How to Install and Setup Mach3 CNC Controller Software ?

From: 本站 Date: 01st September 2021 Author: shengangtong Views: 1965

Mach3 Overview

Mach3 is a powerful and practical CNC controller software designed to control CNC router, CNC mill, CNC plasma,

CNC lathe, and other CNC machine tools. The software interface is simple and intuitive, and users can adjust the

corresponding parameters according to their needs. And it has many functions such as numerical control testing,

high precision machining of complex parts and clearing of corresponding data.

Mach3 CNC controller sofware is an open CNC system, simple operation, convenient maintenance, open, stable

performance, and low-cost new CNC system. The standard PC computer is completely converted into a full-function

CNC controller, and the highest 6-axis CNC control, Directly support a variety of DXF, BMP, JPG, HPGL file format

input, visual G code display, direct G code generation, spindle speed control, multiple relay control, manual pulse

generation, including a large number of processing strategies, video display, and touch screen , Full screen display,

digitization. Three-dimensional dynamic display tracking, automatic tool setting, program jump execution

(breakpoint memory).

Mach3 Features

1. Visual G-code display.

2. Touch screen ability.

3. Fully customizable interface.

4. Spindle speed control.

5. Manual pulse generation.

6. Multiple relay control.

7. Video display of machine.

8. Full screen eligibility.

9. Generates Gcode via L azyCam or Wizards.

10. Customizable M-Codes and Macros using VBscript.

11. Allows direct import of DXF, BMP, JPG, and HPGL files through LazyCam.

12. Converts a standard PC to a fully featured, 6- axis CNC controller.

