Fiber Laser Cutting vs. Traditional Sheet Metal Cutting Techniques

From: 本站 Date: 03rd September 2021 Author: shengangtong Views: 3079

If manufacturing your product requires cutting a shape out a sheet

metal, you will face several processing options. Some factors to

consider when evaluating the suitability of a process include: material

type, material thickness, part geometry, required edge quality,

throughput, tolerable level of heat input or mechanical force,

dimensional tolerance, capital costs, and operating costs.

Learn More About Fiber Laser Cutting

The most popular traditional sheet metal techniques are shearing-type cutting (e.g. punching), waterjet, plasma, EDM, and lasers. Waterjet cutting was commonly used in industrial applications in the 1930s, while EDM and plasma cutting made their debuts in the 1960s. Laser cutting was introduced in the 1970s. It is difficult to date shearing-type cutting methods, as some of its variations go back to ancient times. the laser cutting was the largest segment of metal cutting machine sales in the world [1]. Comparing the cutting processes is the best way to understand what factors have been attracting a major number of fabricators to use lasers for cutting sheet metals. Instead of listing pros and cons for every process, here is a brief one-to-one comparison between cutting and the alternative process.

Shearing-type cutting methods

Cutting processes can be categorized into two main buckets in the way they extract the geometry: shearing-type cutting (e.g. punching), in which the entire geometry can be cut out of the sheet at once with mechanical force, and profile cutting techniques, where a cutting source draws the geometry like a pen (e.g. waterjet, plasma, EDM, lasers, etc.)

Punching vs. laser cutting

Punch cutting can be really fast, because in many cases the entire

geometry can be carved out with a with a single hit. However, it

requires large upfront tooling costs and therefore the production batch

should be large enough to justify the cost. The mechanical forces used

in punching can be limited by some geometrical features, such as thin

webs. Some job shops working in an agile environment may be discouraged

from punch cutting because of geometrical limitations (e.g. post-process

burr removal.)

Profile cutting processes use soft tooling to adapt to the changing

designs at no fixed cost. Therefore, they unlock opportunities for

manufacturers to prototype, run short-term and medium-term production,

and maintain the low-volume customers that have the potential of mass

production in the horizon. Fiber lasers have paved the path to high

power industrial lasers becoming more affordable. More cost-effective

technology as well as advances in automation are rapidly changing the

equations for cross-over point of mass producing sheet metal parts, when

one compares laser to punch. Many manufacturers have used laser cutting

as a complementary process to punch mass production or replacing old

punch machines with laser cutting machines.

Shearing-type cutting methods

This section discusses the major strong and weak performance points of profile cutting methods with a focus on sheet metal cutting rather than plate cutting, as the highest demand for cutting in the market is for sheet metals. Please note that thicknesses up to 0.5” (12 mm) are referred to as sheet metal whereas thicknesses more than 0.5” (12 mm) are named plates.

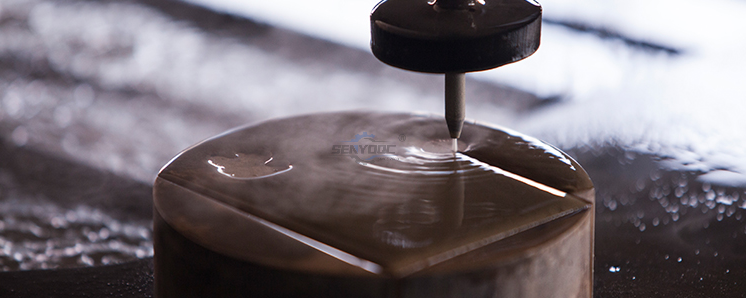

Waterjet vs. laser cutting

Waterjet machines are versatile in cutting both metals and non-metals.

Waterjet is fundamentally a mechanical machining process, so for

materials with higher hardness more cutting forces are needed and

therefore cutting needs to slow down. Cutting metal require using

abrasives in the waterjet, which comes with several challenges. These

include nozzle wear, managing the accumulated abrasive pile, and running

costs of abrasive powders. Interviewing the manufacturers doing sheet

metal fabrication shows that the maintenance and particle/noise

pollution are major complaints about waterjet cutting in a job shop

environment.

Waterjet cutting is flexible in terms of the range of materials and

thicknesses it can cut; the material do not need to be conductive

(unlike EDM or plasma) and can be quite thick (few inches with the right

waterjet equipment.) However, fiber lasers provide faster cuts on sheet

metals, typically with an order-of-magnitude narrower kerfs, 0.004”

(100 µm) vs. 0.04” (1000 µm) They also require no maintenance or

consumables, therefore making it the preferable production solution if

the shop performs a lot of sheet metal cutting.

