What is a Plywood Laser Cutter?

A laser plywood cutting machine is a type of automatic laser wood cutting system for hardwood plywood, softwood plywood, flexible plywood, aircraft plywood, marine plywood, tropical plywood, decorative plywood (overlaid plywood), and other plywood.

Plywood is a 3-layer or multi-layer board-like material that is made of wood segments into veneers or sliced into veneers, and then glued with adhesives. The fiber directions are glued perpendicular to each other.

Plywood is a of the most commonly used materials for furniture. It is a of the 3 major wood-based panels. It can also be used for aircraft, ships, trains, automobiles, buildings, and packaging boxes. A group of veneers is usually formed by gluing the adjacent layers of wood grains perpendicular to each other. Usually, the surface plate and the inner layer are symmetrically arranged on both sides of the center layer or the core. It is a slab made of glued veneers crisscrossed in the direction of the wood grain and pressed under the condition of heating or no heating. The number of layers is generally odd, and a few are even. The physical and mechanical properties in the vertical and horizontal directions are slightly different. Commonly used plywood types are 3 plywood, 5 plywood, and so on. Plywood can improve the utilization rate of wood and is a main way to save wood.

The usual length and width specifications are: 1220×2440mm, while the thickness specifications are generally: 3mm, 5mm, 9mm, 12mm, 15mm, 18mm, and more. The main tree species are beech, camphor, willow, poplar, eucalyptus, and so on.

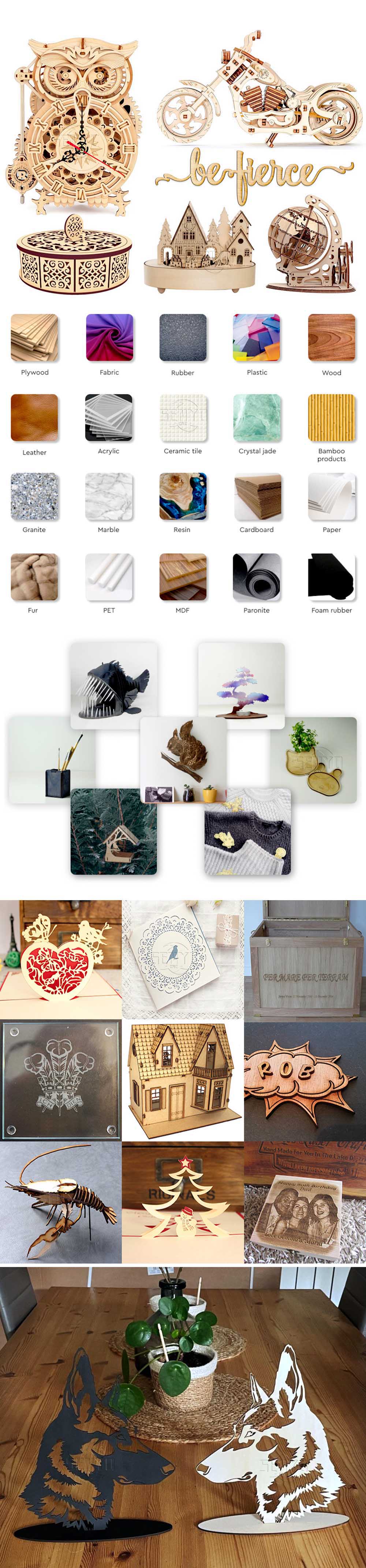

With a laser plywood cutter, you can cut and engrave toys, arts, and crafts, souvenirs, Christmas ornaments, gifts, architectural models, and more. The laser can cut any plywood shape to create the look you like and can cut thicknesses up to 20mm.

What is an MDF Laser Cutter?

A laser MDF cutting machine is a type of wood laser cutter for regular MDF, MDF ultra lite, colored MDF, moisture resistant MDF, no added formaldehyde (NAF), fire-rated MDF, exterior grade MDF, particle board, fiberboard, and laminated board.

