In the early days of baseball, players often made their own bats using hand-held cutters. With the advent of turning tools, standard baseball bats appeared on the playing field. From the original manual wood lathe to today's fully automatic CNC wood lathe, the production of wooden baseball bats has also been upgraded step by step in terms of quality and speed, and most carpenters and manufacturers have begun mass-producing baseball bats.

MLB wooden baseball bats are made from several different types of wood:

70% of baseball bats are made of maple

First, maple bats are hard and quite thick, allowing for extra power after hitting the ball although there is little flexibility when hitting the ball with them. It’s no surprise that sluggers often choose to use Maple Leaf bats. Bats made from maple are less likely to crack or break due to maple's density. The disadvantage of maple bats is that they retain moisture over time, which increases the w8 of the bat and reduces swing speed.

25% of baseball bats are made of ash

Ash was one of the 1st woods used in standard baseball bats. Many MLB players still use baseball bats made of ash wood because they provide greater flexibility, which increases bat speed. The disadvantage of ash bats is that their material is ring-shaped and porous, which can cause the bat to dry out and break over time.

5% of baseball bats are made of birch

Birch is another common wood used in bats. Birch is both soft and naturally durable, somewhere between ash and maple. Birch bats typically combine the durability of maple bats with the flexibility of gray bats. But its drawback is its softness, and hitting the ball often leaves dents in the shaft of the bat. In terms of durability, it is not suitable for long-term use.

Why Choose CNC Wood Lathe for Baseball Bats Making?

Are you still making baseball bats by hand? Or bothered by the inefficiency and dangers of a manual baseball bat lathe? Manual turning and sanding has become a hobby and is no longer in keeping with modern woodworking trends.

Why not upgrade to a fully automatic CNC baseball bat

lathe? It is high-speed, efficient, safe and user-friendly, allowing

both beginners and professional woodworkers to easily turn out

high-quality personalized baseball bats in batches.