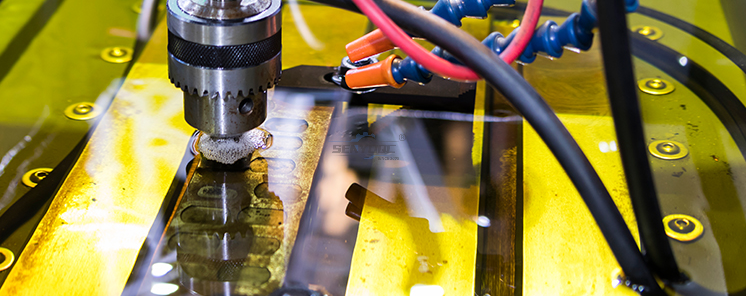

EDM vs. laser cutting

Fabricators who use EDM have at least one thing in common; they need to meet very tight size tolerances, often few microns or smaller. EDM has satisfied the market for cutting high value parts made of thick metal (>0.5” [12 mm]) that needs to be taper-free, and require ultra-precise tolerances and sub-micron surface finish (e.g. die cutting.) However, EDM process is very slow by nature. Because the EDM process works by micro-arcing between a thin wire and the metal, you cannot go too fast before the wire shorts to the metal or trips by the arc being too strong. As a result, the cut speed cannot be significantly scaled up for thinner sheets, unlike laser cutting. Thin parts can be stacked up for batch EDM cutting to increase throughput, but pilot holes need to be pre-drilled on each part as pre-processing step to initiate EDM cuts. In that case, laser cutting can be a complementary process to pre-cut holes and cut the features that do not demand micron level accuracy. For the common range of sheet metal fabrication (0.01” [0.25 mm] to 0.5” [12 mm]), laser cutting is dramatically faster than EDM (even in its stacked-up version) and can maintain high accuracy for many applications.