MDF stands for medium-density fiberboard, MDF is made of wood fiber or other plant fiber as raw material, applied with urea-formaldehyde resin or other synthetic resin, and pressed under heating and pressure conditions to form a board with a density in the range of 0.50 ~ 0.88g/cm3. Other suitable additives can be added to improve sheet properties. MDF has good physical and mechanical properties and processing properties and can be made into boards of different thicknesses, so it is widely used in furniture manufacturing, construction, and interior decoration. MDF is a homogeneous porous material with good acoustic properties and is a good material for making speakers, TV casings, and musical instruments. In addition, it can also be used for ships, vehicles, sports equipment, floors, wall panels, partitions, etc. instead of natural wood. It has the characteristics of low cost, simple processing, high utilization rate, and more economical than natural wood.

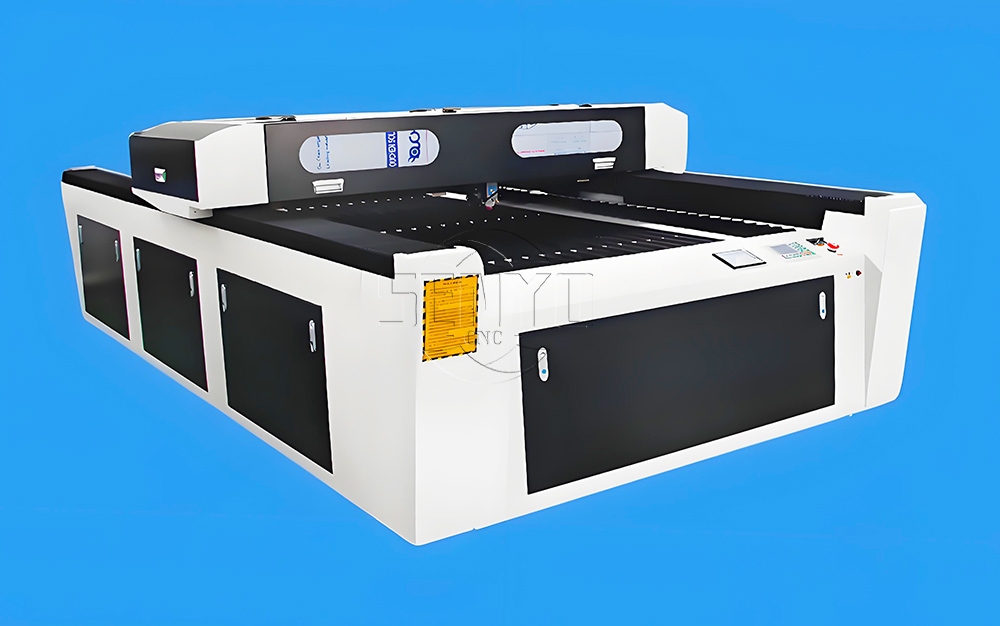

Machine Features

The CO2 laser cutting system has features of accurate cutting, fast speed, simple operation, personalized cutting process, and accuracy, laser head running track simulation display, multiple path optimization functions, and an automatic typesetting system to ensure the greatest possible saving of materials and cost.

