What is Laser Deep Engraving Machine?

Laser deep engraving machine is a type of professional laser marking system with fiber laser source for deep etching on metals.

A fiber laser engraver is the best marker to etch metals without mechanical tools, featuring with high precision, high speed and high quality

A laser deep engraving machine is also known as laser metal engraving machine, metal laser etching machine,

laser metal deep engraver, metal laser deep engraving machine, metal laser engraver, laser metal engraver,

laser metal etcher.Marking ultra-high components has advantages

In some technological occasions, such as molds, guns, jewelery, auto parts and conventional materials such as steel,

ceramics, gold, silver, copper and aluminum in the aerospace industry, as well as new materials such as silicon carbide,

nickel-chromium alloys, and thermal barrier coatings, it is necessary to The outer layer is stripped deeply to achieve a clearer visual result

(such as dots, lines, notches, etc.) and to facilitate subsequent processes (such as plate making, painting, welding).

In addition, because the marking object must be placed in a harsh environment, the adhesion of the marking result is very high,

and the marking needs to be deeply attached to the base material without peeling off due to weather, humidity, and external force.

Traditional methods such as electrical (chemical) corrosion and other methods,

the process is relatively cumbersome and the process that meets the accuracy requirements is difficult.

At the same time, the high pollution of related chemicals makes many companies bear greater pressure on energy conservation and emission reduction.

The surface treatment of laser thermal processing can have micron precision,

a good laser light source that can have a benign effect on the material + customizable laser guidance system + various control systems can ensure fast and deep results,

and flexible software functions It can also define the preset engraving content. Therefore, the laser deep engraving process has begun to have a larger market.

Laser deep engraving is a longitudinal fiber laser marking process that uses advanced fiber resonance technology,

which effectively improves the power density and beam quality of the laser,

allowing the laser to quickly sublimate metal materials into gas in a short time and reduce the thermal impact range.

And with high repetition frequency, the borders or outlines of fonts or graphics are more vertical, and burrs are effectively reduced,

and the bottom texture is clear and beautiful. It only takes one time to complete a series of traditional corrosion process operations,

and requires no consumables and chemical agents, which reduces the cost of use.

The specific laser engraving depth and speed is directly related to the following factors.

• Metallic Materials

The features of different metals have different effects on the deep engraving speed.

Aluminum comes with the lowest melting point, so aluminum deep etching speed is the fastest under the same conditions.

• Pulse Width

Large pulse width is fast and the shading is rough. The small pulse width is slow and the shading is fine.

The pulse width increases and the engraving depth increases. In practical applications,

it is necessary to select appropriate parameters according to the needs of deep etching and take into account the speed and quality of deep engraving.

• Laser Source

The selection of laser source determines the absorption efficiency, which must be measured in multiple aspects such as specific brand, process and budget.

• Laser Power

When other conditions remain unchanged, the power of the laser generator is proportional to the depth.

• Engraving Time

Laser deep engraving is a process of repeated etching many times. The length of engraving time directly determines the depth.

• Surface Condition

Whether the metal surface is smooth, shiny, rough, and whether it has been treated with wire drawing, anodizing,

electroplating, phosphating, passivation, and blackening. Different coatings react differently to laser absorption, and the surface state directly determines the absorption results.

• Scan Range

This is determined by the laser focusing optics. The larger the scanning range, the more difficult the etching will be and the slower the deep engraving will be.

