In the world of woodworking and CNC machining, versatility and efficiency are paramount. A 4-head CNC wood router machine with 4 rotary functions has become an industry game-changer, offering improved productivity, precision, and flexibility for businesses of all sizes. Whether you’re involved in furniture manufacturing, cabinetry, signage, or artistic woodworking, this advanced equipment can enhance both the quality and speed of your projects. In this article, we will explore the benefits, applications, and features of the 4-head CNC router machine with 4 rotary axes.

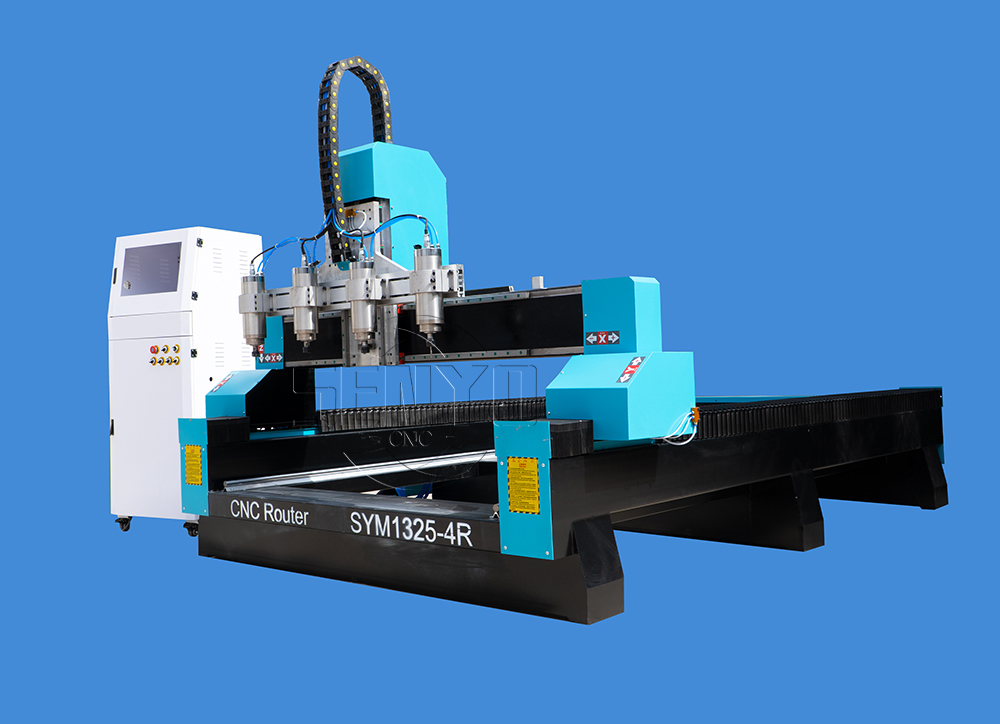

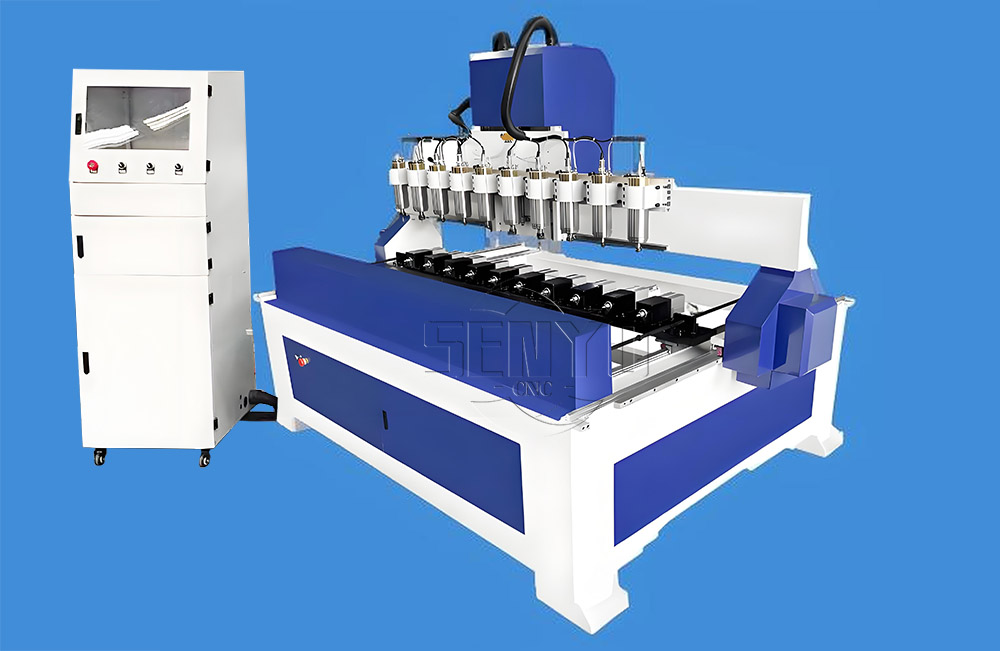

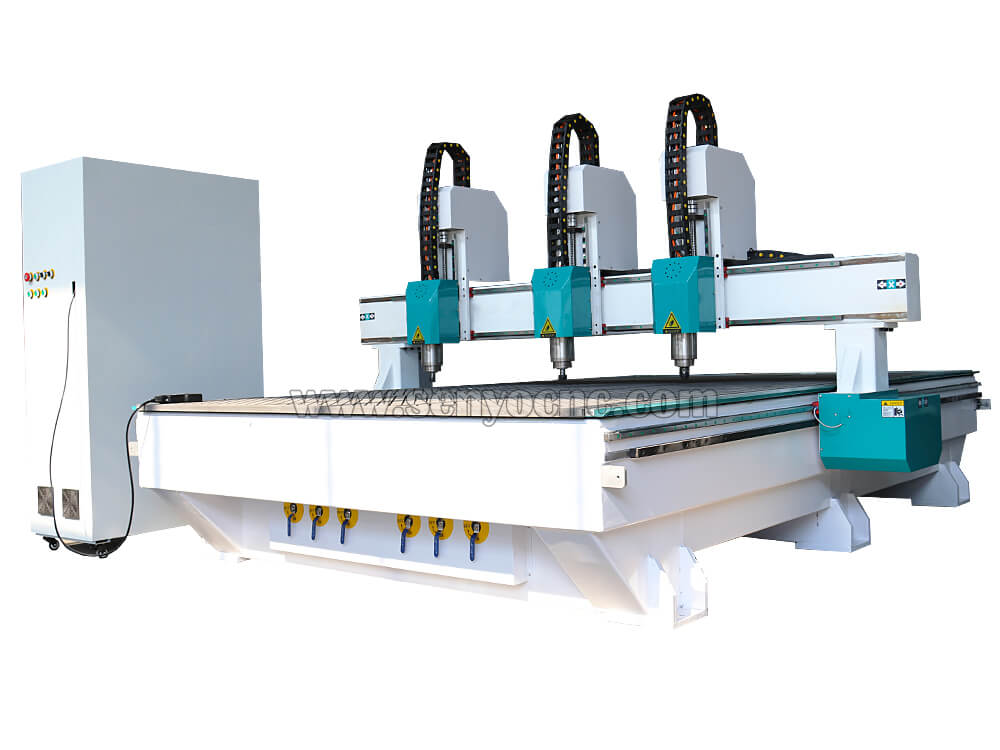

What is a 4-Head CNC Wood Router Machine with 4 Rotary Axes?

