How to inspect the quality of a laser cutting machine ?

From: 本站 Date: 31st August 2021 Author: shengangtong Views: 1126

1.Roughness

Laser cutting cross section will form a vertical lines, the depth of the texture of the cut surface of the roughness of the cut surface,

the more shallow lines, the more smooth cut section. Roughness not only affects the appearance of the edges, but also affect the

friction characteristics, in most cases, it is necessary to minimize the roughness, so the more shallow texture, the higher the quality

of the cut.

2. Verticality

If the sheet thickness exceeds 10mm, the verticality of cutting edge is very important. Away from the focus, the laser beam

becomes divergent, according to the location of the focus, cutting to the top or bottom of the variable width. Cutting edge off the

vertical line of a few millimeters, the edge of the more vertical, the higher the quality of cutting.

3. Cutting width

Kerf width generally does not affect the cutting qualit, only in the internal components formed special precision contour, cutting

width is important. This is because the cutting width determines the contour of the minimum, when the plate thickness increases,

the cutting width also increases. So want to guarantee the same high precision, no matter how much the width of the cut, the

workpiece in the laser cutting machine processing area should be constant.

4. Lines

High speed cutting thick plate, the molten metal will not appear in the vertical laser beam below the incision, but will be sprayed out

at the laser beam side. As a result, the curved lines are formed on the cutting edge, and the lines are closely followed by the laser

beam. In order to correct the problem, the feed rate can be reduced at the end of the cutting process.

5. Burr

Burr formation is a very important factor to determine the quality of laser cutting, because the removal of burr need extra work, so

the amount of burr is serious and how much is able to directly determine the quality of cutting.

6. Material Deposition

Laser atinr mactine oeore he ognin ot mlino and peraonoro he wrpece sutce wh。ayer olonon he stacora

special iqud Gsiaion and al kndns omlaease,s the mateial does not neto use the wind o blow he cut, but the upwardor

downward discharge also can form the depsition on the surface.

7. Sag and Corrosion

Sag and corrosion have adverse effects on the surface of the cutting edge, affecting the appearance. They appear in the error of the

cut which is generally supposed to be avoided.

8. Heat Affected Zone

In the laser cutting,the area in the near the notch is heated, At same time, the structure of the metal changes ,For example ,some of the

metal can be hardened , the heat affected zone refer to the depth of the area that is changed by the internal structure.

9.Deformation

If the cutting makes the component heat , it will deform . This is particularly important in fine processing ,

because the profile and connection pieces are usually only a few millmeters wide . Control of laser power

and use of short laser pulses can reduce the parts become hot to avoid deormation.

• Previous: What is CNC ?

• Next: How to solve type data error limit exceeded for a laser cutting machine?

- The Risks Associated With Laser Welding And How To Mitigate Them

- How To Decide If Laser Welding Is The Right Choice For Your Business?

- The Benefits Of Laser Welding For Businesses

- What Is Laser Welding And How Does It Work?

- Which configuration should I choose for my welding machine?

- Laser Welding Machine What parameters should be checked?

- How to choose the laser beam source?

- Laser welding machine Pulsed or continuous laser?

- Why choose a laser welding machine?

