What Is UV Laser Marking Machine?

UV laser marking machine is developed with 355nm Ultraviolet laser source for plastic, silicon, glass, ceramic,

which adopts a third-order intracavity frequency doubling technology. Compared with infrared lasers,

355nm UV laser has a very small focus spot, which can greatly reduce the material mechanical deformation and processing heat influence is small.

UV laser marking machine are mainly used for ultra-fine marking and engraving.

It is especially suitable for food and medical packaging materials, marking, micro-holes,

high-speed division of glass materials, and complex pattern cutting of silicon wafers.

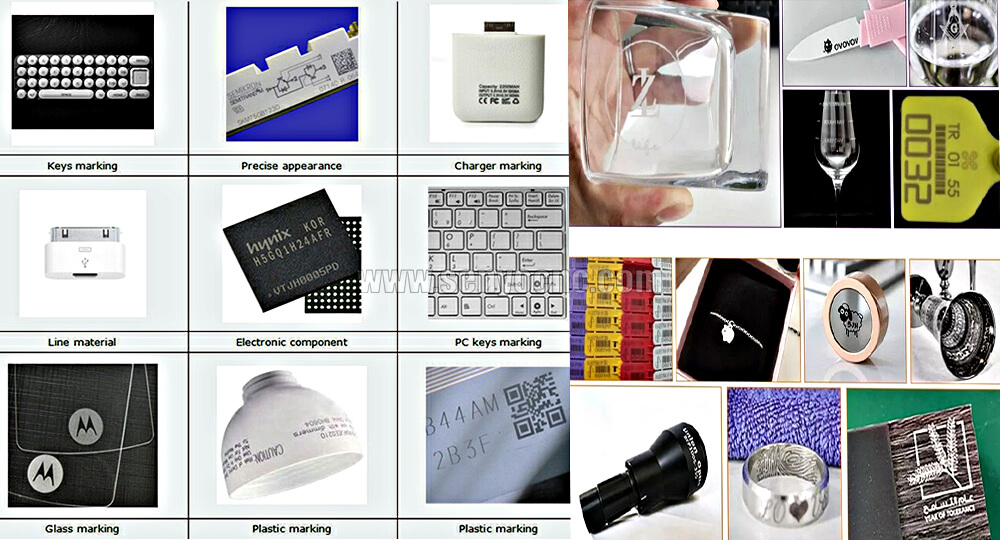

Ultraviolet laser marking machines are widely used in some high-end markets for fine processing.

For example, some high-molecular materials for cosmetics, marking of flexible PCB boards,

micro-controlling of silicon wafers, and 2D code marking of LCD liquid crystal glass, various metals,

plastics, building materials, communication equipment (mobile phone screens, mobile phone cases,

iPhone cases, Huawei mobile phone cases, samsung mobile phone cases, OPPO mobile phone cases, XIAOMI mobile phone cases).

How Does UV Laser Marking Machine Work?

The principle of UV laser marking system is similar to the most common laser marking machines,

which use laser beams to make permanent marks on the surface of various materials.

The effect of marking is to directly break the molecular chain of the substance through the short-wave laser

(different from the evaporation of the surface substance produced by the long-wave laser to expose the deep substance)

to reveal the pattern and text to be etched. Ultraviolet laser marking is a type of cold engraving method.

The engraving process is called the "photoetching" effect. "cold processing" has a very high load of energy (ultraviolet) photons,

which can break the chemical bond in the material (especially organic material) or the surrounding medium.

To cause the material to undergo non-thermal process damage.

There is no heating or thermal deformation on the inner layer and nearby areas of the processed surface.

The high-energy molecules of ultraviolet photons directly detach the molecules on the metal or non-metal materials that need to be processed.

However, this detachment causes the molecules to separate from the material. This way of working does not generate heat,

because it does not generate heat. As a result, the method of UV laser processing has become cold processing,

which is the source of the difference from traditional fiber laser marking systems.

