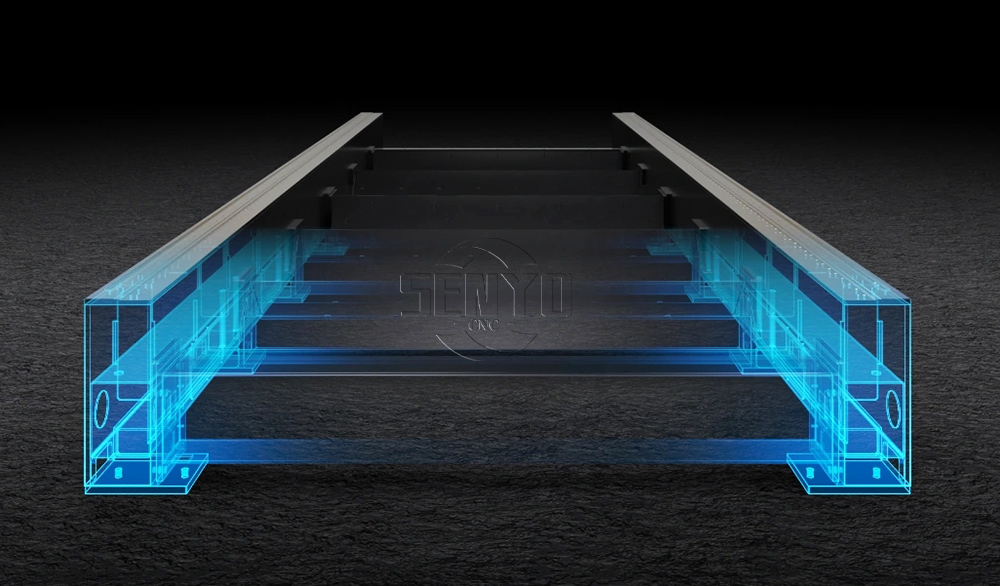

Machine Parts Detials

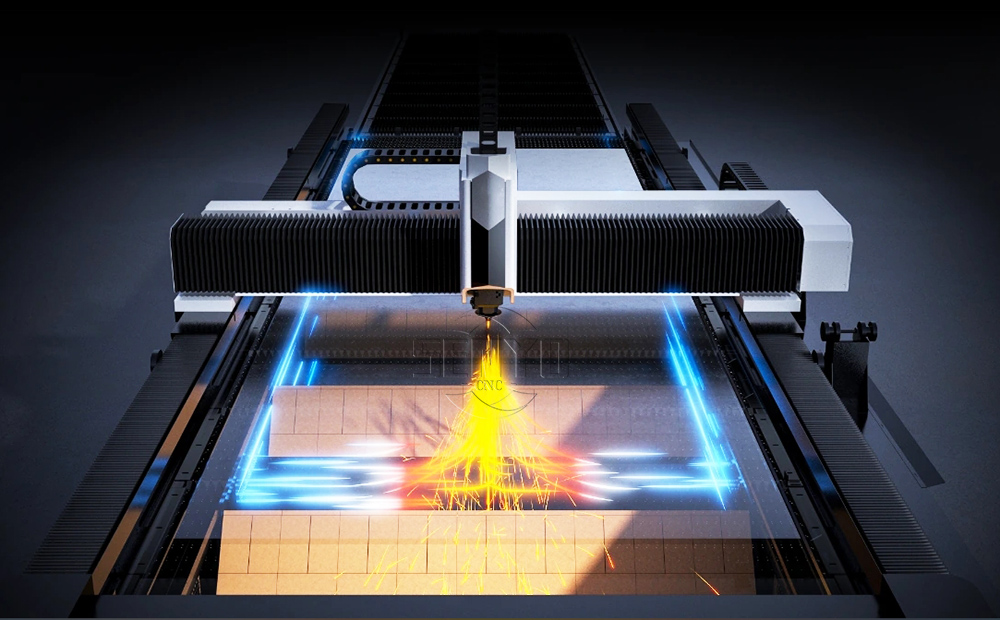

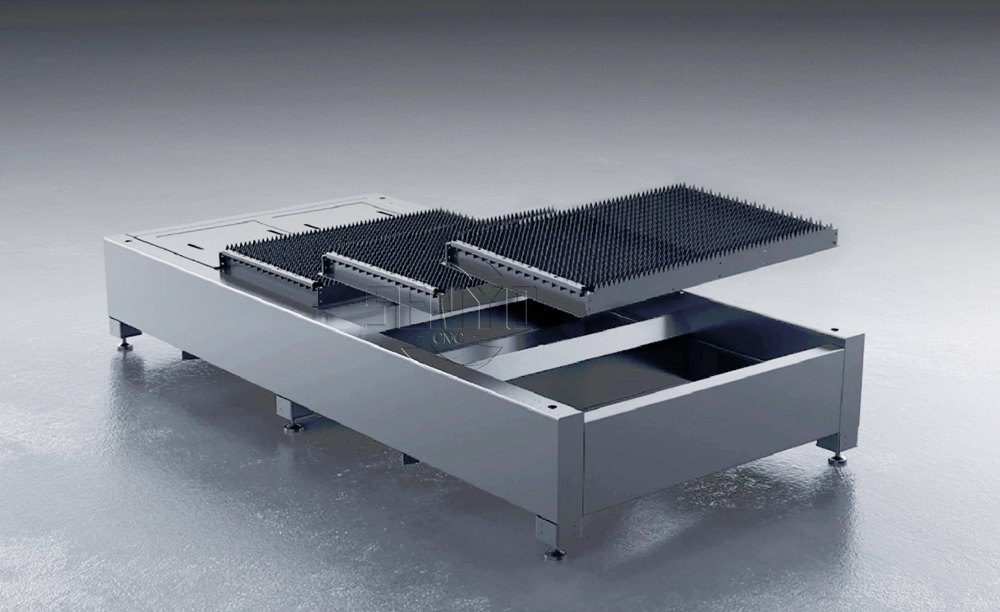

Efficient dust removal

Ultra large diameter air duct design, independent control of partition dust removal, improving smoke and heat removal efficiency

