150x150mm, 175x175mm, 200x200mm, 300x300mm,The small the lens, the powerful the laser beam.,

small lens more suit for cutting work. If user want cut and big area mark, can buy extra lens.

+86 1525 3141 880

+86 1525 3141 880

SYJF50W

Fiber Laser Marking Machine

4059

SENYOQC

/5 based on 310votes/5 based on votes

/5 based on 310votes/5 based on votes

2200USD / Set

2200USDto 2200USD-3600USD / Set According to Configurations

100 Sets / Month In stock! From - Jinan Senyo Machinery Co.,Ltd / Month In stock! From - Jinan Senyo Machinery Co., Ltd

T/T(Telegraphic Transfer), Mastercard, Visa, e-Checking

What is Deep Laser Engraving Machine?

Fiber laser deep engraving machine is a type of laser engraving machine which adopts fiber laser souce for metal deep engraving.

A fiber laser engraver is the best way to engrave metals without tools.

Fiber laser deep engraving machine is also known as laser metal engraving machine,

metal laser engraving machine, laser etching machine for metal, laser deep engraving machine,

deep laser etching machine, laser metal deep etching machine, metal laser deep engraving machine, metal laser engraver, laser metal engraver, laser etcher for metal.

In some technological occasions, such as molds, guns, jewellery, auto parts and conventional materials such as steel,

ceramics, gold, silver, copper and aluminum in the aerospace industry, as well as new materials such as silicon carbide,

nickel-chromium alloys, and thermal barrier coatings, it is necessary to The outer layer is stripped deeply to achieve a clearer visual result

(such as dots, lines, notches, etc.) and to facilitate subsequent processes (such as plate making, painting, welding).

In addition, because the marking object must be placed in a harsh environment, the adhesion of the marking result is very high,

and the marking needs to be deeply attached to the base material without peeling off due to weather, humidity, external force, etc.

Traditional methods such as electrical (chemical) corrosion and other methods,

the process is relatively cumbersome and the process that meets the accuracy requirements is difficult.

At the same time, the high pollution of related chemicals makes many companies bear greater pressure on energy conservation and emission reduction.

The surface treatment of laser thermal processing can have micron precision,

a good laser light source that can have a benign effect on the material + customizable laser guidance system + various control systems

can ensure fast and deep results, and flexible software functions It can also define the preset engraving content.

Therefore, the laser deep engraving process has begun to have a larger market.

Laser deep engraving is actually another form of laser marking. It is a laser marking process in the longitudinal sense of the material

(similarly, cleaning, passivation and cladding have the same effect)Generally speaking,

the specific laser engraving depth of the material is directly related to the following factors.

1. Specific material.The selection of the laser light source that determines the ideal absorption

efficiency-a multi-faceted measurement of factors such as specific brand, process characteristics and budget.

2.The laser power of fiber laser generator.Generally speaking, under other conditions unchanged,

the power of the light source is proportional to the depth.

3. The length of the process time.It directly determines the depth of the logo.

4. The surface condition of the material.Whether it’s smooth, shiny, rough,

and whether it has been treated with wire drawing, anodic oxidation, electroplating, phosphating, passivation, blackening lead water, etc.

Different coatings have different laser absorption reactions, and the surface state directly determines the absorption results,

such as laser on frizzy surfaces. The mark will have discontinuous laser traces,

and some dark shadows will directly affect the aesthetics of the mark.