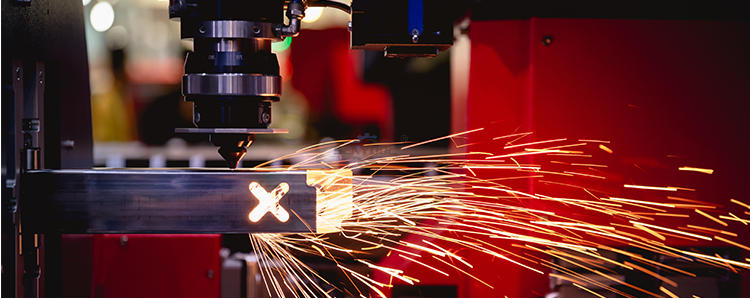

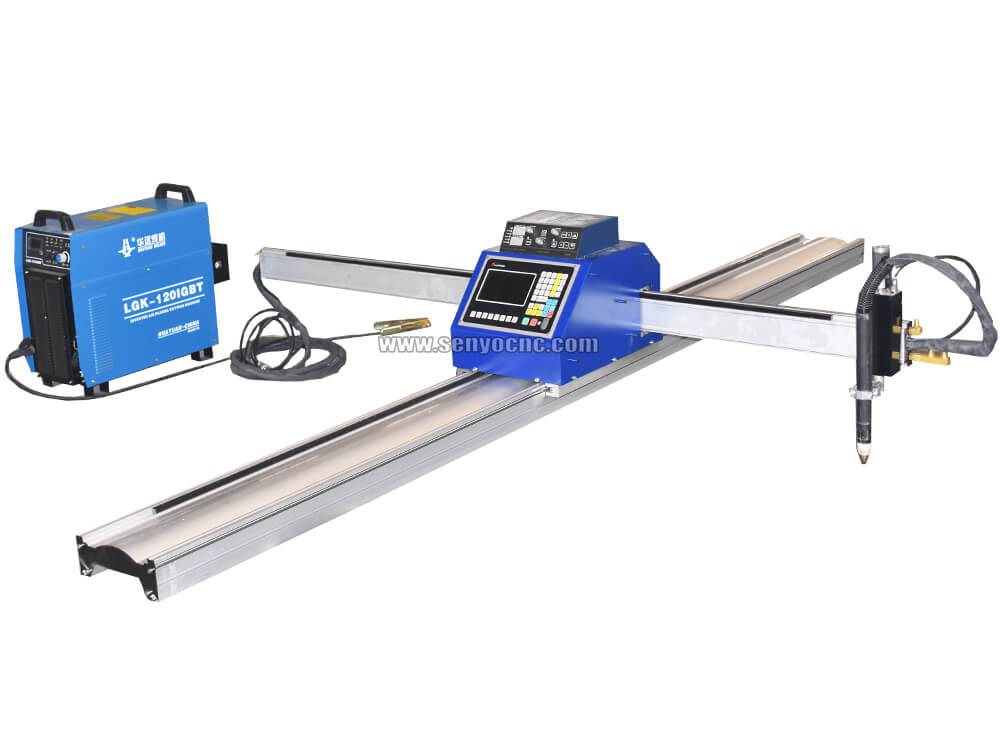

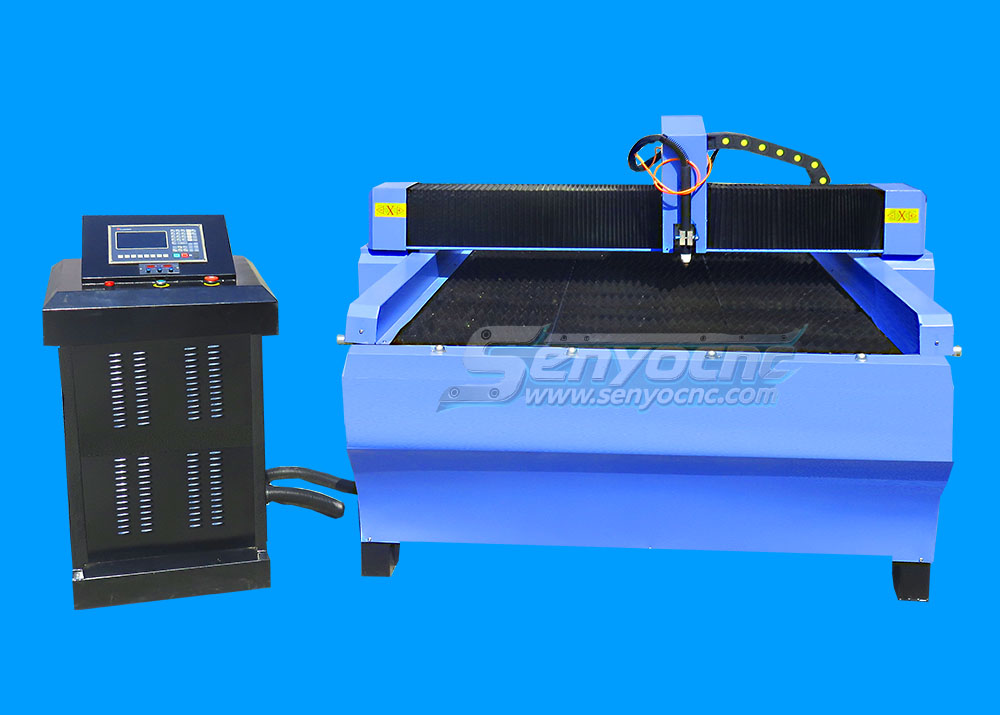

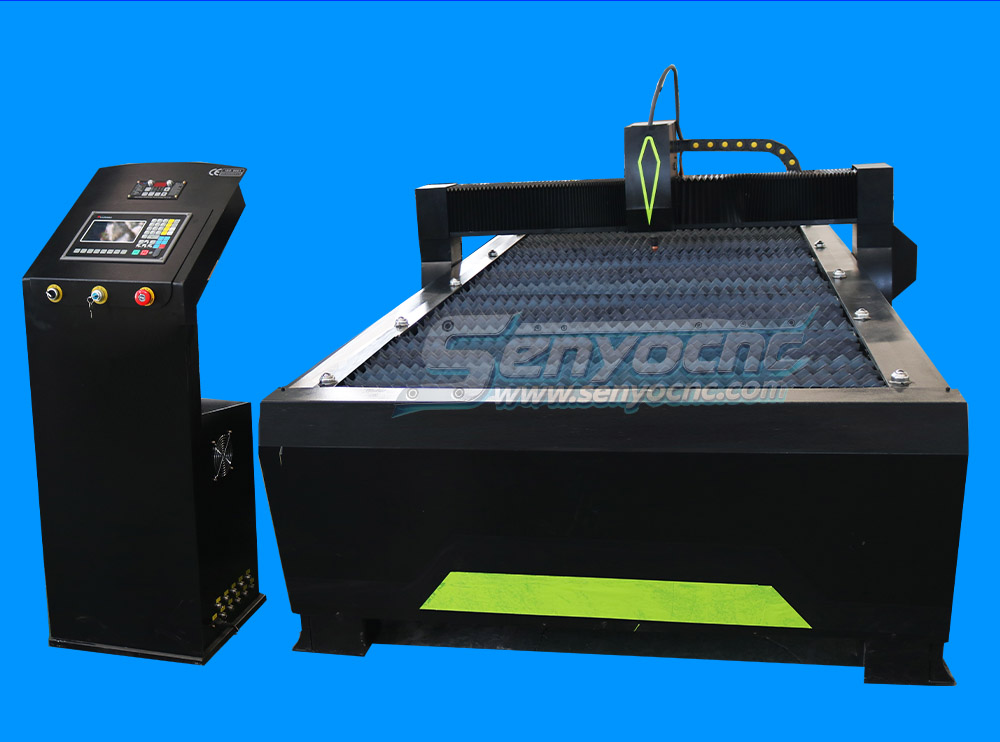

Plasma vs. laser cutting

Plasma cutting can be used for cutting metals, from thin sheets to thick plates (few inches, or tens of mm.) The cut kerf is generally wider than that of the laser kerf, and heat input into the part is significantly higher. Due to the wider kerf, higher heat input into the part, rougher/beveled cut surfaces in some cases, and variability due to nozzle degradation in long runs, plasma cutting is typically considered a less accurate method for cutting sheet metals, compared to lasers. The advantage of plasma cutting over laser has been historically in cutting thick plates and in low-cost cutting of less accurate sheet metal parts. But the rapid rise of fiber laser power at increasingly economical prices has shifted the boundary between the two processes year over year. For example, with 10-12 kW fiber laser systems , high quality, high speed cutting one 1 inch (25 mm) thick stainless steel, mild steel, and aluminum has been demonstrated. The cross-over thickness boundary between the two processes is expected to shift even more in the direction favoring fiber lasers in the foreseeable future. Available laser power continues to increase allowing for cutting of ever increasing thicknesses.

