What Is 5x10 CNC Router?

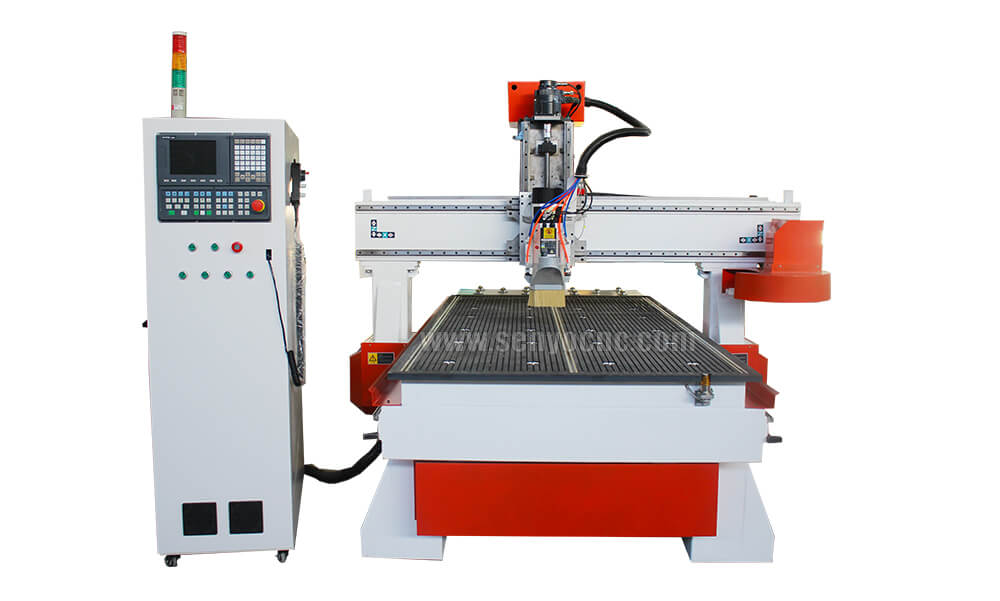

5x10 CNC router is a type of full-size automatic CNC machine with 5' x 10' (60" x 120")

table kit for industrial manufacturing and commercial use with heavy duty structure, 9KW HQD ATC spindle

Leadshine servo motor 1500W + reducer, LNC CNC controller system, linear automatic tool changer kits.

The 5x10 feet table size is large enough to cut and mill full size sheets.

The CNC controller is user friendly and easy to use, compatible with Type3, ArtCam, Ucancam, Castmate, and more CAD/CAM software.

Today, the compactness and limitations of the 4x8 CNC router table are

exposed in full-size machining

As modern industrial manufacturing requires larger automated table kits. In this case,

The 5x10 CNC router machine has evolved into the most popular woodworking tool for cabinet

Furniture making in the United States, Canada, Australia, the United

Kingdom, and some EU countries.

The 5' x 10' CNC router table kit is large enough to handhle most modern woodworking projects,