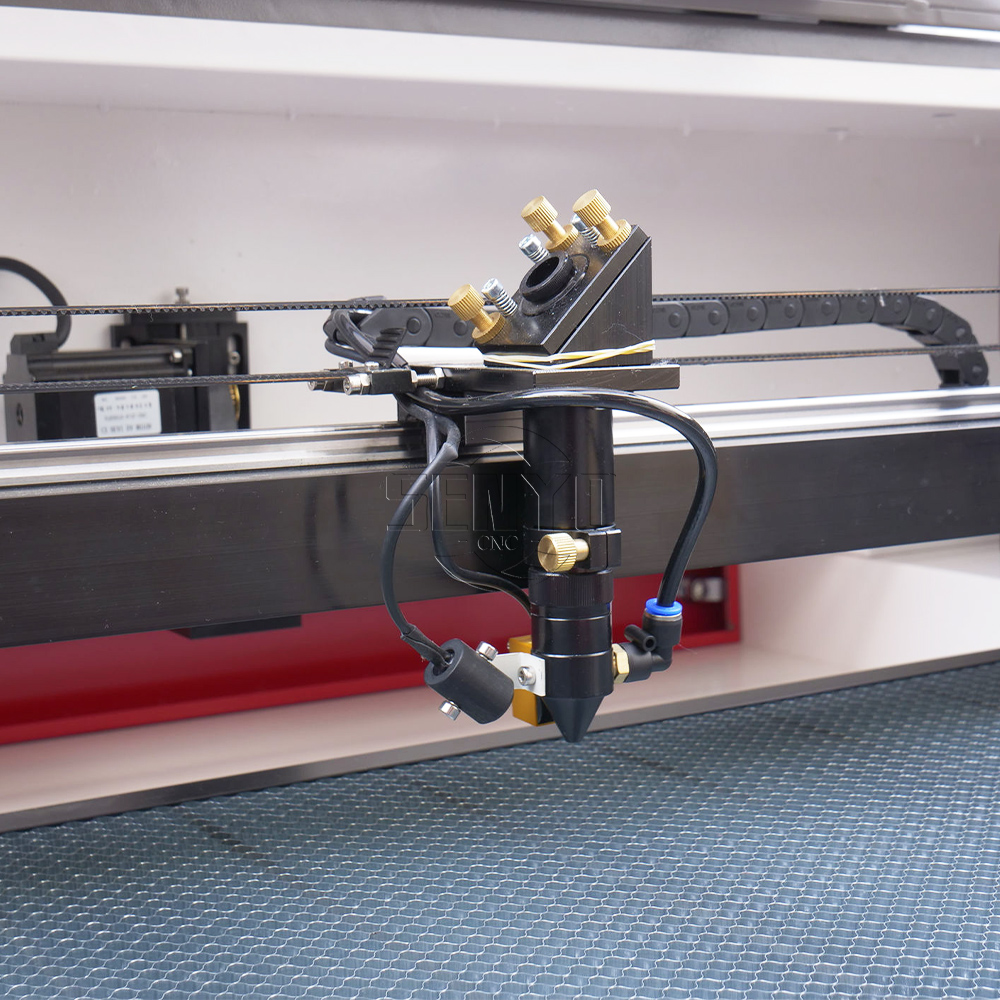

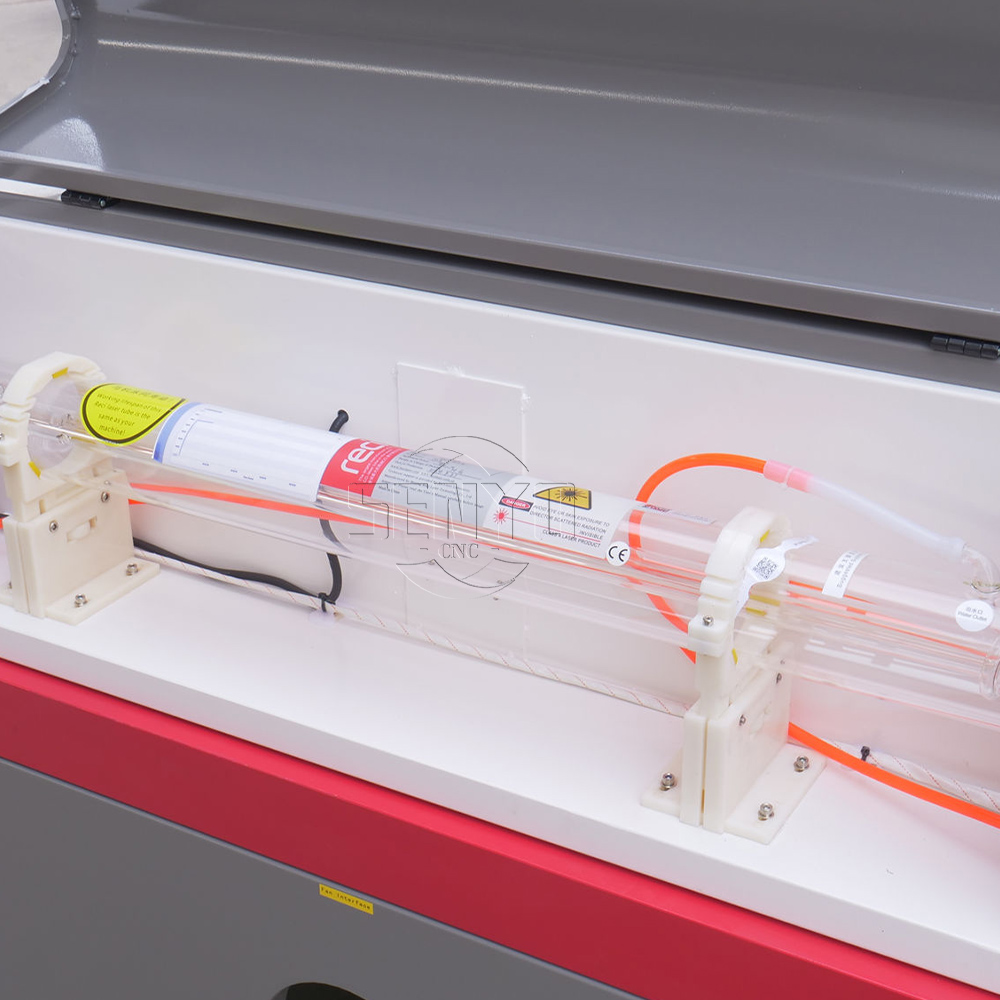

1. New-style high-efficiency RECI laser tube is adopted. A laser beam is more stable than the traditional type. Life span is more than 10,000 hours

2. Lens and mirrors from the USA with good reflective effect.

3. Four laser cutting heads with a distance of 30cm. It can cut 4 same projects at the same time to improve the working efficiency.

4. Double channel exhaust fans to clean the cutting chippings.

