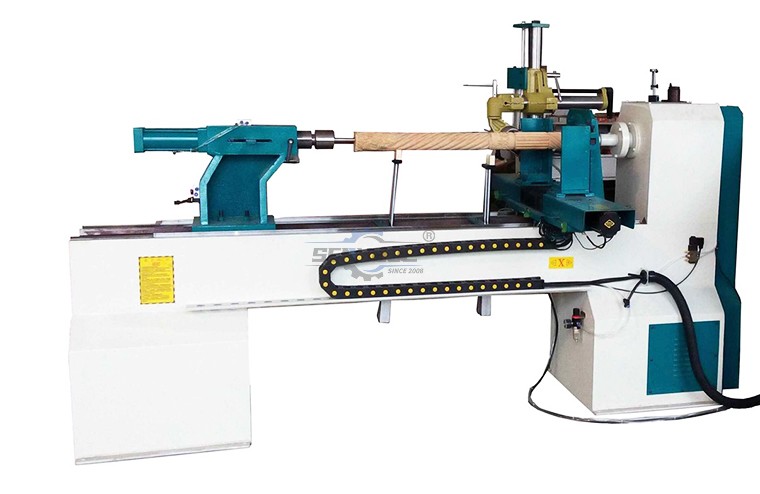

How to Operation a CNC Wood Turning Lathe Machine ?

From: 本站 Date: 01st September 2021 Author: shengangtong Views: 1486

Where to Locate Your CNC Wood L athe Machine?

Before you unpack your machine, select the area where you will use your lathe machine. There are no hard-and-

fast rules for its location, but below are a few guidelines.

1. There should be an area around the machine suitable for the length of wood that you will be machining.

2. Adequate lighting. The better the lighting, the more accurate and safely you will be able to work

3. Solid floor. You should select a solid flat floor, preferably concrete or something similar.

4. Close to power source and dust collection.

Safety Operation for CNC Wood Lathe Machine

As with all machinery, there are certain hazards involved with the operation and use. Using it with caution will

considerably lessen the possibility of personal injury. However, if normal safety precautions are overlooked or

ignored, personal injury to the operator may result. If you have any questions relative to the installation and

operation, do not use the equipment until you have contacted your supplying distributor.

Read carefully before operating the wood CNC lathe machine.

1. Keep the working area clean and be sure adequate lighting is available.

2. Do not wear loose clothing, gloves, bracelets, necklaces or ornaments. Wear face, eye, respiratory and body

protection devices as indicated for the operation or environment.

3. Be sure that the power is disconnected from the machine before tools are serviced or an attachment is to be ftted

or removed.

4. Never leave the machine with the power on.

5. Do not use dull, gummy or cracked cutting tools.

6. Be sure that the keys and adjusting wrenches have been removed and all the nuts and bolts are secured.

How to Maintenance a CNC Wood Lathe Machine?

As with CNC woodworking lathe machine, to ensure optimal performance you must conduct regular maintenance.

Daily Maintenance Operation

1. Clean the machine and lubricate unpainted surfaces with a wax. Wipe off any excess and buff with a dry polishing

cloth. This will reduce the likelihood of rust forming.

2. Check cutter teeth for chips and dullness.

3. Generally inspect the machine for damage and loose or worn parts.

4. Collets and spindle collet hole must be cleaned regularly. Ensure that the slots in the collets are free of sawdust,

as sawdust builds up and will stop the collet compressing. If the collet or spindle hole is not clean, the router bit may

not run true, and this will affect the performance of your machine.

Weekly Maintenance Operation

1. Clean the cutters.

2. Check cutter teeth for chips and dullness.

3. Generally inspect the machine for damage and loose or worn parts.

4. Check the dust extraction for blockages and any large bits that could cause blockages.

• Previous: Panel Durnityre Production Sloution from SENYOQC

Jacob from United States

I am a beginner at CNC, I’ve never used a CNC machine before and with in a day I was carving. An awesome machine for a beginner to learn as hobbyists. I used the manual and the help video. One hour to assemble and test, very friendly and easy to use. It’s a good buy for the money. I would definitely recommend this machine to someone getting into CNCs.