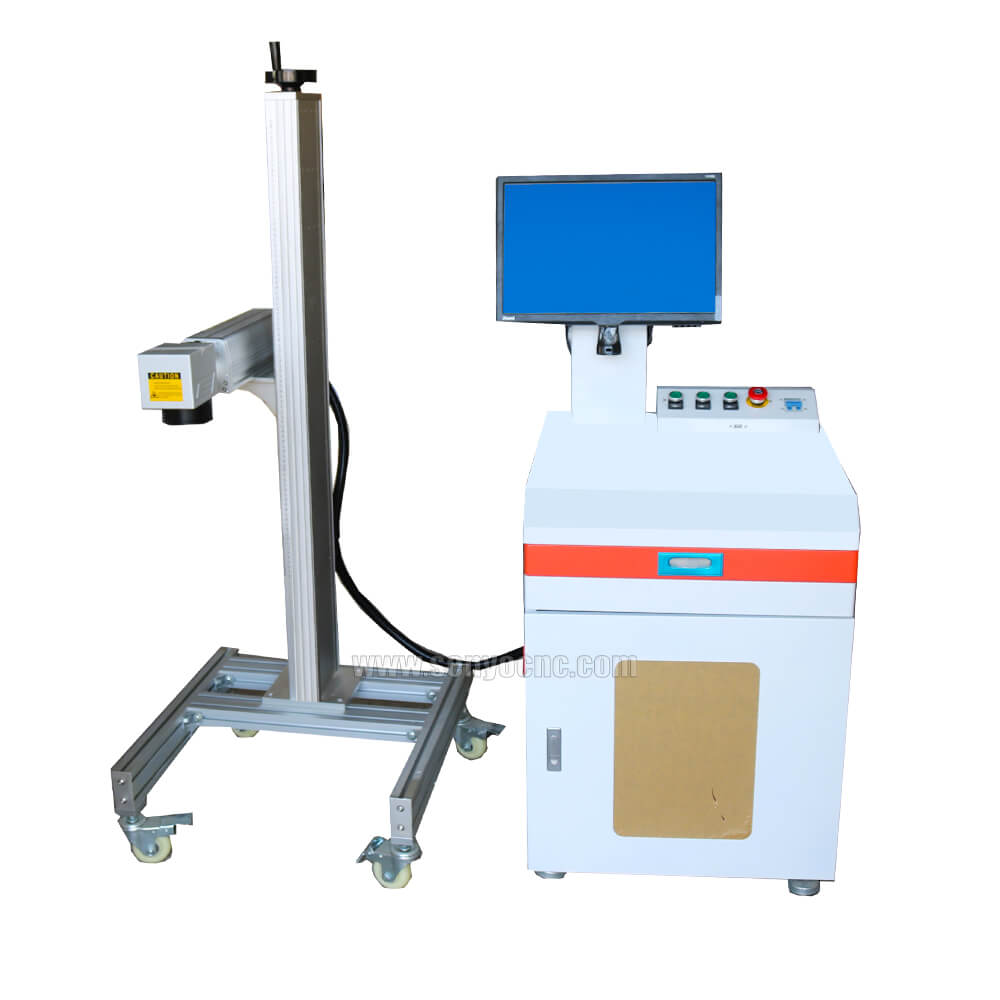

Feature of Laser Marking Machine

No consumables, long service life, maintenance free

Long life, maintenance-free within 100,000 hours, operated in 24 hours and severe working condition;

Multiple power laser light source, available for many industries;

Fast speed, high efficiency, stable output power, high reliability;

Easy to operateHigh electro-optic conversion efficiency, little energy coupling loss, less power consumption with just 0.5 KW/Hour;

Small and compact size, easy to carry, save production space.Patented software, Supports almost all commonly used formats

Parts Detials

LASER SOURCE MAX/Raycus/JPT, top laser brands in China.Lifetime can be up to 100,000 hours.

Galvanometer

Scanning galvanometer, full digital signal, super anti-interference ability.High precision, short delay, fast speed, small

temperature drift, especially suitable for all kinds of high precision, high speed marking requirements.The fiber wavelength is 1064nm.

Singapore Field Lens

Famous brand field lens Wavelength Higher energy conversion rate,

fast speed and long life.75MM*75MM ,100*100MM,150*150MM ,200*200MM ,300*300MM ,

Above working area optical Same power for example 20W if working area smaller,the marking depth by one time is bigger

