Are you looking forward to DIY wood laser cutter kit or need to buy an affordable laser wood cutting machine for beginners with CNC control system?

Review the best laser wood cutter buying guide as follows.

We'll offer you best wood laser cutting machines with custom laser cutting service for wood.

To fit your 2D/3D laser cut wood projectsIdeas and wood laser cutting plans.

What is a Wood Laser Cutter?

Laser wood cutting machine is an awesome CNC laser cutting system that adopts CO2 laser source to engrave and cut wood

Solid wood, hardwood, softwood, MDF, plywood, bamboo, plastic, paper, foam, acrylic, fabric.

Leather and more nonmetal materials into different 2D/3D profiles and shapes.

The cutting ability depends on the CO2 laser power, we have 80W, 100W, 130W, 150W, 180W, 220W and 300W and other CO2 laser powers for option

You can choose different laser powers and laser cutting table sizes to fit your wood cutting and engraving plans & projects.

Laser wood cutting machine is also known as laser wood cutter, wood laser cutting machine, laser wood cutting system, laser wood cutting tool, wood laser cutter.

Why Choose Laser Cutter for Wood?

A wood laser cutter is easy to engrave and cut wood with CNC controller. Just a few easy-to-follow steps.

You can cut out a wood project with the power tool. Unlike a table saw, the laser cutting technology adopts non-contact cutting.

Which can minimize cutting deformation, will not cause cracks on the wood, and reduce material waste.

Moreover, the laser cutting speed and accuracy is more higher than manual and traditional cutting methods.

And the incision and edge is smooth, no need to polish later.

It's the best edge cutter for wood. With a rotary tool, it can even cut 3D cyliners.

These are incomparable with traditional cutting methods for wood. Relatively speaking, the laser cutter is the most cost-effective cutting method for wood.