Mach3 Applications

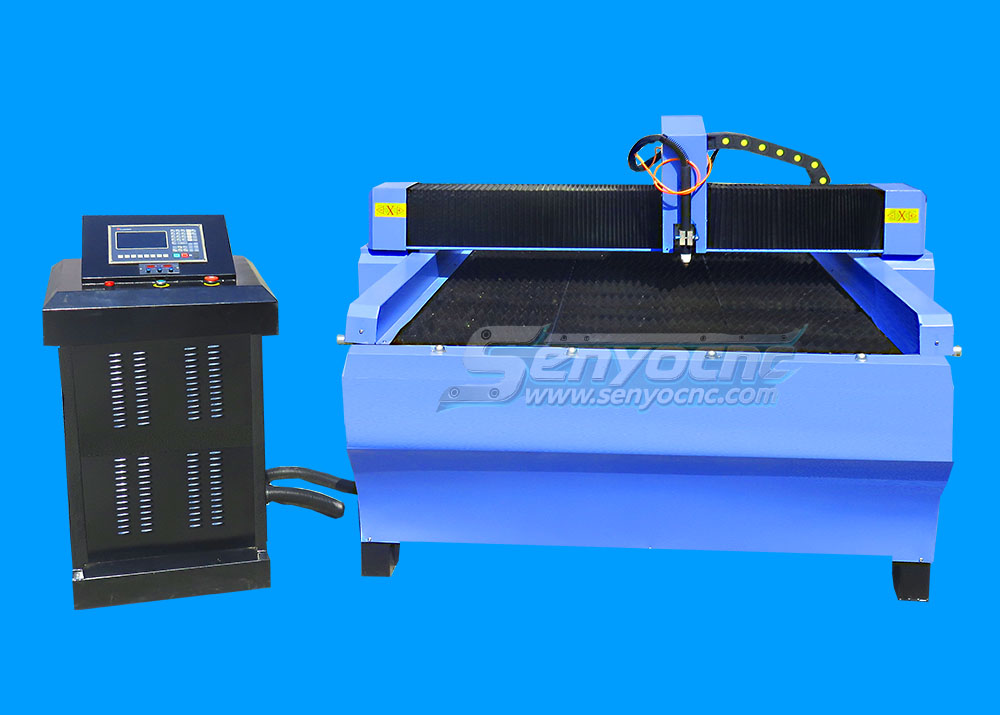

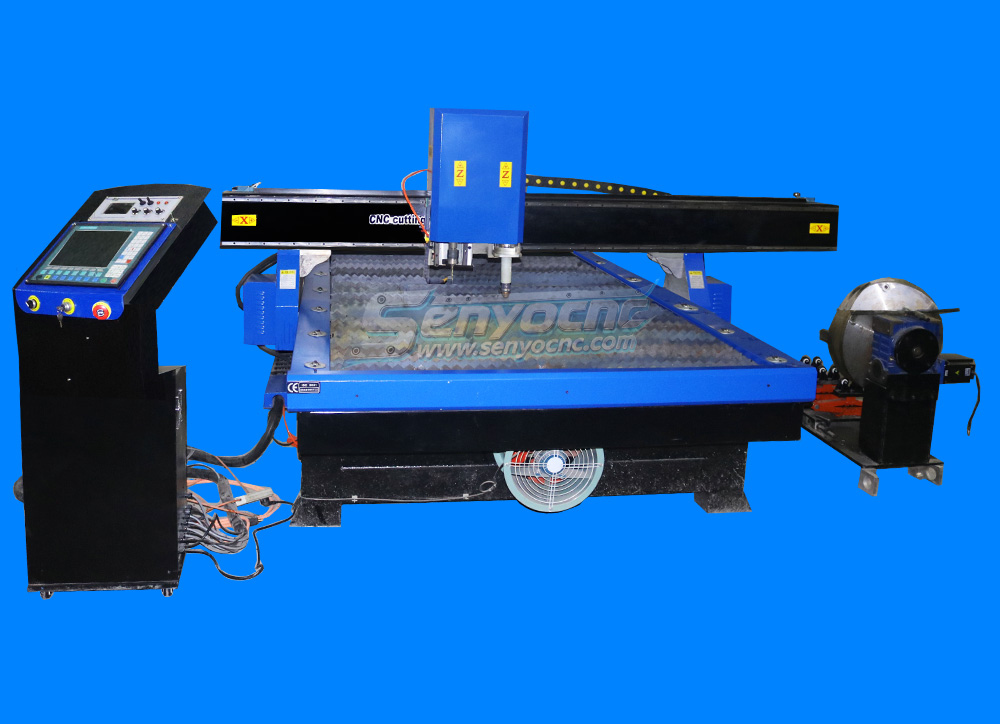

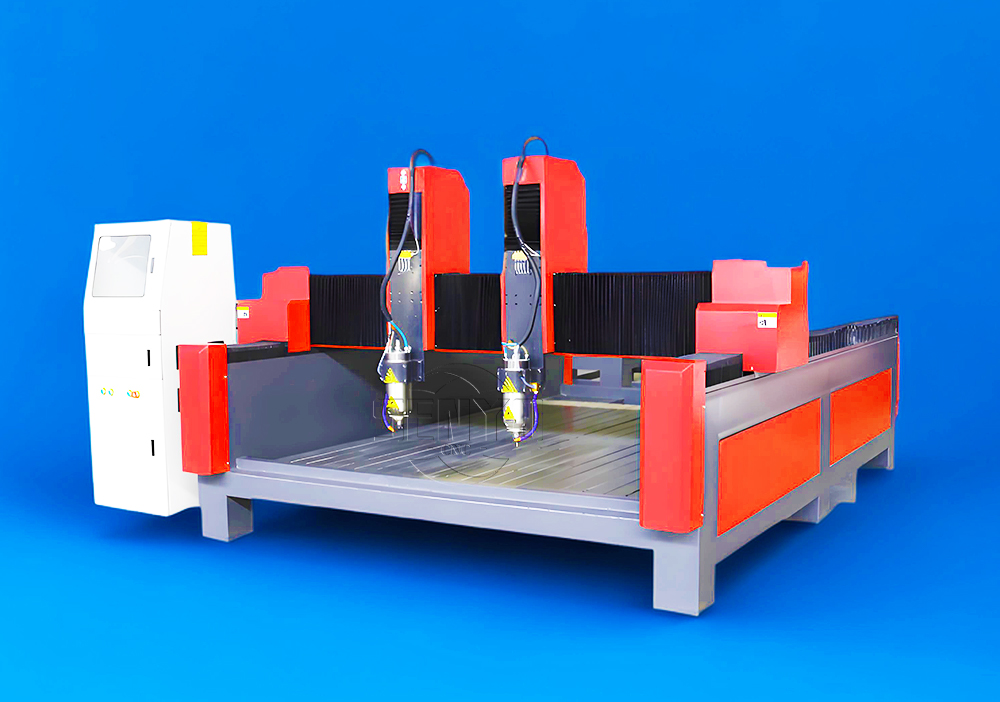

1. CNC Mill.

2. CNC Router.

3. CNC Lathe Machine.

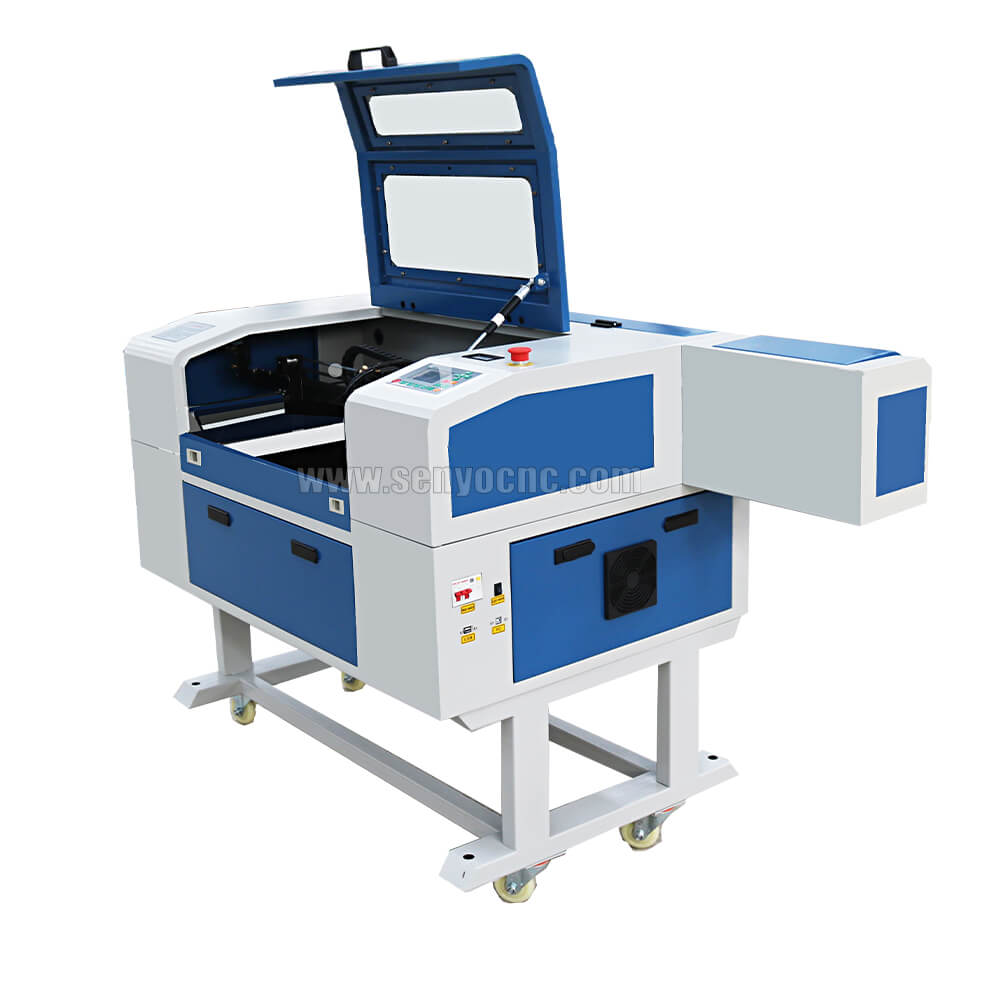

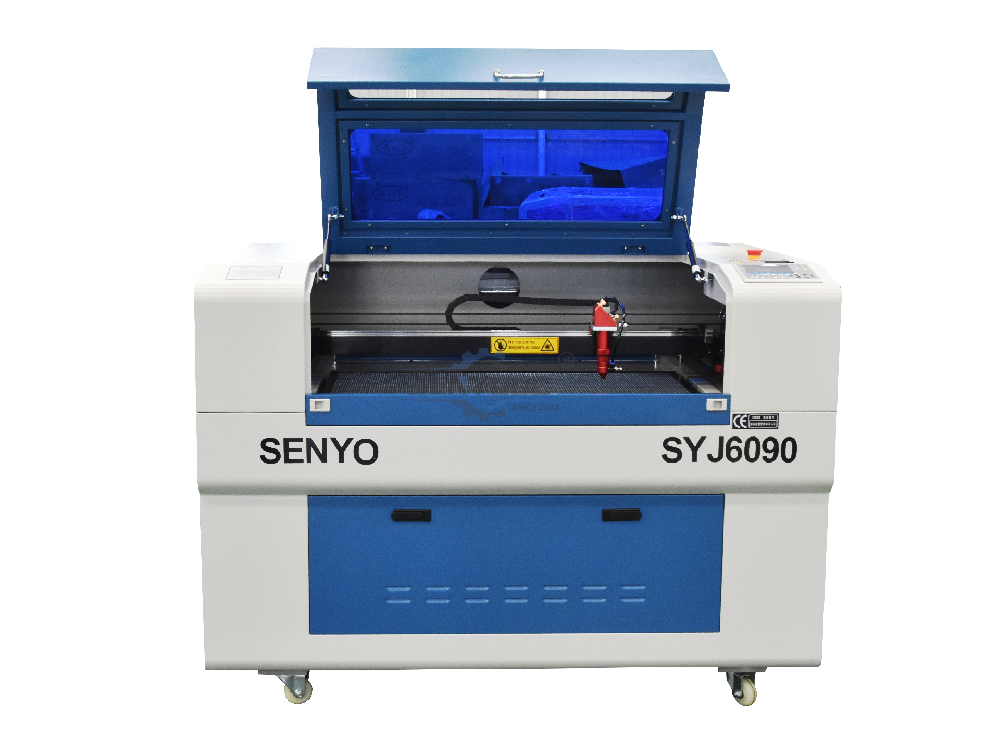

4. CNC Laser Machine.

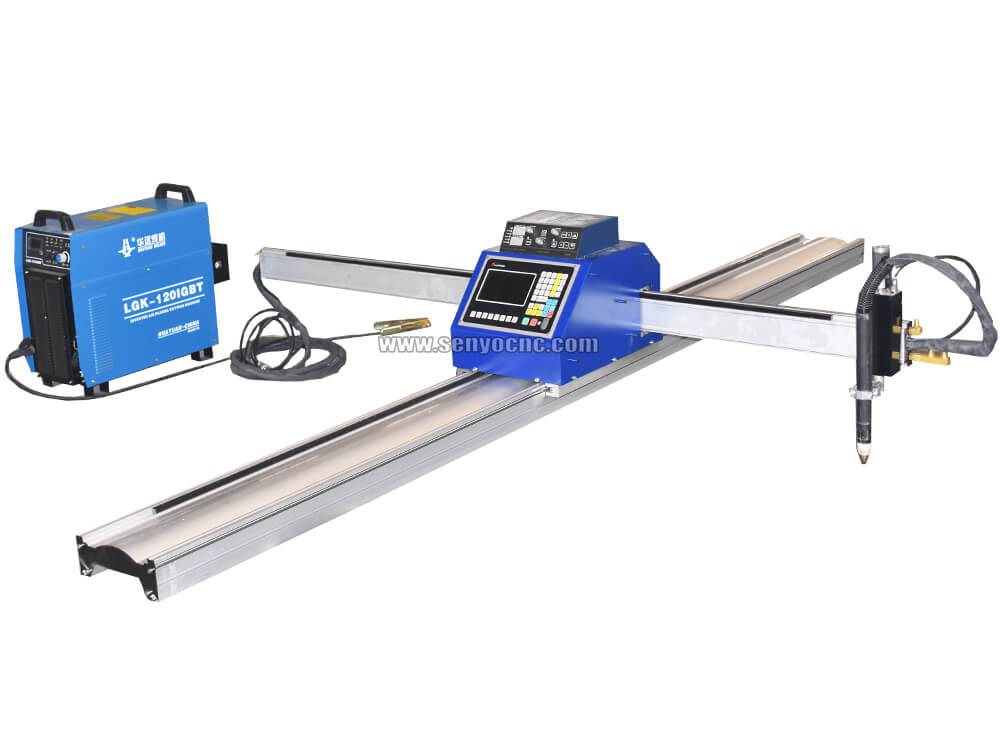

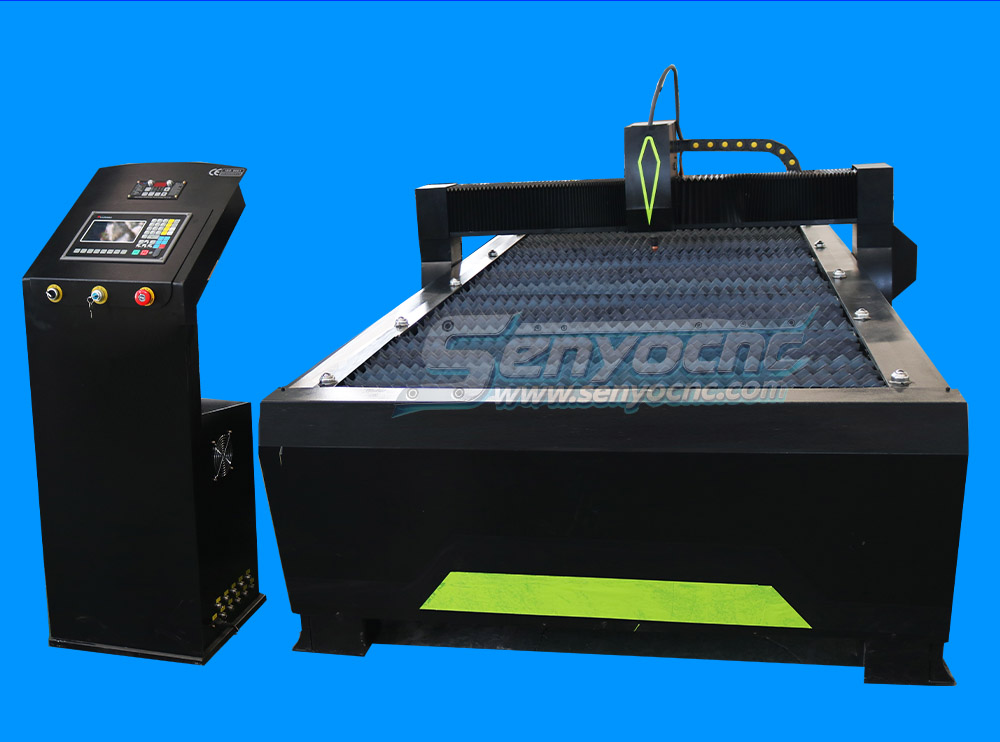

5. CNC Plasma Cutter.

How Does Mach3 Work?