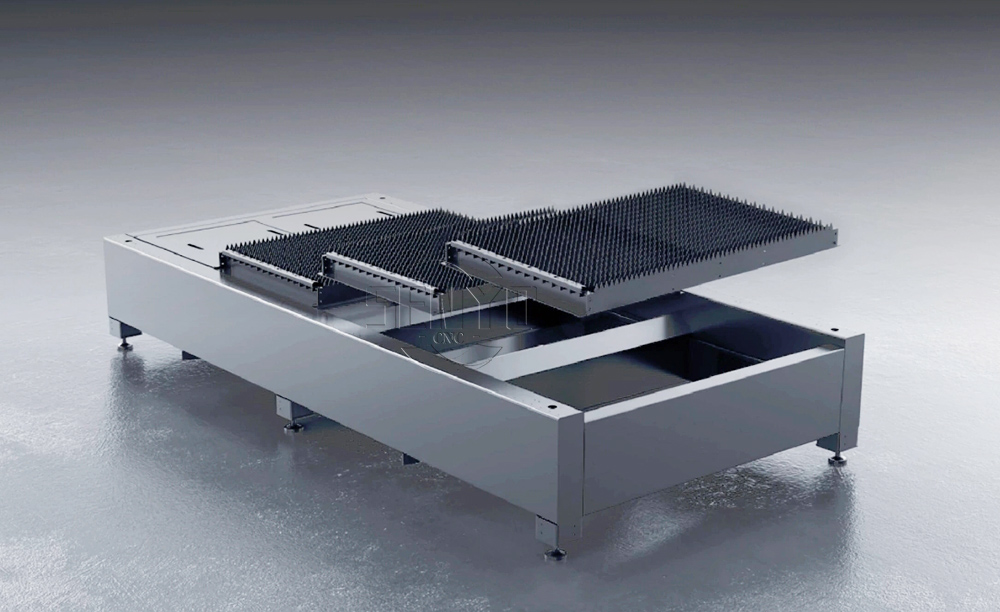

Modular countertop design

The workbench components adopt modular design, the table structure is stable, the load-bearing capacity is strong.

and it is easy to disassemble, replace and maintain.