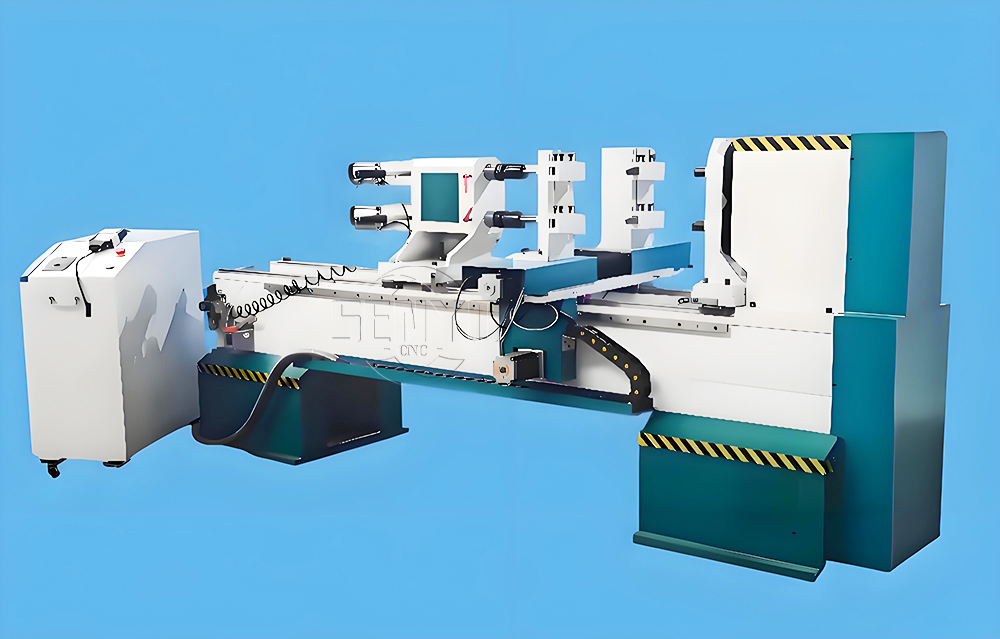

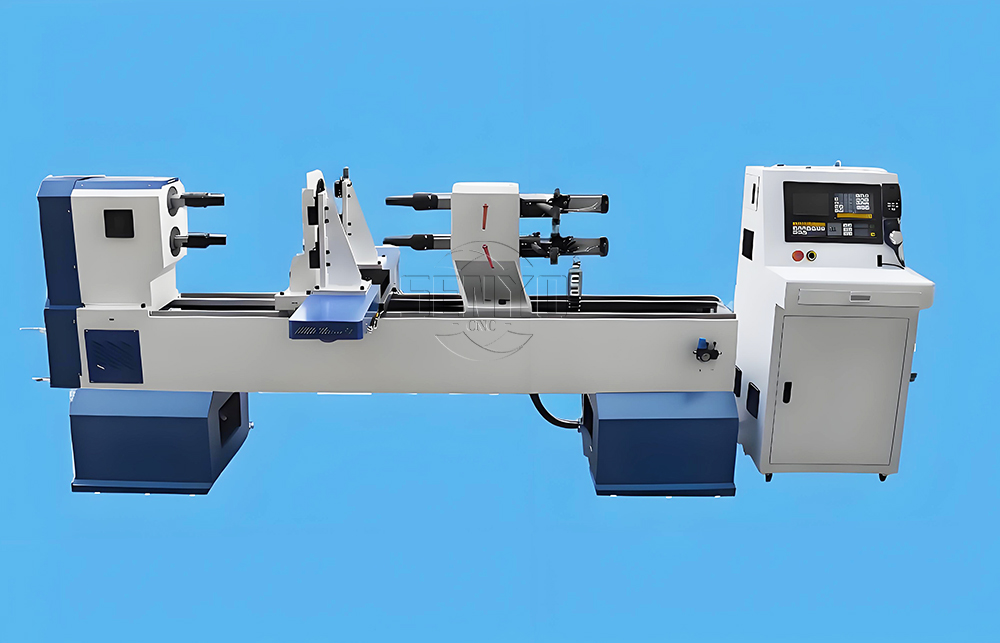

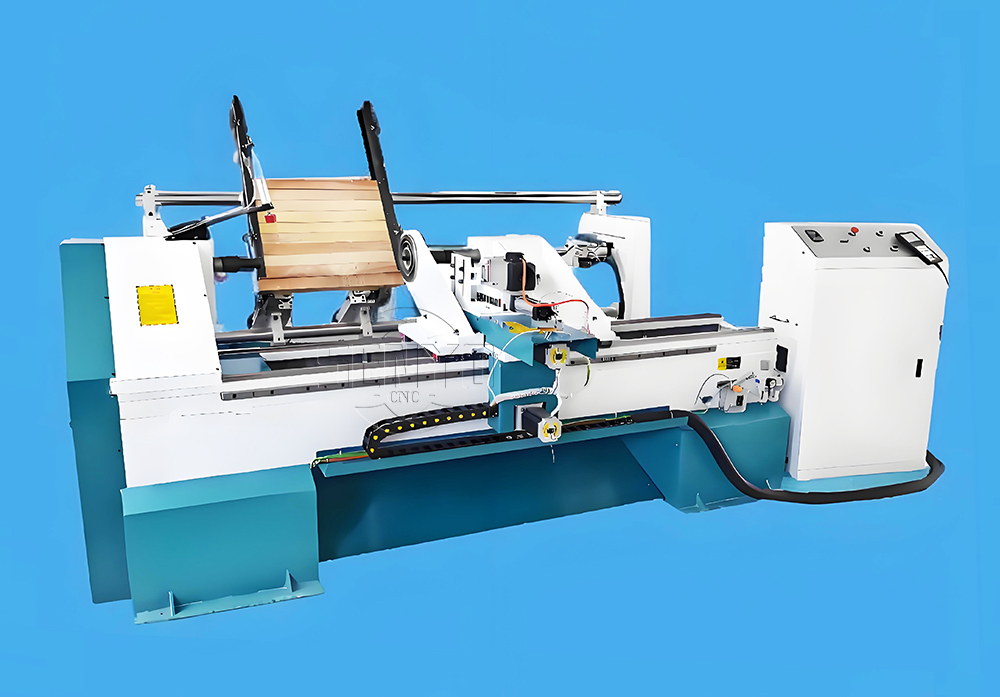

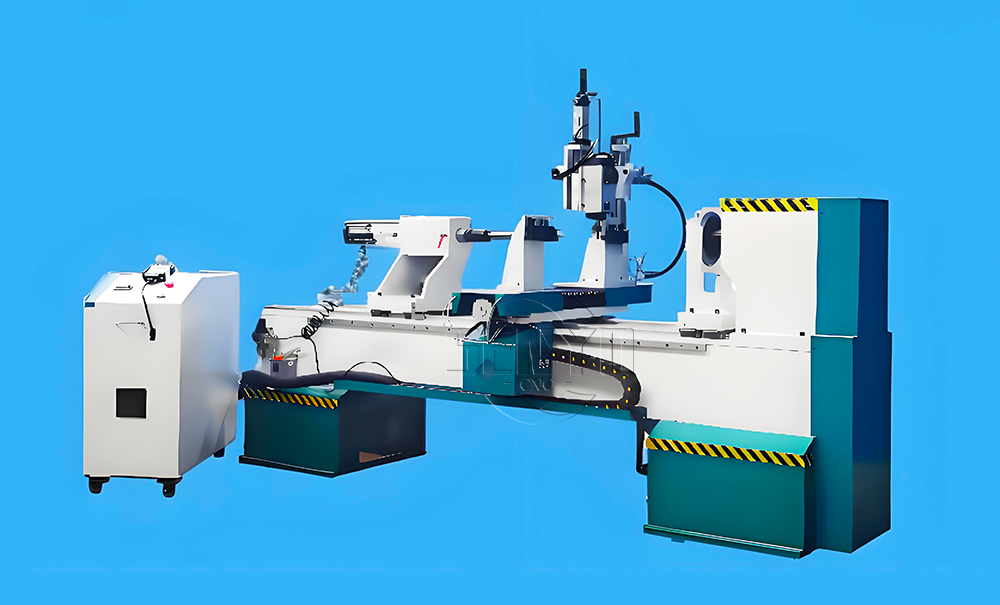

A CNC wood lathe machine is an automatic turning tool kit that can easily create personalized baseball bats. From the initial single-axis lathes to the 2-axis lathes, and the more efficient 3-axis lathes, baseball bat makers have also experienced upgrades from one to more at a time. However, We continues to innovate in the capabilities and performance of lathes. It has been continuously upgraded and launched an automatic loading attachment, which completely frees your hands and makes baseball bat making easier.

