Advantage

1. Drilling: Adopts different diameter drills to drill different sizes hole on various boards.

2. Grooving: With suitable tools to do grooving or slotting, it also can finish Clamex joint slots for Lamello.

3. Cutting: Suitable for the regular shapes and irregular shapes cutting, also can do edging.

4. Milling: Adopts different shapes CNC milling tools to achieve beautiful designs.

5. Hollow-cutting: Solve production of the carved screens, separating boards, or other products that need to be hollowed cut.

6. Carving/engraving: 2D carving design on wooden, composite, or other soft raw materials.

Paramaters

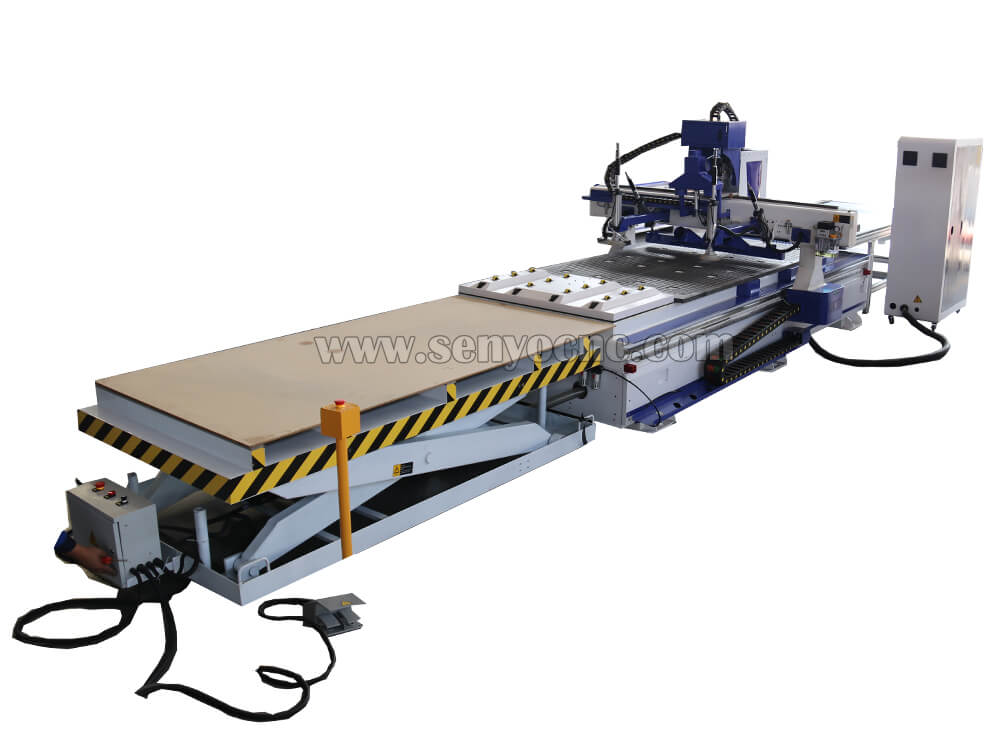

Model | SYM1530-U1ATC with loading and unloading platform |

X,Y axis travel | 1300*2500mm;1500*3000mm,2100x3000mm,option: etc |

Z axis travel | 200mm,option:300mm,etc |

Spindle type | 9.6kw HQDATC air cooling spindle, ER32 |

Inverter type | Fuling inverter |

Tool magazine | Lineartype auto tool changer Option: Carouseltype auto tool changer |

Tool holder with collet | ISO30, ER32 collet: φ4, φ6, 1/8, 1/2 |

Control system | LNC/SYNTEC |

Driving system | 850w YASKAWA servo motors and drivers Option: 1kw Taiwan Syntec servo,1kw Japan YASKAWA servo |

Reducer | Japan Shimpo reducer |

Machine structure | Heavy duty body with quenching treatment |

Work table | Aluminum T-slot & vacuum work table |

Linear guide | Taiwan Hiwin Linear guide with dust proof |

Transmission | X,Y axis: Taiwan /Germany Helical Rack and Pinion Z axis:Taiwan TBI high precision ball screw |