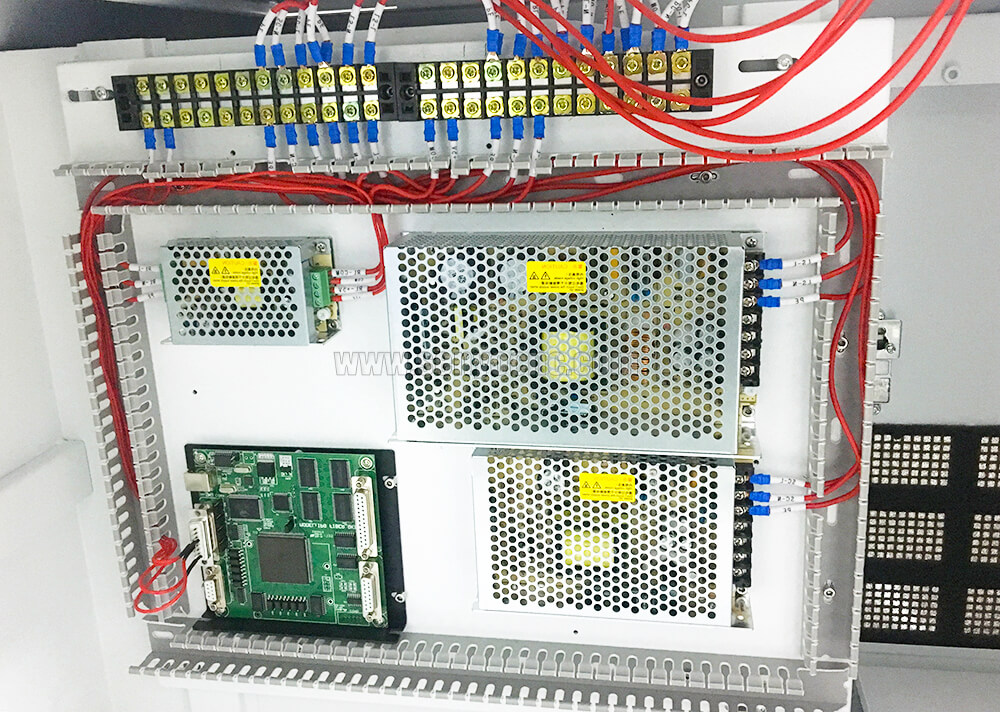

Beijing JCZ Mainboard

Multi-language setting, stable marking, friendly user interfac

Meanwell power supply

configured with high precision

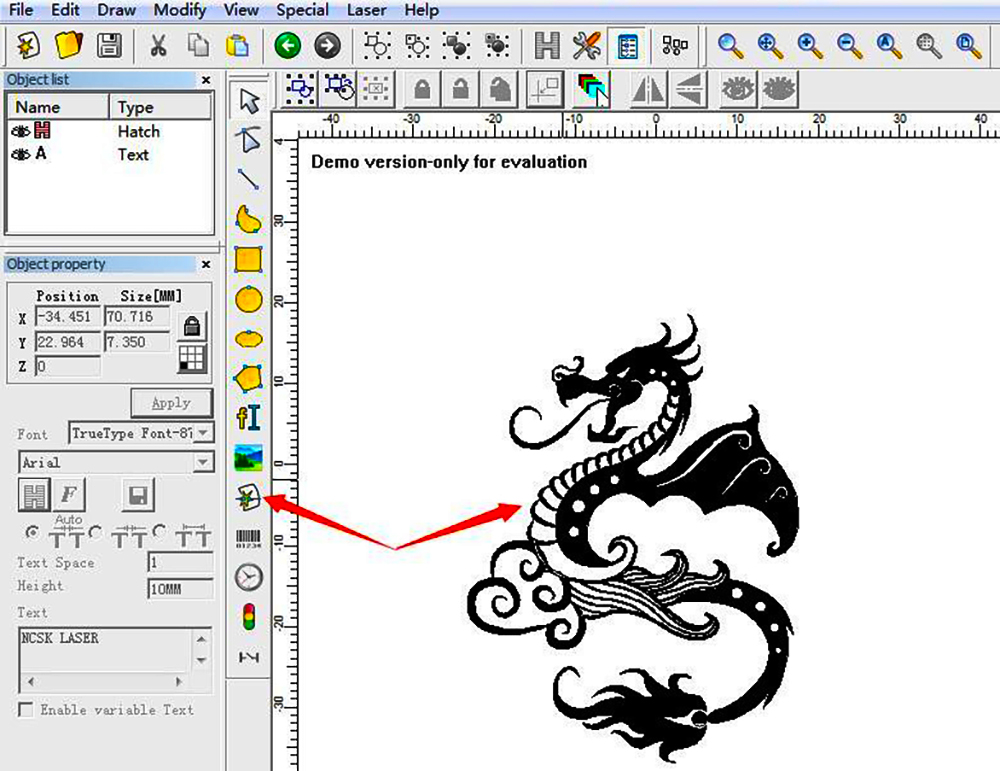

EZCAD Software

Powerful editing function, easy to use, Support any pattern, text, QR code and other processing.

Control software, beautiful interface, powerful function, detailed parameters, simple operation, can describe any pattern, text,

bar code, two dimensional code processing.

Vector graph Marking

The vector graph that designed by Coreldraw/AUTOCAD /Illustrator can be imported to the laser software.