Laser Wood Cutting Machine Features and Advantages

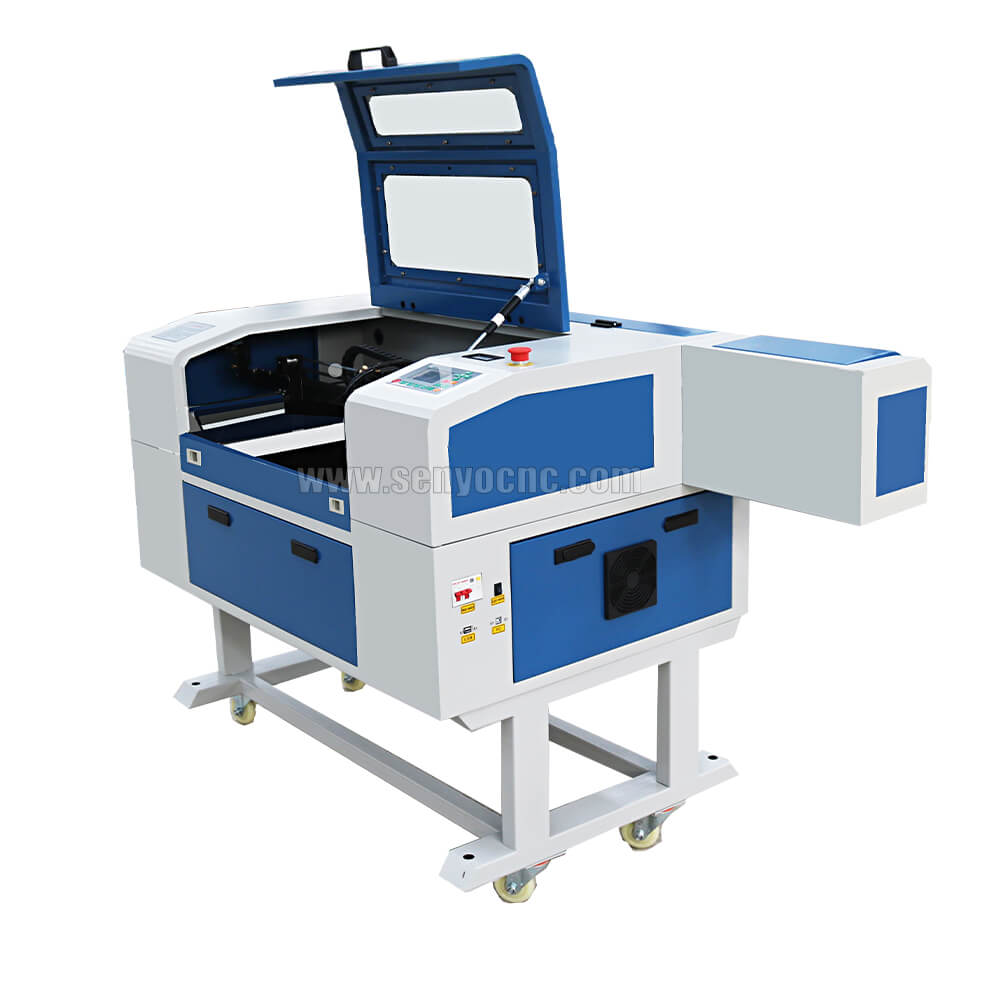

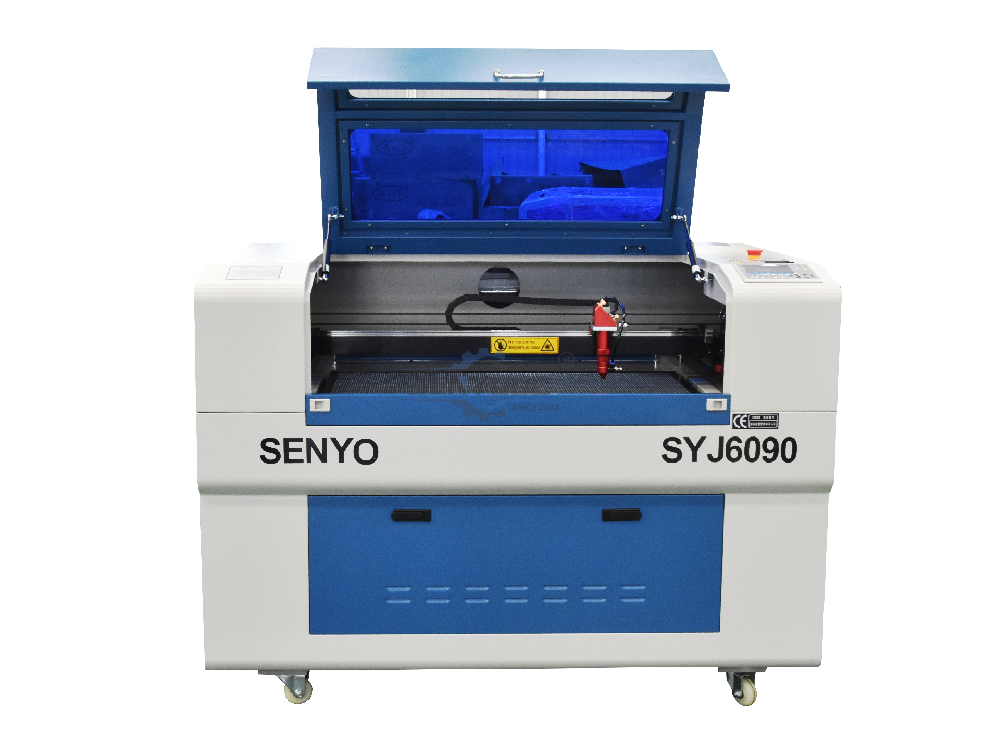

1. The top rated laser wood cutting machine with CO2 laser tube adopts more scientific design and high strength metal plate frame.

which can increase the fuselage strength more than 40% to prevent the machine from distortion during long term work.

In addition, this structure is very stable and not easy to be out of shape. The sound insulation effect is good.

2. Advanced Ruida 6442G control system for CNC wood laser cutter is the latest generation of laser engraving cutting control system,

The control system hardware has better stability, better resistance to high pressure, anti-static properties of interference.

3. New-style high-efficiency RECI laser tube is adopted. Laser beam is more stable than the traditional type. Usage age is more than 10,000 hours.