- Choosing the right laser welding machine

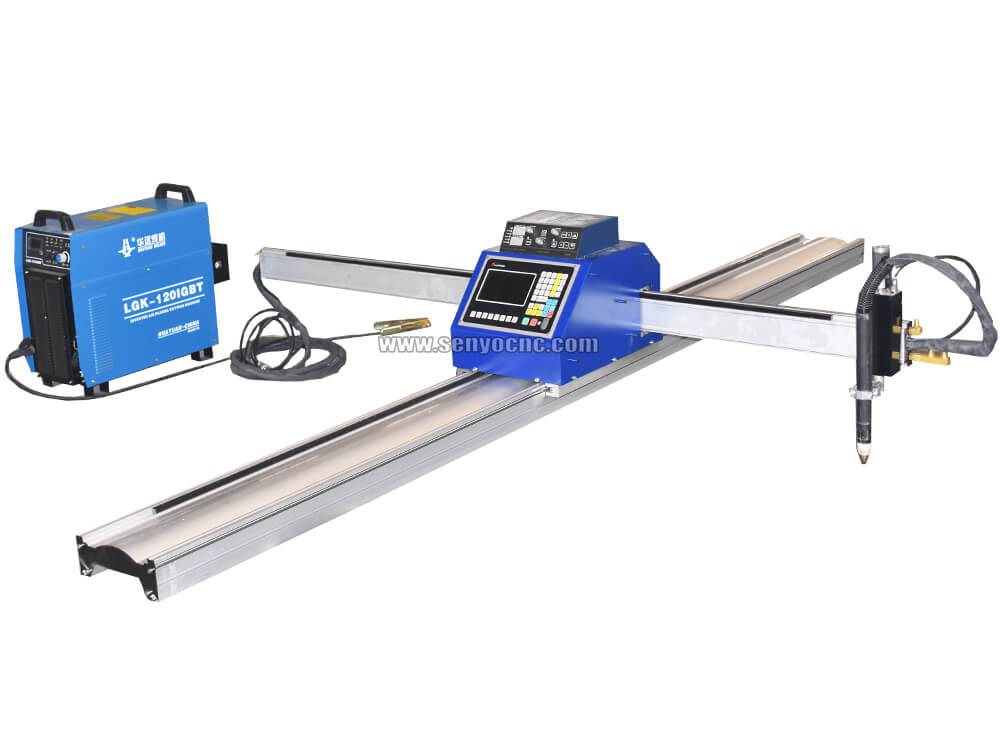

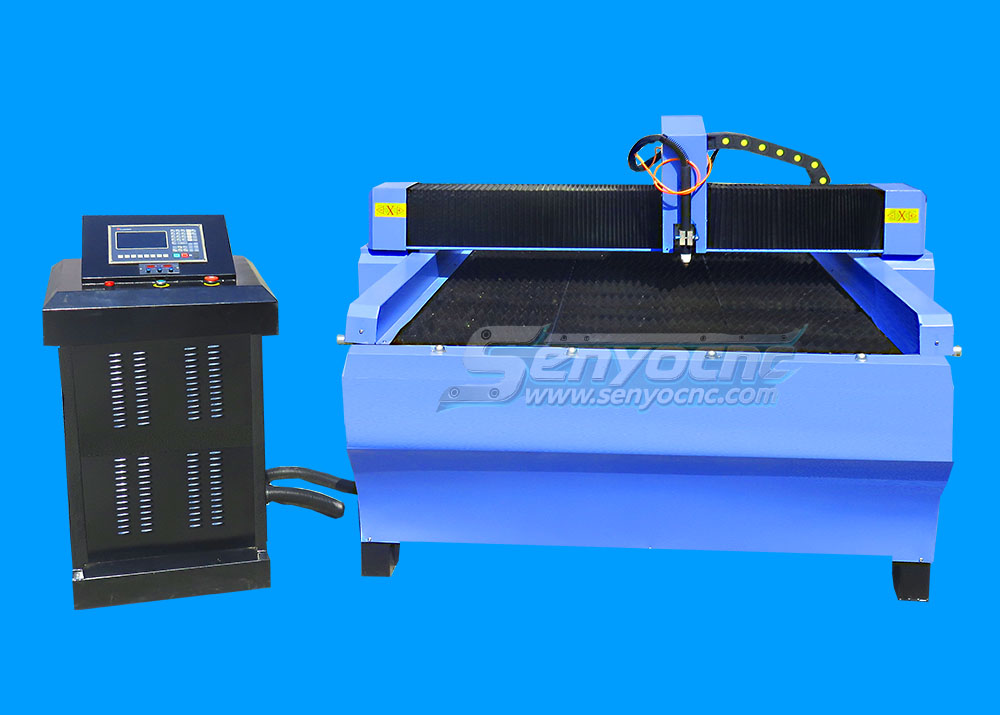

- What Are The Advantages Of CNC Plasma Cutters?

- What are CNC plasma Cutters Used For? What materials can CNC plasma Cutters cut?