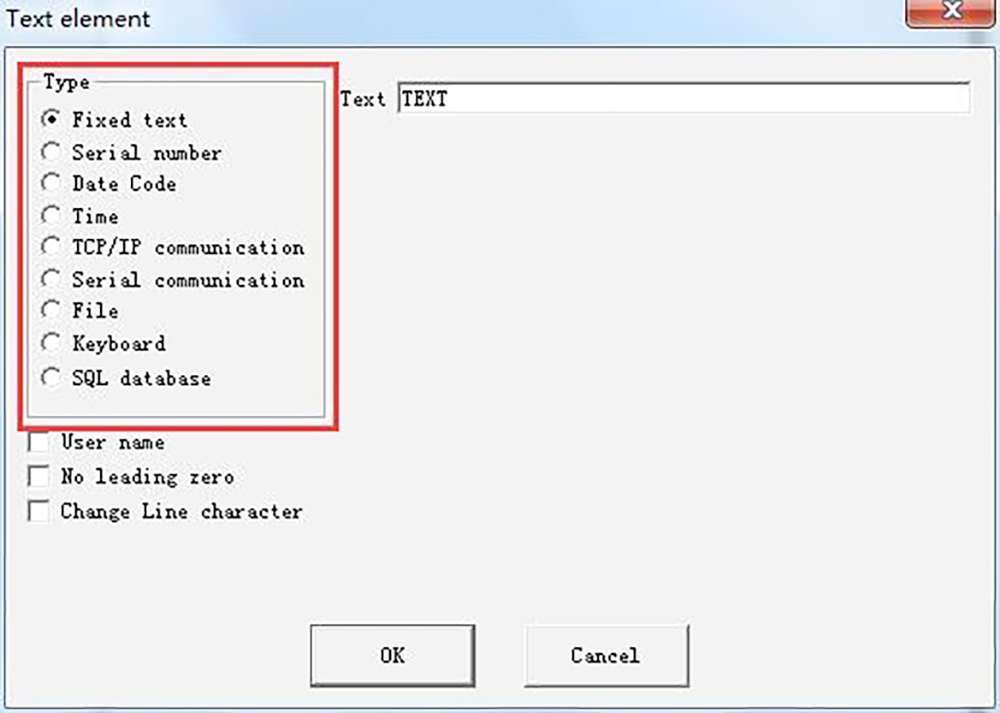

Text Edit

The laser software support variety of text editing.

For example:

Fixed text: Type the words directly.

Serial number: The number will increase/decrease automaticly.

File: Import content from Excell file or TXT file.

Keyboard: Import content from Barcode gun.

Barcode: Support UTF-8 coding and serial number.