4. Taiwan HIWIN square linear guide rail will be installed on X axis and Y axis to ensure the laser wood cutter works stably and precisely.

5. The best CO2 laser wood cutting system adopts high quality professional square tube framework,

With more than 40% higher fuselage strength than iron sheet structure.

This design prevents the laser wood cutting machine from quivering, resonance and distortion during long term work.

6. Red dot position system is added in standard configuration, contributing to simple and precise working position.

7. The best CNC wood laser cutting system adopts advanced LCD Screen + USB port + Offline Control,

With professional motion control chip, which has the functions of consecutively high-speed curve cutting and the shortest path selection,

Which largely improves your working efficiency.

8. USB offline control system makes the wood laser cutter operation more convenient and faster.

9. Automatic up-down table for the wood laser cutter can be chosen for thick materials and high objects.

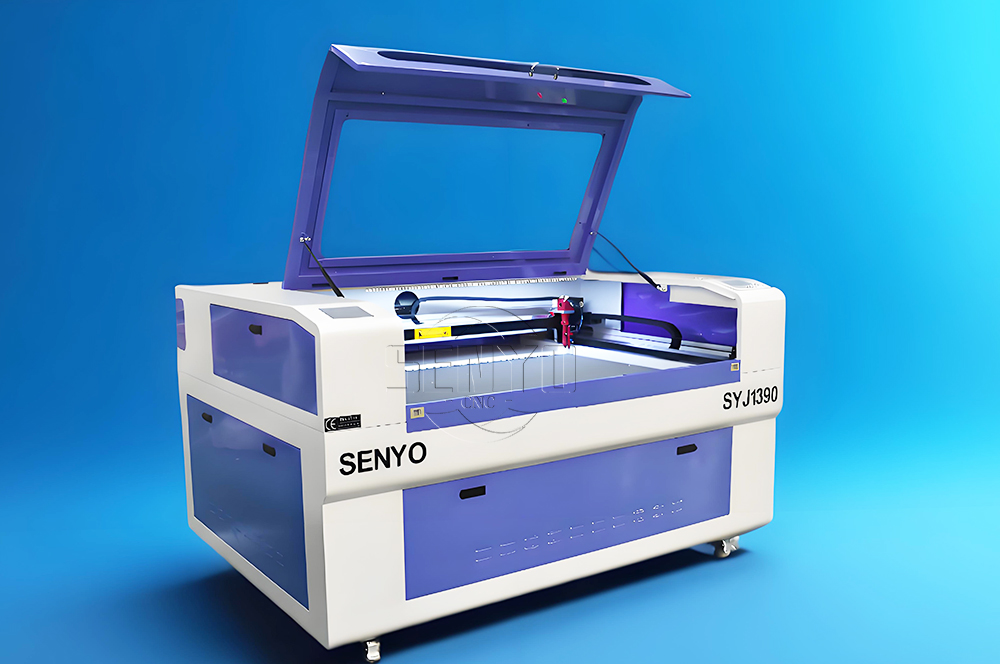

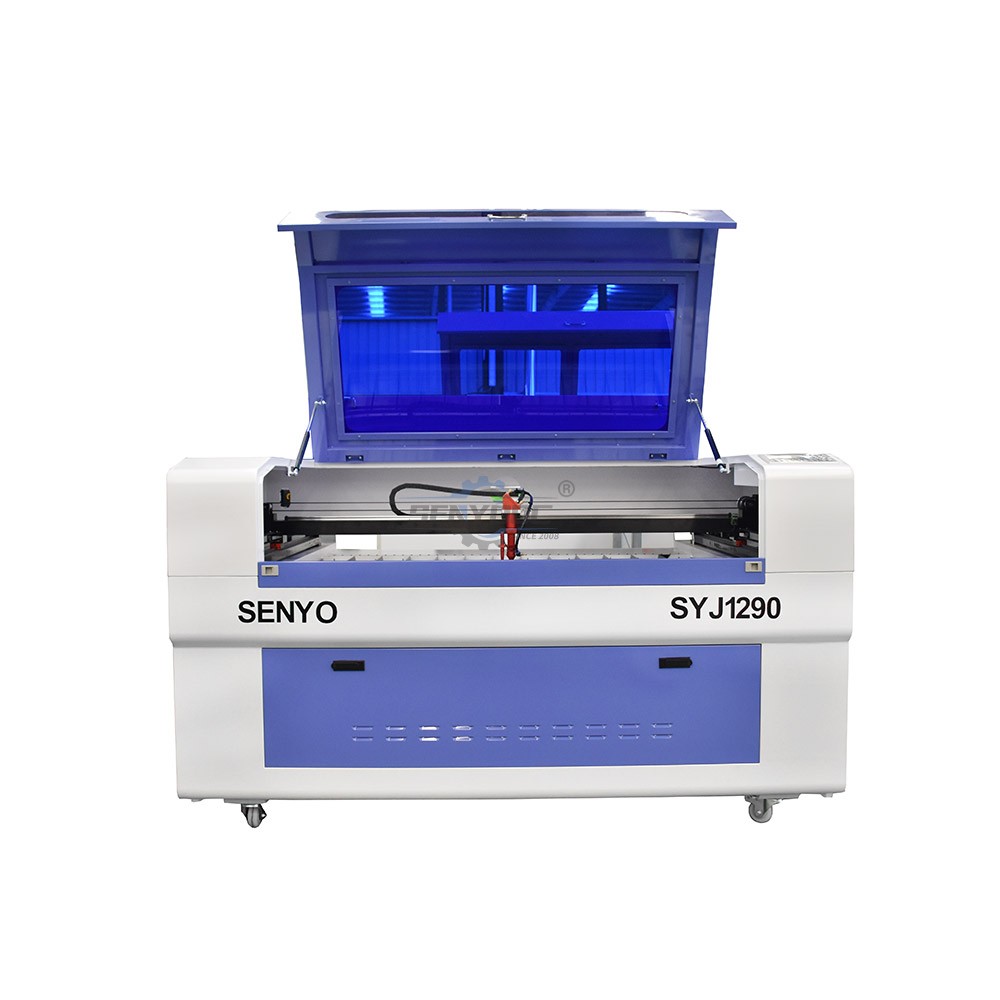

10. The cutting and engraving area is 1300x900mm for most of woodworking projects.

11. Unlike 3D printers, it requires no consumables.

Application industry

Acrylic, organic glass, advertising signage, craft gifts, crystal jewelry, paper-cutting craft, bamboo and wood carving craft.

Printing plate, clothing leather, embroidery, decoration, photo frame production and other industries.

CNC Laser Wood Cutting Machine Details

Ruida controller system, which is best for cnc laser cutting machine . Easy operation and button all on controller pannel ,You can operation in easy.

Adopt the new high-efficiency CO2 laser tube of RECI,the laser beam is more stable,and the laser management theory has a working life of more than 10,000 hours.