5. The scanning range of laser marking & engraving content.This is determined by the laser focusing optics.

Generally speaking, the larger the range, the more difficult it is to engrave

Technical Parameters of 50 Watt Fiber Laser Deep Engraving Machine for Metal

Brand | SENYOQC |

Model | SYJF50W |

Laser Power | 50W |

Laser Wavelength | 1064nm |

Fiber Cable Length | 3m |

Pulse Width | 20ns |

Repetition Frequency Range | 1-600kHz |

M2 | <1.8 |

Max.Single Pulse Energy | 1.25mJ |

Output Power Stability | <5% |

Output Beam Diameter | 7±0.5mm |

Power Range | 0-100% |

Marking Range | 110*110mm/200*200mm/300*300mm |

Minimum Line Width | 0.01mm |

Minimum Character | 0.1mm |

Marking Speed | ≤7000mm/s |

Marking Depth | Depend on materials |

Repeatability Accuracy | ±0.001mm |

Marking Format | Graphics, text, bar codes, QRcode, automatically date, batch number, serial number, etc |

Graphic format supported | Ai, plt, ;dxf, dst, svg, nc, bmp, jpg, jpeg, gif, tga, png, tiff, tif |

Working Voltage | 220V±10%/50Hz or 110V±10%/60Hz or Customized |

Unit Power | <0.5kw |

Working Environment | Clean and dust free or dust less |

Working Condition Humidity | 5%-75%, 0-40 degree |

Free of condensed water Laser lifetime | >100000 hours |

Net weight | 120 kgs |

Packing Size | 770*870*1200mm |

Detial Parts Fiber Laser Deep Engraving Machine

Imported Scanning System

Equipped with the high speed scanning system (galvo head) imported from the USA, which has the advantages of stable laser output,

nice optical mode, excellent laser beam, fast marking speed, perfect effect and high efficiency, etc.

150x150mm, 175x175mm, 200x200mm, 300x300mm,The small the lens, the powerful the laser beam.,

small lens more suit for cutting work. If user want cut and big area mark, can buy extra lens.

Computer

Worktable Aluminum worktable , machine come with complately parts for fix material on worktable and operations .

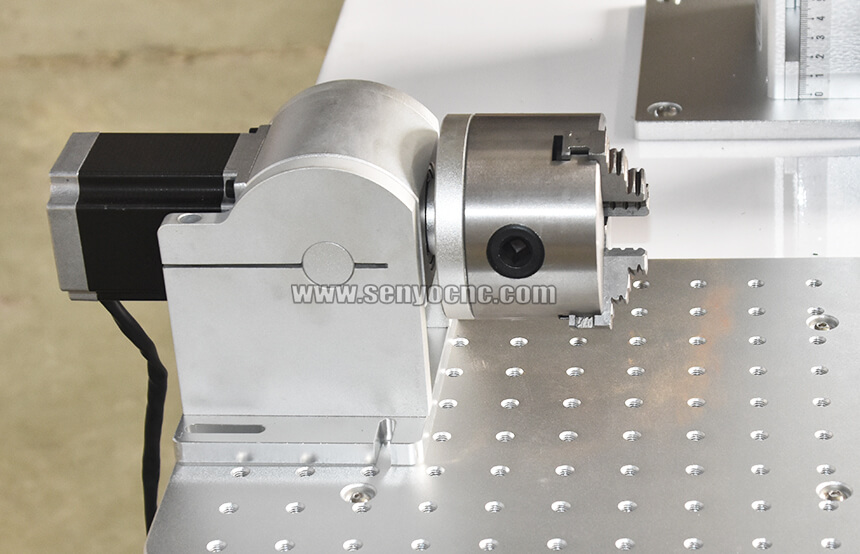

Rotary device, here have different rotary for choose depend on your work .

Table light on worktable

High Electro-optic Conversion Efficiency

Little energy coupling loss, running cost saving, long service life, maintenance-free within 100,000 hours.