Weinstein from France

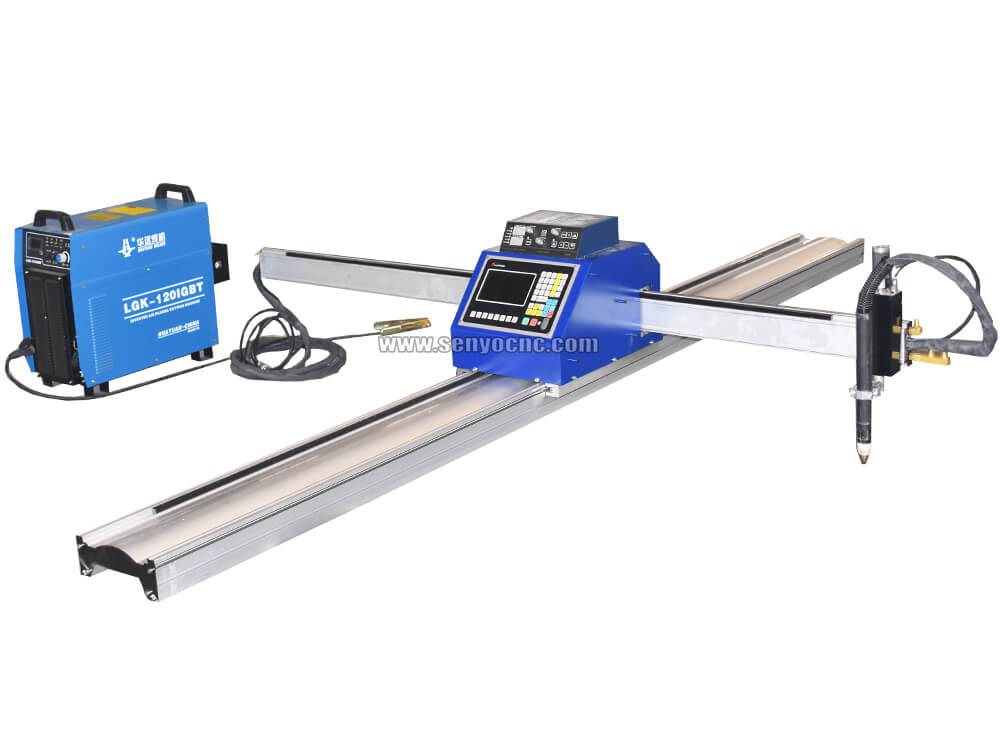

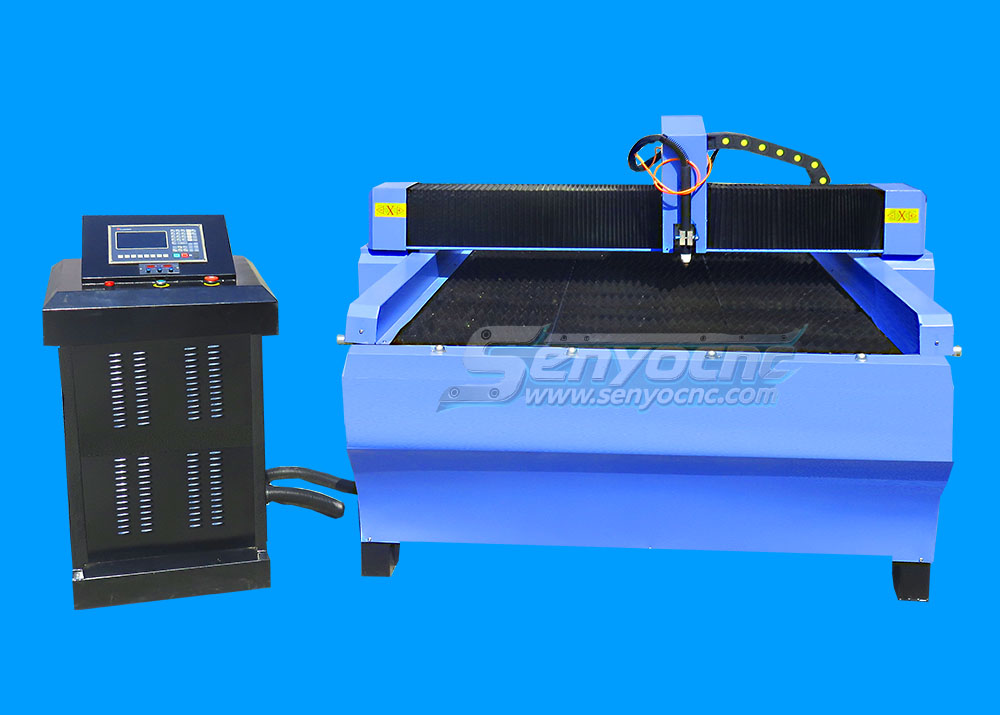

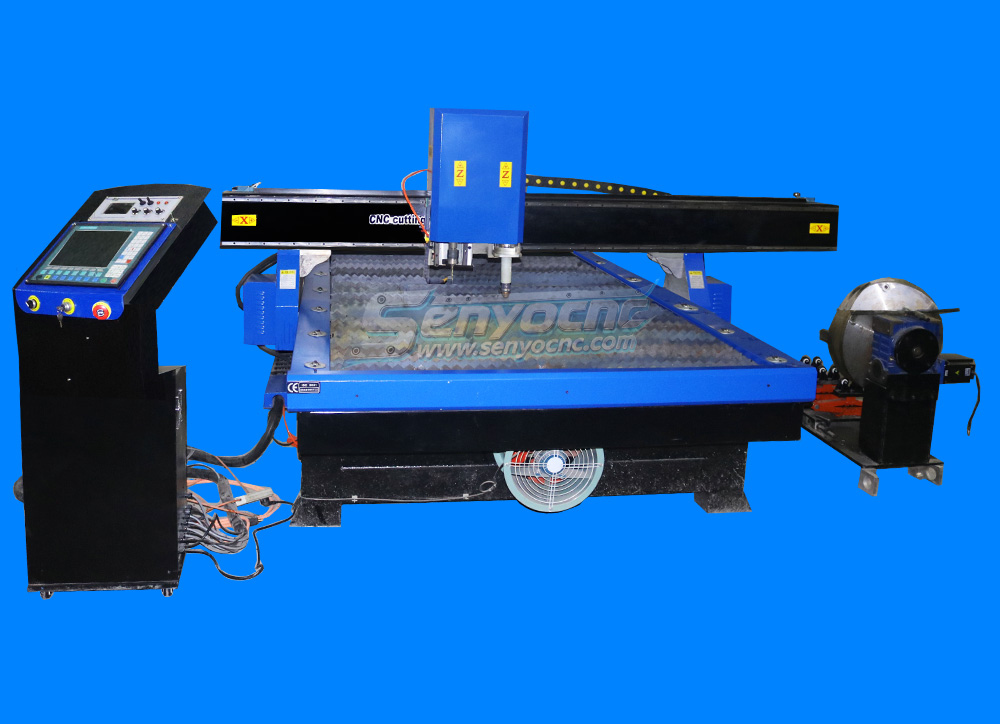

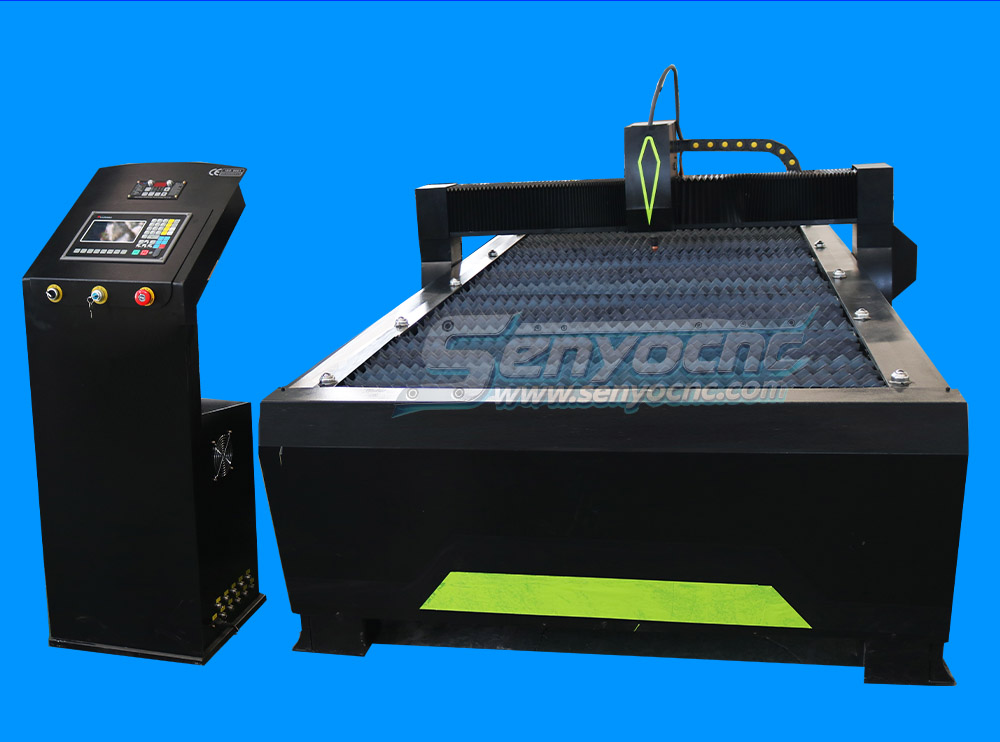

I've been using CNC plasma SYP2060-300A and I am very impressed with this unit.

This unit is of higher quality, made in China. Five stars all the way!