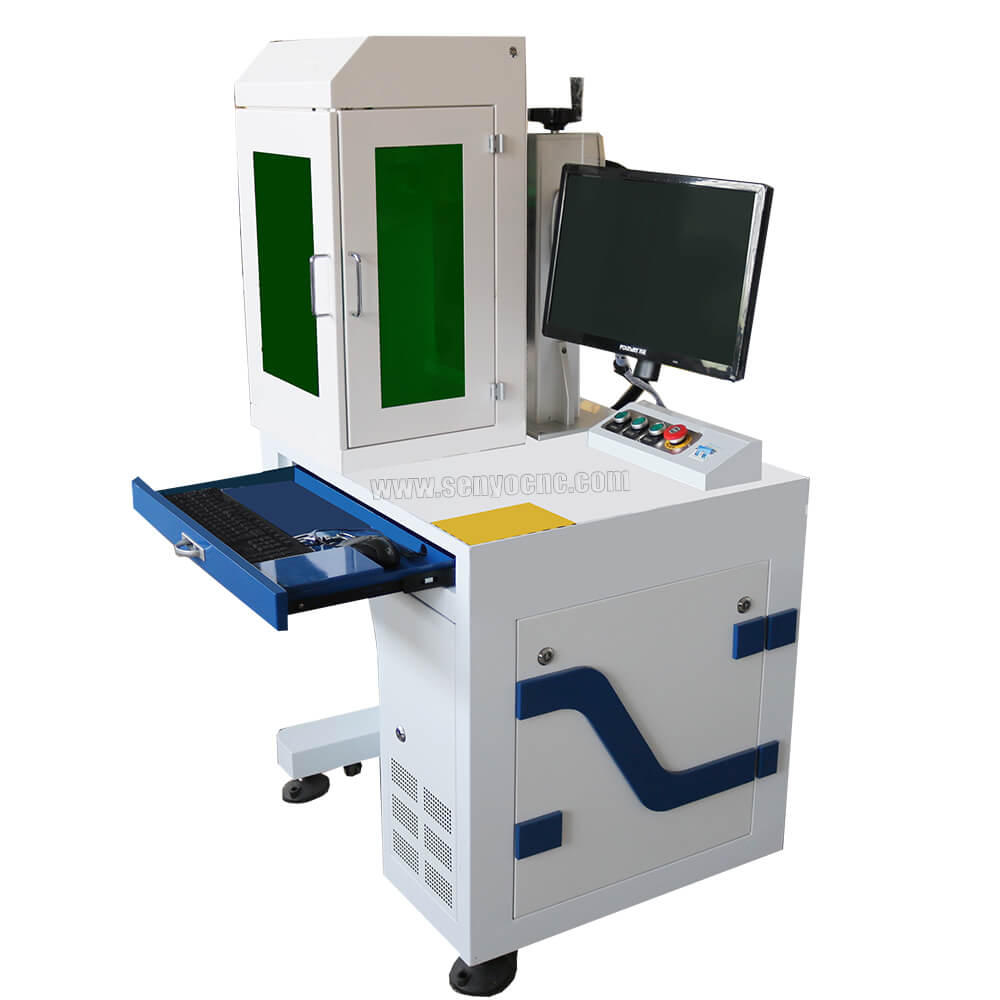

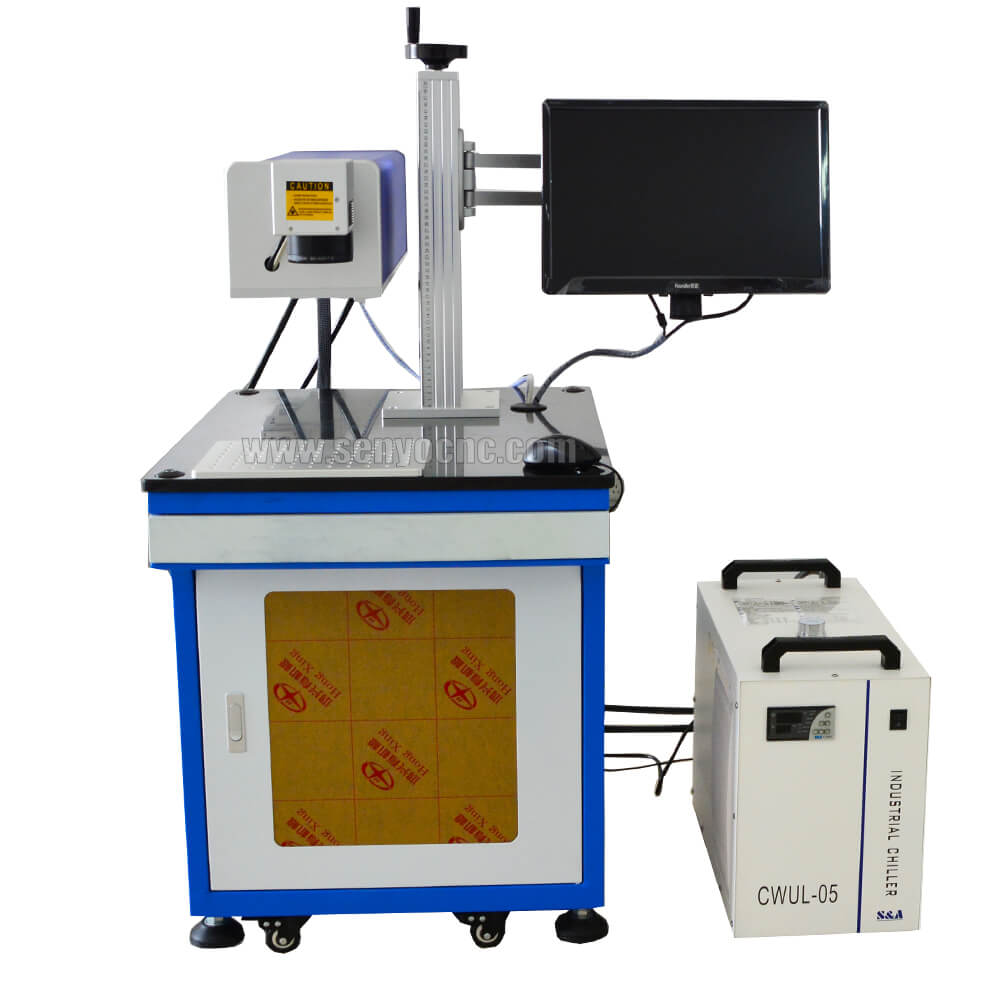

UV Laser Marking Machine with design optional

Why Choose UV Laser Marking Machine for Plastic, Silicon, Glass, Ceramic

The UV laser marking machine is based on its unique low-power laser beam,

so it can perform ultra-fine marking and special material marking. It is the first choice for customers who have higher requirements for marking effects.

It is especially suitable for the high-end market of ultra-fine processing, with fine effects and clear and firm markings.

Ultraviolet laser marking machine has high beam quality and small focused spot,

which makes marking finer and higher definition; and the heat-affected area is small, no thermal effect is generated,

and the deformation or scorching of the processed material is avoided. The applicable materials are particularly wide,

which solves the problems of insufficient detail and poor effect of fiber laser marking for many materials.

The marking speed is fast and the efficiency is high. The function of online flying marking can be realized on the assembly line.

2D Worktable With rotary

Features & Advantages

1.

UV laser marking machine adopts 355nm pumped UV laser device, so as to

get smaller diameter of focusing spot and fine marking effect.

2. The metal absorb UV higher than infrared and therefore more suitable for UV laser marker marking on metal and glass materials compared with infrared pump machine.

New design machine color

3. Narrower pulse width of UV laser makes a shorter time of processing on materials, thus the materials avoid being deformed or burnt due to thermal.

Computer

4. With smaller heat affected area and more beautiful marking effect, our products UV laser marking system can meet customer with higher marking requirements.

5. The UV laser machine is equipped with safety shield, which can effectively isolate the purple radiation, to ensure the safety of UV laser marker operators.

Keyboard

6. UV laser machine is equipped with a professional water cooling machine, air-cooled water circulation cooling, with water-cooled high efficiency and air-cooled small size.

Control box

7. Low energy consumption, environmentally friendly, no consumables. Little affect area, no heat effect, without material burned problem.