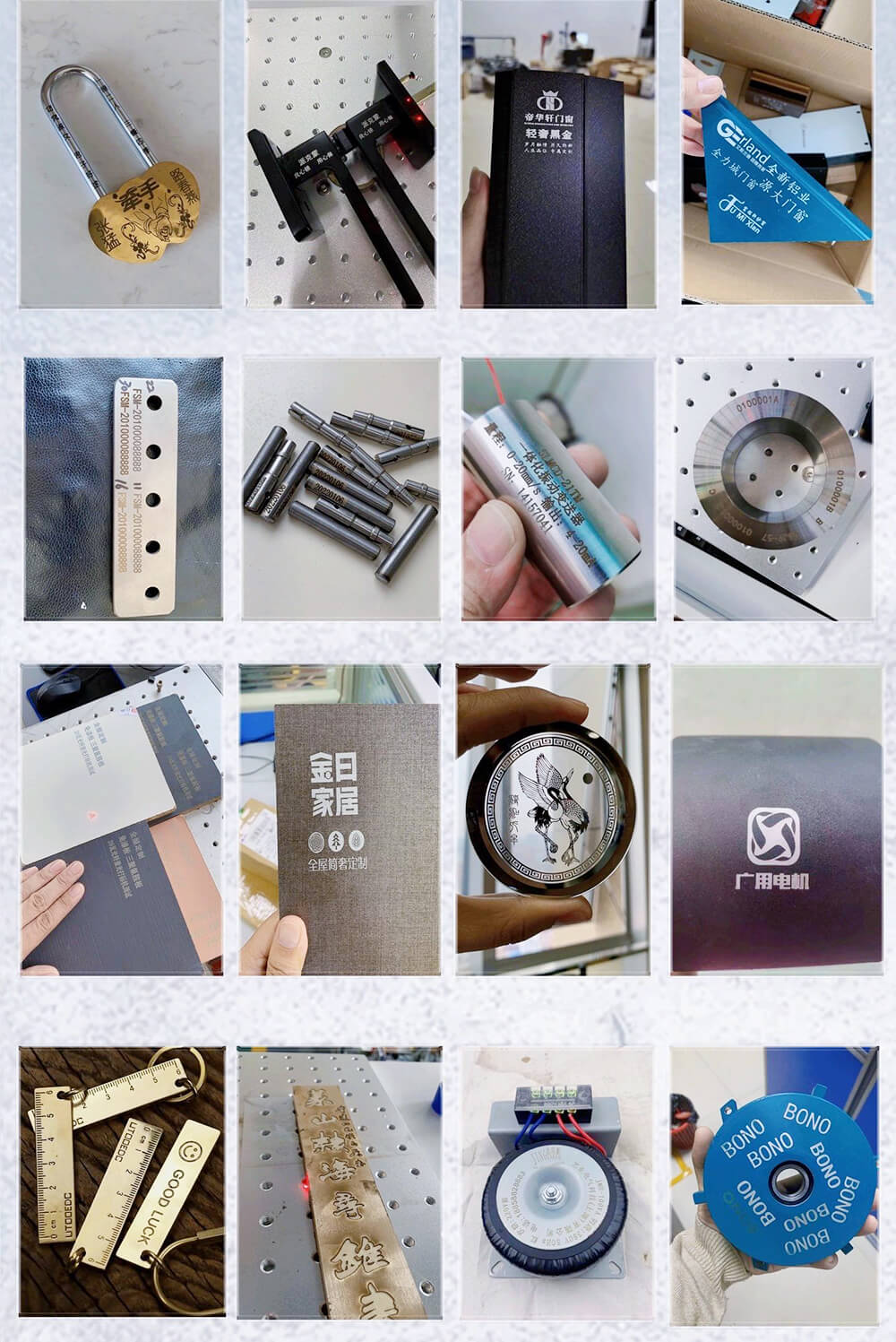

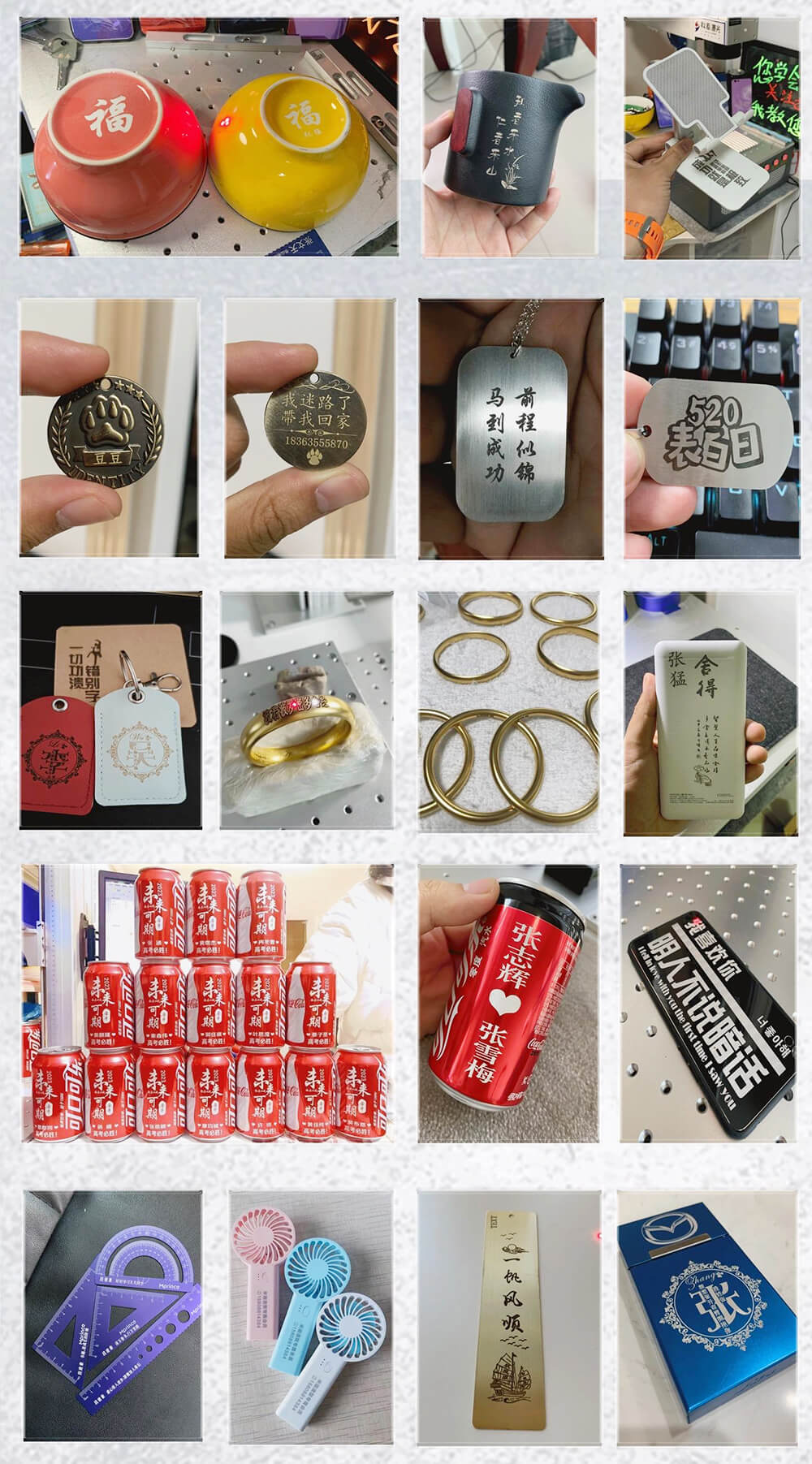

Application Scope:

The fiber laser engraver with full enclosed cover can be used for both metal and non-metal material marking,

and it can mark time, date,text, serial and part numbers, company logos, icon, symbol, bar codes, 2D codes,

matrix and vector fonts on all plain, painted, powder coated, anodized, plated metal surfaces, whether they are flat sheets, curved surfaces, or cylinders.

Application Industry:

Electronics: iPhone, iPad, iPod, Keyboard and more standard parts.

Jewelry Acessories: Rings, Pendant, Bracelet, Necklace, Sunglasses, Watches, etc.

Electronic Components: Phone, Pad, Resistors, Capacitors, Chips, Printed Circuit Boards, etc.

Mechanical Parts: Bearings, Gears, Standard Parts, Motor, etc.

Instrument: Panel Board, Nameplates, Precision equipment, etc.

Hardware Tools: Knives, Tools, Measuring Tools, Cutting Tools, etc.