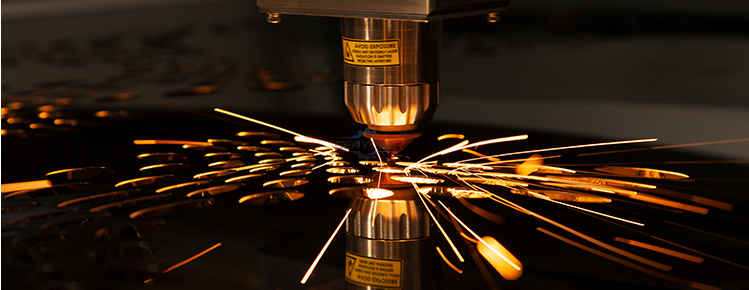

CO2 vs. fiber laser cutting

In recent years, laser cutting of sheet metals has been dominated by fiber laser. The main reasons include process reliability (no cut degradation due to the misalignment or contamination of mirrors), higher cutting speeds, the ability to cut reflective metals such as copper and brass, freedom from maintenance, and lower cost of ownership. CO2 lasers, however, have shown a smoother cut edge for some thicker materials (typically > 0.25” [6 mm]). This advantage is diminishing as advances in the high power fiber lasers and beam/gas delivery techniques are showing promises to close this gap.

Is fiber laser cutting the right solution for your application?

Fiber laser systems have established their capability to cut metals at

high quality and accommodate intricate geometries of parts, which are

challenging to other processes. However, when it comes to final decision

to purchase a fiber laser cutting machine, customers usually focus on

the additional aspects that are specific to their case, including is a

specific system is able to handle their parts’ tolerances and the

question on if it is economical to use a specific fiber laser systems to

product their parts. Below we discuss these two questions at a top

level.

Can fiber lasers handle your parts’ tolerances?