Product Paramenters

Feature/Model | SYJF3015 | SYJF4015 | SYJF4020 |

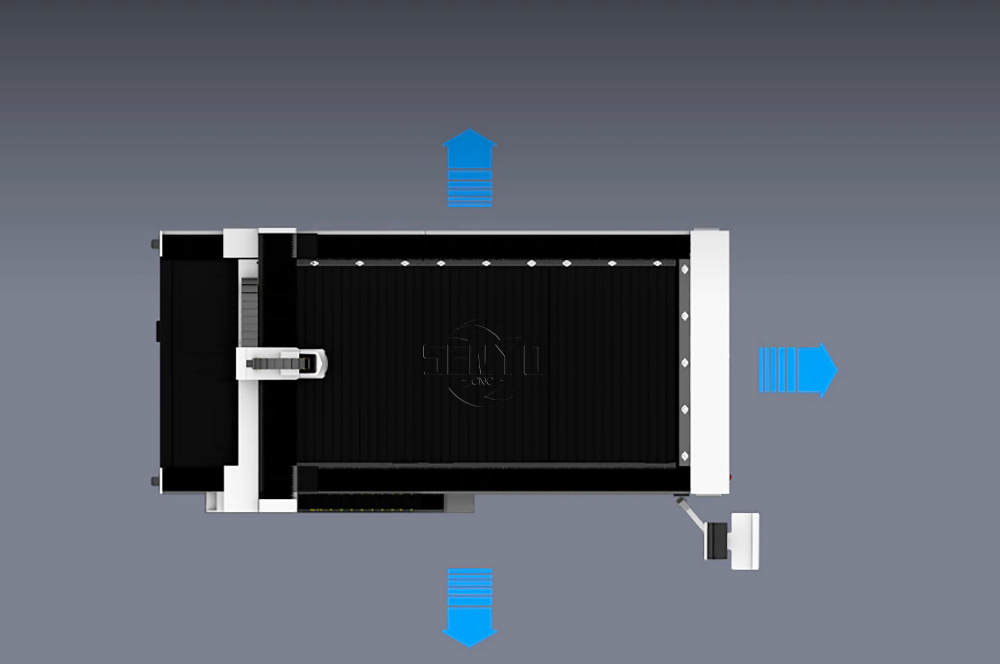

Working Area (L*W) | 3050*1530mm | 4050*1530mm | 4050*2030mm |

X/Y Axis Positioning Accuracy | ±0.05mm/m | ±0.05mm/m | ±0.05mm/m |

X/Y Axis Repositioning Accuracy | ±0.03mm | ±0.03mm | ±0.03mm |

Max. Moving Speed | 115m/min | 115m/min | 115m/min |

Max. Acc. Speed | 0.8G | 0.8G | 0.8G |

Laser Power | 1500W-20kw | 1500W-20kw | 1500W-20kw |

Application Industries

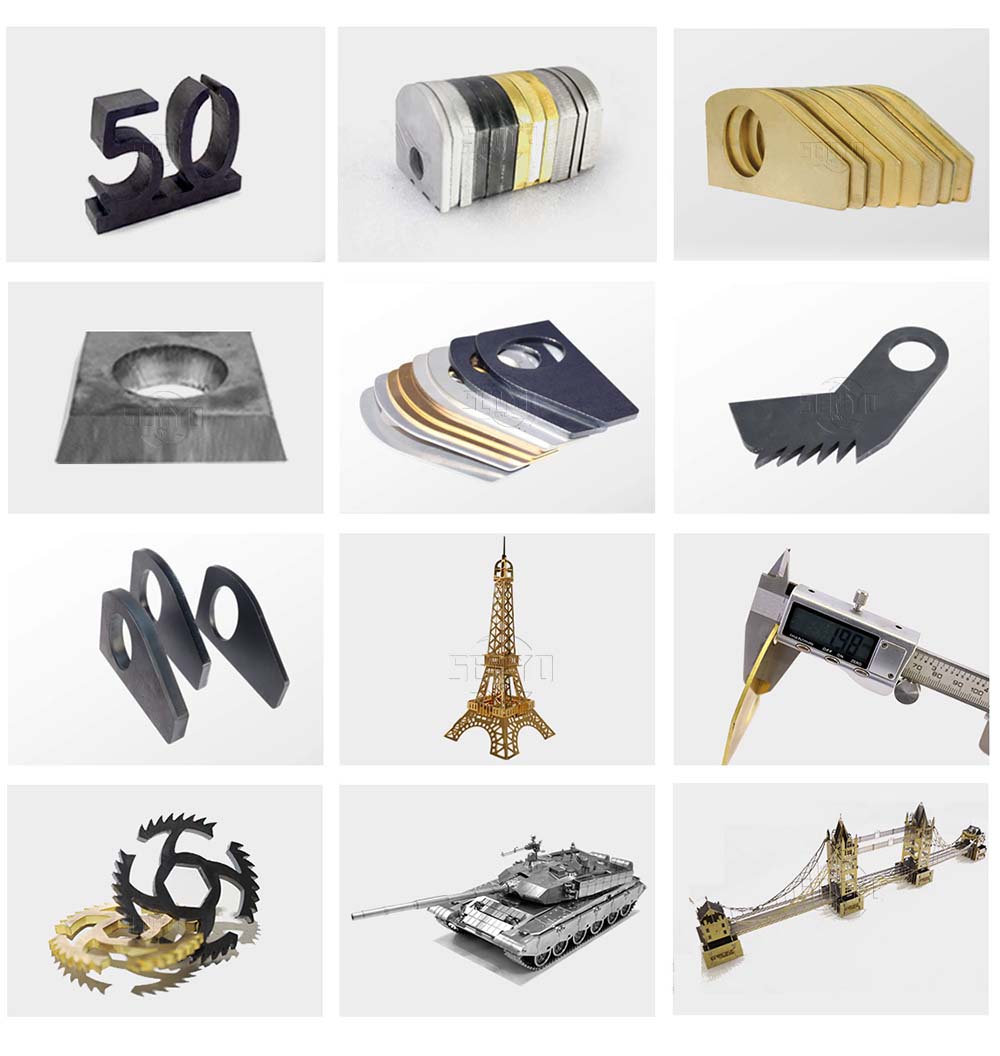

This machine is used in various industries like eyewear, electronics, home appliances, and metal signs. It’s ideal for cutting metal logos, letters, and jewelry names. Precision industries, hardware manufacturing, and microelectronics also benefit from its accuracy and efficiency.

Application Materials

The machine can cut through all types of metals, including stainless steel, carbon steel, and aluminum alloy. It is also effective with titanium alloy, galvanized steel, and copper. Additionally, it works well with coated metals like aluminum-plating zinc plates and pickle plates.

Machine Working Project

For Our Work Steps

1.Before-sale,we will try to know your requirement about our cnc finer laser specification and what kind of work

you will do .then we will offer our best solution for your requirement.

2.During production: we will send photos of machines during making. so you can know more details about

the procession of making your machines.

3.Before shipping,we will take delivery photo and confirm the specification of order to avoid the mistake.

Machine will be adjusted before it is delivered.

4.After shipping: we will sent out the documents for your customs clearance ASAP . and check the

approximate date of arrival.

5.After arrival: we will confirm with you if machine is in good condition.and see if any spare parts missing .

6.About teaching: there are some manual and video about how to use machine , if you have question

about it. we will have professional technicist to help you install and teach how to use through skype ,calling,or mail.