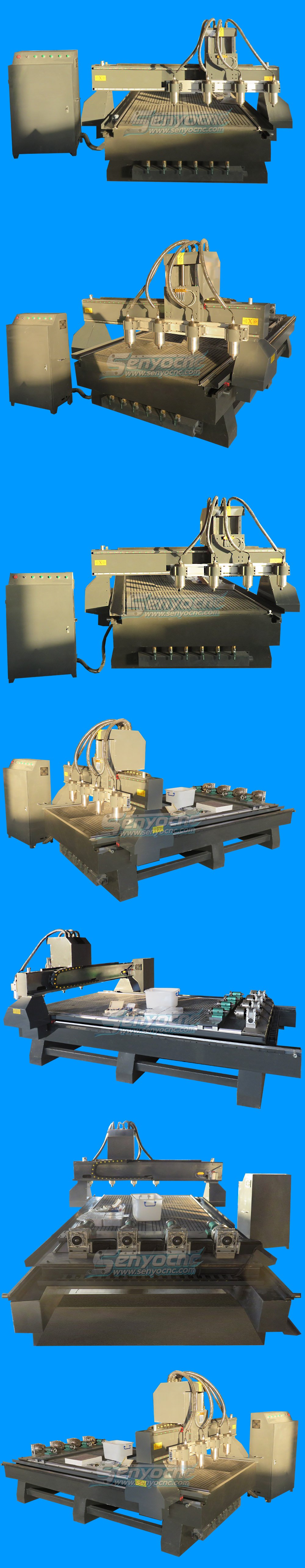

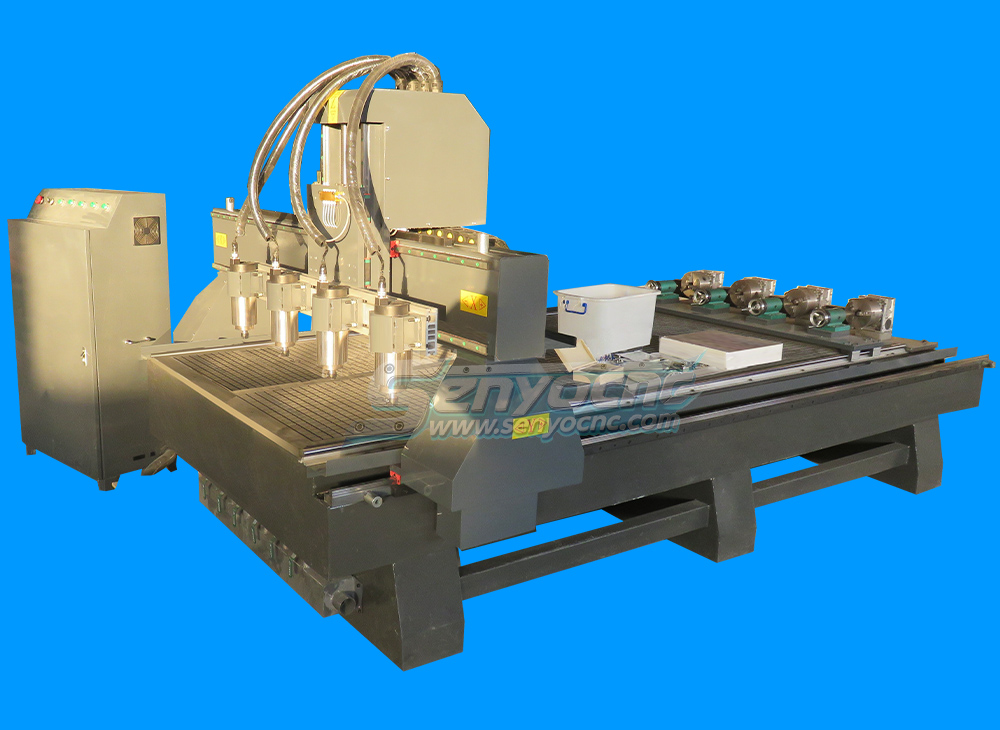

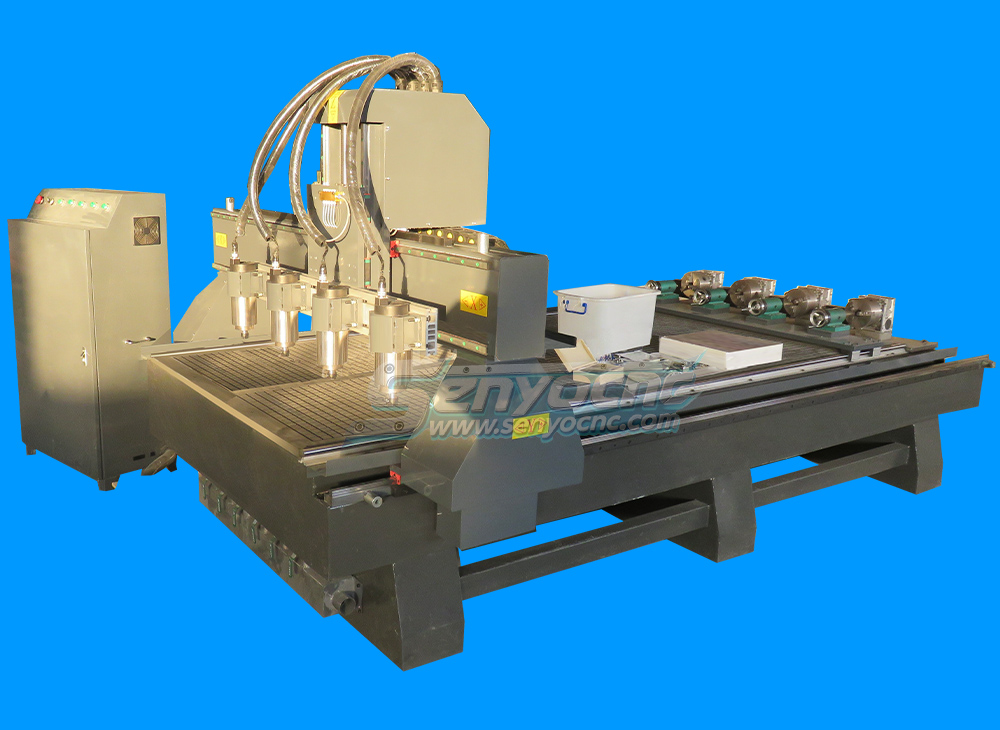

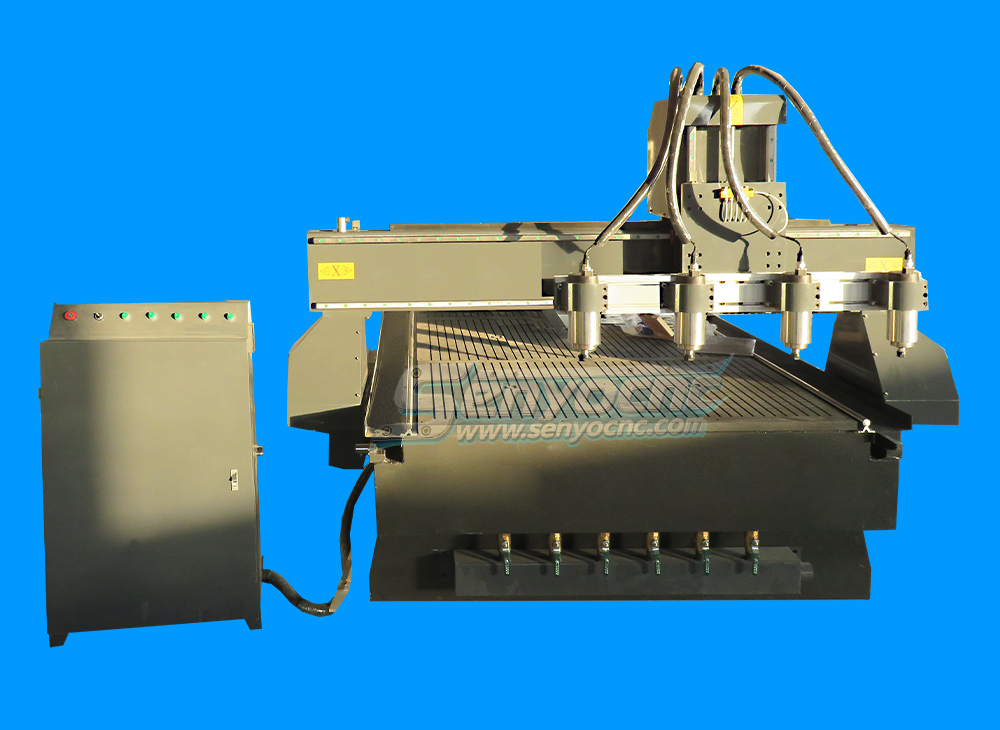

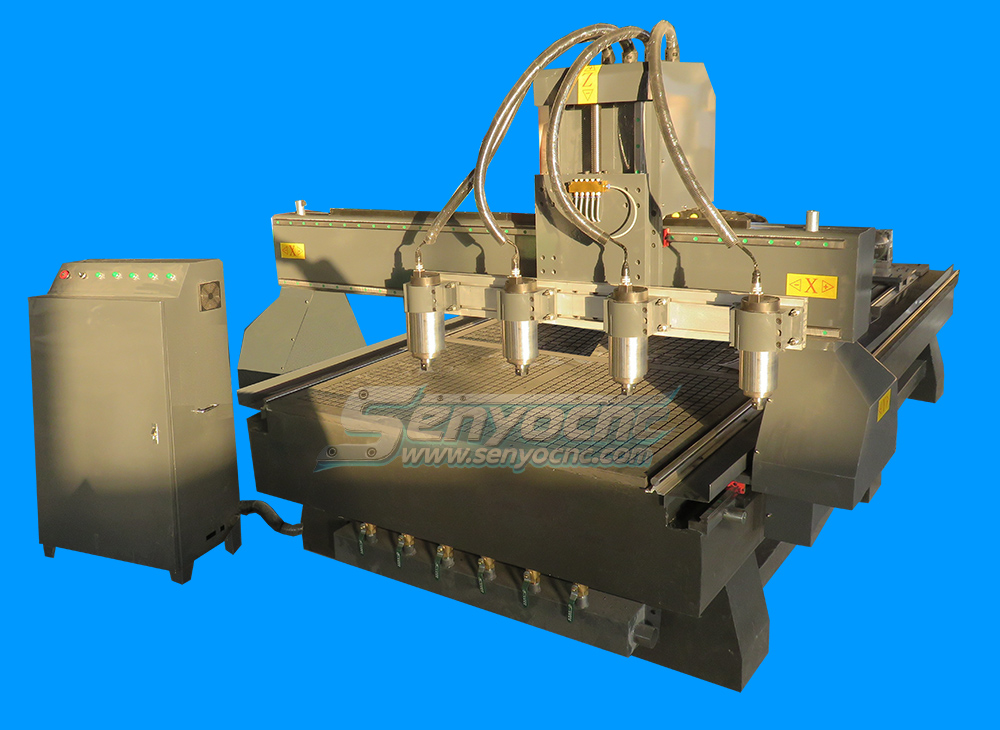

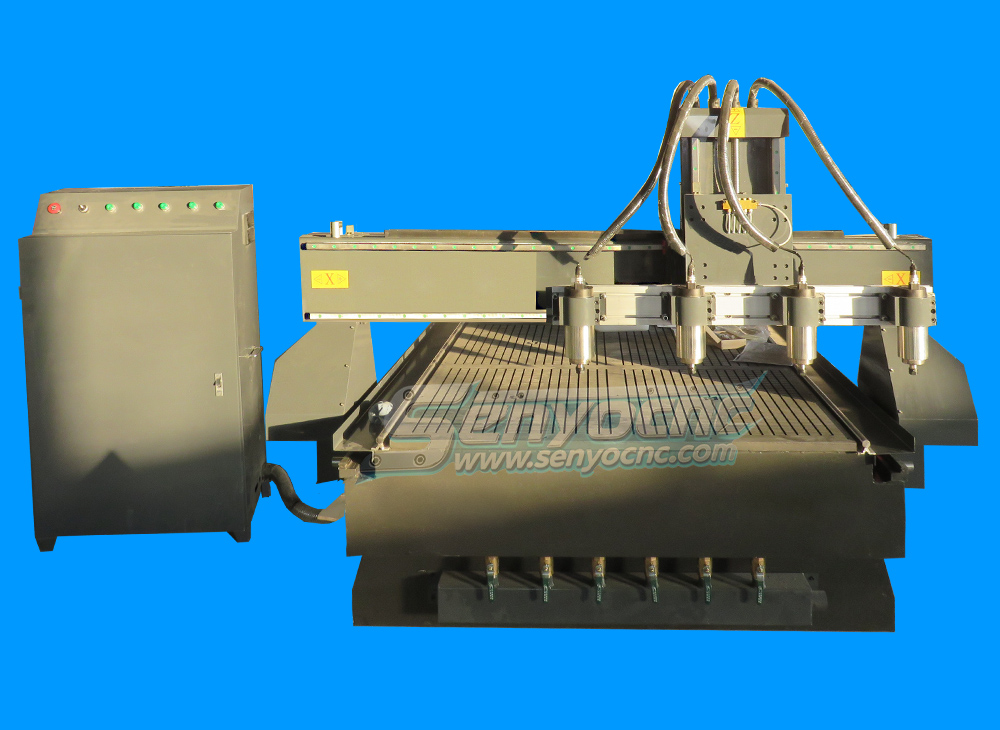