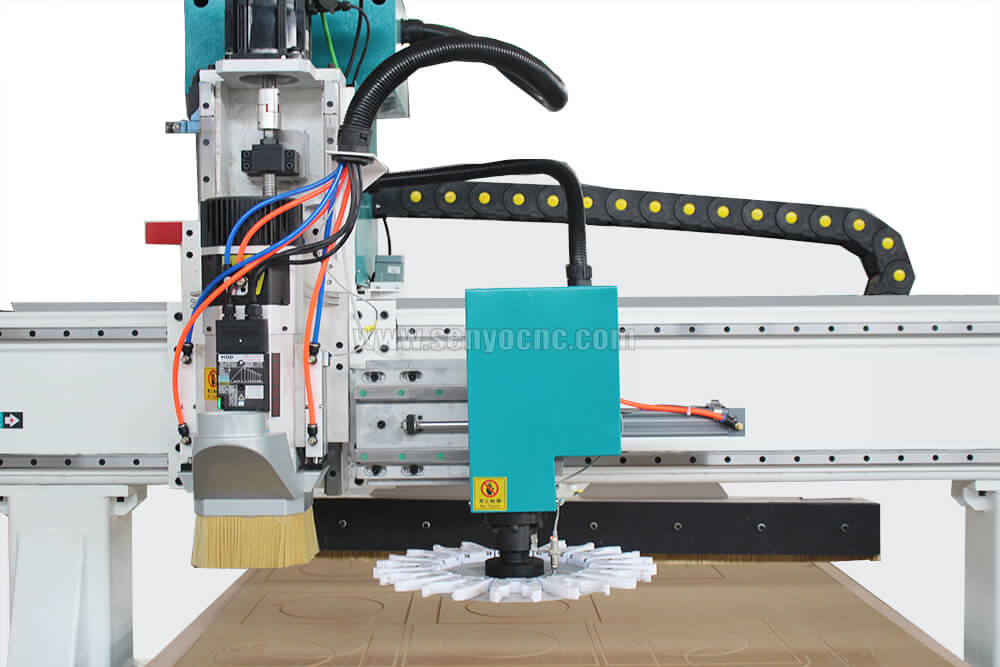

Working with a linear automatic tool changer to maximize woodworking automation,

Vacuum table to hold the workpiece more firmly, and a dust collector to keep wood chips out.