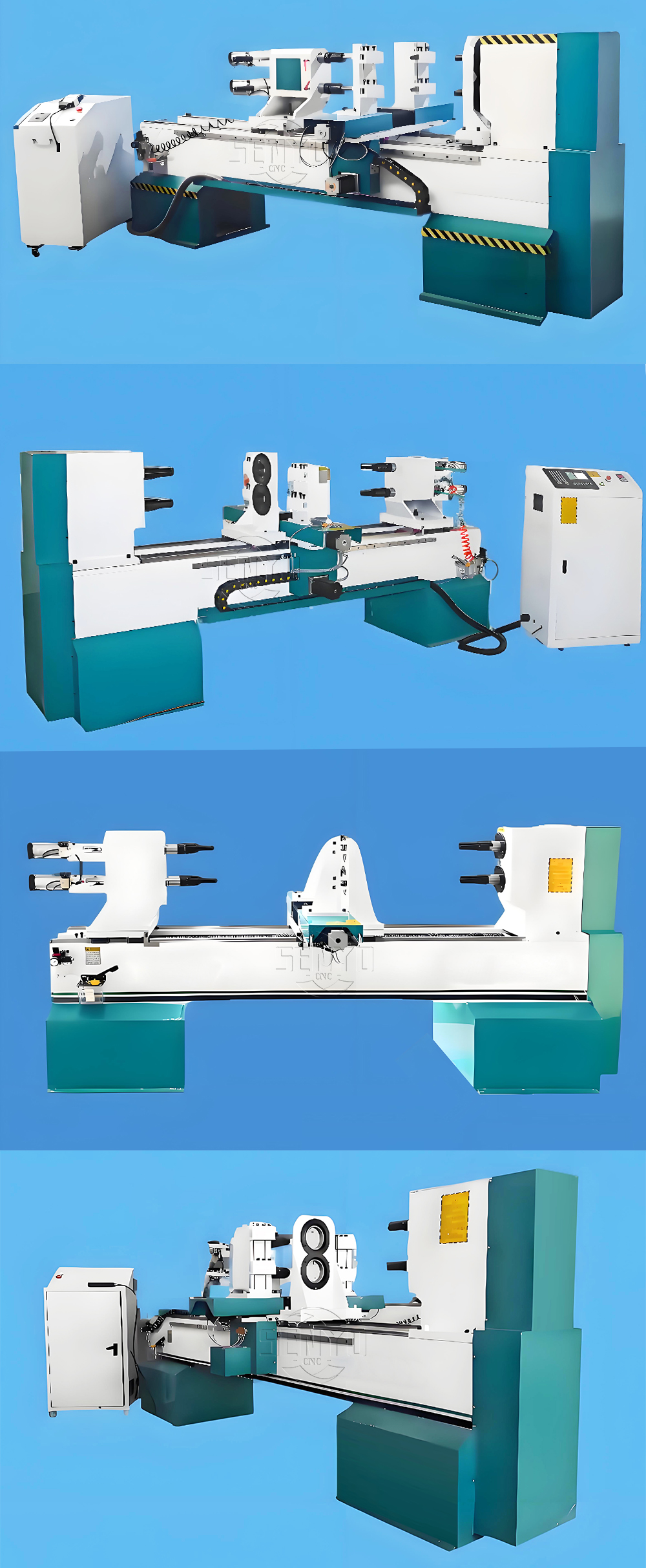

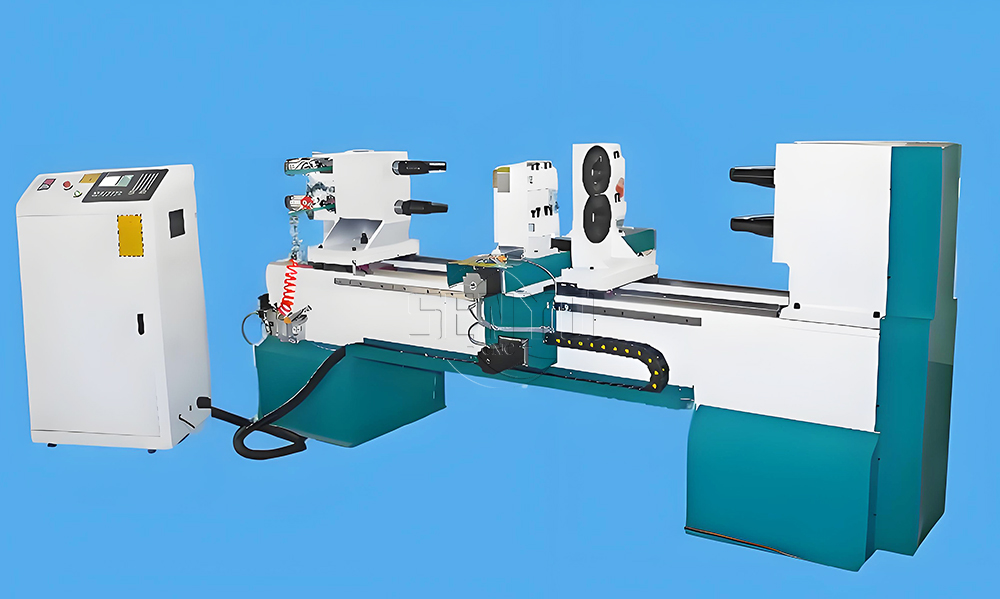

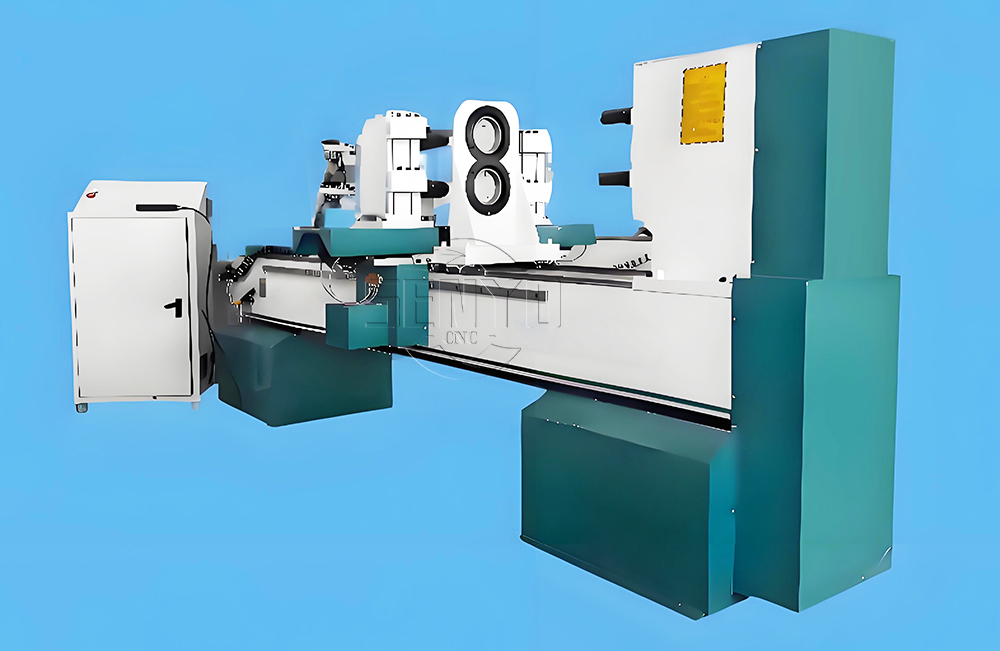

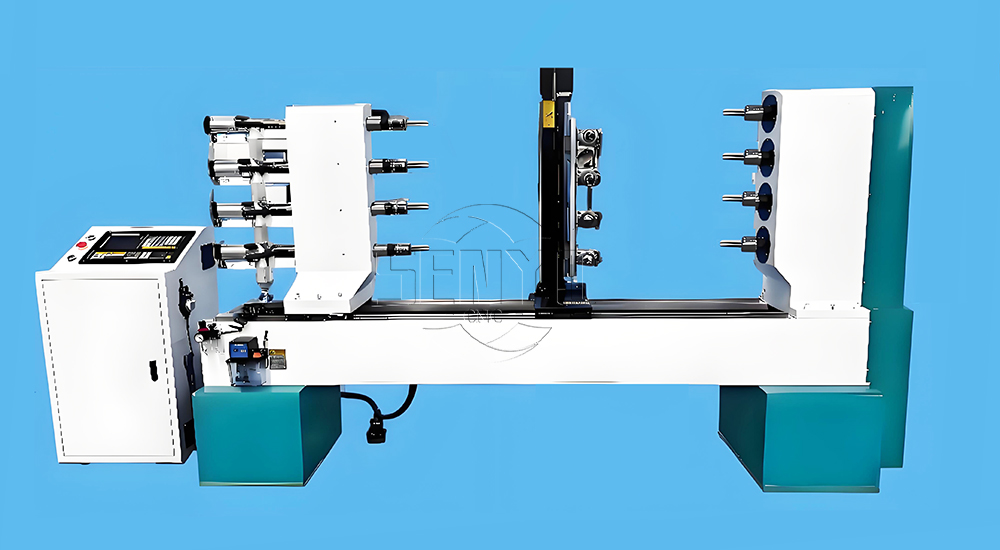

Here we focus on the dual-spindle CNC wood baseball bat making machine that is mostly used by carpenters, woodworkers, and baseball bat manufacturers.

Dual spindle CNC baseball bat lathe machine is an automatic twin-turret turning tool kit to create 2 wooden baseball bats at one time.