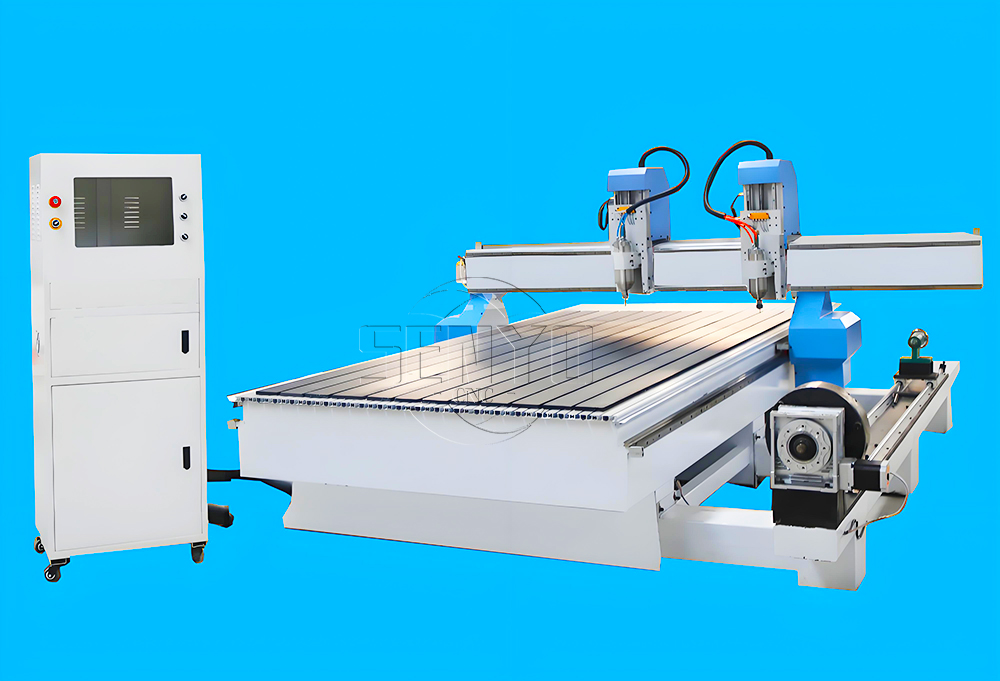

A CNC (Computer Numerical Control) router is a highly specialized machine that automates the process of cutting, carving, and shaping wood and other materials. The “4-head” aspect of the machine refers to the presence of four independent spindle heads, each capable of carrying out operations simultaneously. This greatly reduces the time spent on individual tasks, allowing businesses to handle multiple jobs at once.