Automobile Parts: Pistons, Rings, Gears, Shafts, Bearings, Clutch, Lights

Handicrafts: Zipper, Key Holder, Souvenir, etc.

Stone engraving 2.5d

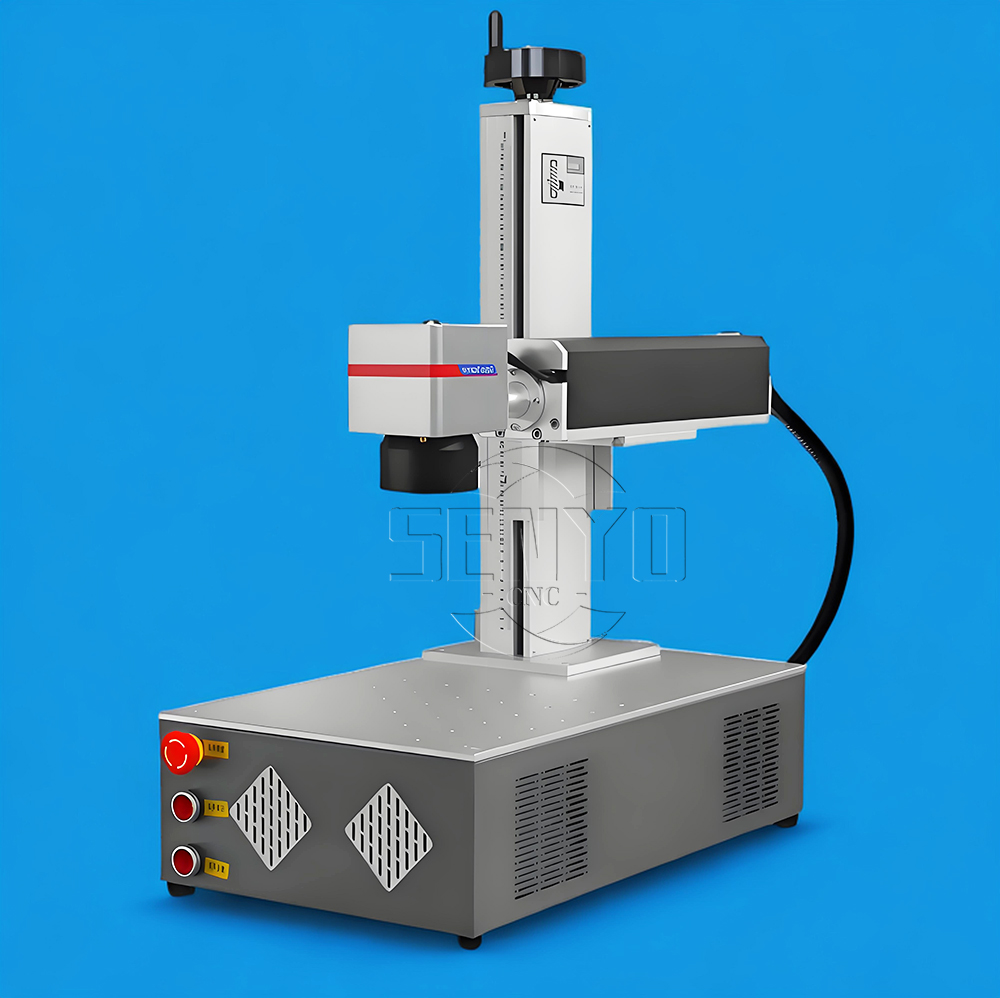

Technical Parameters of 50 Watt Fiber Laser Deep Engraving Machine for Metal

Brand | SENYOQC |

Model | SYJ-50W |

Laser Power | 50W |

Laser Wavelength | 1064nm |

Fiber Cable Length | 3m |

Pulse Width | 20ns |

Repetition Frequency Range | 1-600kHz |

M2 | <1.8 |

Max.Single Pulse Energy | 1.25mJ |

Output Power Stability | <5% |

Output Beam Diameter | 7±0.5mm |

Power Range | 0-100% |

Marking Range | 110*110mm/200*200mm/300*300mm |

Minimum Line Width | 0.01mm |

Minimum Character | 0.1mm |

Marking Speed | ≤7000mm/s |

Marking Depth | Depend on materials |

Repeatability Accuracy | ±0.001mm |

Marking Format | Graphics, text, bar codes, QRcode, automatically date, batch number, serial number, etc. |

Graphic format supported | Ai, plt, ;dxf, dst, svg, nc, bmp, jpg, jpeg, gif, tga, png, tiff, tif |

Working Voltage | 220V±10%/50Hz or 110V±10%/60Hz or Customized |

Unit Power | <0.5kw |

Working Environment | Clean and dust free or dust less |

Working Condition Humidity | 5%-75%, 0-40 degree, free of condensed water |

Laser lifetime | >100000 hours |

Net weight | 120 kgs |

Packing Size | 770*870*1200mm |

Price Range | US$3,900.00 - US$16,000.00 |

How to Laser Deep Engrave Metal?