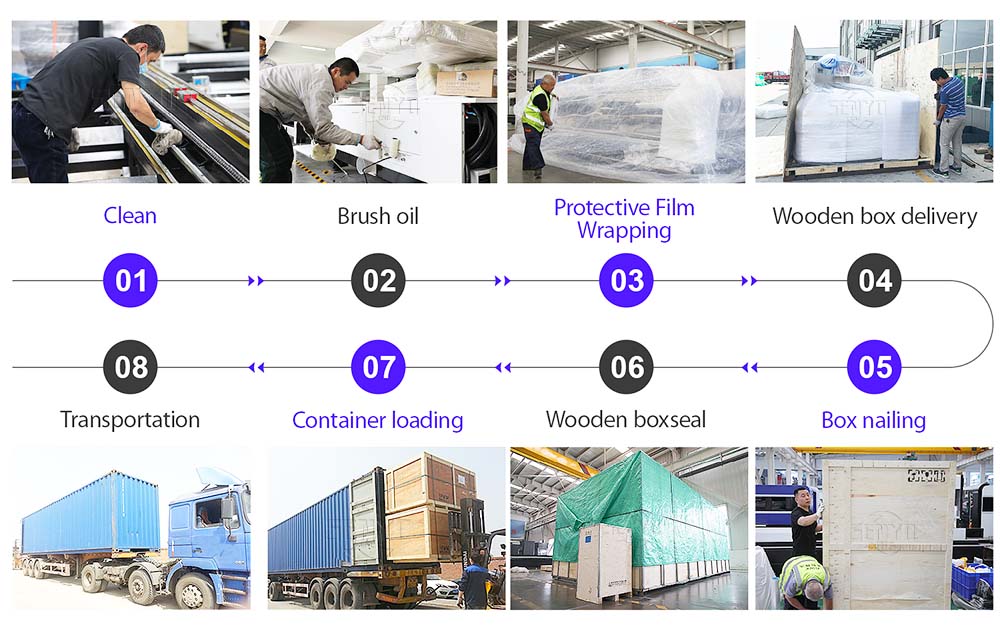

Package and Shipping

1. Strong water resit bottom in plywood.

2. Laser source (separated plywood case) and spare parts on the laser bed.

3. Corner protected by foam and fixed by a protective film.

4. All are covered by strong and hard protective film.

5. Vacuum packing.

6. Inside steel frame protector.

7. Plywood packing and steel strip outside fixed the box.

8. Finishing packing by normal container or frame container.

Maintenance and Safety Guidelines for First-Time Users

Starting with a small metal laser cutter can feel exciting yet daunting, especially if you’re new to this technology. Proper maintenance and adherence to safety protocols are essential to keep your machine running smoothly and ensure safe usage. By following these simple guidelines, you can maximize the lifespan of your laser cutter and minimize risks.

1. Regular Cleaning: Dust, debris, and metal residues can accumulate during cutting. Clean the lens, mirrors, and machine bed after each session to maintain optimal cutting precision and prevent damage to sensitive components.

2. Monitor Cooling Systems: Most metal laser cutters use a water or air cooling system to prevent overheating. Check the coolant levels regularly and replace the water or antifreeze as needed to avoid system failure.

3. Inspect Components: Perform routine inspections of belts, rails, and electrical connections. Tighten loose screws and replace worn-out parts promptly to avoid breakdowns during operation.

4. Wear Protective Gear: Always wear safety goggles designed for laser cutting to protect your eyes from harmful radiation. Avoid wearing loose clothing that could catch fire or interfere with the machine.

5. Follow Ventilation Guidelines: Ensure the laser cutter is placed in a well-ventilated area. Proper exhaust systems are crucial for removing fumes and metal particles generated during cutting.

6. Emergency Preparedness: Keep a fire extinguisher nearby and familiarize yourself with the machine's emergency stop button. Knowing how to react in unexpected situations can prevent serious accidents.

Pre-Sale Service

1. Free Sample Cutting Service

For free sample cutting/testing, please send us your CAD file (.plt or .ai), we will do the cutting in our factory and make a video to show you the cutting process and result or send samples to you to check the cutting quality.

2. Progressing Solution Design

According to the customer’s product processing requirement, we can design a unique solution that supports higher manufacturing efficiency and better processing quality for customers.

3. Customized Machine Design

According to the customer's application, we may revise our machine according to the customer's convenience and high production efficiency.

After-Sale Service

1. We will supply the laser machine with a training video and a user's manual in English for installation, operation, maintenance, and troubleshooting, and shall give technical guidance by remote, such as TeamViewer, E-mail, Telephone, Mobile, WhatsApp, Skype, 24/7 online chat, and so on when you meet some problem of installation, operation or adjusting. (Recommended)

2. You can come to our laser machine factory for training. We will offer professional guidance. Direct and effective face-to-face training. Here we have assembled equipment, all sorts of tools, and a testing facility. Training Time: 3~5 days (Recommended)

3. Our engineer will do a door-to-door instruction training service at your local site. We need your help to deal with the visa formality, prepaid traveling expenses, and accommodation for us during the business trip and service period before their dispatch. It's better to arrange a translator (if not English-speaking) for our engineers during the training period.

