How to solve the common problems of laser engraving machine software?

From: 本站 Date: 31st August 2021 Author: shengangtong Views: 1453

1. When laser engraving with gradient, double phenomenon.

This phenomenon occurs when the slope of words carved smaller, usually the reason is "wide" setting slope too large, cause

calculation errors, please set "wide" itle slope.

2. If you only can move a graphic with one direction, please click " Shft" or "Ctrl" to recover.

3. PLT format cannot to engrave.

There are two reasons, one is the graphic is not closed, the other is graphic double. Please detect this phenomenon with "data

detect" tools.

4. The size is not same with laser engraving and cutting samples.

Open the item "laser engraving machine set", adjust the pulse.

5. The edge is irregularity when laser engraving.

The edge is iregularity maybe happen when you use the DSP laser engraver sofware, that means "burr", this is mainly caused by

mechanical return clearance, this is the solution.

a. Draw a box (rectangular or square), set work mode for the laser engraving machine, the sculpture is 0. 5 mm instead, then see

laser engraving effect, theretically, should be aligned, namely the odd interlaces did edge should be aligned, even did edge also

should be aligned, only the odd and even did not have a ittle.

b. When you open "set laser engraving parameters", the parameters for different. laser engraving speed can be seen, the reverse

gap is '0", you should adjust it as the matter of fact.

c. You can choose "single -track light" when best laser engraving needed ,Not to choose the draw of "dual engrave",but when you choose it, the effciency would be lower.

6. The X-axis or the Y-axis not move.

a. Stir knob to chose the DC 5V, test the voltage between PULX (or PULY) and GND. Take Y axis as example, click the button of "up

or "down", the normal voltage is 2.8V, if it is not, we could confirm the controller was broken, please change the controller. If it is,

please go to next step.

b. Exchange the output terminal of the two drivers, then press "Up" or "Down" button; if X axis works normal, it means there is

something wrong with the motor on Y axis, please change a new one; if X axis doesn't work, it means there is something wrong with

the driver on Y axis, please chance it.

7. X Axis and Y Axis work in only one direction.

a. Test the voltage between the DIRX and GND after pressed the multimeter into grade 5V; take the X Axis for example, press "Ilft",

then press "right" to see if there is some change on high level (>2 8V) and the low level(<0 8V); if not, the control card is broken and

need to change a new one.

b. If with change, please check the driver, if works normal, please change the driver on Y Axis.

8.No Ray

Test the voltage between the LAS and GND after pressed the multimeter into grade 5V; press "fixed fire" in the control panel, to see if

there is some change on high level (<>2 .8V) and the low level(<0 8V); if not, the control card is broken and need to change a new one.

Also set up the time of fixed fir as 0 millisecond, which is in the PAD03 menu.

Adjust the power from 0%~100%, enter and press "fixed fire" button, then test if any change between the DA1 and GND from 0V to

5V; if not, the control card is broken, please change it, if both with, it means there is something wrong with the laser power supply.

• Previous: How to correct CNC router spindle common failures ?

- The Risks Associated With Laser Welding And How To Mitigate Them

- How To Decide If Laser Welding Is The Right Choice For Your Business?

- The Benefits Of Laser Welding For Businesses

- What Is Laser Welding And How Does It Work?

- Which configuration should I choose for my welding machine?

- Laser Welding Machine What parameters should be checked?

- How to choose the laser beam source?

- Laser welding machine Pulsed or continuous laser?

- Why choose a laser welding machine?