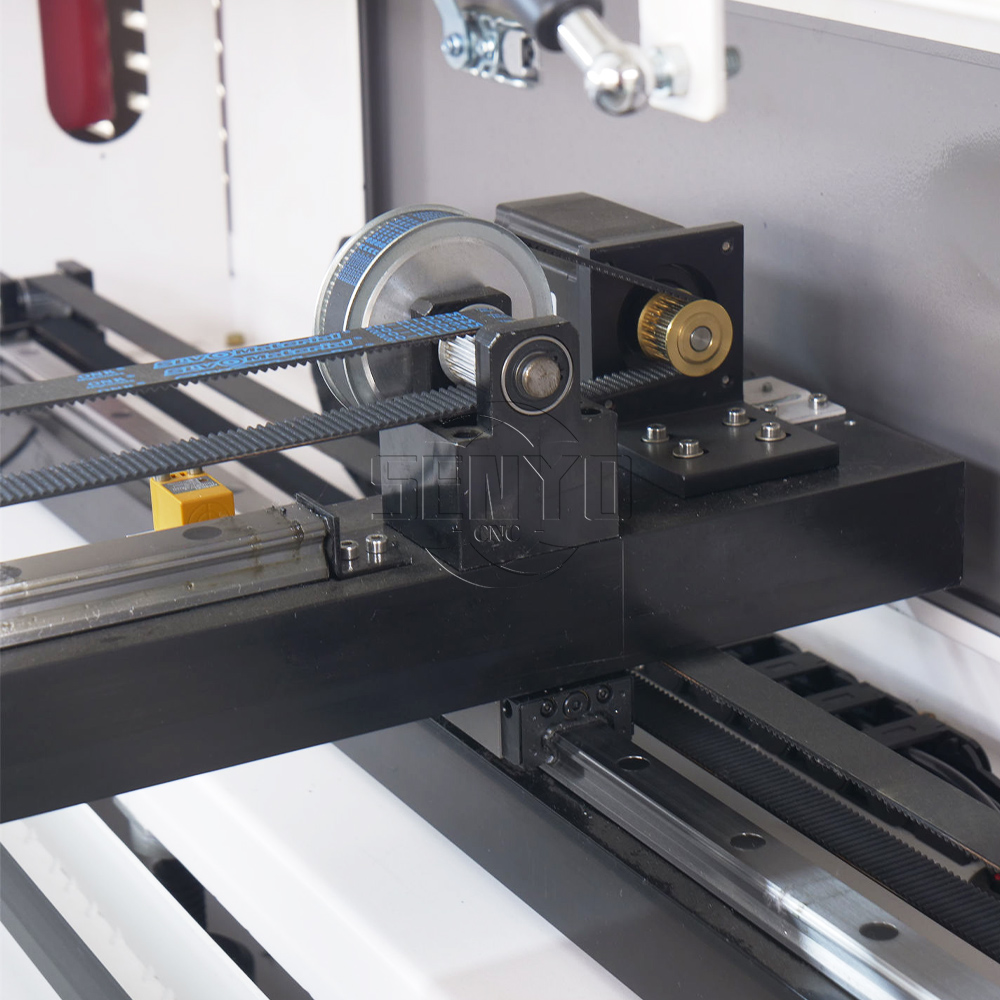

5. Taiwan PMI square linear guide rail installed on X Y axis, make sure the works stably and precisely.

6. Leadshine brand stepper motor and driver transmission, no need for feedback signal to control with high precision.

7. Blade working table, It is mainly designed for hard materials cutting, such as plywood, plastic, and MDF. Honeycomb table for soft materials, such as paper, fabric, leather, and rubber.