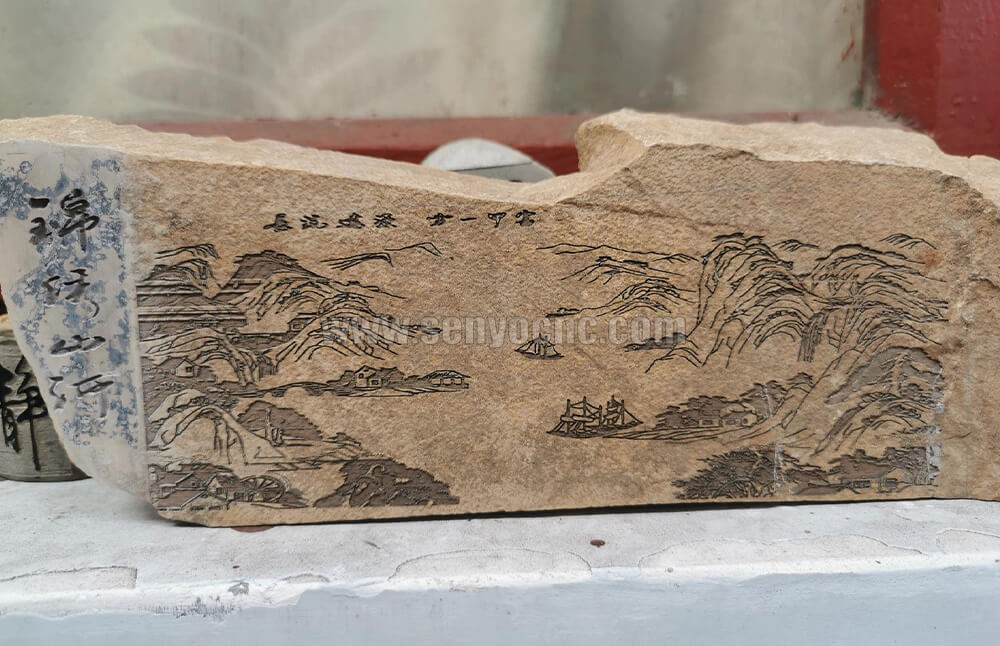

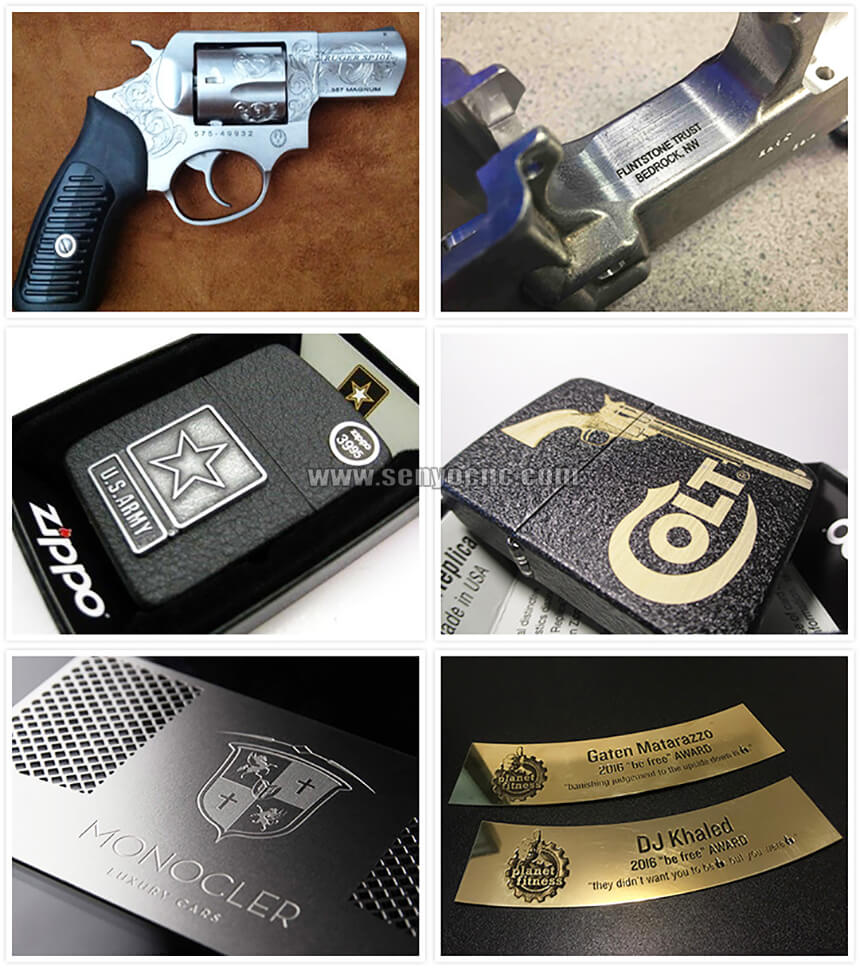

50 Watt Fiber Laser Deep Engraving Machine Applications

Fiber laser deep engraving machine is used for marking and engraving on metals ,stones