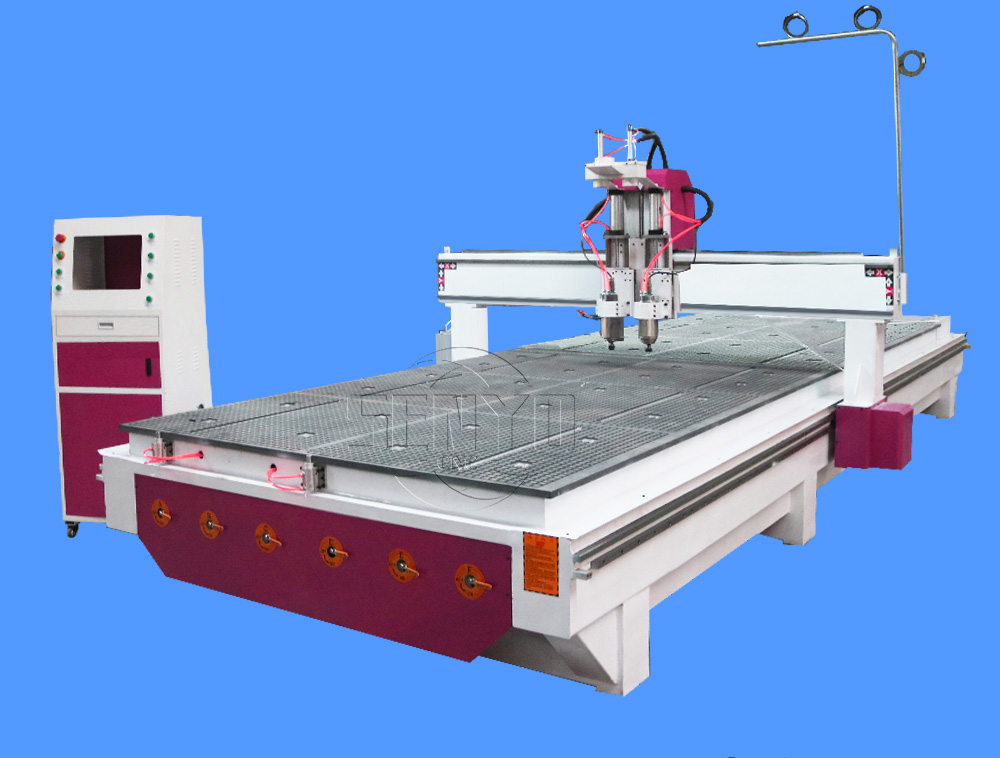

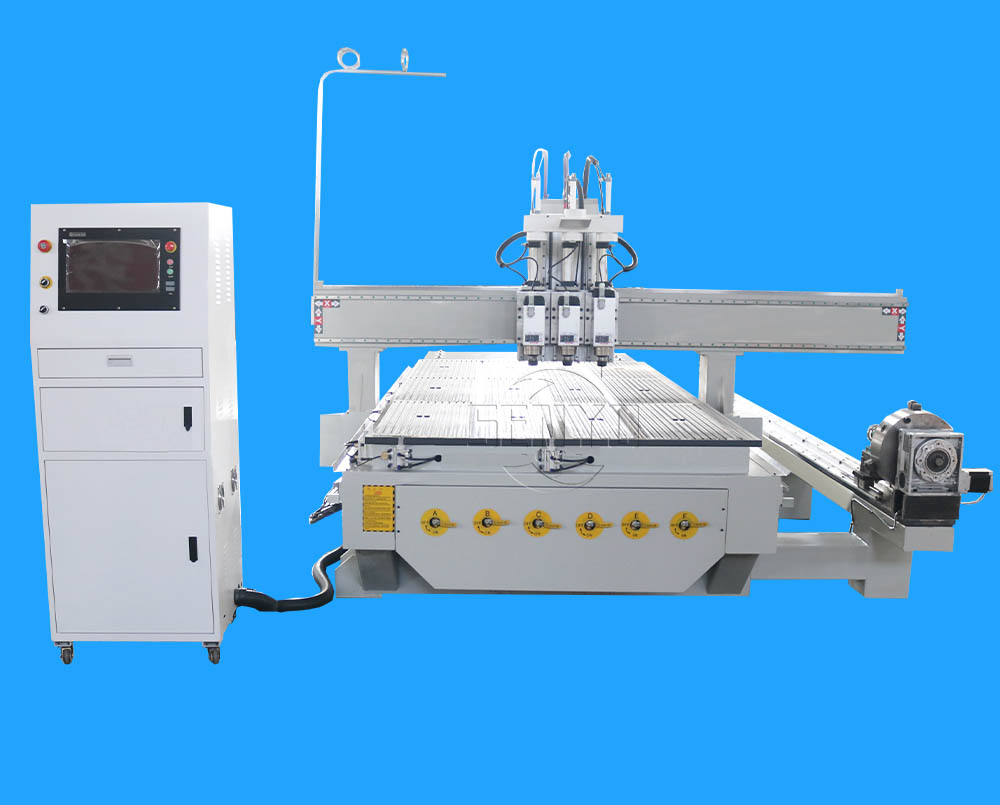

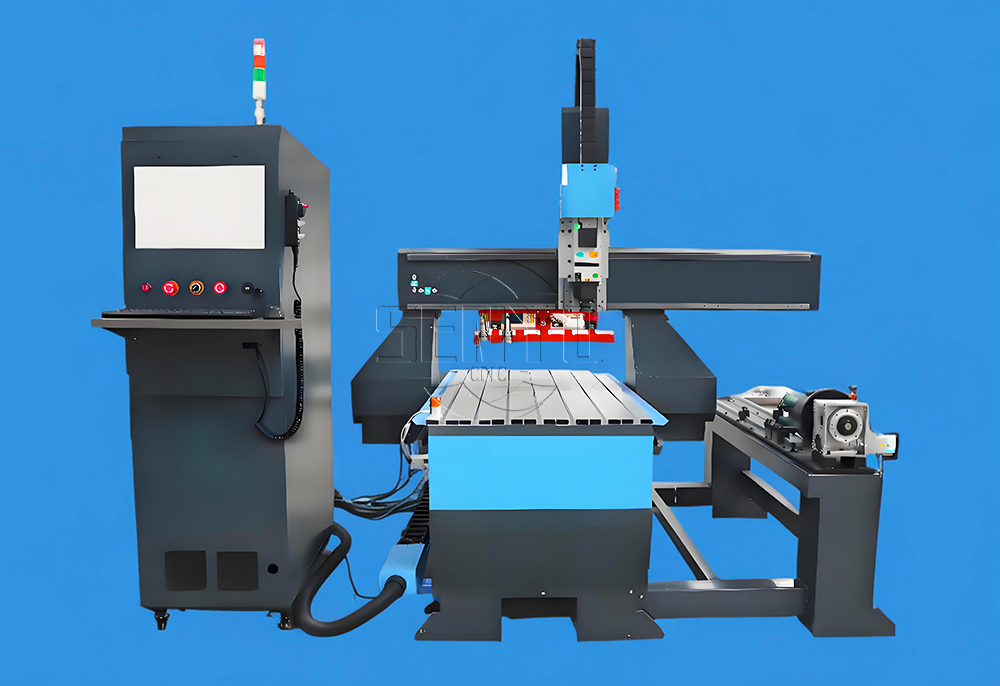

Machine color design for option

Machine with A1 Structure

Machine with A2 structure

Machine with A3 Structure

Features & Advantages of Industrial 5x10 CNC Router Table with Tool Changer

• Sturdy steel tube construction bed features a heavy-duty design for a solid structure and stress relief for a more stable workbench.

• 9.0KW air-cooled ATC spindle is easy to use without water pump required.

• High-performance 1500W servo motor runs smoothly with strong overload capability.

• Linear automatic tool changer kit with 12 tools for fast and reliable changes.