8. Advanced LCD Screen + USB port + Offline Control, with professional motion control chip, the function of consecutively high-speed curve cutting and the shortest path selection, which will highly improve your working efficiency.

CO2 Laser engraving and cutting machine application industry:

It

is used in advertising products, craft making, model craft, fabric art,

leather products, clothing design blanking, craft gifts, wooden toys,

exhibition display, decoration and other industries.

1. Advertising industry: plexiglass cutting, sign engraving, two-color plate engraving, crystal trophy engraving, etc.

2.

Gift industry: Engraving characters and patterns on non-gold materials

such as wood, bamboo chips, marble, two-color boards, density boards,

crystals, and leather.

3. Carton printing industry: engraving

products, used for engraving and cutting of rubber boards, double-layer

boards, and plastic boards.

4. Leather and clothing processing

industry: it can carry out complex process processing on genuine

leather, synthetic leather and cloth.

5. Model decoration: model making, decoration, marking of product packaging, etc.

6. Paper products industry: paper-cutting process, cutting of paper handicrafts, etc.

Main Application :

Advertisement, Arts, and Crafts, Toys, Computerized embroidery and Clipping, garments, Model, and The construction industry.

Specification

Engraving / Working Area | 1300x2500mm |

Laser Source | Sealed CO2 gas filled glass tube,standard 300w with stringintly tested. Average lifespan is 2000-4000 working hours. |

Electrical Requirements | Standard 220v AC 50Hz Single Phase, customized based on your local voltage is available |

Compatible Software | CORTLDRAW,PHOTOSHOP,AUTOCAD,Compatible with Windows, Mac, and Linux |

Motorized Table | Standard solid metal blade knife blade bed, or removable honeycomb. Both are available. |

Laser Heads | Professional adjustment special head |

Exclusive transmission | Ball Screw transmission |

Motion Control | LeadShine Servo Motors with engraving speeds up to 1,000mm/s |

Water Chiller | CW6000 |

Air compressor | 600w air compressor |

Ventilation | 550W Extraction fan |

Resolution | Fully-flexible and user-controlled from 75 - 1200 dpi |

Speed and Power | 120 IPS (3.05m/s) with 5G acceleration. Computer-controlled in .001 increments up to 100%. Color mapping feature links Speed, Power, Frequency, and Raster/Vector mode. |

Working precision | Location precision <0.01mmMinimum character size 1.5mm x 1.5mm Typical design software Adobe Illustrator, AutoCAD, Corel Draw, 2D design Preferred file types .dxf, .plt |

Machine Size | Advanced split structure to save more cost in shipping.Complete size 3800*2030*1120mm , package size 4300*2130*1350mm. |

Weight | 1000kg |

Warranty | 12 months onsite excluding consumables (laser tube and optics). |

Our Service

1). 2

years quality guaranty, the machine with main parts(excluding the

consumables) shall be changed free of charge(some parts will be

maintained) when if any problem during the warranty period.

2). Lifetime maintenance free of charge.

3). Free training course at our plant.

4). 18

hours on line service and email each day, free technical support.We

will reply you in 24 hours after receive your problem of the machine.

5). Machine has been tested and adjusted before delivery.We will take machine photos and make

machine working image for you ,after getting your agreement ,then we will book a ship.

6).

Provide technical services to the door(We have professional engineers

to offer machine installation commissioning and maintenance) if

customers pay the charges of ticket.

7).if you have any problem during your use.you need our technician to judge

where the problem is and help you to solve it. We can provide team viewer and skype with cam till all of your problems solved.

For Our Work Steps

1.Before-sale,we will try to know your requirement about our cnc finer laser specification and what kind of work

you will do .then we will offer our best solution for your requirement.