- Choosing the right laser welding machine

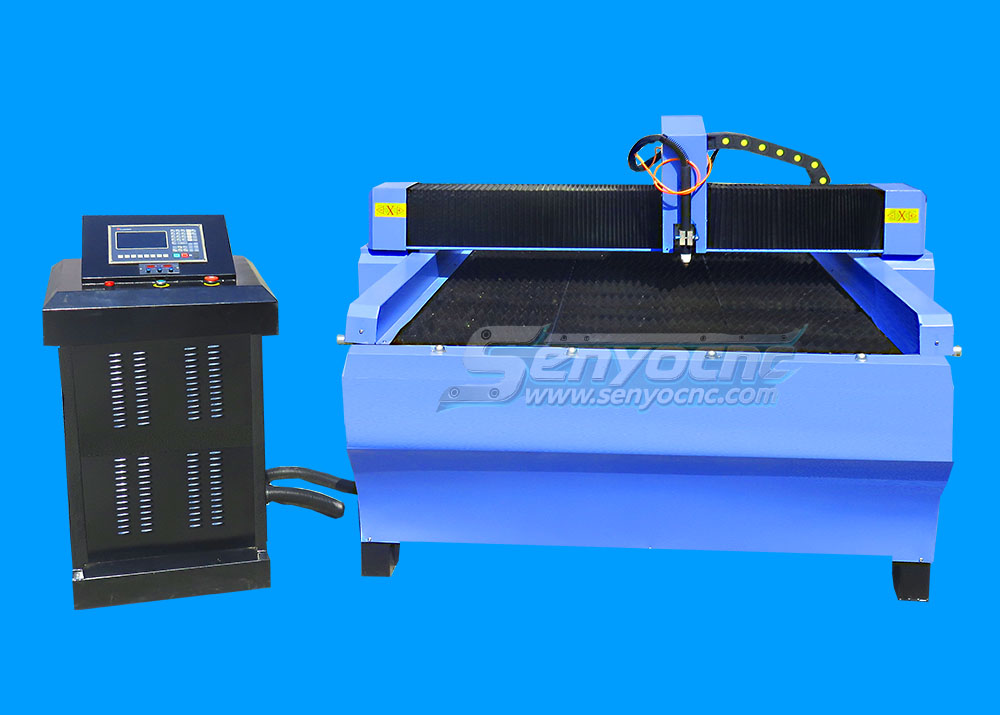

- What Are The Advantages Of CNC Plasma Cutters?

- What are CNC plasma Cutters Used For? What materials can CNC plasma Cutters cut?