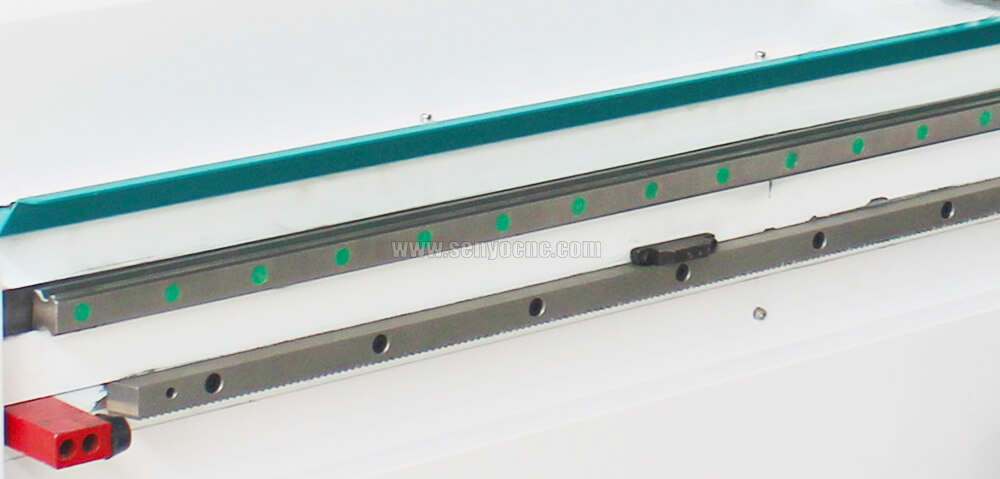

• Automatic lubrication system for maintenance of ball screws, positioning bearings and linear guides.

• The breakpoint memory feature allows the machine to continue cutting after a power outage and predicts the processing time.

• Compatible with Artcam, Type3, Castmate, Ucancame, and other CAD/CAM software.

• Hiwin rail guide with gear rack transmission

Applications

Applicable Materials

Wood, MDF, plywood, acrylic, artificial stone, artificial marble, bamboo, organic board.

Double-color board, PVC board, copper, aluminum, brass, and other materials.

lightbox, acrylic cutting, display panels, decorations, LED/Neon channel, billboard, 3D letters cutting, literal hole cutting.

Artworks & Decorations: Wood crafts, jewelry box, gift box, and more exquisite arts & crafts.

Music Industry: Musical instruments and loudspeaker box.

Applicable Industries

Woodworking: Home doors, windows, beds, cabinets, tables, chairs, kitchenware, exquisite european furniture

Redwood classical and antique furniture, decorative products sculpture.

Mold Making: Copper molds, aluminum molds, metal molds, building models, shoe molds, badge molds, biscuit

Chocolate molds, embossed molds, candy molds, plastic sheeting, artificial marble, wood, foam, PVC, and more nonmetal mold.

Advertising: Signage, logo making, company plate, sign making, emblem, badges, building numbers

Technical Parameters of Industrial 5x10 CNC Router Machine with Tool Changer

Model | SYM1530-D2A2 |

Working Area | 1500x3000x300mm |

Table Size | 5' x 10' |

Traveling Positioning Accuracy | 0.03/300mm |

Repositioning Accuracy | 0.03mm |

Table Surface | Vacuum and T-slot Combined (Option: T-slot table) |

Frame | Welded structure |

X, Y Structure | Hiwin Linear Rail, Helical Rack & Pinion Drive, |

Z Structure | Hiwin Linear Bearings & Rails, TBI Ball Screw |

Max Rapid Travel Rate | 50000mm/min |

Max Working Speed | 30000mm/min |

Spindle Power | Air Cooling ATC Spindle 9KW |

Spindle Speed | 0-24000RPM |

Drive Motors | Leadshine servo motor 1500W + reducer |

Working Voltage | AC 380V/50/60Hz, 3PH or AC 220V/50/60Hz |

Command Language | G Code |

Operating System | SYNTEC / LNC CNC Controller |

Flash Memory | 128M |

Collet | ER32 |

X,Y Resolution | <0.03mm |

Software Compatibility | Type3 and Ucancam software (Option: ArtCAM Software) |

Running Environment and Temperature | 0 - 45 Centigrade |

Relative Humidity | 30% - 75% |

How Much Does A 5x10 CNC Router Cost?

If you're starting a profitable woodworking business or looking to make money with a 5x10 CNC machine,

you might want to consider the price of a 5x10 CNC machine in calculating the cost to CNC machining.

5x10 CNC routers are priced from US$5,080 to US$18,000, depending on the configurations,

including the machine bed, X, Y table (T-slot table or vacuum table),

CNC controller, gantry, spindle, guide rail, ball screw, vacuum pump, motor, driver, software, collet, operating system,

4th rotary axis, power supply, limit switch, rack and pinion.