Lubrication system | 1.5L automatic lubrication system |

Tool calibration | Automatictool sensor calibration |

Cables | Import cables |

Compatible software | Artcam, Hisoon, etc |

Command language | G Code&M Code |

Traveling speed | 80m/min |

Working speed | 0-25m/min |

Re-positioning accuracy | ±0.03mm |

Working accuracy | ±0.03mm |

Working voltage | 220V 1PH/3PH 50HZ/60HZ 380V 3PH 50HZ/ 60HZ |

System resolution | ±0.0025mm |

Working air pressure | 0.6MPa |

Parts Detials

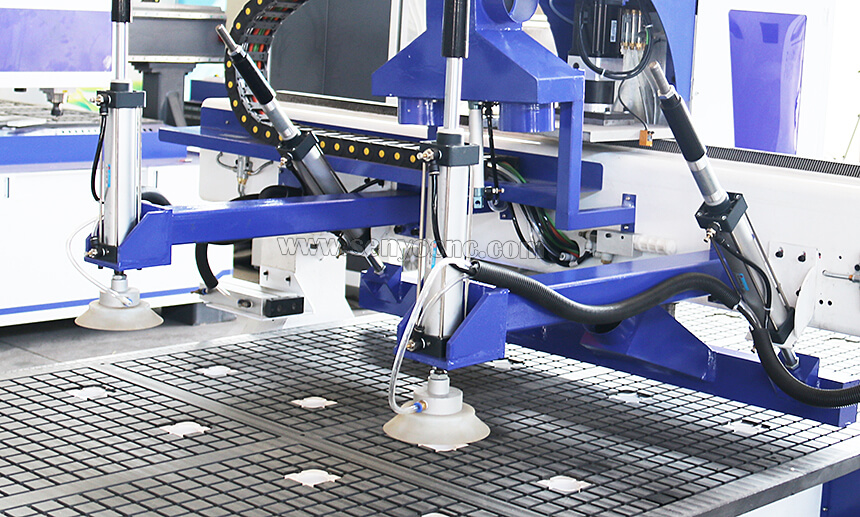

Back & Side Pusher: Adjust the panel to the right position before processing it

The suction cup load system is installed on the gantry, it can automatic go to hydraulic platform to grab the board

then drive it to the working table.

Automatic oil-lubrication system

It could oil the rail automatically ,one touch can finish periodic maintenance easily .

Automatic loading auxiliary device

When the suction cup load a sheet, the auxiliary device will help to reduce resistance and more easier to travel.

The automatic loading system is consist of a lifting platform which support and raise the stack of material to height same

CNC router machine's vacuum bed, which is monitored with optical sensor.

When one piece of material is taken to process, then the Hydraulic Platform will go up

when it arrival to the senor, it will automatic stop and wait the Suction Cup Load System to come.