Factors such as kerf size, taper, surface roughness, heat input of the

process, and the variability of the process during the long production

runs eventually determine in practice if you can hold parts within a

tight tolerance. Combination of small kerf, low heat input, good surface

finish, and stable cutting makes fiber lasers a safe choice when it

comes to cutting precise parts. The cutting precision partly depends on

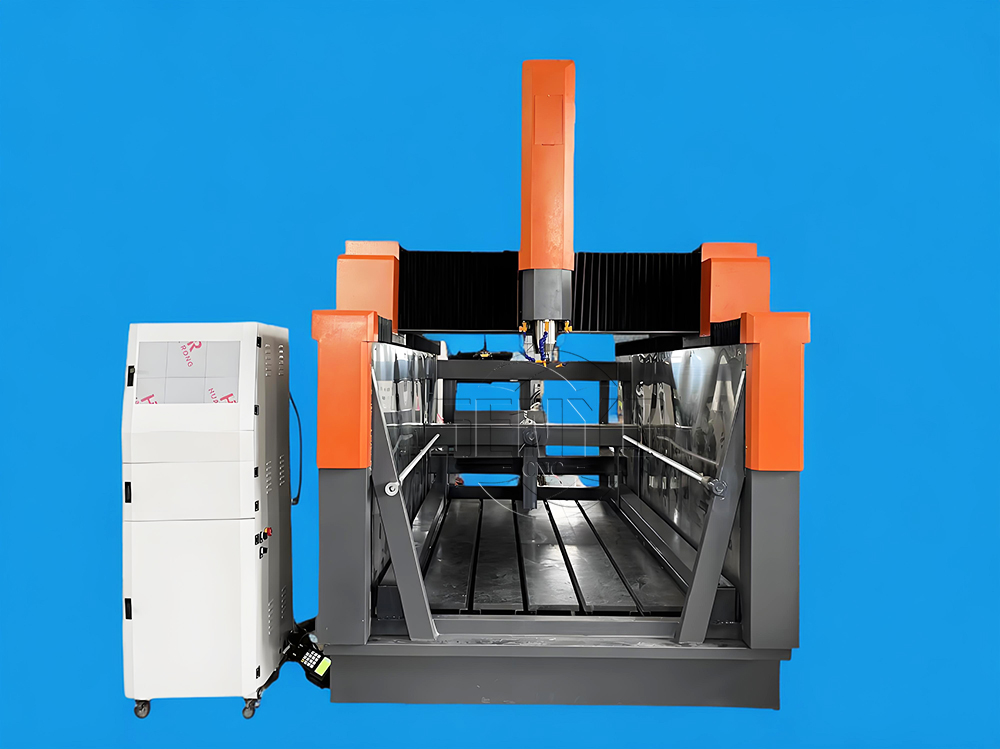

the motion system of the cutting machine. The SENYO Laser platform has complemented the inherent accuracy of fiber laser cutting

with high accuracy motion system and look-ahead motion controls that

achieve features with tolerance down to ± 0.001” (± µm).

Is fiber laser cutting economical for your project?

The capital costs and running costs of cutting processes are very

different. Given the high speed and reliability of fiber lasers, and

depending on the dosage of sheet metal cutting, they typically come

ahead of other processes in terms of cost per part. In addition, fiber

lasers have made economical parts that were not possible before (when

using older generation of lasers or any other technique.) Availability

of increasing laser power and wall-plug efficiency at a lower cost year

after year will shift the cost calculation in favor of fiber laser

cutting even more in the foreseeable future. SENYO is a small-footprint cost-effective cutting system that uses high-speed

linear motors on a granite base to harness the high-speed cutting

potentials of fiber lasers in sheet metal cutting.