5x10 CNC table kits from different manufacturers and brands have different customer service and support, which will lead to different costs.

5x10 CNC machines from different countries have different different shipping costs, different customs, and tax rates. All will result in the final price.

Most entry level 5x10 CNC router kits for beginners start at US$4,080 and up to US$6,280,

while the professional 5x10 CNC table kits with multi spindles range from US$6,180 to US$15,000,

and the industrial 5x10 CNC router machines with automatic tool changer can cost anywhere from US$13,800 to US$223,000

Industrial 5x10 CNC Router Machine for Woodworking Project

Different types of 5' x 10' CNC machines vary in features and capabilities,

and how to choose the best one for your budget and needs is a puzzle.

But we has collected a wide range of popular and professional 5x10 CNC routers for every purpose - from hobby to enterprise,

from home to commercial use, and gives you high performance and professional routing experience at a great price -

from budget friendly models to top-of-the-line.

Overall, you can easily find and buy the best model from our selection for your budgets and needs, whether you're an expert or a beginner.

Let's take you hands-on with all new 5x10 CNC table kits, and help you save time and money with smart tips.

Service & Support for Industrial 5x10 CNC Router Kits with Automatic Tool Changer

In order to expand awareness and enhance corporate image,

we adhere to the spirit of "pursuing high quality and customer satisfaction in everything" and the standards of "excellent product quality,

outstanding service and support, strict corporate management" to work with you in good faith cooperate.

Quality Control

• For quality inspection, we sincerely invite you to inspect the entire manufacturing process on-site or via live video,

as well as experience the performance of the product in person. The product will be packed and shipped after it's confirmed to be qualified.

• Quality inspection records and data in the 5x10 CNC wood carving machine manufacturing are available.

Pricing

• Under the same competitive conditions, We will sincerely provide you with most affordbale prices

on the basis of not reducing the technical performance of the 5x10 CNC wood cutting machin or changing product components.

• In order to maintain the high performance and stability of the product, the raw materials come from world-renowned brand manufacturers.

Delivery Time

• When delivering the product, we will provide the following documents to you:

- Instructional documents and videos.

- Technical maintenance and repair manual.

- List of wearing parts and additional accessories.

• Shipping typically takes 15-30 days, but If there are special requirements that need to be completed in advance,

we'll try our best to organize specially manufacturing to meet your requirements

How To Choose The Right Router Bits for Woodworking?

What router bit to use for woodworking will strike the final quality, accuracy and appearance of your woodworking project.

Choosing appropriate cutting tools according to different materials and techniques will take hold of fast and efficient machining.

Which tool is best for woodworking? What is each tool used for in woodworking?

• Flat bottom or column router bits, mostly rely on the side edge for cutting, and the bottom edge is mainly used for flat polishing.

The end face of the head of the column router bit is large, and the working efficiency is high.

It is mainly used for contour cutting, milling plane, area and surface rough carving.

• Another relatively common type is straight, which is often used to carve large characters.

The edge of the material cut by it is straight, which is generally used for PVC and acrylic cutting to make characters.

• Milling cutter is the most common tool in automatic woodworking.

Milling cutters are divided into many types according to their shapes.

For example, double-edged spiral milling cutters used when cutting acrylic and MDF,

single-edged spiral ball-end milling cutters for large deep relief processing of cork, MDF,

solid wood, and acrylic. It is a prismatic milling cutter used when making high-density boards, solid wood doors, and furniture.

Of course, many tool manufacturers will also make special tools according to the special requirements of many customers,

such as large chip-removing spiral milling cutters that are more suitable for cutting density boards and chip removal.

The round bottom cutter is more suitable for precision small relief carving.

• The cutting edge of a ball end tool is arc-shaped, forming a hemisphere during the carving process of the wood cutting machine,

the process is evenly stressed and the cutting is stable. Ball tools are not suitable for milling planes.

• Bullnose bit is a mixture of fluted column bit and ball end bit. In addition, it has the features of a ball end bit to carve curved surfaces,

and on the other hand, it has the features of a fluted column bit and can be used for plane milling.

• Tapered flat bottom bits, abbreviated as tapered bits. They have the widest range of applications in the carpentry.

The bottom edge of the cone bit, commonly known as the tip, is similar to a column bit, and can be used for the finishing of small planes.

The side edge of the cone bit is inclined at a certain angle to form an inclined side surface during the working process.

The structural features of the cone bit can enable it to achieve the unique three-dimensional angle clearing effect of the carving industry.

Cone bits are mainly used for single-line carving, area rough carving, area fine carving, 3D clear angle, projection carving, image gray scale carving.