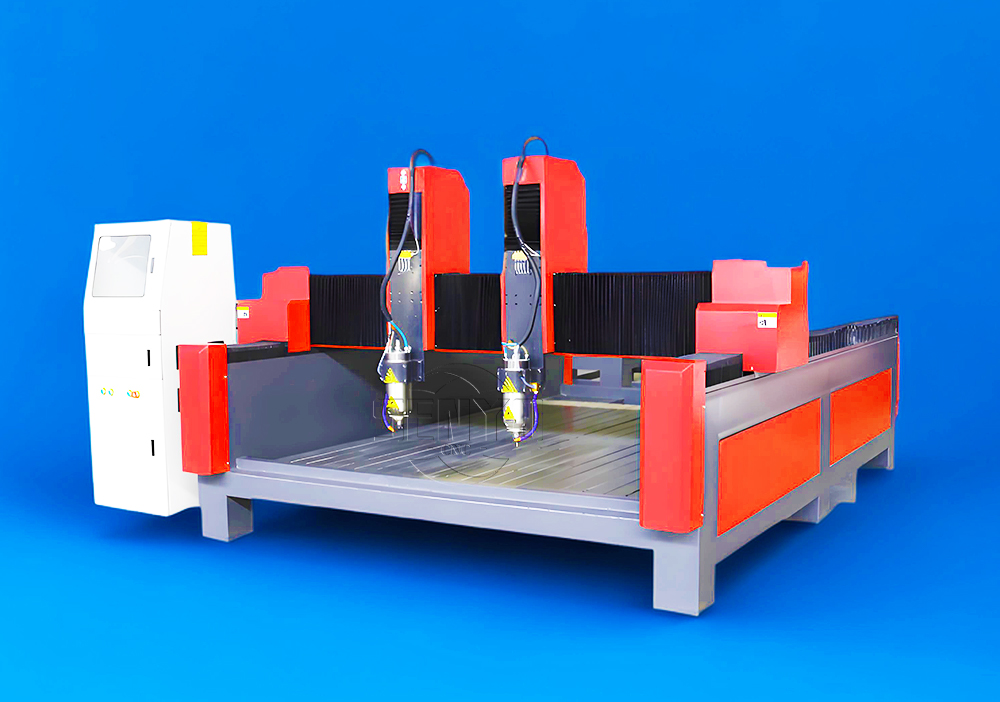

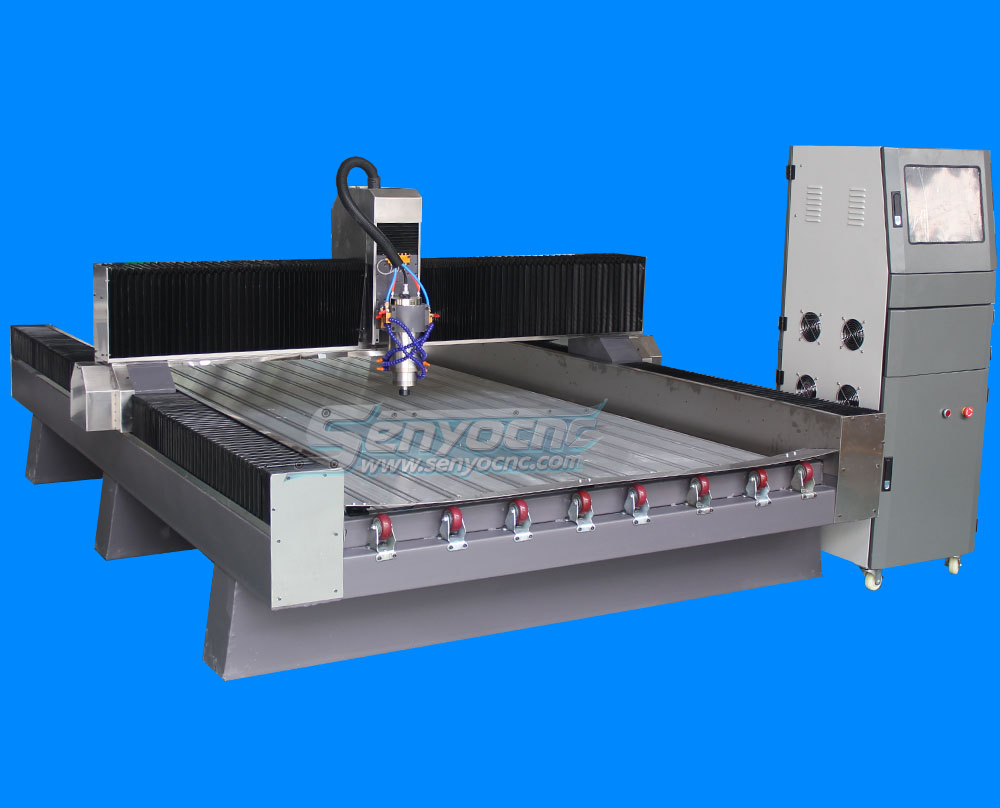

2040 from INDIAN

Best 2040 CNC Router Good Price and Quality ! Thank SENYOQC

10w uv laser from American

Best supplier ! I bought 3 machines for laser and router , thank you Aillen ! --Alec

12KW Fiber Cutting - 2000X6000mm -- 이병헌 from Korea

Good machine for metal cut ! Thanks Senyo , Its prefect , I like your business patient kind!

I am a furniture manufacturer, and this machine is very good and fast. thanks Senyoqc Team ! from Bangladesh

Metal ArtWork from Denmark

The plasma cutting machine makes my artistic creation more convenient and precise!! Created more artistic ideas and value! Thank you Aillen team!

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen. from

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen.