Warranty

1. The entire machine comes with 1-year limited warranty (excluding consumable parts).

2. Long lifetime maintenance, the after-sale department will offer 24/7 English online support.

3. Except for the damage artificially, we are responsible for offering the fittings free of charge during warranty.

4. After the warranty period expires, the buyer only needs to pay the actual maintenance cost.

- 1000W/1500W/3000W fiber laser cutter

- Automatic laser cutting machine

- Precision fiber laser cutting

- Fiber laser for stainless steel cutting

- Affordable fiber laser cutter

- Best fiber laser cutting machine

- Fiber laser cutting machine price

• Previous: Entry Level Small Metal Laser Cutter for Beginners

• Next: None

Fiber metal Laser Sensor And Its Application

Category: SENYO NEWS 11th Mar, 2021A CNC wood router will use 3D machining in relief carving, the effect is more artistic beauty, but also has a strong sense of three-dimensional 3D, realization of this function is to ...

Precision Cutting Stents with Fiber Lasers

A CNC wood router will use 3D machining in relief carving, the effect is more artistic beauty, but also has a strong sense of three-dimensional 3D, realization of this function is to ...

How to Laser Cut Copper and Other Reflective Metals

Laser cutting of mild steel and stainless steel has a long history and has been one of the primary applications for CO2lasers. However CO2lasers have not traditionally offered a good solution for cutting highly reflective materials.Fiber lasers have an emission wavelength of around