Jacob from United States

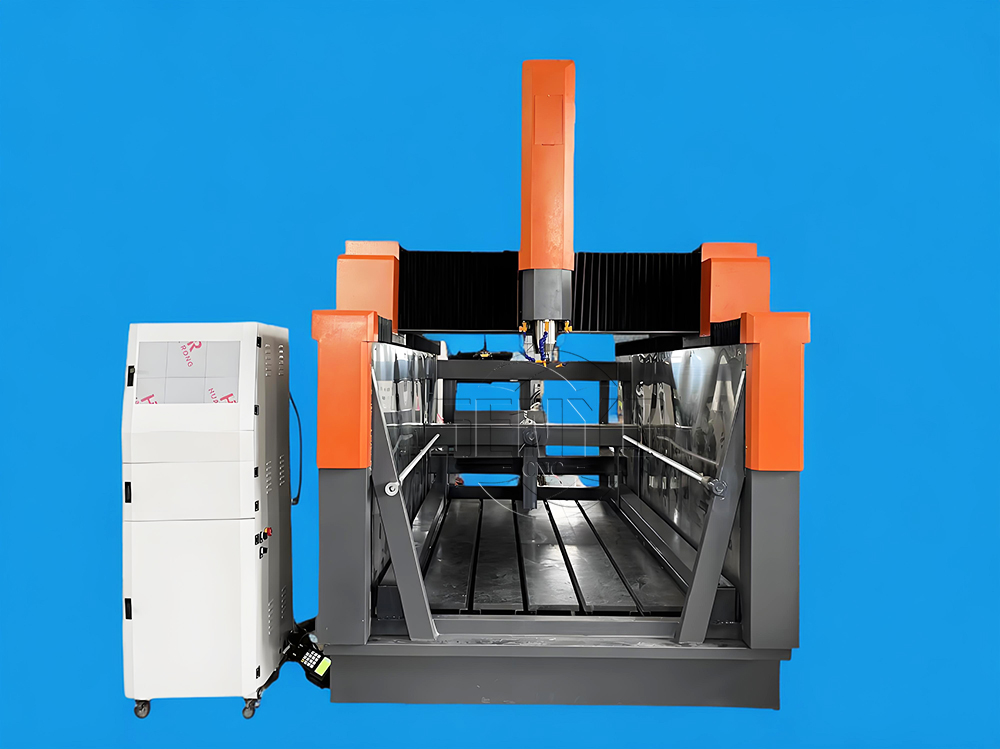

I am a beginner at CNC, I’ve never used a CNC machine before and with in a day I was carving. An awesome machine for a beginner to learn as hobbyists. I used the manual and the help video. One hour to assemble and test, very friendly and easy to use. It’s a good buy for the money. I would definitely recommend this machine to someone getting into CNCs.