• Tapered end mill, referred to as tapered ball nose bit. It's a mixture of cone milling cutter and ball milling cutter.

Furthermore, it has the features of a cone cutter with a small tip, and on the other hand,

it has the features of a ball bit, which can mill relatively fine curved surfaces.

• Tapered bullnose bit is a mixture of cone bit and bullnose bit.

Moreover, it has the features of a cone shaped bit to cut relatively fine curved surfaces,

and on the other hand, it has a bullnose shaper cutter. Because of its features, the tapered bullnose router bit is often used for relief carving.

• The V-Groove router bits are designed to cut deep or shallow V-shaped grooves.

• Drill bits are mainly used for drilling. When the hole is relatively shallow, clearing bottom router bits can be used to drill holes.

How To Install and Use 5' x 10' CNC Machining Tools for Beginners?

The installation and operation of the router bit is a very important task for precise cutting and milling.

Improper installation of the bit will increase the wear, and cause inaccurate accuracy and difficulty in machining, which must be paid enough attention to.

We will share the following methods for proper installation and use of router bits and tools for beginners and professionals alike.

• Before installing the tool, check the wear of the bit first.

If there are defects such as chipping or severe wear, replace the bit with a new one or use it after it is repaired to make accurate cuts.

• The relevant surface must be cleaned and wiped clean before installation,

and the gasket and hole burrs must be carefully removed to prevent dirt and burrs from affecting the accuracy of the tool installation position.

• When clamping the tool with a washer, the two ends of the washer must be as parallel to each other as possible.

If it is found that the bit is skewed after installation,

the position of the washer should be adjusted to minimize the cumulative error of the washer. Until the bit does not shake after driving.

• Straight shank milling cutters are usually installed with spring chucks.

When installing, tighten the nut to make the spring sleeve shrink radially to clamp the shank of the milling cutter

• Installation of taper shank milling cutter:

When the size of the taper shank of the milling cutter is the same as the taper hole at the end of the spindle,

it can be directly installed in the taper hole and tightened with a tie rod. Otherwise, use transitional taper sleeves for installation.

• After the tool holder is inserted into the spindle, tighten the bit with the tightening screw.

It should be noted that the direction of rotation of the bit must be consistent with the thread direction of the tie rod,

so that the thread of the tie rod and the milling cutter can be connected more tightly during rotation, otherwise the milling tool may come out.

• Without affecting the routing, try to make the bit as close to the spindle bearing as possible,

and make the hanger bearing as close as possible to the bit. If the bit is far away from the main bearing,

a rack bearing should be installed between the spindle bearing and the milling cutter.

• When installing the bit, the key should not be removed. Because there is no key on the cutter shaft,

if there is uneven force during milling or under heavy load cutting, the bit tends to slip. At this time,

the cutter shaft itself bears great radial resistance and resistance, which will easily cause the cutter shaft to bend, and damage to the fixing gasket.

• After the bit is installed, check all the related washers and nuts again to prevent loosening.

And use a dial indicator to check the radial jump or end jump of the bit to see if it is within the allowable range.

• After the tool axis shaft is removed, it should be hung on the rack to prevent the tool axis shaft from bending and deforming.

Under special circumstances, when it needs to be stored horizontally, wood chips or soft items should be used to pad it to prevent scratches and deformation.

Things To Consider

Drive System

At present, the driving system of the engraving machine is mainly divided into two types: the stepping system and the AC servo system.

The stepping system belongs to the semi-closed loop system, and the precision is calculated by the step angle.

The AC servo system belongs to the closed-loop mode completely, and there is a measurement feedback system inside,

so the accuracy is relatively high. If the funds are sufficient,

Users who have higher requirements on the engraving machine can choose the machine with the AC servo drive system.

CNC Controller

The control system of the 5x10 CNC machine is currently dominated by Weihong controller, DSP controller,

MACH3 controller, LNC control system, and SYNTEC controller. The difference is not too more, and users can choose according to their actual needs.

CAD/CAM Software

There are many CAD/CAM softwares for CNC machines, but the most common ones on the market are TYPE3 and Artcam.

These softwares can import CAD drawings well, and can further do simple graphic processing.

Transmission Mode

There are three transmission modes of the CNC machine, namely screw drive, rack drive and synchronous belt drive.

The advantages and disadvantages of different transmission modes are different. You can choose according to your actual needs.

Trial Machining Before Buying

Before the official purchase of the machine, you can conduct a trial machining first,

use the pattern that needs to be cut from yourself, and see what the sample actually cut by the machine is, so that you can know what you want.