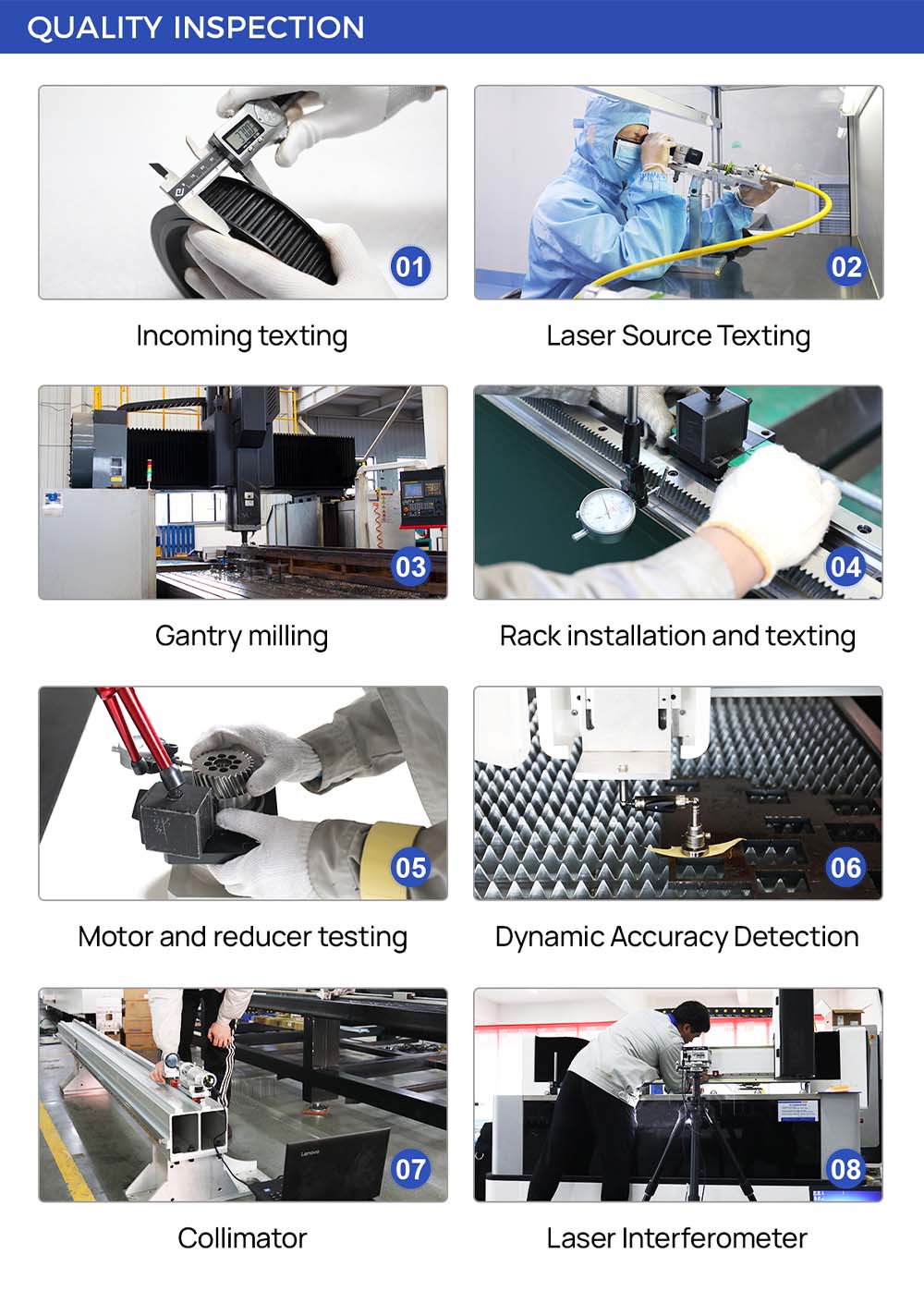

Laser Cutting Machine Inspection Process For Manufacture

SENYOCNC Have Strict quality monitoring will be carried out when the parts are in the factory.

How Control Costs Use of UV Printers ?

UV flatbed printers are rapidly being used by more and more manufacturers, thanks to its efficient production efficiency, and the control of production costs also needs to arouse our attention.

Why UV flat printing machine is popular in market ?

For the majority of designers, give full play to the creative ability, the design sample can be arbitrarily modified on the computer, the effect on the computer, is the effect after the finished product, customer satisfaction can be directly produced. UV flat printing pattern fine, rich and clear layers, high artistry, strong three-dimensional sense, many high precision equipment can also print photography and painting style patterns.

How does UV ink jet printer save UV ink?

UV inkjet printer use process is an important consumable UV ink, reasonable use of equipment, can save UV ink , it can be said to be the best choice to directly save the cost. In the process of using some skills you need to be familiar with, the following small make up to share with you:1. Try to us

Waterjet Machine delivery and Shipping

Please tell us your max working size and what materials will cutting , also what max cutting thickeness.If you have Working photo sample please also send us , it will be helpful to choose machine with suitable models .

Waterjet Machine finish manufacture 5axis

Waterjet cutting technology is one of the fastest growing major machine tool processes in the world due to its versatility and ease of operation.

Waterjet Machine delivery and Shipping

Waterjet cutting technology is one of the fastest growing major machine tool processes in the world due to its versatility and ease of operation.There are multiple advantages to adding waterjet cutting capabilities to your shop.We are company leading ultrahigh-pressure waterjet system so

How to Create Connected Text – Inkscape for Laser Cutting

Step 1: Create Some TextFirst, we need some text to work with. To create the text, select the Text Tool (keyboard shortcut: T), click somewhere on the canvas, and type your text.You can use the drop-down list on the top left to select your desired font.Step 2: Convert Text to PathNext, we need to tu

Jacob from United States

I am a beginner at CNC, I’ve never used a CNC machine before and with in a day I was carving. An awesome machine for a beginner to learn as hobbyists. I used the manual and the help video. One hour to assemble and test, very friendly and easy to use. It’s a good buy for the money. I would definitely recommend this machine to someone getting into CNCs.

Weinstein from France

I've been using CNC plasma SYP2060-300A and I am very impressed with this unit.

This unit is of higher quality, made in China. Five stars all the way!

2040 from INDIAN

Best 2040 CNC Router Good Price and Quality ! Thank SENYOQC

10w uv laser from American

Best supplier ! I bought 3 machines for laser and router , thank you Aillen ! --Alec

12KW Fiber Cutting - 2000X6000mm -- 이병헌 from Korea

Good machine for metal cut ! Thanks Senyo , Its prefect , I like your business patient kind!

I am a furniture manufacturer, and this machine is very good and fast. thanks Senyoqc Team ! from Bangladesh

Metal ArtWork from Denmark

The plasma cutting machine makes my artistic creation more convenient and precise!! Created more artistic ideas and value! Thank you Aillen team!

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen. from

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen.

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo from

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo

Thank you Senyo for SYJ1290-150W! from

Retired, ex mainframe systems programmer. Now full-time recreational woodworker majoring in puzzles, pens, boxes, Toys and occasional small furniture. Thank you Senyo for SYJ1290-150W!

manager@senyocnc.com

manager@senyocnc.com

SENYOCNC

SENYOCNC

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

2061579344

2061579344