2.During production: we will send photos of machines during making. so you can know more details about

the procession of making your machines.

3.Before shipping,we will take delivery photo and confirm the specification of order to avoid the mistake.

Machine will be adjusted before it is delivered.

4.After shipping: we will sent out the documents for your customs clearance ASAP . and check the

approximate date of arrival.

5.After arrival: we will confirm with you if machine is in good condition.and see if any spare parts missing .

6.About teaching: there are some manual and video about how to use machine , if you have question

about it. we will have professional technicist to help you install and teach how to use through skype ,calling,or mail.

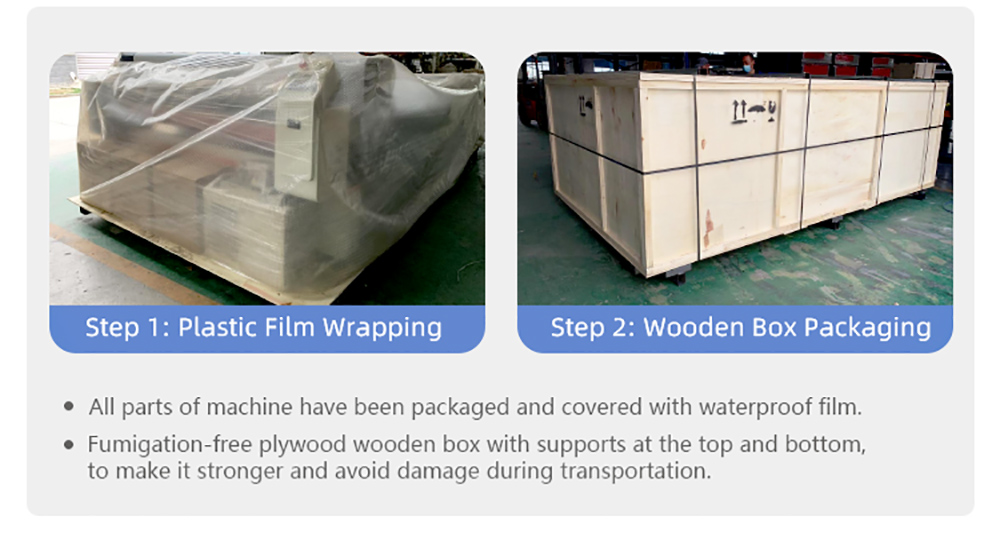

Packing & Shipping

1. Outside package: Standard plywood package.

2. Inner package:Stretchy film and plastic protective film for humidity.

3. We can package according to your requirements.

For

standard machines, 7-15 working days after payment.

For LCL Shipping (Less than Container Load),it is recommended to use export standard fumigation-free wooden boxes, which are

stronger and suitable for long-distance transportation.For FCL Shipping (Full Container Load).

it can be loaded directly at the factory without wooden boxes, and the maximum number of machines can be loaded to reduce costs.

Service & Support

1. Our engineers available to service machinery overseas.

2. 2 years guarantee for the whole machine.

3. Technical support by calling, mail, whatsapp and skype. If you have any problems, we will help you to solve it within 12 hours.

4. You will be get free training advice towards our machine in our factory.

5. If you need any component of the machine, we will provide most affordable price for you.

6. Friendly English version manual and operation video CD disk.

Working Environment

The machine is a high-tech mechatronics equipment, which has certain requirements for the working environment.

1. Avoid strong electricity, strong magnetism,

and other equipment that seriously affect the signal transmission of the machine, such as electric welding machine, launch tower, etc.

2. Use a 3-core power supply to ensure a good grounding of the machine and reduce interference.

3. The voltage is required to be stable and avoid large fluctuations. It is best to use a voltage stabilizer.

4. The machine should not work for a long time in a strong acid or alkaline environment.

CO2 laser machine , CO2 laser cutter , CO2 laser engraver , CO2 laser engraving machine , CO2 laser cutting machine ,Best CO2 laser machine

CO2 laser for metal engraving , CO2 laser for wood cutting , Industrial CO2 laser machine , Desktop CO2 laser engraver

Affordable CO2 laser cutter , 1325 CO2 laser machine price , 100W CO2 laser cutter

• Previous: CO2 Laser Wood Marking Machine for MDF & Plywood

• Next: None

Fiber metal Laser Sensor And Its Application

Category: SENYO NEWS 11th Mar, 2021A CNC wood router will use 3D machining in relief carving, the effect is more artistic beauty, but also has a strong sense of three-dimensional 3D, realization of this function is to ...