Literature

[1] Metal Cutting Machine (MCM) Market Analysis, by Product (Laser,

Waterjet, Plasma, Flame), by Application (Automotive, Aerospace &

Defense, Construction, Marine, Electronics) and Segment Forecasts, 2014 –

2025, Research and Markets, Dublin, Ireland

• Previous: How to Laser Cut Copper and Other Reflective Metals

• Next: None

Jacob from United States

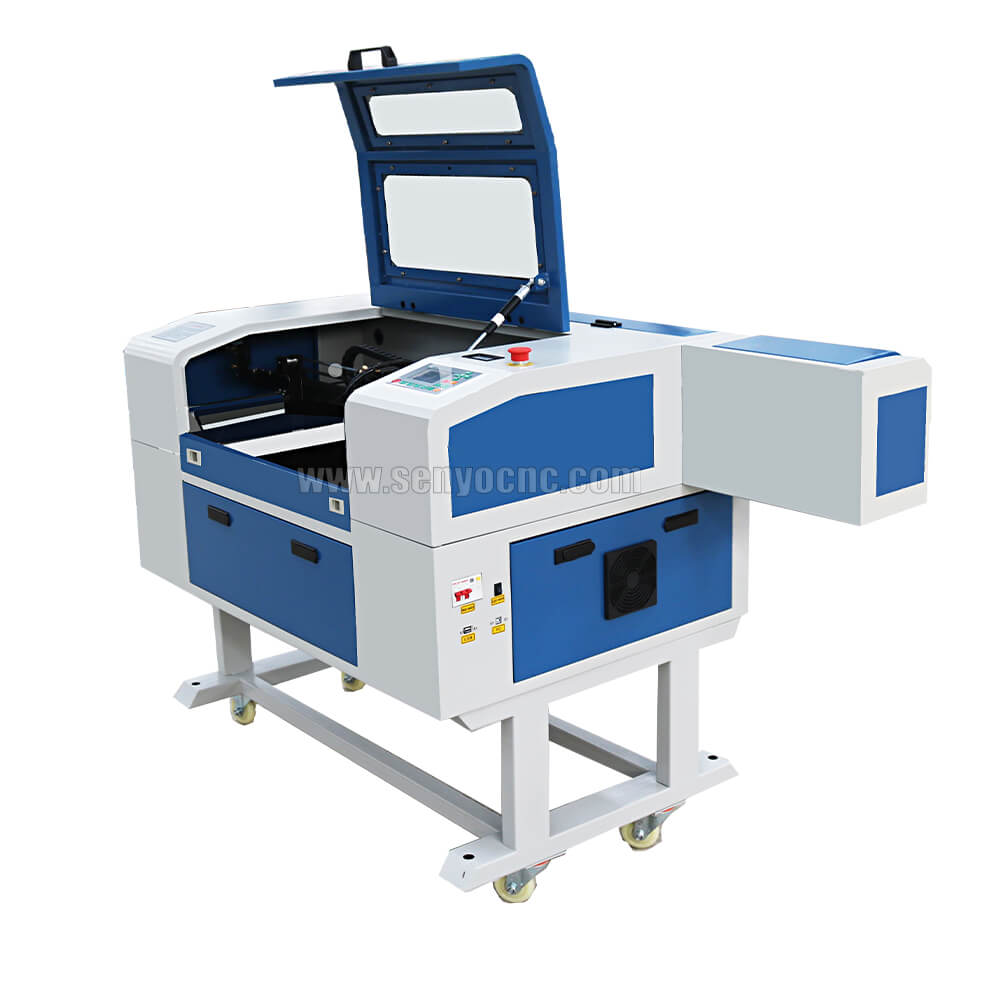

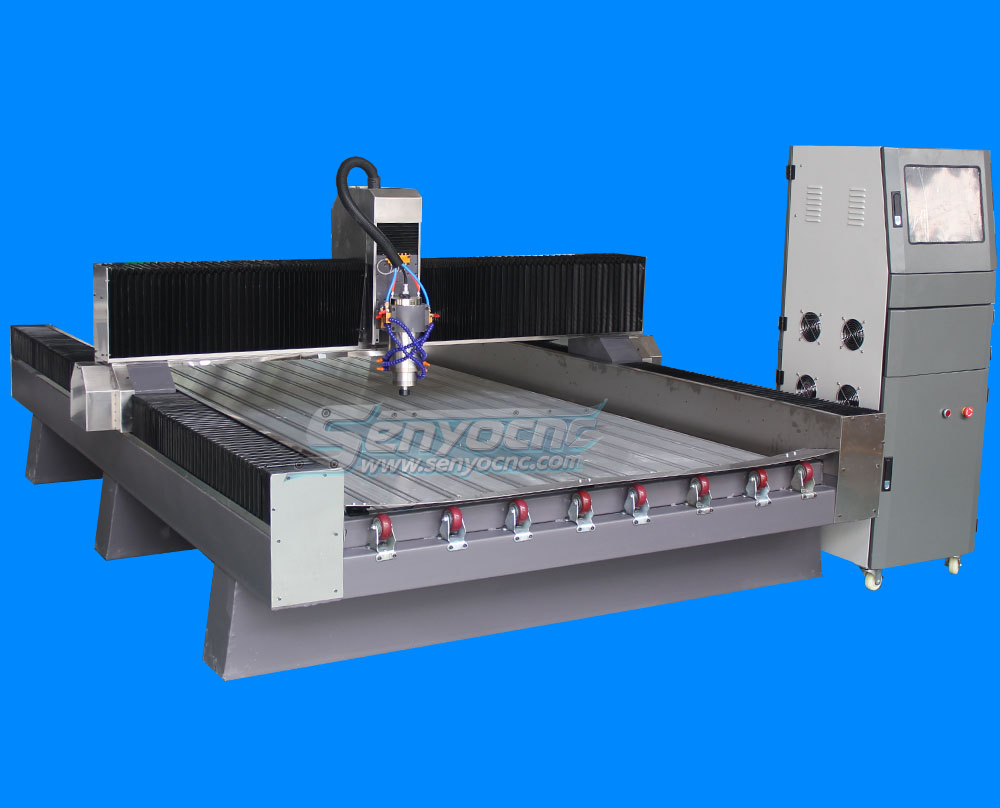

I am a beginner at CNC, I’ve never used a CNC machine before and with in a day I was carving. An awesome machine for a beginner to learn as hobbyists. I used the manual and the help video. One hour to assemble and test, very friendly and easy to use. It’s a good buy for the money. I would definitely recommend this machine to someone getting into CNCs.