Laser deep engraving is achieved by using a higher power and higher frequency laser generator to concentrate and scan multiple times.

Higher power is easy to understand. Higher output power means larger pulse energy per unit area and more natural depth.

At the same time, the current light source can be adjusted during laser processing (such as 10-100%).

Under the principle that the depth and the result need to be balanced (high power-fast speed-rougher shading;

low power-slow speed-finer shading and greater controllability), you can first use higher power to outline the main line direction, and then sculpt the details with lower power.

Higher repetition frequency is an important indicator describing the number of laser pulses per unit time.

The higher the repetition frequency, the more the number of working pulses per unit time, and higher quality processing results can be obtained during high-speed engraving.

Concentrate and scan multiple times, so there is no need to say more about this.

The ergonomics of laser deep engraving is an important factor that needs to be considered together with budget and laser parameter performance.

Of course, there are also some lasers for deep laser engraving technology. Customers can choose according to their budget and specific materials of processed parts.

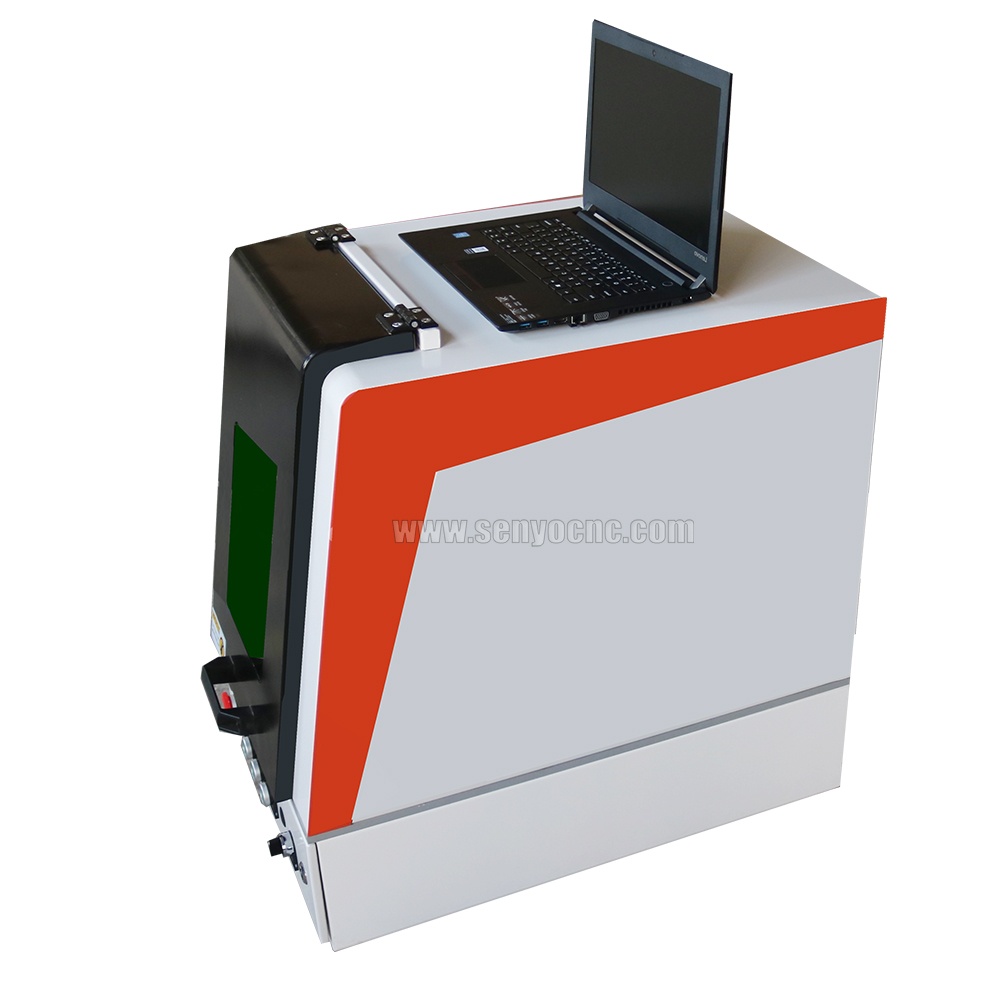

Packing & Shipping

1. Outside package: Standard plywood package.

2. Inner package:Stretchy film and plastic protective film for humidity.

Standard Accessories inside package

Foot switch, U disk, power cable, tools, focal length ruler, laser goggles.etc

Lifting handle

High quality and stable

Adjust the up and down for different height material marking

3. We can package according to your requirements.

For standard machines, 7-15 working days after payment;

For non-standard machines and customized machines according to clients' specific requirements, it will be 15 to 30 working days after payment.