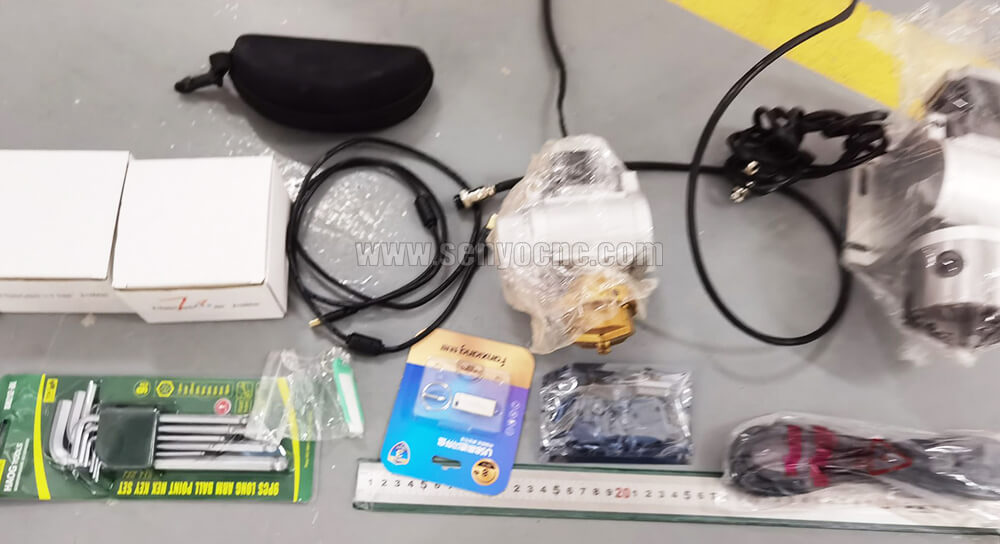

Machine Tools All Include

Technical Parameters

| Model | SYJU-10W |

| Laser type | Ultraviolet laser |

| Laser wavelength | 355nm |

| Laser power | 10W (3W 5W for choose) |

| Pulse length | <18ns@40kHz |

| Marking area | 110mmX110mm 200mmX200mm 300mmX300mm |

| Frequency range | 20kHz-200kHz |

| Min line width | 0.01mm |

| Min character | 0.2mm |

| Accuracy of repetition | ±0.003mm |

| Machine power | <1.8KW |

| Electrical power requirement | 220V/50HZ/60HZ or 110V/60HZ |

Applicable Materials:

PP (polypropylene), PC (polycarbonate), PE (polyethylene), ABS, PA, PMMA, Silicon, Glass, and Ceramics.

Applicable Industries:

1. Electronic components, battery chargers, electric wire, computer accessories, mobile phone accessories

(mobile phone screen, LCD screen) and communication products.

2. Automobile and motorcycle spare parts, auto glass, instrument appliance, optical device, aerospace, military industry products,

hardware machinery, tools, measuring tools, cutting tools, sanitary ware.

3. Pharmaceutical, food, beverage and cosmetics industry.

4. Plastic, glass, crystal, arts and crafts of surface and internal thin film etching, ceramic cutting or engraving, clocks and watches and glasses.

Leaf and stone Jade agate

5. Polymer material, majority of the metal and non-metallic materials for surface processing and coating film processing,

previous to light polymer materials, plastic, fire prevention materials, etc.

Types of Plastics You can Engrave with UV Laser Marking System

Silicone.

| Polyamide (PA).

| Polyimide (PI).

| Polyester (PES).

| Polystyrene (PS).

|

Polyethylene (PE).

| Acrylonitrile butadiene styrene copolymer (ABS).

| Polyethylene terephthalate (PET).

| Polymethylmetacrylate (PMMA).

| Polyarylsulfone (PSU, PPSU).

|

Poly ether ketone (PEEK).

| Polyoxymethylene (POM).

| Polycarbonate (PC).

| Polypropylene (PP).

| Ceramics |

Advantages of UV Laser Marking Machine

1. Perfect marking quality: 355nm output wavelength to reduce the thermal impact on the workpiece,

high-precision galvanometer marking head can ensure fine and repeatable marking,

high-precision fine spot to ensure the perfect marking results,

he marking process is non-contact, the marking effect is permanent.

2. UV laser engraver machine has a large marking range.

3. Heat affected area is very small, there will be no thermal effect, the material is not deformed and charred.

4. High speed and high efficiency.

5. Machine performance is stable, small size, low power consumption.

6. The UV laser engraving machine is suitable for heat radiation reaction of large materials processing,

if it's used for the production line with the automatic loading and unloading, it can realize automatic access to materials.

It's suitable for the vast majority of metal and non-metallic materials on the marking industry.

Packaging Details:

• Outside package: Standard marine export plywood case.

• Inner package: Stretch film and plastic film for humidity.

We can package according to your requests.

Delivery Detail: Shipped in 10 working days after payment.

Quality Control

• We have a skilled and strict quality inspection team during material procurement and production.

• All finished machines we deliver are 100% strictly tested by our quality control department and engineering department.

OEM Service

• We have rich experience and welcome customized and OEM orders.

• All OEM services are free, customers only need to provide us with your logo image, functional requirements, colors, etc.

• No minimum order quantity required.

• None of your personally identifiable information (such as your name, address, email address, bank information, etc.)

will be disclosed or shared with any third party.

• Contact: All your inquiries, questions or help will be responded within 24 hours, even on holidays,

if you have any urgent questions, please feel free to call us.

Warranty And Service

• 24 months whole machine warranty and maintenance for a lifetime.

• Free installation and testing before shipping and free training for operators

• Advice for the best CNC solutions for customer's requirements.