(stainless steel, aluminum, alloy, brass, sliver, gold, titanium, iron) and nonmetal surface,

such as guns, firearms, rings, bearings, gears, automotive parts, hardware and tools, aerospace components.

integrated circuit chips, computer accessories, watches, electronics and communications products.

home appliances, wire and cable, jewelry, adornments, necklace, bracelet and many other areas of graphics and text markup.

The deep laser engraving machine can also cut thin metals.

such as stainless steel, aluminum, alloy, brass, sliver, gold, titanium.

Technical Parameters of 50 Watt Fiber Laser Deep Engraving Machine for Metal:

How to Deep Laser Engrave Metal?

Generally speaking, laser engraving can be achieved by using higher power/higher frequency lasers,

concentrated scanning/multiple scanning and other process techniques. Higher power is easy to understand.

Higher output power means larger pulse energy per unit area and more natural depth.

At the same time, the current light source can be adjusted during laser processing (such as 10-100%).

Under the principle that the depth and the result need to be balanced (high power-fast speed-rougher shading;

low power-slow speed-finer shading and greater controllability), you can first use higher power to outline the main line direction,

and then sculpt the details with lower power.

Higher repetition frequency is an important indicator describing the number of laser pulses per unit time.

The higher the repetition frequency, the more the number of working pulses per unit time,

and higher quality processing results can be obtained during high-speed engraving.Concentrate and scan multiple times,

so there is no need to say more about this.The ergonomics of laser deep engraving is an important factor

that needs to be considered together with budget and laser parameter performance.Of course,

there are also some lasers for deep laser engraving technology. Customers can choose according to their budget and specific materials of processed parts.

Warranty of fiber laser deep engraving machine for metal

1. 2 years warranty for fiber laser engraving machine for metal.

2. Our customer will be fully trained for the operation and maintaining technology after the order confirmed.

3. 24-hour full after sales service: our skilled engineer will help customer to solve the problem by Whatsapp,

Skype, Teamviewer or Online Chat in time when problems happen, if necessary, overseas service is available.

Quality Control of fiber laser engraving machine for metal

1. Skilled and Strict Quality Inspection Team is available during the material purchasing and production procedure.

2. All finished machine we delivered are 100% strictly tested by our QC department and engineering department.

OEM Service for fiber laser engraving machine for metal

1. Customized and OEM orders are welcome due to our aboundant experiences.

2. All the OEM services are free, customer only need to provide us with your logo drawing, function requirements, colors, etc.

3. No MOQ required.

4. None of your personally identifiable information ( such as your name, address, email address, bank info, etc ) will be disclosed or shared with any third parties.

5. Contact: All of your inquiries or questions or helps will be answered within 24 hours, even in holiday, also, please feel free to call us if you have any emergency questions.

Payment Terms of fiber laser deep engraving machine for metal

1. 30% T/T paid in advance as deposit, the balance paid before shipment.

2. Alibaba Trade Assurance. International Shipping Around the World All the CNC laser machines can be shipped worldwide by sea,

by air or by international express logistics via DHL, FEDEX, UPS. You are welcome to get a free quotation by filling up the form with name,

email, detailed address, product and requirements,

we will shortly contact you with the full information including the most suitable delivery method (fast, secure, discreet) and freight.

International Shipping Around the World

All the CNC laser machines can be shipped worldwide by sea, by air or by international express logistics via DHL, FEDEX, UPS.