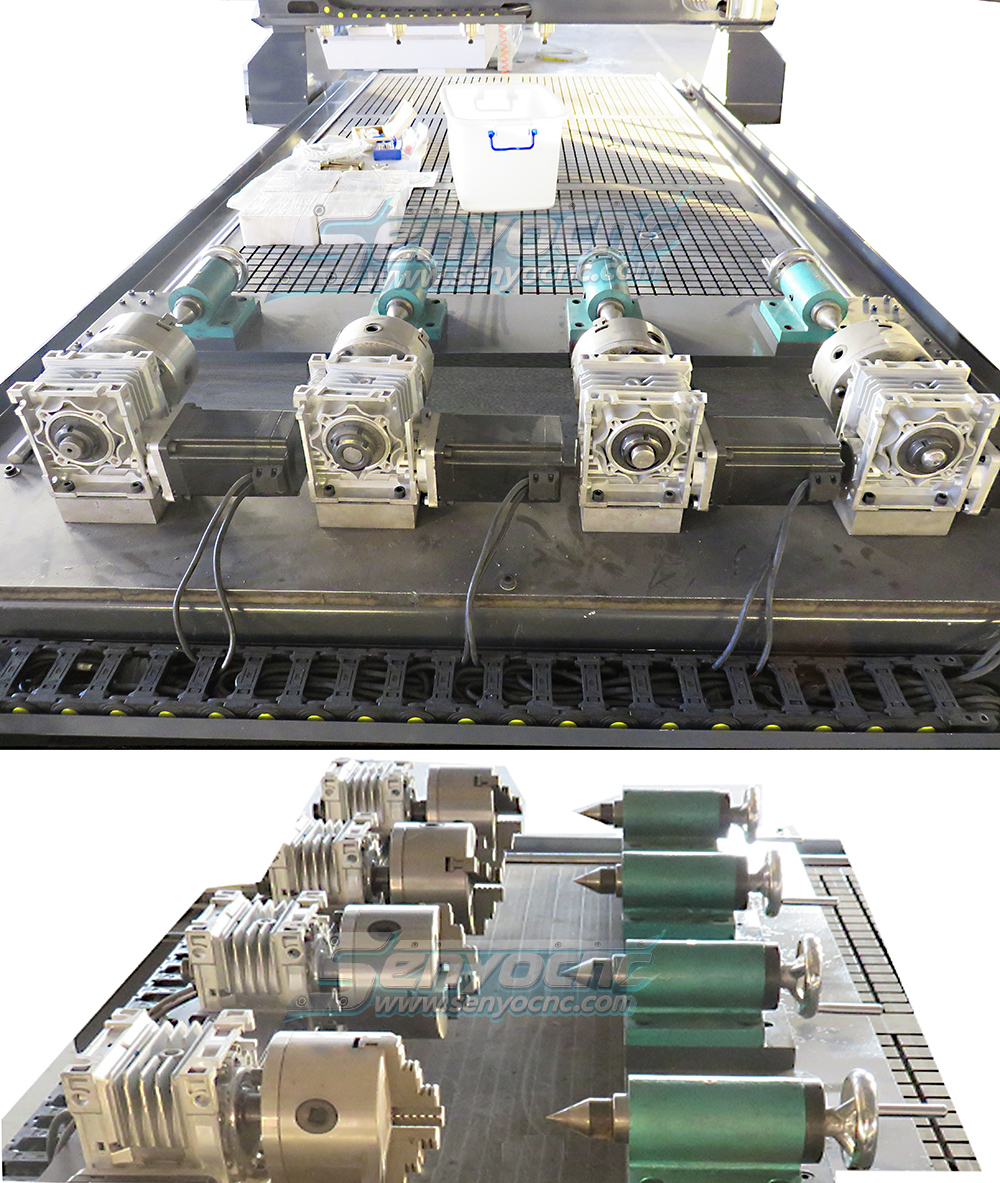

The “4 rotary axes” feature takes it a step further by incorporating rotational capabilities, meaning the machine can rotate the workpiece during the cutting process. This ensures precise and efficient machining of complex geometries, such as 3D carvings or cylindrical objects, that would otherwise require multiple setups or specialized equipment.

Advantages of a 4-Head CNC Router with Rotary Functions

1. Increased Productivity

The most significant advantage of a 4-head CNC router with 4 rotary functions is its ability to process multiple parts at the same time. With four spindles, the machine can simultaneously work on several pieces, drastically cutting down production times and increasing throughput. Whether you’re cutting, engraving, or carving, this capability ensures that multiple tasks can be done in parallel, resulting in faster turnaround times.

2. Enhanced Precision

CNC routers are known for their ability to execute tasks with high levels of accuracy, and the 4-head, 4-rotary design only adds to this. The machine can precisely cut, drill, and carve wood with a level of detail that is difficult to achieve manually. The four rotary axes ensure that intricate, multi-dimensional designs can be executed smoothly, further improving the quality of your finished products.

3. Versatility in Applications

Whether you’re working with flat panels, intricate carvings, or cylindrical objects, this CNC machine can handle a wide variety of woodworking tasks. It excels in producing complex, detailed designs that would be time-consuming or impossible with traditional machines. Common applications include furniture production, cabinet making, wood signage, decorative pieces, moldings, and more.

4. Reduced Labor Costs

By automating various processes, the 4-head CNC router reduces the reliance on manual labor. Operators can focus on overseeing the machines rather than performing repetitive tasks. This not only saves on labor costs but also minimizes human errors, leading to a more efficient and error-free production process.

5. Ability to Work with a Variety of Materials

While primarily used for wood, a 4-head CNC router with 4 rotary axes can often handle a variety of materials, including MDF, acrylic, plastics, and even soft metals. This opens up new opportunities for businesses to diversify their product offerings and target different market segments.