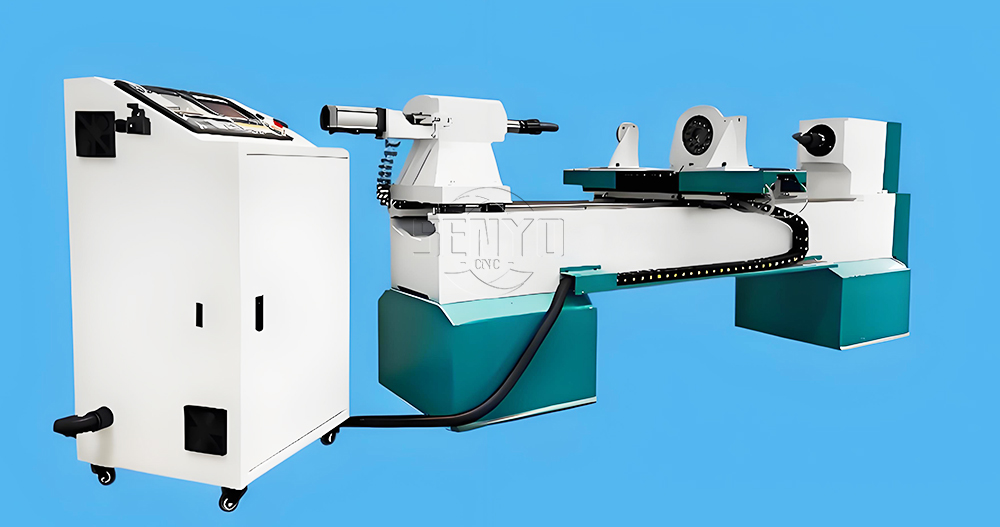

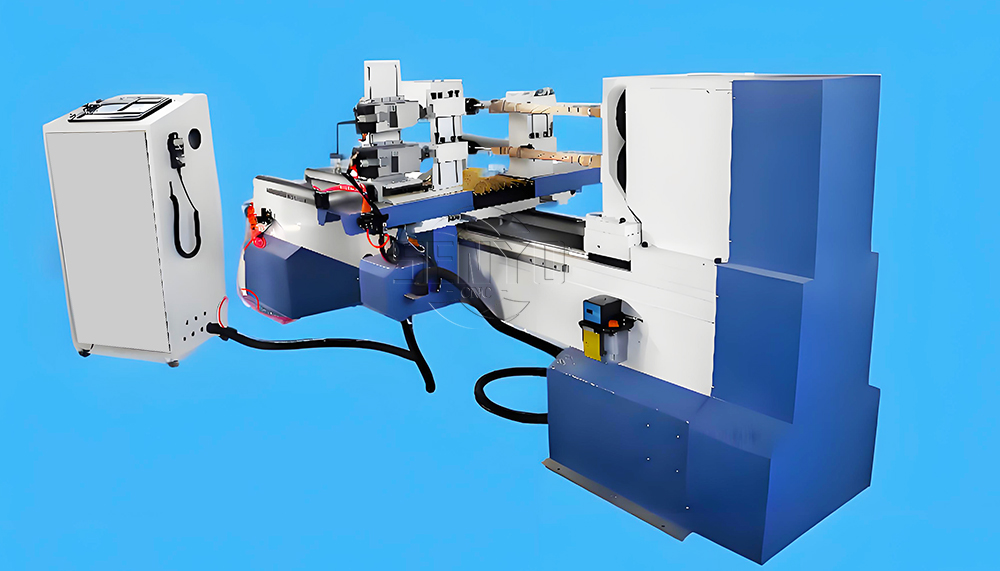

Machine Color Option

Features of Dual-Spindle Automatic CNC Wood Baseball Bat Turning Lathe Machine

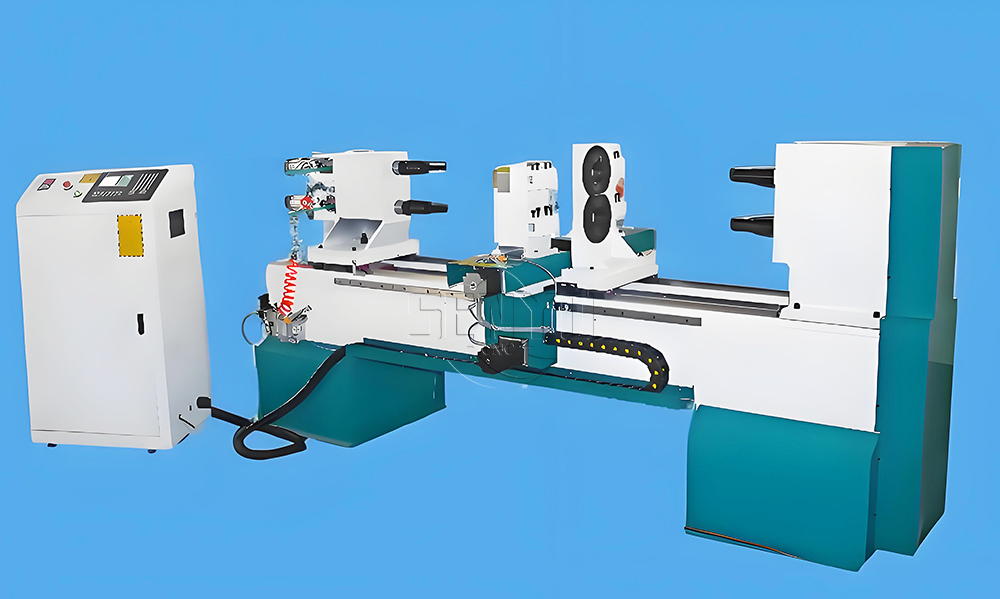

• Controller

High reliability and easy-to-use CNC controller, as well as DSP handle controller with USB interface, which is easier for align turning tools.

• Operating System

User-friendly operating interface. The entire turning can be completed with just one tool setting.