Weinstein from France

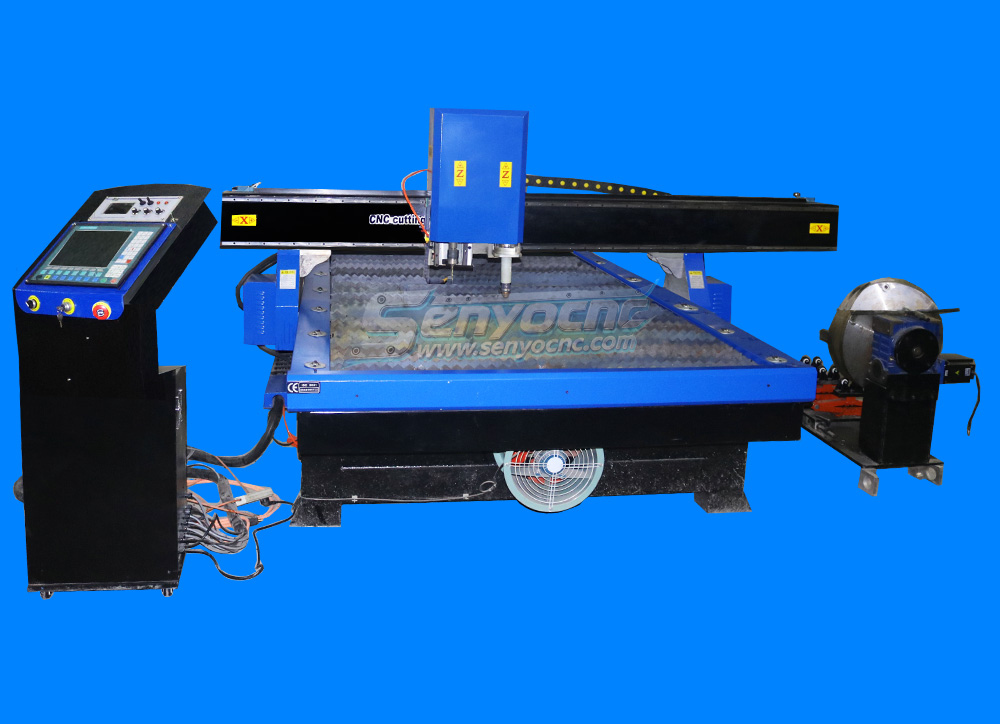

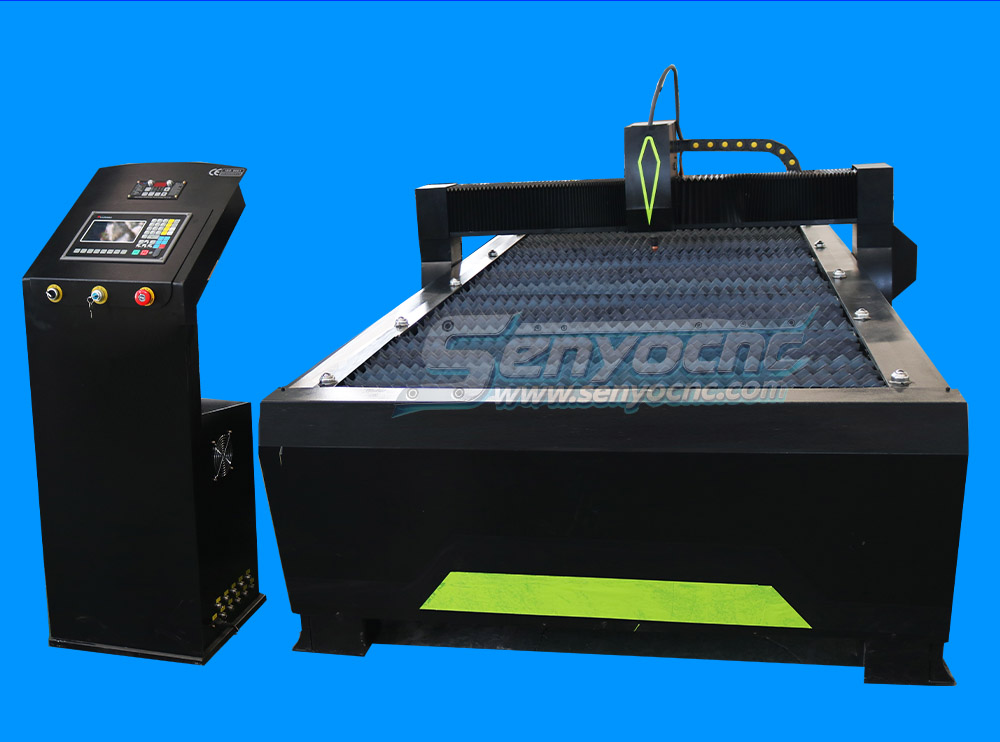

I've been using CNC plasma SYP2060-300A and I am very impressed with this unit.

This unit is of higher quality, made in China. Five stars all the way!