Service & Support

1. Our engineers available to service machinery overseas.

2. 2 years guarantee for the whole machine.

3. Technical support by calling, mail, whatsapp and skype. If you have any problems, we will help you to solve it within 12 hours.

4. You will be get free training advice towards our machine in our factory.

5. If you need any component of the machine, we will provide most affordable price for you.

6. Friendly English version manual and operation video CD disk.

fiber laser marking machine, Customized marking machine, metal engraving machine, cnc fiber laser machine ,100w laser, 50w fiber laser

• Previous: Handheld Fiber Laser Marking Machine

• Next: Top Rated enclosed 3d Deep Laser Engraving Machine for Sale

Fiber metal Laser Sensor And Its Application

Category: SENYO NEWS 11th Mar, 2021A CNC wood router will use 3D machining in relief carving, the effect is more artistic beauty, but also has a strong sense of three-dimensional 3D, realization of this function is to ...

Precision Cutting Stents with Fiber Lasers

A CNC wood router will use 3D machining in relief carving, the effect is more artistic beauty, but also has a strong sense of three-dimensional 3D, realization of this function is to ...

How to Laser Cut Copper and Other Reflective Metals

Laser cutting of mild steel and stainless steel has a long history and has been one of the primary applications for CO2lasers. However CO2lasers have not traditionally offered a good solution for cutting highly reflective materials.Fiber lasers have an emission wavelength of around

Laser Cutting Machine Inspection Process For Manufacture

SENYOCNC Have Strict quality monitoring will be carried out when the parts are in the factory.

How Control Costs Use of UV Printers ?

UV flatbed printers are rapidly being used by more and more manufacturers, thanks to its efficient production efficiency, and the control of production costs also needs to arouse our attention.

Why UV flat printing machine is popular in market ?

For the majority of designers, give full play to the creative ability, the design sample can be arbitrarily modified on the computer, the effect on the computer, is the effect after the finished product, customer satisfaction can be directly produced. UV flat printing pattern fine, rich and clear layers, high artistry, strong three-dimensional sense, many high precision equipment can also print photography and painting style patterns.

How does UV ink jet printer save UV ink?

UV inkjet printer use process is an important consumable UV ink, reasonable use of equipment, can save UV ink , it can be said to be the best choice to directly save the cost. In the process of using some skills you need to be familiar with, the following small make up to share with you:1. Try to us

Waterjet Machine delivery and Shipping

Please tell us your max working size and what materials will cutting , also what max cutting thickeness.If you have Working photo sample please also send us , it will be helpful to choose machine with suitable models .

Waterjet Machine finish manufacture 5axis

Waterjet cutting technology is one of the fastest growing major machine tool processes in the world due to its versatility and ease of operation.

Waterjet Machine delivery and Shipping

Waterjet cutting technology is one of the fastest growing major machine tool processes in the world due to its versatility and ease of operation.There are multiple advantages to adding waterjet cutting capabilities to your shop.We are company leading ultrahigh-pressure waterjet system so

How to Create Connected Text – Inkscape for Laser Cutting

Step 1: Create Some TextFirst, we need some text to work with. To create the text, select the Text Tool (keyboard shortcut: T), click somewhere on the canvas, and type your text.You can use the drop-down list on the top left to select your desired font.Step 2: Convert Text to PathNext, we need to tu

Jacob from United States

I am a beginner at CNC, I’ve never used a CNC machine before and with in a day I was carving. An awesome machine for a beginner to learn as hobbyists. I used the manual and the help video. One hour to assemble and test, very friendly and easy to use. It’s a good buy for the money. I would definitely recommend this machine to someone getting into CNCs.

Weinstein from France

I've been using CNC plasma SYP2060-300A and I am very impressed with this unit.

This unit is of higher quality, made in China. Five stars all the way!

10w uv laser from American

Best supplier ! I bought 3 machines for laser and router , thank you Aillen ! --Alec

12KW Fiber Cutting - 2000X6000mm -- 이병헌 from Korea

Good machine for metal cut ! Thanks Senyo , Its prefect , I like your business patient kind!

I am a furniture manufacturer, and this machine is very good and fast. thanks Senyoqc Team ! from Bangladesh

Metal ArtWork from Denmark

The plasma cutting machine makes my artistic creation more convenient and precise!! Created more artistic ideas and value! Thank you Aillen team!

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen. from

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen.

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo from

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo

Thank you Senyo for SYJ1290-150W! from

Retired, ex mainframe systems programmer. Now full-time recreational woodworker majoring in puzzles, pens, boxes, Toys and occasional small furniture. Thank you Senyo for SYJ1290-150W!

CNC Router I love woodworking and the Joy in the Journey! It's a Blessing! from Ricky

CNC Router I love woodworking and the Joy in the Journey! It's a Blessing!

manager@senyocnc.com

manager@senyocnc.com

SENYOCNC

SENYOCNC

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

2061579344

2061579344