• Execution Part

High-precision stepper motor drive ensures the accuracy of turning dimensions through program calculation.

• Feed Part

High-quality HIWIN linear slide rail and precision ball screw drive.

• Power Part

Frequency converter allows variable speed to solve the problem of wood vibration.

• Spindle

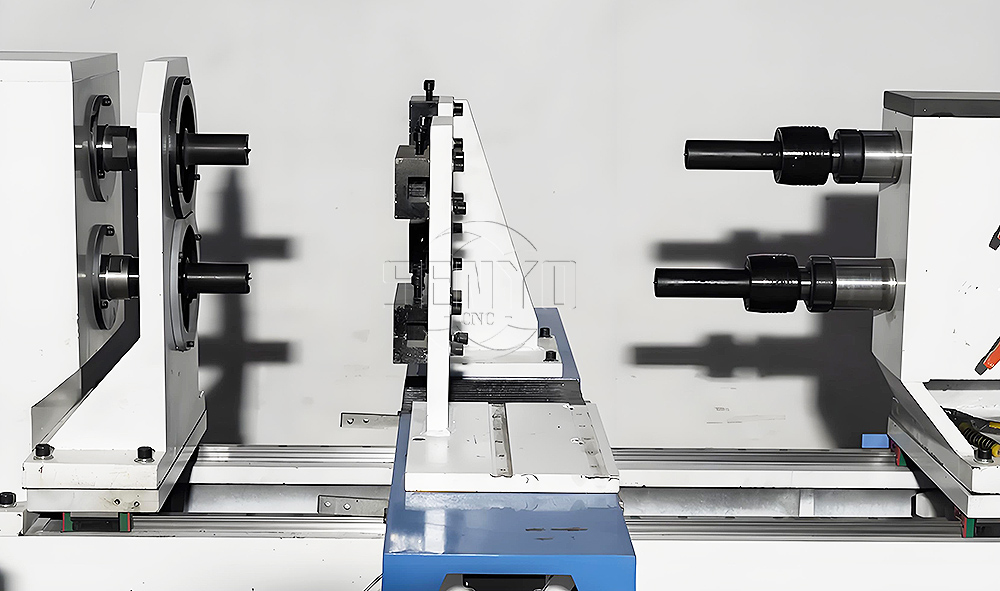

Dual spindle can turn 2 baseball bats at the same time, and the spindle speed data is shown on the control panel.

• Bed Frame

Heavy-duty cast iron bed is stable when the spindle rotates with high speed or when turning large format workpieces