Multi-Head 3D CNC Wood Carving Machine Features

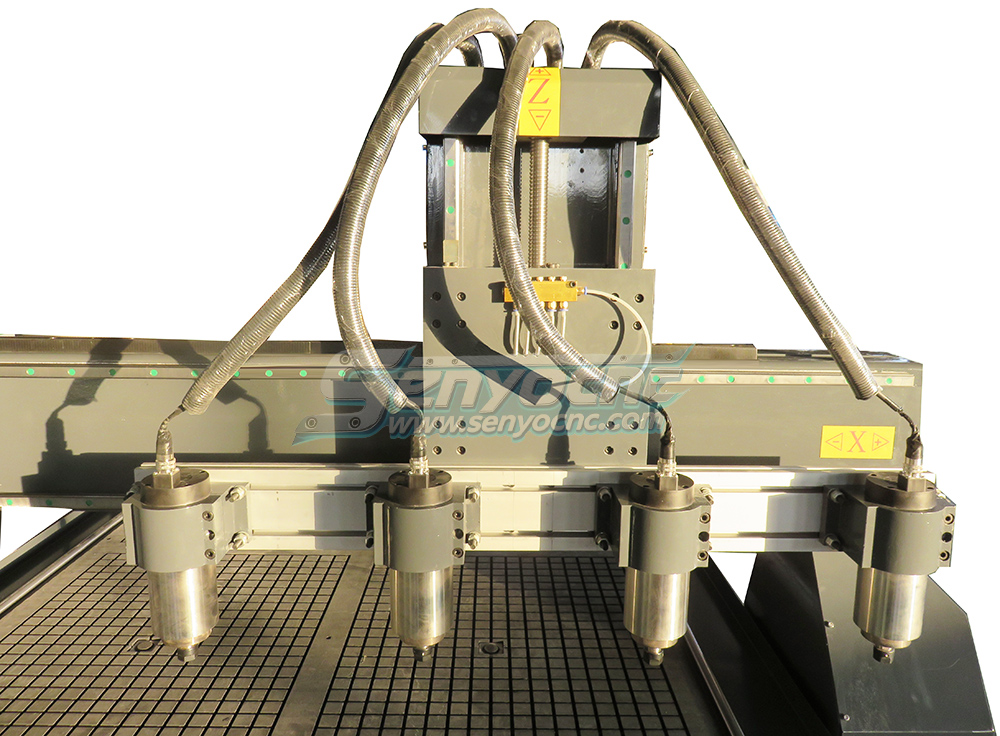

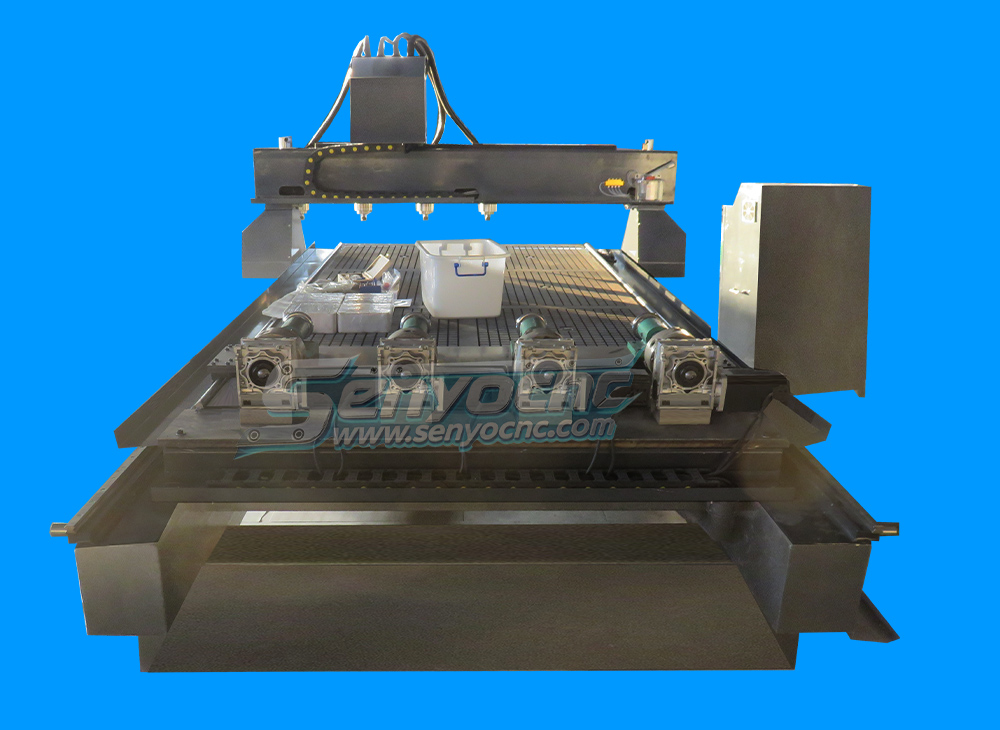

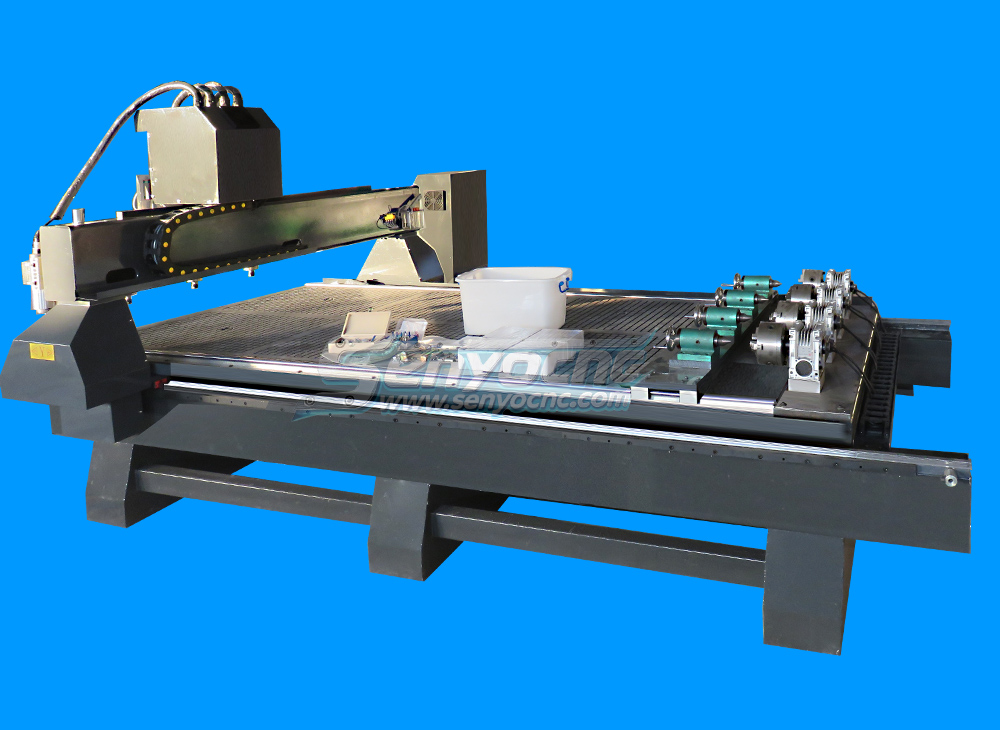

1. 4th axis CNC wood router with four rotary axes and four spindles, which can work at the same time or independently, and every one's max effective working area is 300mm (diameter) by 2500mm (length).

2. The whole machine is welded with seamless steel structure, the stability is excellent, not easy to be deformed.

3. It can not only do rotary engraving but also flat engraving. It can engrave several materials at one time, which greatly increasing the working efficiency.

4. Taiwan TBI dual screw-nut anti-gap ballcsrew with high accuracy and long life.

5. Equipped with high speed spindle motor, low noise and high performance division drive.

6. Adopted with advanced controlled system, with simple operating software, its easy to learn.

7. Powerful compatibility for most of software such as: Type3, Artcam, Proe, Wentai, CAD/CAM.

8. Humanized design, convenient for removing and installing

9. XYZ axis use anti-dust system, prevent dust during working, make sure the long life span of square parts.

10. 4th axis rotary CNC router with four heads has the function of re-carving after break point and power failure.