Mach3 is a type of CNC software that runs on a PC and turns it into a very powerful and economical machine

controller. To run Mach3, you need a PC running the Windows operating system with at least a 1GHz processor

with a 1024 x 768 pixel resolution screen. Mach3 and its parallel port driver communicate with the machine

hardware through one parallel ports or printer ports. If your computer does not have a parallel port, you can buy a

motion controller board from a third-party vendor that uses a USB port or Ethernet for communication. Use of a

motion controller board can remove considerable processing load from the computer, so you may want to consider

using one to get the performance advantage even if your computer does have a parallel port available. Mach3

generates step pulses and direction signals to perform the steps defined by a GCode part program and sends them

to the port or motion controller board. The drivers for your machine's axis motors must accept March3's step pulses

and direction signals. Virtually all stepper motor drivers work like this, as do modern DC and AC servo systems with

digital encoders. Beware if you are converting an old NC machine whose servos may use resolvers to measure

position of the axes as you will have to provide a complete new drive for each axis. To set up a CNC system to use

Mach3 software, you must install the Mach3 CNC controller software on your computer, and properly connect your

motor drives to the computer's ports.

Mach3 Installation

Computer operating system requirements for parallel port:

1. Desktop PC (L aptops are not supported) with at least one parallel port.

2.32-bit version of Windows 2000, Windows XP, Windows Vista, or Windows 7. (64-bit versions will not be

supported)

3.1Ghz CPU, 512MB RAM.

4. Non-integrated Video Card with 32MB RAM. (L arge G-code files, especially 3D fles will require a video card with

512MB RAM or higher)

Computer operating system requirements with an external motion device:

1. An external motion controller. (USB UC100, or Ethernet Smooth Stepper, etc.)

2. Desktop or Laptop with Windows 2000, Windows XP, Windows Vista, Windows 7, Windows 8 or Windows 10.

3.1Ghz CPU, 512MB RAM.

4. Video Card with 32MB RAM. (L arge G-code files, especially 3D fles will require a video card with 512MB RAM or

higher)

If you already have an old version of Mach3 installed on your computer, you can install the new version on top of it.

You do not need to uninstall the old version first.

1. Turn off the PC, the CNC machine tool, and its drives.

2. Switch the PC back on.

3. Run the Mach3 CNC software installation package.

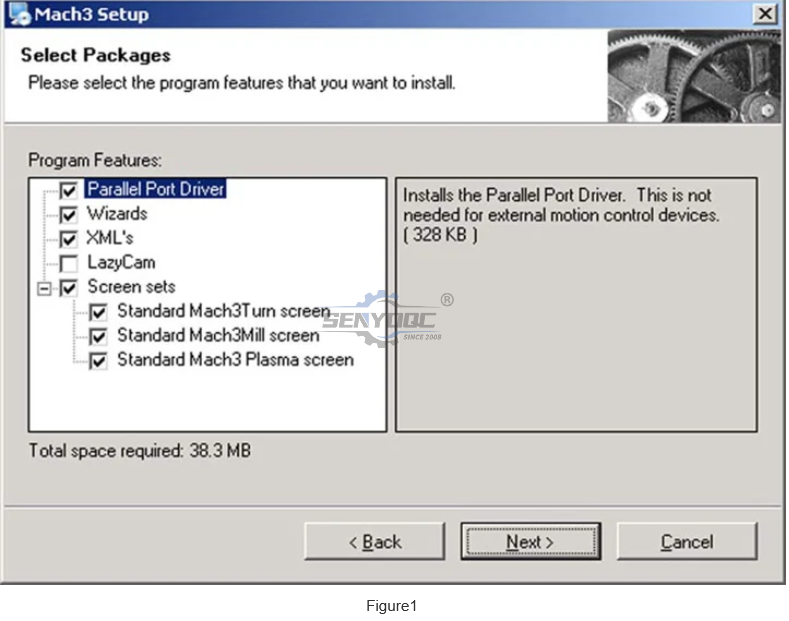

When you run the downloaded file, you will be guided through the usual installation steps for a windows program

such as accepting the license conditions and selecting the folder for Mach3. SENYOQC recommends that you

allow Mach3 to use its default installation folder "C:lMach3". You will be asked if you want to install various program

components, as shown in Figure 1:

4. Select program components screen.

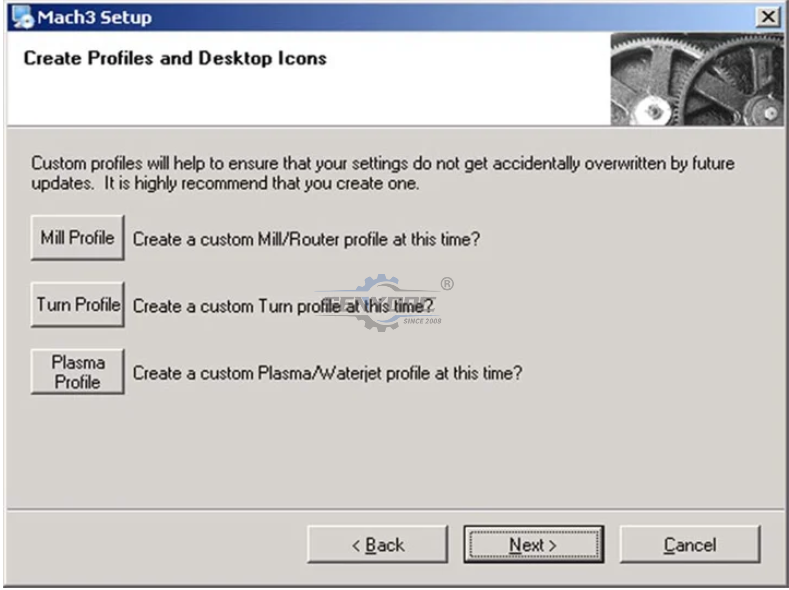

When you have selected the components you want, click the Next button. The installation procedure will ask if you

want to create a custom profile, as shown in Figure 2:

5. Create a custom profile screen.

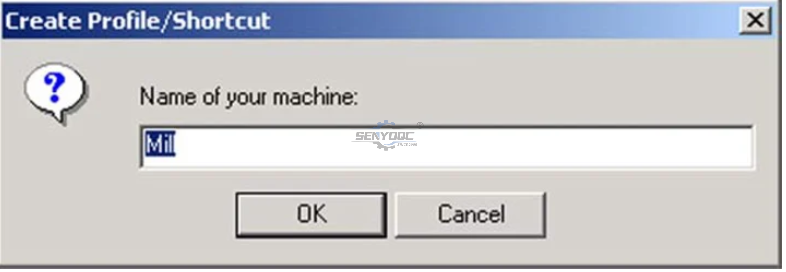

For example, If you click the "Mill Profile" button, the screen shown in Figure 3 appears. Of course, you should

choose the right profile button for your CNC machine tool.

6. Create "Mill Profile".

Enter the name you want to assign to the profle and click the "OK" button. If you want, you can create several

different profiles. When you have created your custom profile, click the "Next" button.

7. Vital reboot.

You must reboot Windows before running Mach3 software. This reboot is vital. If you do not do it, you will get into

great dficulties which can only be overcome by using the "Windows Control Panel" to uninstall the driver manually.

So please reboot now.

8. Testing Mach3 installation with your CNC machine.

Up to now, Mach3 CNC controller software is installed, we hope you can enjoy this software with your CNC

machine tool.

• Previous: How Install and use EZCAD software for Laser Marking Machine ?