Jacob from United States

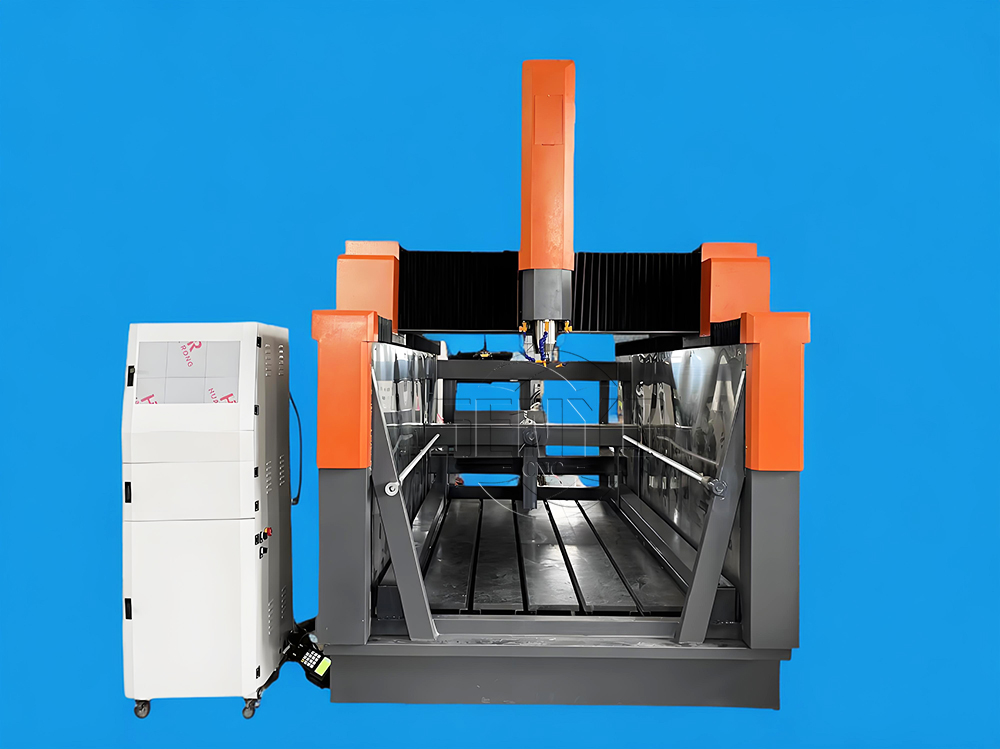

I am a beginner at CNC, I’ve never used a CNC machine before and with in a day I was carving. An awesome machine for a beginner to learn as hobbyists. I used the manual and the help video. One hour to assemble and test, very friendly and easy to use. It’s a good buy for the money. I would definitely recommend this machine to someone getting into CNCs.