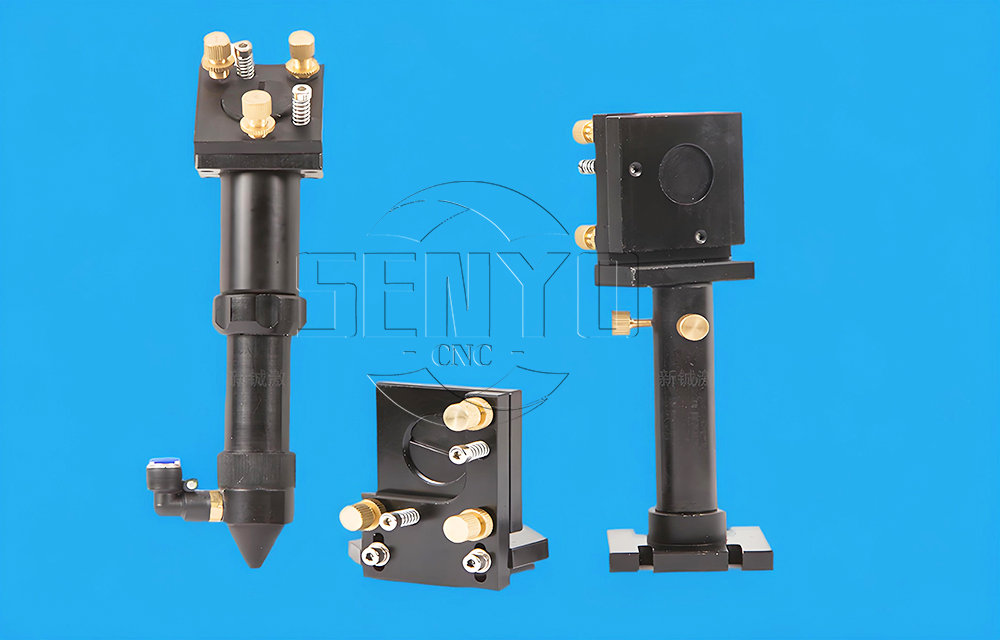

Industrial grade laser head with red point, air assistant to prevent burning,automatic focus,high speed and precision.

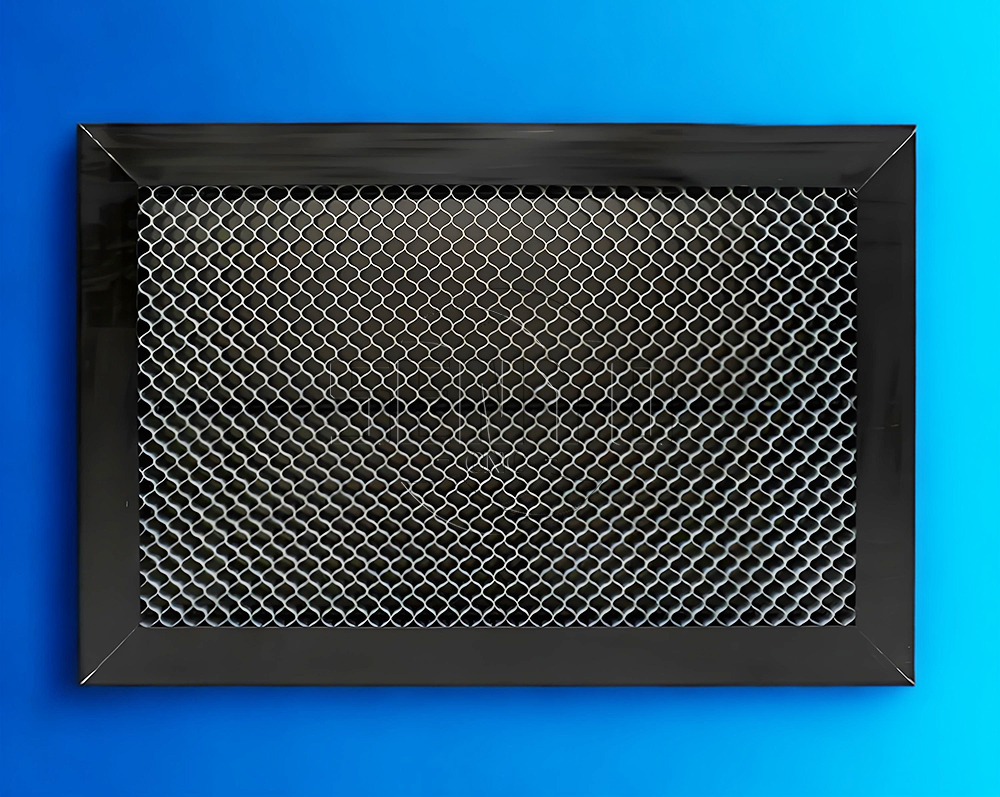

Honeycomb/Blade Platform

Customized cutting platform,easy to take,reinforced and encrypted ,high flatness,triple reinforced structure,strong and durable,can bepushed and pulled.

Silicon reflective lens,5 layers of silicon coating,laser reflctivity of 99.9%. Imported zinc selenide laser focusing lens,the light transmittance is 99.8%.

High temperature and wear resistance.