• Next: None

Jacob from United States

I am a beginner at CNC, I’ve never used a CNC machine before and with in a day I was carving. An awesome machine for a beginner to learn as hobbyists. I used the manual and the help video. One hour to assemble and test, very friendly and easy to use. It’s a good buy for the money. I would definitely recommend this machine to someone getting into CNCs.

Weinstein from France

I've been using CNC plasma SYP2060-300A and I am very impressed with this unit.

This unit is of higher quality, made in China. Five stars all the way!

2040 from INDIAN

Best 2040 CNC Router Good Price and Quality ! Thank SENYOQC

10w uv laser from American

Best supplier ! I bought 3 machines for laser and router , thank you Aillen ! --Alec

12KW Fiber Cutting - 2000X6000mm -- 이병헌 from Korea

Good machine for metal cut ! Thanks Senyo , Its prefect , I like your business patient kind!

I am a furniture manufacturer, and this machine is very good and fast. thanks Senyoqc Team ! from Bangladesh

Metal ArtWork from Denmark

The plasma cutting machine makes my artistic creation more convenient and precise!! Created more artistic ideas and value! Thank you Aillen team!

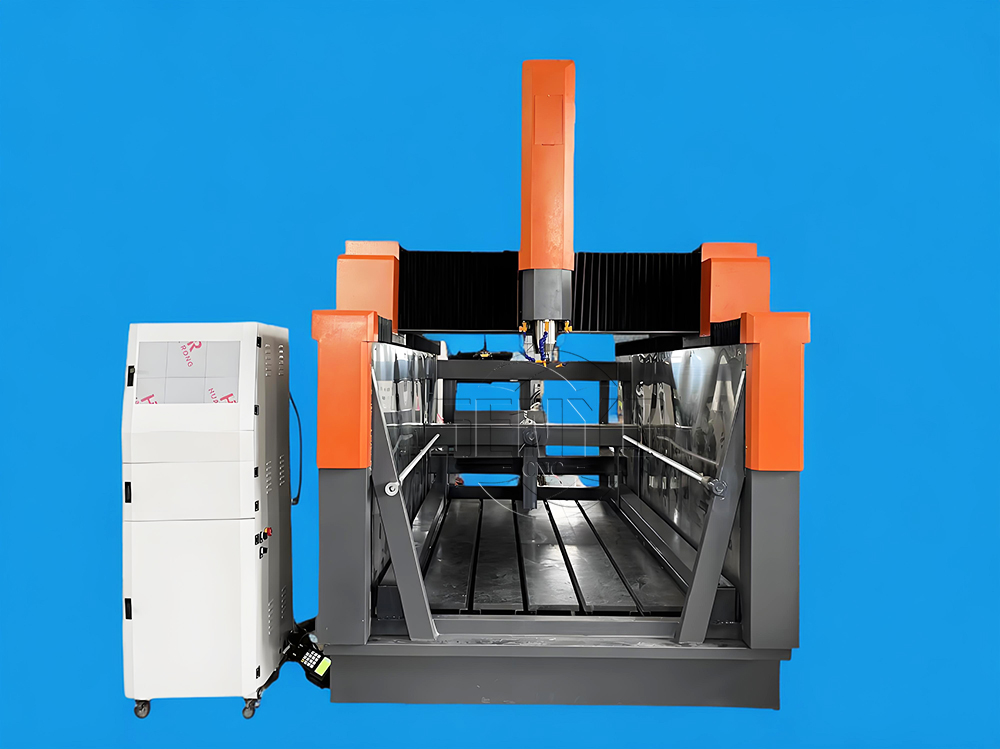

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen. from

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen.

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo from

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo

Thank you Senyo for SYJ1290-150W! from

Retired, ex mainframe systems programmer. Now full-time recreational woodworker majoring in puzzles, pens, boxes, Toys and occasional small furniture. Thank you Senyo for SYJ1290-150W!

manager@senyocnc.com

manager@senyocnc.com

SENYOCNC

SENYOCNC

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

2061579344

2061579344