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo from

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo

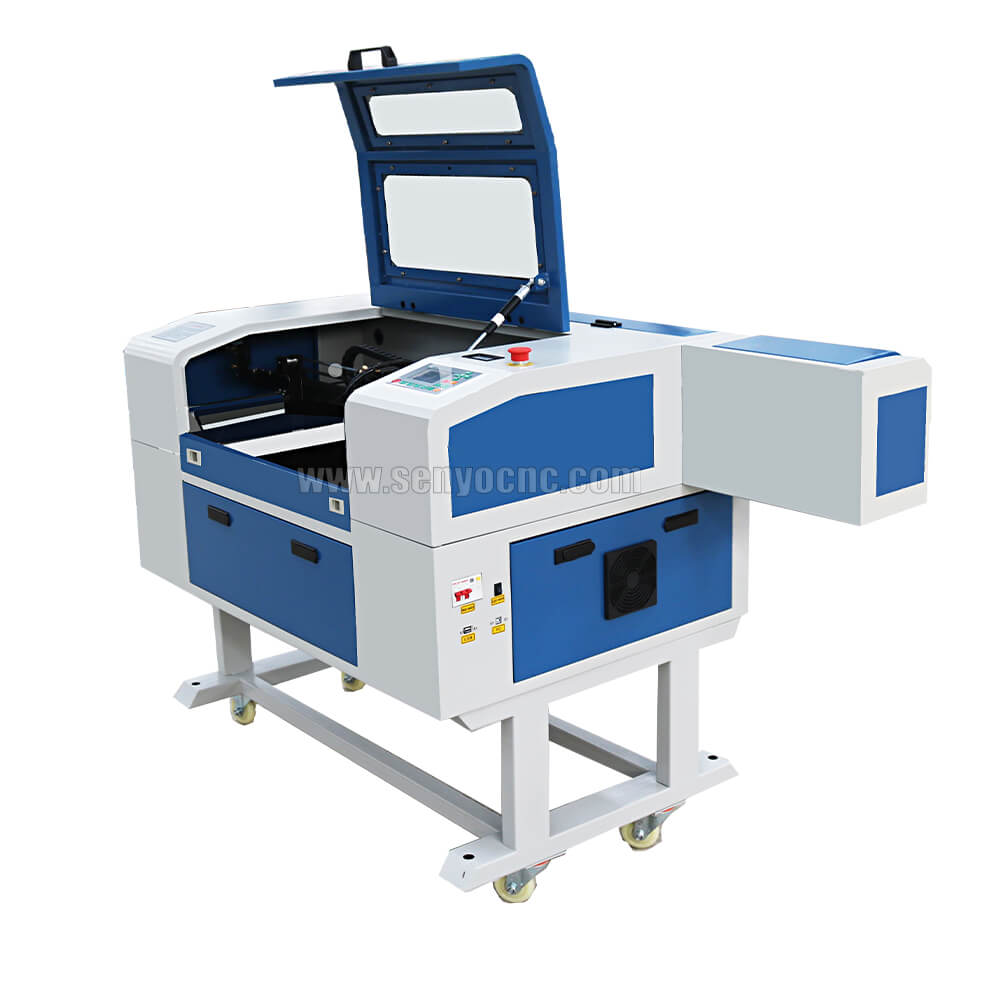

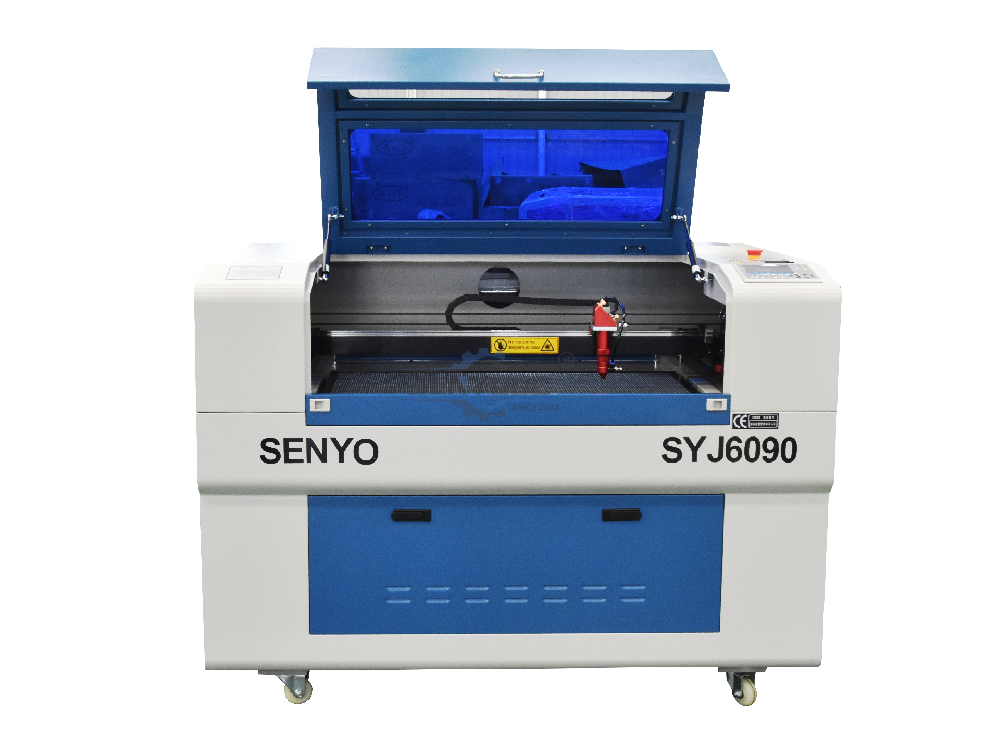

Thank you Senyo for SYJ1290-150W! from

Retired, ex mainframe systems programmer. Now full-time recreational woodworker majoring in puzzles, pens, boxes, Toys and occasional small furniture. Thank you Senyo for SYJ1290-150W!

manager@senyocnc.com

manager@senyocnc.com

SENYOCNC

SENYOCNC

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

2061579344

2061579344