CW5200 Chiller Exclusive no water warning and automatic protection system.

Can protect the working life of laser tube to ensure the satbility and safety of the machine to the best.

Taiwan Hiwin Square rails

Compared to the ordinary slider.It can adapt to the precise ensure that the laser machine runs efficiently and stably for a long time.

RDCAM control system and control panel

Control panel English,easy to operate and control.It has the function of re-engraving after breakpoint and power failure.

Laser Protection glass for optional , It can protect your eyes when laser work.

Lens and mirror are best in china . We advice you prepare this parts for Consumables as backup .

Leadshine Stepper motor and gear box

High-precision belt-driven leadshine stepper motor to improve response speed and cutting engraving accuracy,low noise.

Machine with all parts for your operation . Also we advice you prepare Consumables as backup .

Best Wood Laser Cutter Machine Specifications

Model | SYJ1390 |

Working Area | 1300mm*900mm |

Laser Power | 100W (80W, 130W, 150W, 180W, 220W and 300W for option) |

Laser Type | CO2 sealed laser tube |

Driving System | Stepper motor |

Transmission | Belt transmission |

Guide Way | Taiwan Hiwin square guide rails |

Control System | Ruida control system RD6445S |

Lens and Mirrors | 3pcs mirrors and 1pcs lens from Singapore |

Working Table | Blade table or Honeycomb table for option |

Water Chiller | Included |

Laser Engraving Speed | 0-7500mm/min |

Laser Cutting Speed | 0-4000mm/min |

Graphic Formats | PLT, BMP, DST, AI, DXF |

Laser Software | AutoCAD, PhotoShop, CorelDraw, TAJIMA |

Red Pointer | Yes |

Power Supply | 110V 220V / 50HZ 60HZ |

Optional Parts | Rotary Device |

Up-down Worktable + 200usd | |

Auto Focus | |

CCD Camera |

How to Use a Wood Laser Cutter for Beginners?

Laser

wood cutting has the advantages of high precision, narrow cutting seam,

high speed, and smooth cutting edge.

Which is different from circular saw blade to cut wood. However, because the laser focus energy melts the wood.

There will be blackening during the cutting process, that is, the cutting edge is carbonized.

The first thing to note is that if you are cutting a thicker wood board, it is difficult to not blacken it, but after my test.

I conclude that the wood board with a thickness of 5mm or less can be cut without much blackening.

while 5mm The above depends on the situation, the following is a detailed description of what to do to prevent the laser wood cutting from turning black:

Maybe everyone knows that to avoid the carbonization effect of laser cutting, use high speed and low power.

This is correct, but some are misunderstood. Some users think that the faster the speed, the better, and the lower the power, the better.

In order to reduce the blackening, use fast and low power to cut multiple times. This is very bad, and the carbonization effect may be darker than normal.

Our low power and fast speed must ensure that the wooden board can be cut through at one time.

The faster the speed is, the better, and the lower the power, the better.

However, if the power is reduced and multiple cuttings are required, the carbonization phenomenon is actually more serious.

Because the cut part will be burnt a second time, the more you cut, the more serious the carbonization.

So the first thing to pay attention to is to ensure that it is cut in one time, not secondary cutting, to avoid secondary damage.

Fast speed and low power are contradictory.

The faster the speed, the more difficult it is to cut through, and the lower the power, the more difficult it is to cut through.

We have to prioritize between the two. According to our experience, fast speed is more important than low power.

Use larger power to try the fastest speed that can be cut through. Of course, this needs to be tested to get the best value.

The following is the data we tested with SENYOCNC 80W CO2 laser cutting machine.

To cut 3mm glulam boards, we use 55% power and 45mm/s speed. Under this parameter, there is basically no blackening.

We use 40% power and 45mm/s speed to cut 2mm plywood. We used 65% power to cut the 5mm plywood at a speed of 20mm/s.

The 5mm wood board has started to turn black, but the situation is okay, and the hands are still not dirty.

And we tried the maximum cutting thickness of this laser cutting machine, 18mm solid wood panels.