Vacuum table+T-solt table

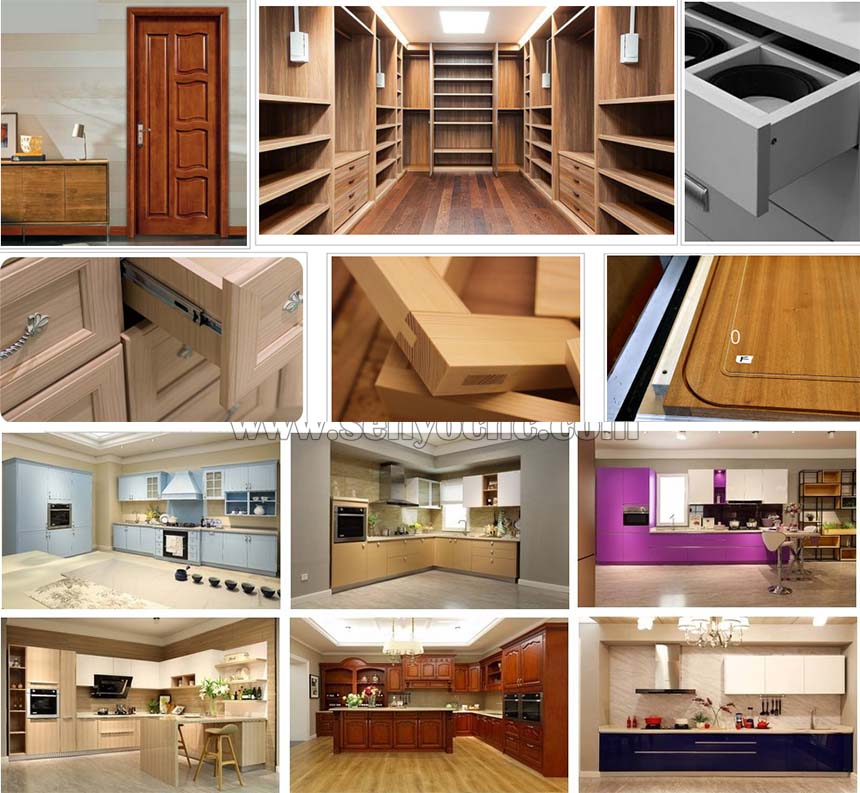

Application

1) Furniture industries: cabinet doors, wooden doors, solid woods, plates, antique furniture, doors, windows, desks and chairs.

2) Decoration industries: screens, wave boards, large-size wall hangings, advertising boards and sign making.

3) Arts & Crafts industries: Engrave on artificial stones, woods, bamboos, marbles, organic boards

double-color boards and so on for achieveing effects of exquisite patterns and characters.

4) Processing material: engraving, milling and cutting processing for acrylic, PVC, density boards, artificial stones

organic glass, plastics and soft metal sheets such as copper and aluminum

Calibration process: Technician will make X/Y axis perpendicularity adjustment

Z/X axis Spindle alignment adjustment, Z/Y axis Spindle alignment adjustment.

Acceptance process: CNC Router machine need more than 10h testing in our factory.

We will make test video with yourself cnc rourter machine according your request

then send the video and sample for you check. Of course, welcom to our factory if you want come to our factory for inspection.

Finished production: After cnc router is finished, our technicians will thoroughly inspect the machine

to ensure your cnc router machine matches the production order (We have talked.)

Product packing: We will arrange machine packing after confirmed with our customer

All machine parts will packaged into one plywood box together with cnc router

Our shipping department will check the production order and make sure there are no missing parts

Delivery process: Transport master has extensive experience in unloading, fixing, transporting machines

We will always pay attention to whether the goods arrive in Hong Kong, whether or not we arrive at the destination.

Packaging & Shipping

Three layers

The innermost layer is EPE pearl cotton film package;

The middle layer is wrapping up with environmental protection material ;

And the outermost layer is winding up with PE stretch film.

Wooden box, we will make a wooden box outside the machine

International Shipping Around the World

All the CNC routers can be shipped worldwide by sea, by air or by international express logistics via DHL, FEDEX, UPS.

You are welcome to get a free quotation by filling up the form with name, email, detailed address, product and requirements.

We will shortly contact you with the full information including the most suitable delivery method (fast, secure, discreet) and freight.

ATC CNC Router, Door Furniture Line Making Machine, Automatic Loading Unloading Atc Cnc Router, Nesting cnc router with drilling labelling center, ATC CNC Router

• Previous: Nesting CNC router ATC tool changer with drilling wood machine designed for cabinet door making

• Next: Nesting CNC Wood Cutting Machine for Custom Furniture Maker

Fiber metal Laser Sensor And Its Application

Category: SENYO NEWS 11th Mar, 2021A CNC wood router will use 3D machining in relief carving, the effect is more artistic beauty, but also has a strong sense of three-dimensional 3D, realization of this function is to ...