Air cylinder to stable

Oil Lubrication

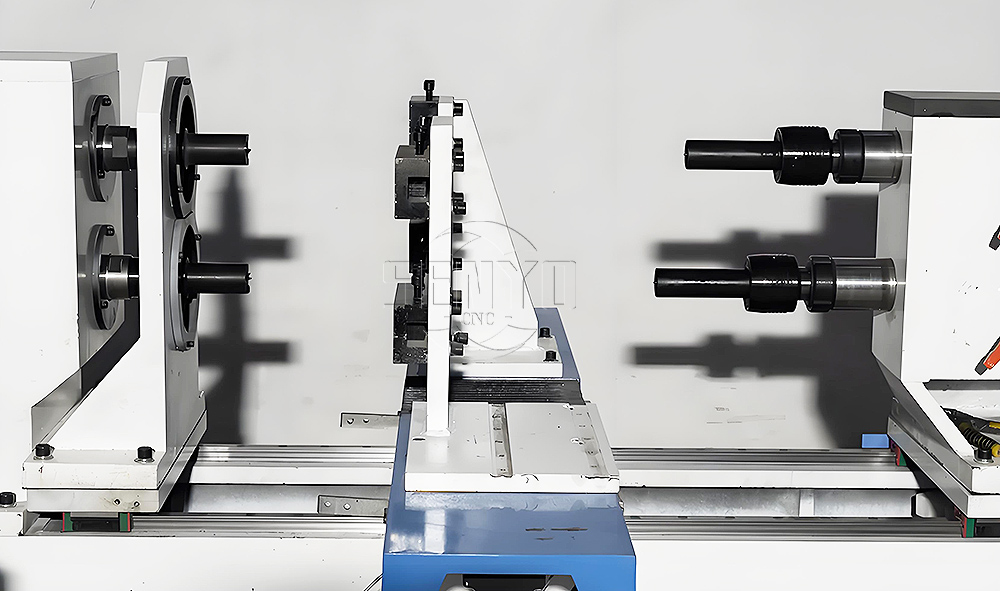

Details of Twin-Spindle CNC Wood Baseball Bat Lathe Machine

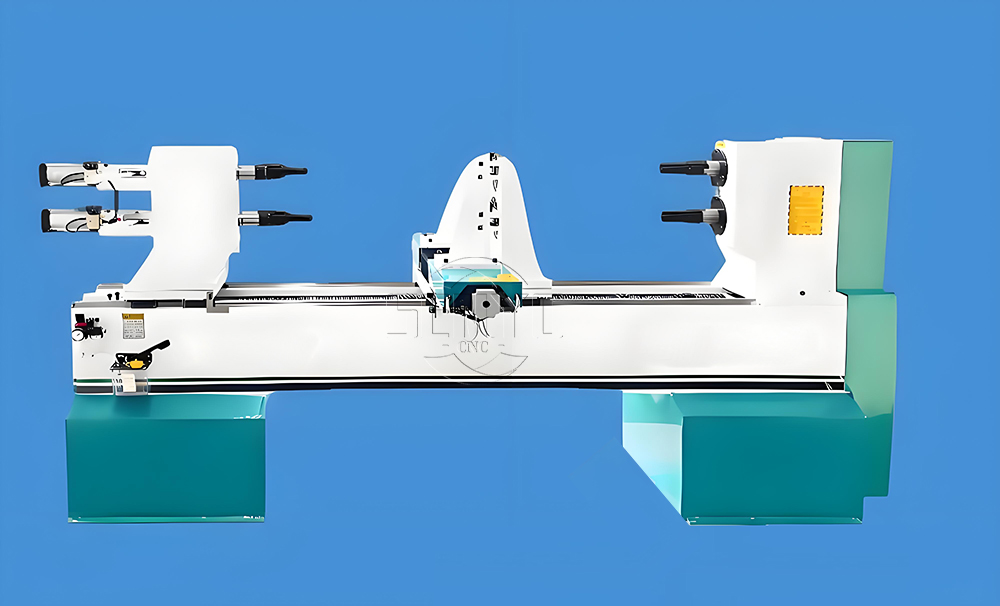

• Center support to avoid the vibration, the steady rings inside with 2.67 inch for thin wood sticks.

• Air cylinder to stable the baseball bats, cast iron machine body more heavy and stable.

• Two spindles with 4 cutters, more fast and smooth turning.

Applications of Twin-Spindle Automatic CNC Baseball Bat Lathe Machine

The CNC baseball bat lathe is a professional automatic woodworking tool for bat manufacturers and enthusiasts, offering precision and efficiency in customizing bats. Its computer-controlled turning capabilities allow for intricate designs and consistent dimensions, ensuring that each bat meets specific performance requirements. You can appreciate the ease of programming various bat profiles and the ability to quickly switch between different sizes and styles. Additionally, the lathe's robust construction minimizes vibration during operation, resulting in a smooth finish. Overall, this lathe machine significantly enhances productivity and quality in the mass production of baseball bats, making it a worthwhile investment for serious manufacturers.

A twin-spindle wood turning lathe machine with CNC controller can automatically create a personalized baseball bat from the knob to grip, from the taper to barrel, as well as the end.

A baseball bat lathe is an turning tool kit capable of making bats made of ash, maple, birch, hickory, bamboo and composite with turn models of 271, M110, 243, I-13 and 141.

In addition, it can also turn various cylindrical workpiece, bowl sharp, tubular sharp and vehicle wood crafts, such as various stair blasters and spindles, Roman columns, candle holders, table legs or chair legs, pens, rings, wooden vases, lampstands, wooden bowls, pool cues, sofa legs, furniture legs, and more woodworking projects.

Technical Parameters of Dual-Spindle Automatic CNC Wood Lathe for Baseball Bats

| Model | SYL1516-2 |

| Max turning length | 100mm - 1500mm |

| Max turning diameter | 20mm - 160mm |

| Number of axis | double axis |

| Maximum feed rate | 200cm/min |

| Minimum setting unit | 0.01cm |

| software | including |

| Power supply | AC380v/50hZ or AC220V/60HZ |

| Overall dimensions | 329*127*154cm |

| Weight | 1600kg |

| Price Range | $6,380.00 - $7,680.00 |

FAQ

What is a baseball bat lathe?

A baseball bat lathe is an automatic wooden stick turning tool kit used to make bats for baseballs, working with a CNC controller to achieve personalized customized sticks for players and mass production of bats.

What types of baseball sticks can a wood lathe turn?

A wood lathe is capable of turning baseball sticks from the knob (standard, tapered, cone, axe) to grip, from the taper to barrel, as well as the end with turn models of 271, M110, 243, I-13 and 141.

Which woods of baseball bats can be turned with a wood lathe?

A wood lathe can shape wooden baseball bats made of maple, ash, birch, hickory, bamboo and composite. Whether it's a simple design or a complex shape, a CNC lathe can easily turn out the baseball bat you want.

For Our Work Steps

1.Before-sale,we will try to know your requirement what kind of work

you will do .then we will offer our best solution for your requirement.

2.During production: we will send photos of machines during making. so you can know more details about

the procession of making your machines.

3.Before shipping,we will take delivery photo and confirm the specification of order to avoid the mistake.

Machine will be adjusted before it is delivered.

4.After shipping: we will sent out the documents for your customs clearance ASAP . and check the

approximate date of arrival.

5.After arrival: we will confirm with you if machine is in good condition.and see if any spare parts missing .

6.About teaching: there are some manual and video about how to use machine , if you have question

about it. we will have professional technicist to help you install and teach how to use through skype ,calling,or mail.

Machine More Detials Functions Show, Welcome option depend on your work requirement.

Packing & Shipping

1.Outside:Standard plywood package.

2.Inner package:Stretchy film and plastic film for humidity.

And we can package according to you requests

Delivery Detail:For standard machines,

it will be 7-15 working days after payment;

For non-standard machines and customized machines according to clients’ specific requirements,it will be 15-30 working days after payment.