• Free training and sample making.

• 7/24 free service and support.

UV laser,cnc uv marking machine,10w uv laser,5w uv laser,3w uv laser,cnc laser machine ,metal marking machine,cnc laser

• Previous: None

Fiber metal Laser Sensor And Its Application

Category: SENYO NEWS 11th Mar, 2021A CNC wood router will use 3D machining in relief carving, the effect is more artistic beauty, but also has a strong sense of three-dimensional 3D, realization of this function is to ...

Precision Cutting Stents with Fiber Lasers

A CNC wood router will use 3D machining in relief carving, the effect is more artistic beauty, but also has a strong sense of three-dimensional 3D, realization of this function is to ...

How to Laser Cut Copper and Other Reflective Metals

Laser cutting of mild steel and stainless steel has a long history and has been one of the primary applications for CO2lasers. However CO2lasers have not traditionally offered a good solution for cutting highly reflective materials.Fiber lasers have an emission wavelength of around

Laser Cutting Machine Inspection Process For Manufacture

SENYOCNC Have Strict quality monitoring will be carried out when the parts are in the factory.

How Control Costs Use of UV Printers ?

UV flatbed printers are rapidly being used by more and more manufacturers, thanks to its efficient production efficiency, and the control of production costs also needs to arouse our attention.

Why UV flat printing machine is popular in market ?

For the majority of designers, give full play to the creative ability, the design sample can be arbitrarily modified on the computer, the effect on the computer, is the effect after the finished product, customer satisfaction can be directly produced. UV flat printing pattern fine, rich and clear layers, high artistry, strong three-dimensional sense, many high precision equipment can also print photography and painting style patterns.

How does UV ink jet printer save UV ink?

UV inkjet printer use process is an important consumable UV ink, reasonable use of equipment, can save UV ink , it can be said to be the best choice to directly save the cost. In the process of using some skills you need to be familiar with, the following small make up to share with you:1. Try to us

Waterjet Machine delivery and Shipping

Please tell us your max working size and what materials will cutting , also what max cutting thickeness.If you have Working photo sample please also send us , it will be helpful to choose machine with suitable models .

Waterjet Machine finish manufacture 5axis

Waterjet cutting technology is one of the fastest growing major machine tool processes in the world due to its versatility and ease of operation.

Waterjet Machine delivery and Shipping

Waterjet cutting technology is one of the fastest growing major machine tool processes in the world due to its versatility and ease of operation.There are multiple advantages to adding waterjet cutting capabilities to your shop.We are company leading ultrahigh-pressure waterjet system so

How to Create Connected Text – Inkscape for Laser Cutting

Step 1: Create Some TextFirst, we need some text to work with. To create the text, select the Text Tool (keyboard shortcut: T), click somewhere on the canvas, and type your text.You can use the drop-down list on the top left to select your desired font.Step 2: Convert Text to PathNext, we need to tu

Jacob from United States

I am a beginner at CNC, I’ve never used a CNC machine before and with in a day I was carving. An awesome machine for a beginner to learn as hobbyists. I used the manual and the help video. One hour to assemble and test, very friendly and easy to use. It’s a good buy for the money. I would definitely recommend this machine to someone getting into CNCs.

Weinstein from France

I've been using CNC plasma SYP2060-300A and I am very impressed with this unit.

This unit is of higher quality, made in China. Five stars all the way!

10w uv laser from American

Best supplier ! I bought 3 machines for laser and router , thank you Aillen ! --Alec

12KW Fiber Cutting - 2000X6000mm -- 이병헌 from Korea

Good machine for metal cut ! Thanks Senyo , Its prefect , I like your business patient kind!

I am a furniture manufacturer, and this machine is very good and fast. thanks Senyoqc Team ! from Bangladesh

Metal ArtWork from Denmark

The plasma cutting machine makes my artistic creation more convenient and precise!! Created more artistic ideas and value! Thank you Aillen team!

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen. from

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen.

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo from

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo

Thank you Senyo for SYJ1290-150W! from

Retired, ex mainframe systems programmer. Now full-time recreational woodworker majoring in puzzles, pens, boxes, Toys and occasional small furniture. Thank you Senyo for SYJ1290-150W!

CNC Router I love woodworking and the Joy in the Journey! It's a Blessing! from Ricky

CNC Router I love woodworking and the Joy in the Journey! It's a Blessing!

manager@senyocnc.com

manager@senyocnc.com

SENYOCNC

SENYOCNC

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

2061579344

2061579344