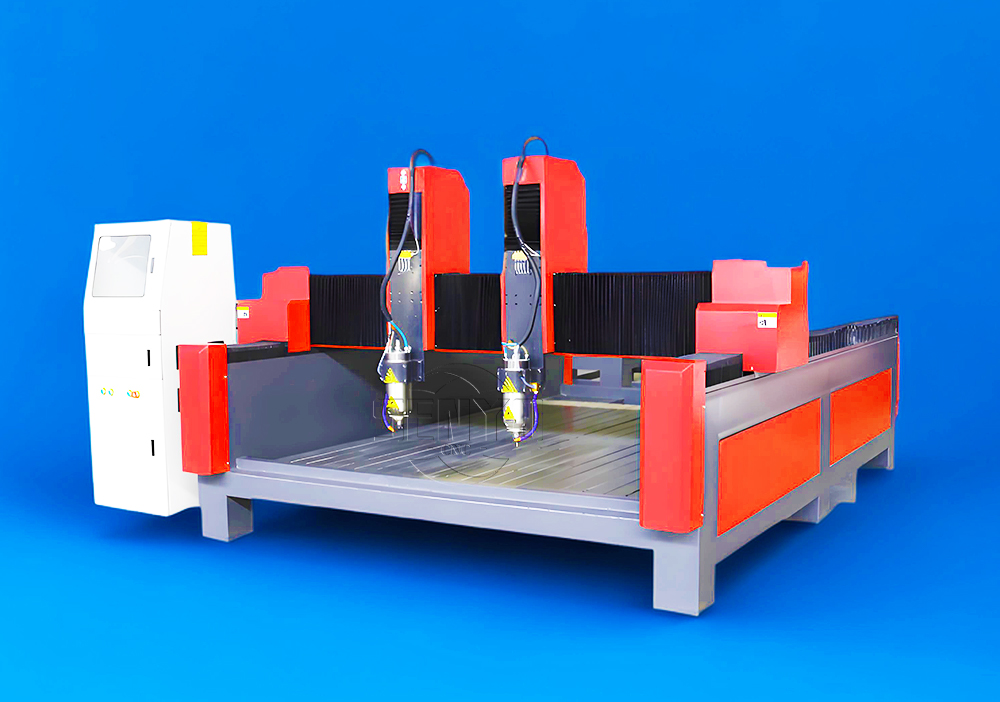

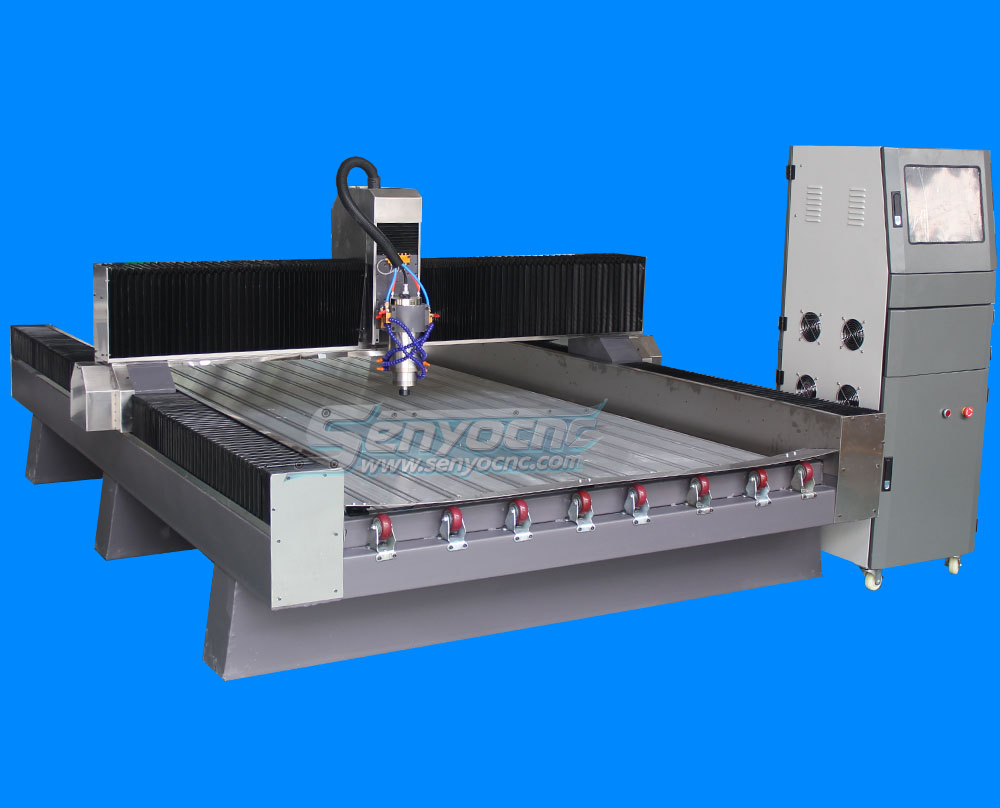

2040 from INDIAN

Best 2040 CNC Router Good Price and Quality ! Thank SENYOQC

10w uv laser from American

Best supplier ! I bought 3 machines for laser and router , thank you Aillen ! --Alec

12KW Fiber Cutting - 2000X6000mm -- 이병헌 from Korea

Good machine for metal cut ! Thanks Senyo , Its prefect , I like your business patient kind!

I am a furniture manufacturer, and this machine is very good and fast. thanks Senyoqc Team ! from Bangladesh

Metal ArtWork from Denmark

The plasma cutting machine makes my artistic creation more convenient and precise!! Created more artistic ideas and value! Thank you Aillen team!