Maximum power, turtle speed... (80 Watts is impractical, if you want to cut thick wooden boards, you can buy a 150 Watts CO2 laser tube),

it's already dark, and the carbonization is very serious. You can use it with sandblasting machine to process if you care the final result.

Of course, in addition to the power speed that affects the blackening, there is also a very important factor, that is, blowing.

You must blow strongly when cutting wood. It is best to use a high-power air compressor.

because the other factor of blackening and yellowing is cutting The gas produced is blackened, and blowing can assist in cutting to make cutting easier and prevent fire.

Our test data are not limit numbers, they are for reference only, and some redundancy is left.

Because the experimental data can be faster and lower power, but it cannot guarantee a cut through.

Because other factors must be considered in practical applications: uneven platform, focal length problems caused by uneven wooden boards,

Uneven material of the three-ply plywood, etc., all have an impact, so be careful not to use the limit value to cut, it may be poor A little cut through.

If you find that it is black no matter how you cut it, it may be a material problem, and the glue content of the plywood will also affect it.

It is also very important to find more suitable materials.

For Our Work Steps

1.Before-sale,we will try to know your requirement about our cnc finer laser specification and what kind of work

you will do .then we will offer our best solution for your requirement.

2.During production: we will send photos of machines during making. so you can know more details about

the procession of making your machines.

3.Before shipping,we will take delivery photo and confirm the specification of order to avoid the mistake.

Machine will be adjusted before it is delivered.

4.After shipping: we will sent out the documents for your customs clearance ASAP . and check the

approximate date of arrival.

5.After arrival: we will confirm with you if machine is in good condition.and see if any spare parts missing .

6.About teaching: there are some manual and video about how to use machine , if you have question

about it. we will have professional technicist to help you install and teach how to use through skype ,calling,or mail.

Packing & Shipping for CO2 Laser Machines From SENYOCNC

The machine is packed with great care and tough material.

The machine is packed with cling films first and then film bags.

The machine is packed with wooden case which is reinforced with the iron bar on the top and bottom.

With this kind of package, all our laser machine can protect well during long trip by sea or by train.

Warranty and Service for CO2 Laser Cutters from SENYOCNC

⇲ The whole machine: one year.

⇲ CO2 laser tube: 12 months.

⇲ 24 hour technical support online like skype/whatsapp/remote, you can calling us if urgent.

⇲ We offer free training in our factory, and our engineers available to service machinery overseas,

but the round-trip air tickets, hotel and meals for the engineers should be paid by our buyer.

Benefits of Using Laser Cutter

Laser cutters have been a profitable tool in all sectors. These machines have adapted and gained advancement over a long time.

Using a laser cutter is still fun and profitable. Let’s take a look at the benefits of a laser cutter.

✔ Laser cutters offer unparalleled precision and detailed accuracy.

✔ These are highly versatile and can handle a wide range of application.

✔ Features better efficiency and speed and reduces production waste.

✔ Nowadays, laser cutters come with more flexibility that enables designers to make complex projects.

✔ These machines are clean and environmentally friendly.

✔ Laser cutters require low maintenance cost.

✔ Features versatile usage using different tools.

Service & Support

1. Our engineers available to service machinery overseas.

2. 2 years guarantee for the whole machine.

3. Technical support by calling, mail, whatsapp and skype. If you have any problems, we will help you to solve it within 12 hours.

4. You will be get free training advice towards our machine in our factory.

5. If you need any component of the machine, we will provide most affordable price for you.

6. Friendly English version manual and operation video CD disk.

CO₂ laser engraver,CO₂ laser engraving machine,Laser cutting and engraving,Desktop laser engraver,Industrial laser engraver,Laser engraving equipment, Laser engraving system,Laser etching machine

• Previous: Best Laser Cutting and Engraving High-Speed Laser Engraving Acrylic Fabric Paper Laser Cutting

• Next: Best Laser Cutting and Engraving High-Speed Laser Engraving Acrylic Fabric Paper Laser Cutting

Fiber metal Laser Sensor And Its Application

Category: SENYO NEWS 11th Mar, 2021A CNC wood router will use 3D machining in relief carving, the effect is more artistic beauty, but also has a strong sense of three-dimensional 3D, realization of this function is to ...