Multi-Spindle 3D 4 Axis CNC Wood Carving Machine Technical Parameters

| Model | SYM1525-4R |

| X,Y,Z Working Area | 1500x2500x200mm |

| X,Y,Z Reposition Accuracy | ±0.03mm |

| Frame | Welded Structure |

| Driving system | Helical Rack and Pinion Drive |

| Guide way | Taiwan Hiwin square rails |

| Max. Rapid Travel Rate | 33000mm/min |

| Max. Working Speed | 25000mm/min |

| Spindle Power | 3kw water-cooling spindle |

| Spindle Speed | 0-24000rpm |

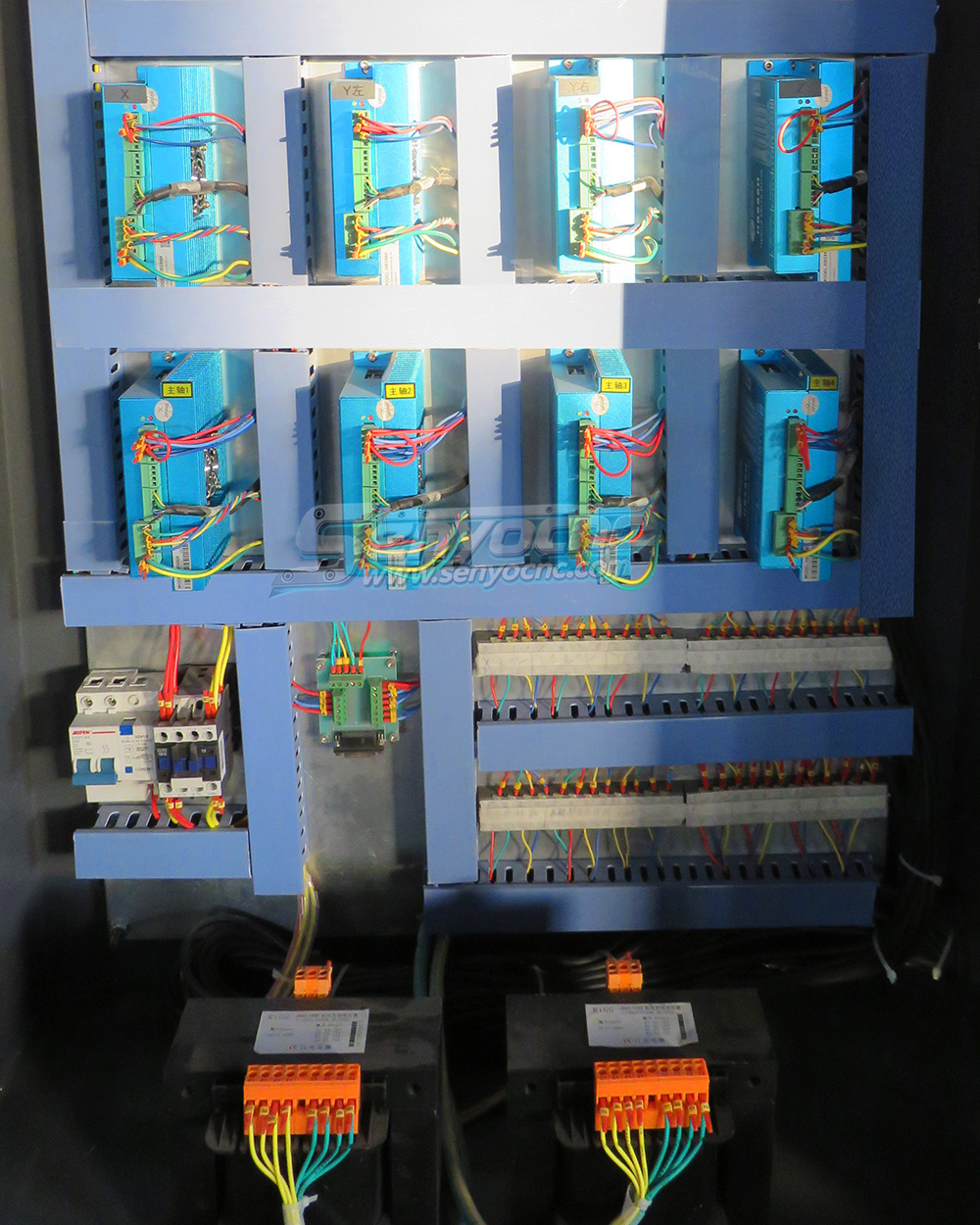

| Drive Motors | Stepper System |

| Working Voltage | 220V,single phase or 380V,3 phase |

| Command Language | G Code |

| Operating System | RichAuto DSP control system |

| Computer Interface | USB |

| Flash Memory | 128M(U Disk) |

| Collet | ER20 |

| Software Compatibility | Artcam Software and JDpaint software or other CAD software |

| N/G weight | 1000/1100kg |

| Package dimension | 3300*2150*1800mm |

Key Features to Look for in a 4-Head CNC Wood Router

1. High-Quality Spindles

Each spindle head should be robust and designed for high-performance cutting. Look for machines equipped with powerful, durable spindles that can handle continuous operation without compromising on quality.

2. Rotary Axis Configuration

The more advanced the rotary system, the more complex your designs can be. Ensure the machine supports multi-axis rotation and comes with a variety of rotational speeds and torque settings.

3. Advanced Software Compatibility

Modern CNC routers come with integrated software solutions that can read CAD and CAM files. This allows for easy conversion of your designs into machine-readable instructions. Look for machines that support popular software like AutoCAD, SolidWorks, or other industry-standard CAD programs.

4. Precision Control Systems

Precision control is crucial for achieving the finest details. Choose a router machine with advanced control systems, such as servo motors or stepper motors, that guarantee high accuracy and minimal deviation in the cutting process.

5. Multi-Function Tooling

Some 4-head CNC routers are designed to accommodate different types of cutting tools, allowing users to switch between engraving bits, drills, and saws. This adds to the versatility of the machine and ensures that it can be used for a wide variety of tasks without additional equipment.

Applications of 4-Head CNC Routers with Rotary Functions

1. Furniture Manufacturing

Custom furniture makers and large-scale manufacturers alike benefit from the speed and precision offered by the 4-head CNC router. With multiple spindles working simultaneously, you can create complex, detailed designs for tables, chairs, cabinets, and other pieces, all while maintaining consistent quality.

2. Cabinetry and Millwork

The ability to engrave, carve, and cut with high precision makes the 4-head CNC router an excellent choice for cabinetry and millwork. The machine can efficiently produce custom cabinetry, moldings, and intricate woodwork designs, reducing time spent on intricate handcrafting.

3. Wood Signage and Carving

If you’re in the business of creating custom wood signs, sculptures, or decorative carvings, the 4-head CNC router machine allows you to create detailed, high-quality pieces with ease. The rotary functions enable precise carvings on cylindrical or curved surfaces, perfect for producing unique signage and artwork.

4. Architectural Models

Architectural firms and designers often use CNC machines to create accurate, scaled models of buildings and landscapes. The multi-head and rotary capabilities enable the machine to quickly and precisely cut, carve, and model complex designs.