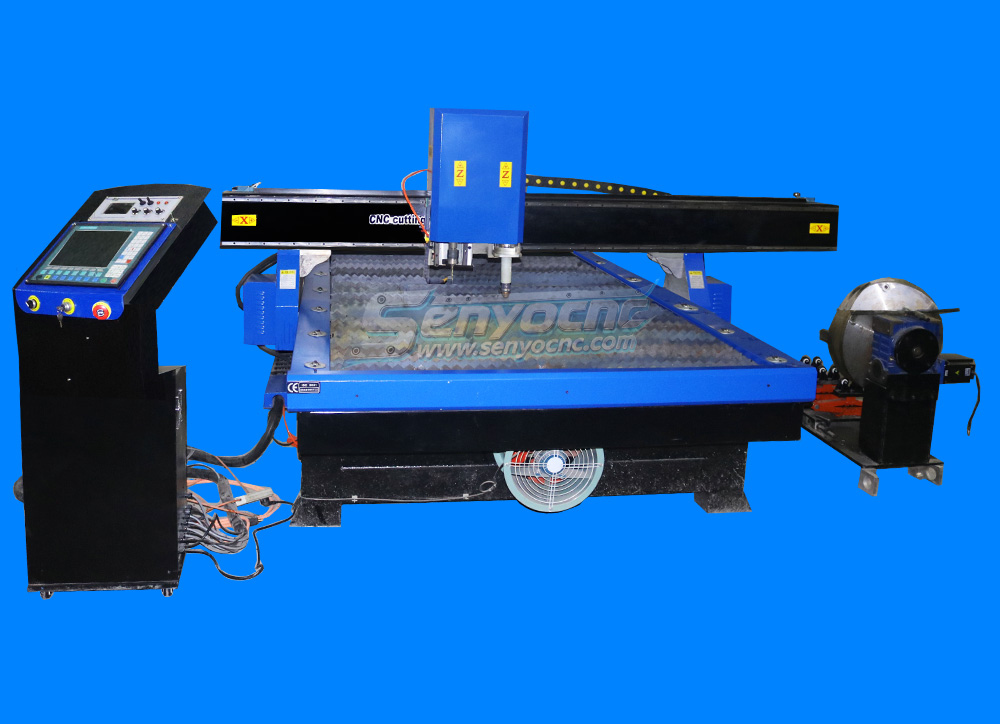

Weinstein from France

I've been using CNC plasma SYP2060-300A and I am very impressed with this unit.

This unit is of higher quality, made in China. Five stars all the way!