Precision Cutting Stents with Fiber Lasers

A CNC wood router will use 3D machining in relief carving, the effect is more artistic beauty, but also has a strong sense of three-dimensional 3D, realization of this function is to ...

How to Laser Cut Copper and Other Reflective Metals

Laser cutting of mild steel and stainless steel has a long history and has been one of the primary applications for CO2lasers. However CO2lasers have not traditionally offered a good solution for cutting highly reflective materials.Fiber lasers have an emission wavelength of around

Laser Cutting Machine Inspection Process For Manufacture

SENYOCNC Have Strict quality monitoring will be carried out when the parts are in the factory.

How Control Costs Use of UV Printers ?

UV flatbed printers are rapidly being used by more and more manufacturers, thanks to its efficient production efficiency, and the control of production costs also needs to arouse our attention.

Why UV flat printing machine is popular in market ?

For the majority of designers, give full play to the creative ability, the design sample can be arbitrarily modified on the computer, the effect on the computer, is the effect after the finished product, customer satisfaction can be directly produced. UV flat printing pattern fine, rich and clear layers, high artistry, strong three-dimensional sense, many high precision equipment can also print photography and painting style patterns.

How does UV ink jet printer save UV ink?

UV inkjet printer use process is an important consumable UV ink, reasonable use of equipment, can save UV ink , it can be said to be the best choice to directly save the cost. In the process of using some skills you need to be familiar with, the following small make up to share with you:1. Try to us

Waterjet Machine delivery and Shipping

Please tell us your max working size and what materials will cutting , also what max cutting thickeness.If you have Working photo sample please also send us , it will be helpful to choose machine with suitable models .

Waterjet Machine finish manufacture 5axis

Waterjet cutting technology is one of the fastest growing major machine tool processes in the world due to its versatility and ease of operation.

Waterjet Machine delivery and Shipping

Waterjet cutting technology is one of the fastest growing major machine tool processes in the world due to its versatility and ease of operation.There are multiple advantages to adding waterjet cutting capabilities to your shop.We are company leading ultrahigh-pressure waterjet system so

How to Create Connected Text – Inkscape for Laser Cutting

Step 1: Create Some TextFirst, we need some text to work with. To create the text, select the Text Tool (keyboard shortcut: T), click somewhere on the canvas, and type your text.You can use the drop-down list on the top left to select your desired font.Step 2: Convert Text to PathNext, we need to tu

Jacob from United States

I am a beginner at CNC, I’ve never used a CNC machine before and with in a day I was carving. An awesome machine for a beginner to learn as hobbyists. I used the manual and the help video. One hour to assemble and test, very friendly and easy to use. It’s a good buy for the money. I would definitely recommend this machine to someone getting into CNCs.

Weinstein from France

I've been using CNC plasma SYP2060-300A and I am very impressed with this unit.

This unit is of higher quality, made in China. Five stars all the way!

I am a furniture manufacturer, and this machine is very good and fast. thanks Senyoqc Team ! from Bangladesh

Metal ArtWork from Denmark

The plasma cutting machine makes my artistic creation more convenient and precise!! Created more artistic ideas and value! Thank you Aillen team!

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen. from

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen.

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo from

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo

Thank you Senyo for SYJ1290-150W! from

Retired, ex mainframe systems programmer. Now full-time recreational woodworker majoring in puzzles, pens, boxes, Toys and occasional small furniture. Thank you Senyo for SYJ1290-150W!

CNC Router I love woodworking and the Joy in the Journey! It's a Blessing! from Ricky

CNC Router I love woodworking and the Joy in the Journey! It's a Blessing!

CO2 1530H-300W Europe from

CO2 1530H-300W All really well done. these are something ive always wanted to do.

4040 Mini Desktop CNC Router for Small Business from France

Good Machine! Wonderful Service !

Thanks Senyoqc Team for whatsapp Group services , Excellent enginner ! Good work!

manager@senyocnc.com

manager@senyocnc.com

SENYOCNC

SENYOCNC

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

2061579344

2061579344