Precision Cutting Stents with Fiber Lasers

A CNC wood router will use 3D machining in relief carving, the effect is more artistic beauty, but also has a strong sense of three-dimensional 3D, realization of this function is to ...

How to Laser Cut Copper and Other Reflective Metals

Laser cutting of mild steel and stainless steel has a long history and has been one of the primary applications for CO2lasers. However CO2lasers have not traditionally offered a good solution for cutting highly reflective materials.Fiber lasers have an emission wavelength of around

Laser Cutting Machine Inspection Process For Manufacture

SENYOCNC Have Strict quality monitoring will be carried out when the parts are in the factory.

How Control Costs Use of UV Printers ?

UV flatbed printers are rapidly being used by more and more manufacturers, thanks to its efficient production efficiency, and the control of production costs also needs to arouse our attention.

Why UV flat printing machine is popular in market ?

For the majority of designers, give full play to the creative ability, the design sample can be arbitrarily modified on the computer, the effect on the computer, is the effect after the finished product, customer satisfaction can be directly produced. UV flat printing pattern fine, rich and clear layers, high artistry, strong three-dimensional sense, many high precision equipment can also print photography and painting style patterns.

How does UV ink jet printer save UV ink?

UV inkjet printer use process is an important consumable UV ink, reasonable use of equipment, can save UV ink , it can be said to be the best choice to directly save the cost. In the process of using some skills you need to be familiar with, the following small make up to share with you:1. Try to us

Waterjet Machine delivery and Shipping

Please tell us your max working size and what materials will cutting , also what max cutting thickeness.If you have Working photo sample please also send us , it will be helpful to choose machine with suitable models .

Waterjet Machine finish manufacture 5axis

Waterjet cutting technology is one of the fastest growing major machine tool processes in the world due to its versatility and ease of operation.

Waterjet Machine delivery and Shipping

Waterjet cutting technology is one of the fastest growing major machine tool processes in the world due to its versatility and ease of operation.There are multiple advantages to adding waterjet cutting capabilities to your shop.We are company leading ultrahigh-pressure waterjet system so

How to Create Connected Text – Inkscape for Laser Cutting

Step 1: Create Some TextFirst, we need some text to work with. To create the text, select the Text Tool (keyboard shortcut: T), click somewhere on the canvas, and type your text.You can use the drop-down list on the top left to select your desired font.Step 2: Convert Text to PathNext, we need to tu

Jacob from United States

I am a beginner at CNC, I’ve never used a CNC machine before and with in a day I was carving. An awesome machine for a beginner to learn as hobbyists. I used the manual and the help video. One hour to assemble and test, very friendly and easy to use. It’s a good buy for the money. I would definitely recommend this machine to someone getting into CNCs.

Weinstein from France

I've been using CNC plasma SYP2060-300A and I am very impressed with this unit.

This unit is of higher quality, made in China. Five stars all the way!

2040 from INDIAN

Best 2040 CNC Router Good Price and Quality ! Thank SENYOQC

10w uv laser from American

Best supplier ! I bought 3 machines for laser and router , thank you Aillen ! --Alec

12KW Fiber Cutting - 2000X6000mm -- 이병헌 from Korea

Good machine for metal cut ! Thanks Senyo , Its prefect , I like your business patient kind!

I am a furniture manufacturer, and this machine is very good and fast. thanks Senyoqc Team ! from Bangladesh

Metal ArtWork from Denmark

The plasma cutting machine makes my artistic creation more convenient and precise!! Created more artistic ideas and value! Thank you Aillen team!

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen. from

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen.

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo from

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo

Thank you Senyo for SYJ1290-150W! from

Retired, ex mainframe systems programmer. Now full-time recreational woodworker majoring in puzzles, pens, boxes, Toys and occasional small furniture. Thank you Senyo for SYJ1290-150W!

/5 based on 200votes/5 based on votes

/5 based on 200votes/5 based on votes

manager@senyocnc.com

manager@senyocnc.com

SENYOCNC

SENYOCNC

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

2061579344

2061579344