Precision Cutting Stents with Fiber Lasers

A CNC wood router will use 3D machining in relief carving, the effect is more artistic beauty, but also has a strong sense of three-dimensional 3D, realization of this function is to ...

How to Laser Cut Copper and Other Reflective Metals

Laser cutting of mild steel and stainless steel has a long history and has been one of the primary applications for CO2lasers. However CO2lasers have not traditionally offered a good solution for cutting highly reflective materials.Fiber lasers have an emission wavelength of around

Laser Cutting Machine Inspection Process For Manufacture

SENYOCNC Have Strict quality monitoring will be carried out when the parts are in the factory.

How Control Costs Use of UV Printers ?

UV flatbed printers are rapidly being used by more and more manufacturers, thanks to its efficient production efficiency, and the control of production costs also needs to arouse our attention.

Why UV flat printing machine is popular in market ?

For the majority of designers, give full play to the creative ability, the design sample can be arbitrarily modified on the computer, the effect on the computer, is the effect after the finished product, customer satisfaction can be directly produced. UV flat printing pattern fine, rich and clear layers, high artistry, strong three-dimensional sense, many high precision equipment can also print photography and painting style patterns.

How does UV ink jet printer save UV ink?

UV inkjet printer use process is an important consumable UV ink, reasonable use of equipment, can save UV ink , it can be said to be the best choice to directly save the cost. In the process of using some skills you need to be familiar with, the following small make up to share with you:1. Try to us

Waterjet Machine delivery and Shipping

Please tell us your max working size and what materials will cutting , also what max cutting thickeness.If you have Working photo sample please also send us , it will be helpful to choose machine with suitable models .

Waterjet Machine finish manufacture 5axis

Waterjet cutting technology is one of the fastest growing major machine tool processes in the world due to its versatility and ease of operation.

Waterjet Machine delivery and Shipping

Waterjet cutting technology is one of the fastest growing major machine tool processes in the world due to its versatility and ease of operation.There are multiple advantages to adding waterjet cutting capabilities to your shop.We are company leading ultrahigh-pressure waterjet system so

How to Create Connected Text – Inkscape for Laser Cutting

Step 1: Create Some TextFirst, we need some text to work with. To create the text, select the Text Tool (keyboard shortcut: T), click somewhere on the canvas, and type your text.You can use the drop-down list on the top left to select your desired font.Step 2: Convert Text to PathNext, we need to tu

Jacob from United States

I am a beginner at CNC, I’ve never used a CNC machine before and with in a day I was carving. An awesome machine for a beginner to learn as hobbyists. I used the manual and the help video. One hour to assemble and test, very friendly and easy to use. It’s a good buy for the money. I would definitely recommend this machine to someone getting into CNCs.

Weinstein from France

I've been using CNC plasma SYP2060-300A and I am very impressed with this unit.

This unit is of higher quality, made in China. Five stars all the way!

2040 from INDIAN

Best 2040 CNC Router Good Price and Quality ! Thank SENYOQC

10w uv laser from American

Best supplier ! I bought 3 machines for laser and router , thank you Aillen ! --Alec

12KW Fiber Cutting - 2000X6000mm -- 이병헌 from Korea

Good machine for metal cut ! Thanks Senyo , Its prefect , I like your business patient kind!

I am a furniture manufacturer, and this machine is very good and fast. thanks Senyoqc Team ! from Bangladesh

Metal ArtWork from Denmark

The plasma cutting machine makes my artistic creation more convenient and precise!! Created more artistic ideas and value! Thank you Aillen team!

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen. from

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen.

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo from

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo

Thank you Senyo for SYJ1290-150W! from

Retired, ex mainframe systems programmer. Now full-time recreational woodworker majoring in puzzles, pens, boxes, Toys and occasional small furniture. Thank you Senyo for SYJ1290-150W!

manager@senyocnc.com

manager@senyocnc.com

SENYOCNC

SENYOCNC

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

2061579344

2061579344