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen. from

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen.

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo from

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo

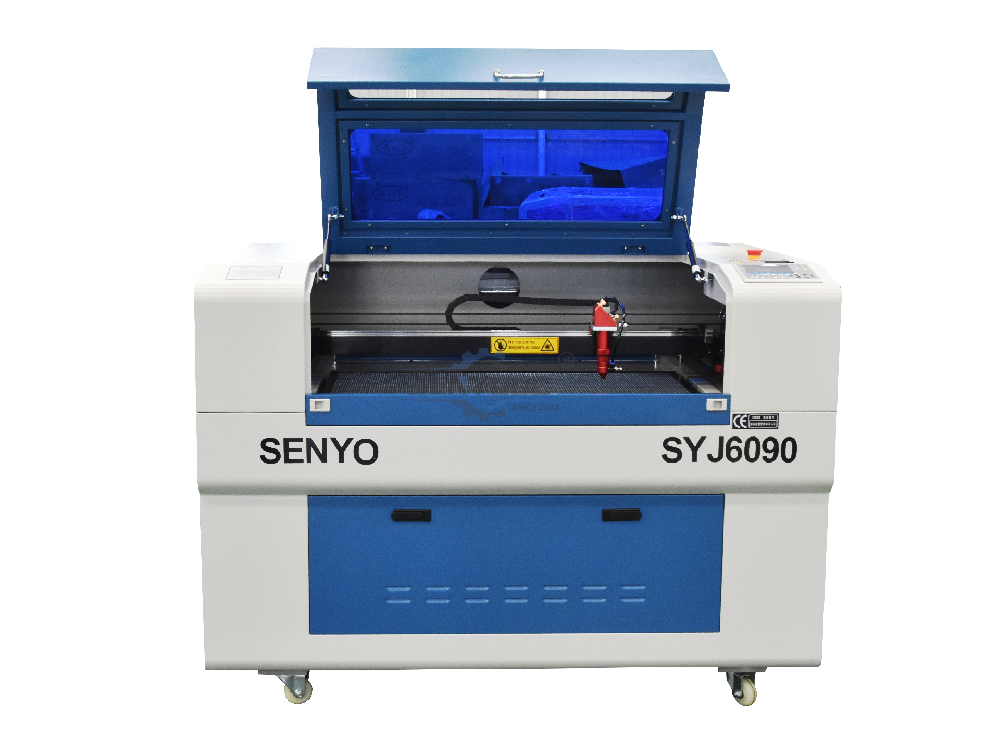

Thank you Senyo for SYJ1290-150W! from

Retired, ex mainframe systems programmer. Now full-time recreational woodworker majoring in puzzles, pens, boxes, Toys and occasional small furniture. Thank you Senyo for SYJ1290-150W!

manager@senyocnc.com

manager@senyocnc.com

SENYOCNC

SENYOCNC

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

2061579344

2061579344