For LCL Shipping (Less than Container Load),it is recommended to use export standard fumigation-free wooden boxes.

Which are stronger and suitable for long-distance transportation.

For FCL Shipping (Full Container Load),it can be loaded directly at the factory without wooden boxes.

And the maximum number of machines can be loaded to reduce costs.

Service & Support

1. Our engineers available to service machinery overseas.

2. 2 years guarantee for the whole machine.

3. Technical support by calling, mail, whatsapp and skype. If you have any problems, we will help you to solve it within 12 hours.

4. If you need any component of the machine, we will provide most affordable price for you.

5. Friendly English version manual and operation video CD disk.

CNC wood lathe

machine.Woodturning CNC machine. Automatic wood lathe. CNC lathe for

wood. Woodworking lathe machine. 3-axis CNC wood lathe. 4-axis CNC wood

lathe.CNC wood turning machine. CNC lathe machine for

furniture.Affordable CNC wood lathe

• Previous: 1530 Single Axis CNC Wood Lathe Machine

• Next: None

Fiber metal Laser Sensor And Its Application

Category: SENYO NEWS 11th Mar, 2021A CNC wood router will use 3D machining in relief carving, the effect is more artistic beauty, but also has a strong sense of three-dimensional 3D, realization of this function is to ...

Precision Cutting Stents with Fiber Lasers

A CNC wood router will use 3D machining in relief carving, the effect is more artistic beauty, but also has a strong sense of three-dimensional 3D, realization of this function is to ...

How to Laser Cut Copper and Other Reflective Metals

Laser cutting of mild steel and stainless steel has a long history and has been one of the primary applications for CO2lasers. However CO2lasers have not traditionally offered a good solution for cutting highly reflective materials.Fiber lasers have an emission wavelength of around

Laser Cutting Machine Inspection Process For Manufacture

SENYOCNC Have Strict quality monitoring will be carried out when the parts are in the factory.

How Control Costs Use of UV Printers ?

UV flatbed printers are rapidly being used by more and more manufacturers, thanks to its efficient production efficiency, and the control of production costs also needs to arouse our attention.

Why UV flat printing machine is popular in market ?

For the majority of designers, give full play to the creative ability, the design sample can be arbitrarily modified on the computer, the effect on the computer, is the effect after the finished product, customer satisfaction can be directly produced. UV flat printing pattern fine, rich and clear layers, high artistry, strong three-dimensional sense, many high precision equipment can also print photography and painting style patterns.

How does UV ink jet printer save UV ink?

UV inkjet printer use process is an important consumable UV ink, reasonable use of equipment, can save UV ink , it can be said to be the best choice to directly save the cost. In the process of using some skills you need to be familiar with, the following small make up to share with you:1. Try to us

Waterjet Machine delivery and Shipping

Please tell us your max working size and what materials will cutting , also what max cutting thickeness.If you have Working photo sample please also send us , it will be helpful to choose machine with suitable models .

Waterjet Machine finish manufacture 5axis

Waterjet cutting technology is one of the fastest growing major machine tool processes in the world due to its versatility and ease of operation.

Waterjet Machine delivery and Shipping

Waterjet cutting technology is one of the fastest growing major machine tool processes in the world due to its versatility and ease of operation.There are multiple advantages to adding waterjet cutting capabilities to your shop.We are company leading ultrahigh-pressure waterjet system so

How to Create Connected Text – Inkscape for Laser Cutting

Step 1: Create Some TextFirst, we need some text to work with. To create the text, select the Text Tool (keyboard shortcut: T), click somewhere on the canvas, and type your text.You can use the drop-down list on the top left to select your desired font.Step 2: Convert Text to PathNext, we need to tu

Jacob from United States

I am a beginner at CNC, I’ve never used a CNC machine before and with in a day I was carving. An awesome machine for a beginner to learn as hobbyists. I used the manual and the help video. One hour to assemble and test, very friendly and easy to use. It’s a good buy for the money. I would definitely recommend this machine to someone getting into CNCs.

Weinstein from France

I've been using CNC plasma SYP2060-300A and I am very impressed with this unit.

This unit is of higher quality, made in China. Five stars all the way!

10w uv laser from American

Best supplier ! I bought 3 machines for laser and router , thank you Aillen ! --Alec

12KW Fiber Cutting - 2000X6000mm -- 이병헌 from Korea

Good machine for metal cut ! Thanks Senyo , Its prefect , I like your business patient kind!

I am a furniture manufacturer, and this machine is very good and fast. thanks Senyoqc Team ! from Bangladesh

Metal ArtWork from Denmark

The plasma cutting machine makes my artistic creation more convenient and precise!! Created more artistic ideas and value! Thank you Aillen team!

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen. from

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen.

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo from

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo

Thank you Senyo for SYJ1290-150W! from

Retired, ex mainframe systems programmer. Now full-time recreational woodworker majoring in puzzles, pens, boxes, Toys and occasional small furniture. Thank you Senyo for SYJ1290-150W!

CNC Router I love woodworking and the Joy in the Journey! It's a Blessing! from Ricky

CNC Router I love woodworking and the Joy in the Journey! It's a Blessing!

manager@senyocnc.com

manager@senyocnc.com

SENYOCNC

SENYOCNC

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

2061579344

2061579344