Linear Tool Changer VS Disc Tool Changer - Which Is Better?

Automatic tool changer kits come in linear and disc tool changers.

The mostly used linear tool changers include 8-tool, 10-tool, and 12-tool.

Nowadays, most users choose the 12-tool tool magazine.

The linear tool magazine can be installed under the gantry or behind the bed.

In comparison, the tool magazine under the gantry has faster tool changing speed and lower guide rail wear.

In addition, The linear tool changer does not rely on drives and motors like servo tool magazines,

so it lacks a set of drives and motors. The cost will be lower and the price is more affordable than conventional ones.

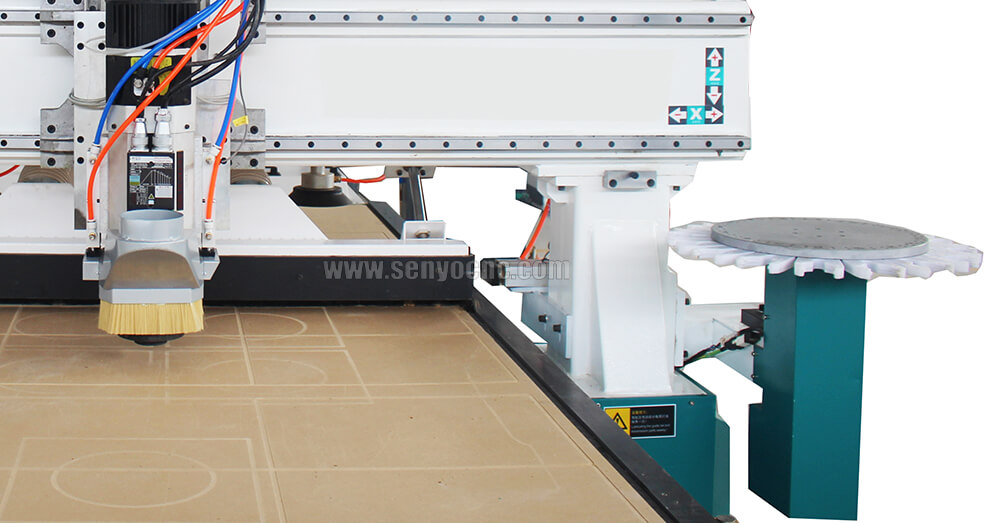

Disc tool changer (also known as drum tool changer) is typically installed next to the spindle or on the side of the gantry.

The advantage of the former is that the tool change speed is faster, usually within 14 tools, and 16 or 20 tools for option.

If 20 tools are used, the load-bearing requirements of the Z-axis and the gantry are too high,

especially the screw rod and the guide rail slider require high strength.

After long-term use, the accuracy decreases quickly. The tool magazine installed on one side of the gantry can hold 12-20 tools with strong stability.

The tool changing speed is a little slower than that next to the spindle, but the machine accuracy and stability are not affected.

Compared with the linear tool changer, the disc tool changer can change tools faster and with higher accuracy.

However, the cost of the disc tool magazine is higher for an additional set of servo drives and motors.

The automatic tool changer kits typically works with Yaskawa servo and SYNTEC control system,

and the cost is relatively higher. WEIHONG and LNC CNC controller are optional with corresponding servo and lower cost, but there is not much difference in performance.

After-Sales Service

• Service Goal - Excellent service quality wins customer satisfaction.

• Service Tenet - Fast, decisive, accurate, thoughtful and thorough.

• Service Principle - The product warranty period is 24 months. During the warranty period,

we will repair and replace parts damaged due to quality reasons free of charge.

If parts are damaged outside the warranty period, only the cost will be charged for the parts provided.

For machine damage caused by human factors on the customer, repairs or accessories will be priced at cost.

Outside the warranty period,we's technical staff will follow-up on customers via mail or calling more than three times a year to investigate the user's usage.

• Service Efficiency - If your machine fails to run during or outside the warranty period, we can get in touch with you within 24 hours after receiving your notification.

Packing & Shipping

1. Outside package: Standard plywood package.

2. Inner package:Stretchy film and plastic protective film for humidity.

3. We can package according to your requirements.

For

standard machines, 7-15 working days after payment.

Service & Support

1. Our engineers available to service machinery overseas.

2. 2 years guarantee for the whole machine.

3. Technical support by calling, mail, whatsapp and skype. If you have any problems, we will help you to solve it within 12 hours.