5. 3D and Artistic Carvings

For artists or businesses focusing on decorative wood carvings, a 4-head CNC machine opens up the possibility of creating intricate 3D designs with multiple textures. Whether you’re working on sculptures, artistic signs, or furniture with elaborate carvings, this machine can help you achieve the desired results.

Working Samples Project

Conclusion

Investing in a 4-head CNC wood router machine with 4 rotary functions can revolutionize your woodworking operations, making them faster, more efficient, and more precise. With enhanced productivity, versatility, and the ability to execute complex designs, this machine is a must-have for any woodworking business looking to stay competitive in today’s fast-paced market. Whether you are working in furniture manufacturing, signage, or custom carpentry, a 4-head CNC router with 4 rotary axes will significantly improve your workflow, reduce labor costs, and allow you to tackle more ambitious projects.

Package & Shipping

Firstly, packed the cnc router machine with stretch film for clearing and damp proofing.

Secondly, put the cnc router machine in plywood case for safety and clashing.

Thirdly, transport the plywood case into container.

Service & Support

1. Our engineers available to service machinery overseas.

2. 2 years guarantee for the whole machine.

3. Technical support by calling, mail, whatsapp and skype. If you have any problems, we will help you to solve it within 12 hours.

4. You will be get free training advice towards our machine in our factory.

5. If you need any component of the machine, we will provide most affordable price for you.

6. Friendly English version manual and operation video CD disk.

1. 4-head CNC wood router machine

2. CNC wood router with 4 spindles

3. 4 rotary CNC wood router

4. CNC router machine with rotary axes

5. 4-axis rotary CNC wood router

6. Woodworking CNC router with 4 heads

7. CNC router for wood with rotary functions

8. Multi-head CNC wood router machine

9. 4-head CNC router for furniture making

10. CNC wood router with 4-axis rotation

11. CNC router with rotary axis for wood

12. Wood carving CNC router with 4 heads

13. Advanced CNC wood router with rotary functions

14. 4-head rotary CNC router for woodworking

15. CNC router machine for custom wood designs

16. High-precision CNC wood router with 4 spindles

17. CNC machine for multi-dimensional wood cutting

18. 4-axis CNC wood router for 3D carving

19. CNC router with multiple rotary axes for wood

20. CNC rotary wood router for custom designs

• Previous: 2025 Best 2Heads CNC Router Lathe Machine with 4th Rotary Axis

• Next: None

Fiber metal Laser Sensor And Its Application

Category: SENYO NEWS 11th Mar, 2021A CNC wood router will use 3D machining in relief carving, the effect is more artistic beauty, but also has a strong sense of three-dimensional 3D, realization of this function is to ...

Precision Cutting Stents with Fiber Lasers

A CNC wood router will use 3D machining in relief carving, the effect is more artistic beauty, but also has a strong sense of three-dimensional 3D, realization of this function is to ...

How to Laser Cut Copper and Other Reflective Metals

Laser cutting of mild steel and stainless steel has a long history and has been one of the primary applications for CO2lasers. However CO2lasers have not traditionally offered a good solution for cutting highly reflective materials.Fiber lasers have an emission wavelength of around

Laser Cutting Machine Inspection Process For Manufacture

SENYOCNC Have Strict quality monitoring will be carried out when the parts are in the factory.

How Control Costs Use of UV Printers ?

UV flatbed printers are rapidly being used by more and more manufacturers, thanks to its efficient production efficiency, and the control of production costs also needs to arouse our attention.

Why UV flat printing machine is popular in market ?

For the majority of designers, give full play to the creative ability, the design sample can be arbitrarily modified on the computer, the effect on the computer, is the effect after the finished product, customer satisfaction can be directly produced. UV flat printing pattern fine, rich and clear layers, high artistry, strong three-dimensional sense, many high precision equipment can also print photography and painting style patterns.

How does UV ink jet printer save UV ink?

UV inkjet printer use process is an important consumable UV ink, reasonable use of equipment, can save UV ink , it can be said to be the best choice to directly save the cost. In the process of using some skills you need to be familiar with, the following small make up to share with you:1. Try to us

Waterjet Machine delivery and Shipping

Please tell us your max working size and what materials will cutting , also what max cutting thickeness.If you have Working photo sample please also send us , it will be helpful to choose machine with suitable models .

Waterjet Machine finish manufacture 5axis

Waterjet cutting technology is one of the fastest growing major machine tool processes in the world due to its versatility and ease of operation.

Waterjet Machine delivery and Shipping

Waterjet cutting technology is one of the fastest growing major machine tool processes in the world due to its versatility and ease of operation.There are multiple advantages to adding waterjet cutting capabilities to your shop.We are company leading ultrahigh-pressure waterjet system so

How to Create Connected Text – Inkscape for Laser Cutting

Step 1: Create Some TextFirst, we need some text to work with. To create the text, select the Text Tool (keyboard shortcut: T), click somewhere on the canvas, and type your text.You can use the drop-down list on the top left to select your desired font.Step 2: Convert Text to PathNext, we need to tu

Jacob from United States

I am a beginner at CNC, I’ve never used a CNC machine before and with in a day I was carving. An awesome machine for a beginner to learn as hobbyists. I used the manual and the help video. One hour to assemble and test, very friendly and easy to use. It’s a good buy for the money. I would definitely recommend this machine to someone getting into CNCs.

Weinstein from France

I've been using CNC plasma SYP2060-300A and I am very impressed with this unit.

This unit is of higher quality, made in China. Five stars all the way!

2040 from INDIAN

Best 2040 CNC Router Good Price and Quality ! Thank SENYOQC

10w uv laser from American

Best supplier ! I bought 3 machines for laser and router , thank you Aillen ! --Alec

12KW Fiber Cutting - 2000X6000mm -- 이병헌 from Korea

Good machine for metal cut ! Thanks Senyo , Its prefect , I like your business patient kind!

I am a furniture manufacturer, and this machine is very good and fast. thanks Senyoqc Team ! from Bangladesh

Metal ArtWork from Denmark

The plasma cutting machine makes my artistic creation more convenient and precise!! Created more artistic ideas and value! Thank you Aillen team!

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen. from

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen.

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo from

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo

Thank you Senyo for SYJ1290-150W! from

Retired, ex mainframe systems programmer. Now full-time recreational woodworker majoring in puzzles, pens, boxes, Toys and occasional small furniture. Thank you Senyo for SYJ1290-150W!

manager@senyocnc.com

manager@senyocnc.com

SENYOCNC

SENYOCNC

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

2061579344

2061579344