You are welcome to get a free quotation by filling up the form with name, email, detailed address, product and requirements,

we will shortly contact you with the full information including the most suitable delivery method (fast, secure, discreet) and freight.

Laser Engraving Metal, Laser EngraverMetal,Laser Engraving Machine,Laser Metal Engraver,Laser Metal Engraving Machine,Metal Laser Enrgaving,Deep Laser Engraving,Laser Engraving Metal,Metal Laser

• Previous: Fiber laser metal marking machine SYF-30W

• Next: Portable Fiber Laser Marking Machine for Sale at Affordable Price

A CNC wood router will use 3D machining in relief carving, the effect is more artistic beauty, but also has a strong sense of three-dimensional 3D, realization of this function is to ...

A CNC wood router will use 3D machining in relief carving, the effect is more artistic beauty, but also has a strong sense of three-dimensional 3D, realization of this function is to ...

Laser cutting of mild steel and stainless steel has a long history and has been one of the primary applications for CO2lasers. However CO2lasers have not traditionally offered a good solution for cutting highly reflective materials.Fiber lasers have an emission wavelength of around

SENYOCNC Have Strict quality monitoring will be carried out when the parts are in the factory.

UV flatbed printers are rapidly being used by more and more manufacturers, thanks to its efficient production efficiency, and the control of production costs also needs to arouse our attention.

For the majority of designers, give full play to the creative ability, the design sample can be arbitrarily modified on the computer, the effect on the computer, is the effect after the finished product, customer satisfaction can be directly produced. UV flat printing pattern fine, rich and clear layers, high artistry, strong three-dimensional sense, many high precision equipment can also print photography and painting style patterns.

UV inkjet printer use process is an important consumable UV ink, reasonable use of equipment, can save UV ink , it can be said to be the best choice to directly save the cost. In the process of using some skills you need to be familiar with, the following small make up to share with you:1. Try to us

Please tell us your max working size and what materials will cutting , also what max cutting thickeness.If you have Working photo sample please also send us , it will be helpful to choose machine with suitable models .

Waterjet cutting technology is one of the fastest growing major machine tool processes in the world due to its versatility and ease of operation.

Waterjet cutting technology is one of the fastest growing major machine tool processes in the world due to its versatility and ease of operation.There are multiple advantages to adding waterjet cutting capabilities to your shop.We are company leading ultrahigh-pressure waterjet system so

Step 1: Create Some TextFirst, we need some text to work with. To create the text, select the Text Tool (keyboard shortcut: T), click somewhere on the canvas, and type your text.You can use the drop-down list on the top left to select your desired font.Step 2: Convert Text to PathNext, we need to tu

Jacob from United States

I am a beginner at CNC, I’ve never used a CNC machine before and with in a day I was carving. An awesome machine for a beginner to learn as hobbyists. I used the manual and the help video. One hour to assemble and test, very friendly and easy to use. It’s a good buy for the money. I would definitely recommend this machine to someone getting into CNCs.

Weinstein from France

I've been using CNC plasma SYP2060-300A and I am very impressed with this unit.

This unit is of higher quality, made in China. Five stars all the way!

2040 from INDIAN

Best 2040 CNC Router Good Price and Quality ! Thank SENYOQC

10w uv laser from American

Best supplier ! I bought 3 machines for laser and router , thank you Aillen ! --Alec

12KW Fiber Cutting - 2000X6000mm -- 이병헌 from Korea

Good machine for metal cut ! Thanks Senyo , Its prefect , I like your business patient kind!

I am a furniture manufacturer, and this machine is very good and fast. thanks Senyoqc Team ! from Bangladesh

Metal ArtWork from Denmark

The plasma cutting machine makes my artistic creation more convenient and precise!! Created more artistic ideas and value! Thank you Aillen team!

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen. from

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen.

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo from

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo

Thank you Senyo for SYJ1290-150W! from

Retired, ex mainframe systems programmer. Now full-time recreational woodworker majoring in puzzles, pens, boxes, Toys and occasional small furniture. Thank you Senyo for SYJ1290-150W!