4. You will be get free training advice towards our machine in our factory.

5. If you need any component of the machine, we will provide most affordable price for you.

6. Friendly English version manual and operation video CD disk.

Tool change cnc router machine ,ATC CNC Router, cnc router , round tool change machine, cnc wood center

• Previous: Cabinet Door Woodworking Furniture With Disc Round Tools changer and uploading unloading table

• Next: ATC 3D CNC Woodworking Router with 4th Axis Rotary Table

Fiber metal Laser Sensor And Its Application

Category: SENYO NEWS 11th Mar, 2021A CNC wood router will use 3D machining in relief carving, the effect is more artistic beauty, but also has a strong sense of three-dimensional 3D, realization of this function is to ...

Precision Cutting Stents with Fiber Lasers

A CNC wood router will use 3D machining in relief carving, the effect is more artistic beauty, but also has a strong sense of three-dimensional 3D, realization of this function is to ...

How to Laser Cut Copper and Other Reflective Metals

Laser cutting of mild steel and stainless steel has a long history and has been one of the primary applications for CO2lasers. However CO2lasers have not traditionally offered a good solution for cutting highly reflective materials.Fiber lasers have an emission wavelength of around

Laser Cutting Machine Inspection Process For Manufacture

SENYOCNC Have Strict quality monitoring will be carried out when the parts are in the factory.

How Control Costs Use of UV Printers ?

UV flatbed printers are rapidly being used by more and more manufacturers, thanks to its efficient production efficiency, and the control of production costs also needs to arouse our attention.

Why UV flat printing machine is popular in market ?

For the majority of designers, give full play to the creative ability, the design sample can be arbitrarily modified on the computer, the effect on the computer, is the effect after the finished product, customer satisfaction can be directly produced. UV flat printing pattern fine, rich and clear layers, high artistry, strong three-dimensional sense, many high precision equipment can also print photography and painting style patterns.

How does UV ink jet printer save UV ink?

UV inkjet printer use process is an important consumable UV ink, reasonable use of equipment, can save UV ink , it can be said to be the best choice to directly save the cost. In the process of using some skills you need to be familiar with, the following small make up to share with you:1. Try to us

Waterjet Machine delivery and Shipping

Please tell us your max working size and what materials will cutting , also what max cutting thickeness.If you have Working photo sample please also send us , it will be helpful to choose machine with suitable models .

Waterjet Machine finish manufacture 5axis

Waterjet cutting technology is one of the fastest growing major machine tool processes in the world due to its versatility and ease of operation.

Waterjet Machine delivery and Shipping

Waterjet cutting technology is one of the fastest growing major machine tool processes in the world due to its versatility and ease of operation.There are multiple advantages to adding waterjet cutting capabilities to your shop.We are company leading ultrahigh-pressure waterjet system so

How to Create Connected Text – Inkscape for Laser Cutting

Step 1: Create Some TextFirst, we need some text to work with. To create the text, select the Text Tool (keyboard shortcut: T), click somewhere on the canvas, and type your text.You can use the drop-down list on the top left to select your desired font.Step 2: Convert Text to PathNext, we need to tu

Jacob from United States

I am a beginner at CNC, I’ve never used a CNC machine before and with in a day I was carving. An awesome machine for a beginner to learn as hobbyists. I used the manual and the help video. One hour to assemble and test, very friendly and easy to use. It’s a good buy for the money. I would definitely recommend this machine to someone getting into CNCs.

Weinstein from France

I've been using CNC plasma SYP2060-300A and I am very impressed with this unit.

This unit is of higher quality, made in China. Five stars all the way!

2040 from INDIAN

Best 2040 CNC Router Good Price and Quality ! Thank SENYOQC

10w uv laser from American

Best supplier ! I bought 3 machines for laser and router , thank you Aillen ! --Alec

12KW Fiber Cutting - 2000X6000mm -- 이병헌 from Korea

Good machine for metal cut ! Thanks Senyo , Its prefect , I like your business patient kind!

I am a furniture manufacturer, and this machine is very good and fast. thanks Senyoqc Team ! from Bangladesh

Metal ArtWork from Denmark

The plasma cutting machine makes my artistic creation more convenient and precise!! Created more artistic ideas and value! Thank you Aillen team!

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen. from

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen.

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo from

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo

Thank you Senyo for SYJ1290-150W! from

Retired, ex mainframe systems programmer. Now full-time recreational woodworker majoring in puzzles, pens, boxes, Toys and occasional small furniture. Thank you Senyo for SYJ1290-150W!

manager@senyocnc.com

manager@senyocnc.com

SENYOCNC

SENYOCNC

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

2061579344

2061579344