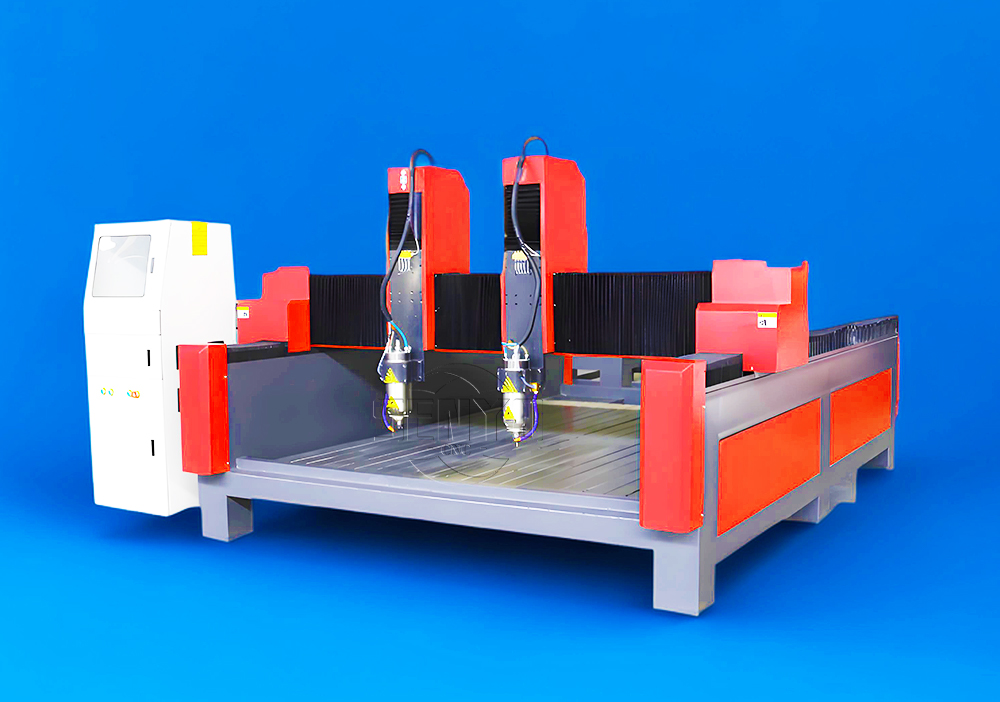

2040 from INDIAN

Best 2040 CNC Router Good Price and Quality ! Thank SENYOQC

10w uv laser from American

Best supplier ! I bought 3 machines for laser and router , thank you Aillen ! --Alec

12KW Fiber Cutting - 2000X6000mm -- 이병헌 from Korea

Good machine for metal cut ! Thanks Senyo , Its prefect , I like your business patient kind!

I am a furniture manufacturer, and this machine is very good and fast. thanks Senyoqc Team ! from Bangladesh

Metal ArtWork from Denmark

The plasma cutting machine makes my artistic creation more convenient and precise!! Created more artistic ideas and value! Thank you Aillen team!

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen. from

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen.

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo from

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo

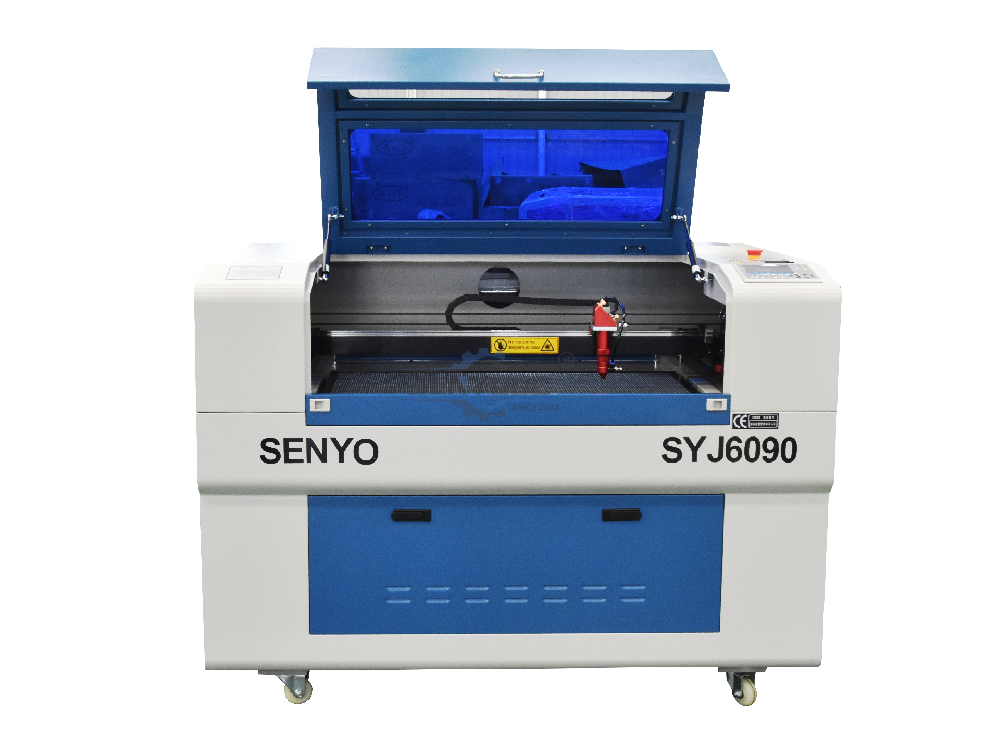

Thank you Senyo for SYJ1290-150W! from

Retired, ex mainframe systems programmer. Now full-time recreational woodworker majoring in puzzles, pens, boxes, Toys and occasional small furniture. Thank you Senyo for SYJ1290-150W!

manager@senyocnc.com

manager@senyocnc.com

SENYOCNC

SENYOCNC

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

2061579344

2061579344