Weinstein from France

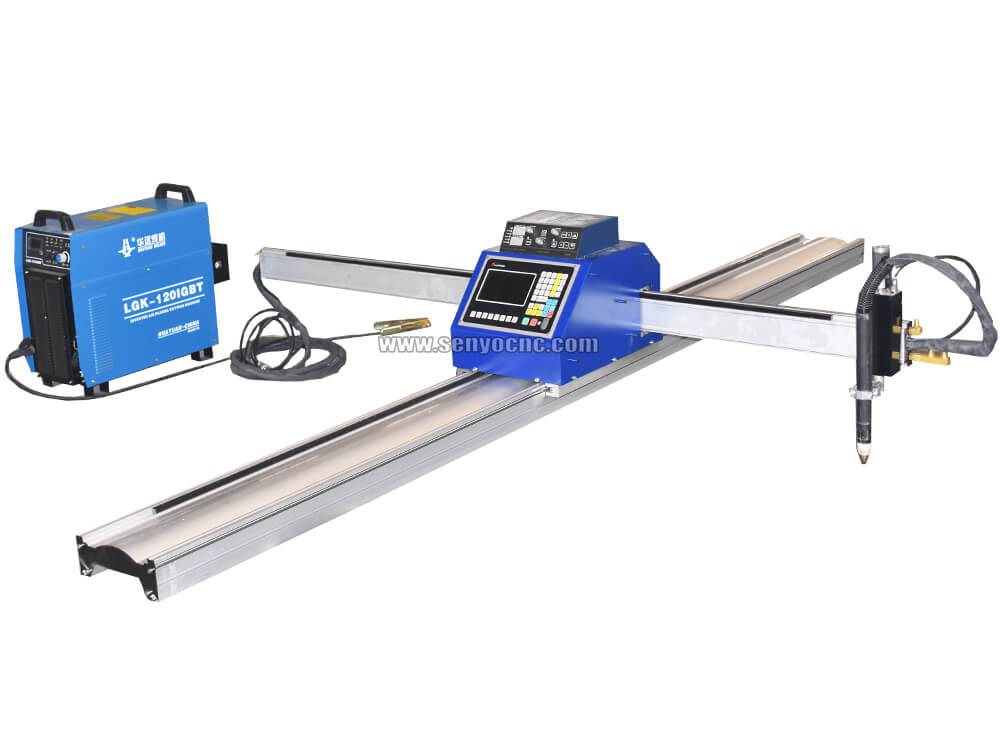

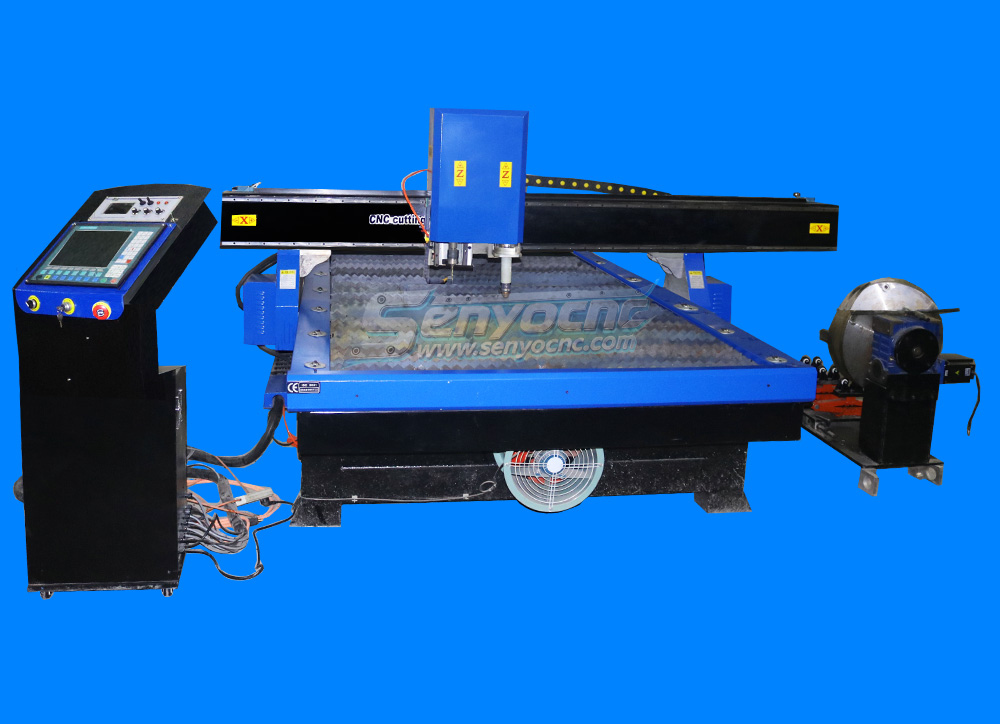

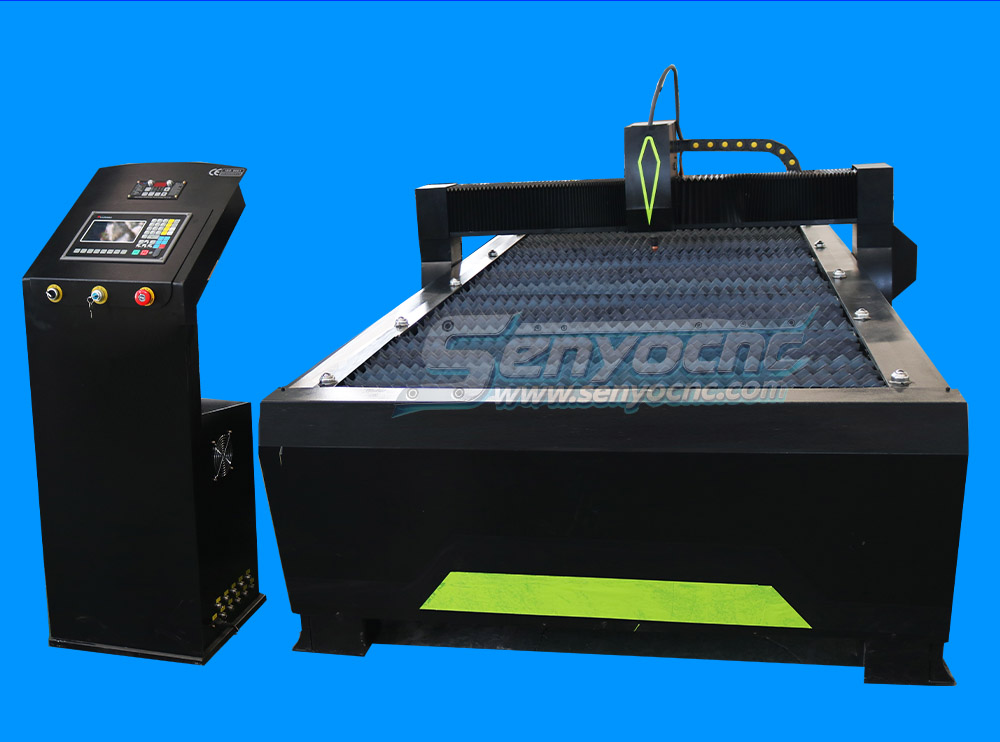

I've been using CNC plasma SYP2060-300A and I am very impressed with this unit.

This unit is of higher quality, made in China. Five stars all the way!

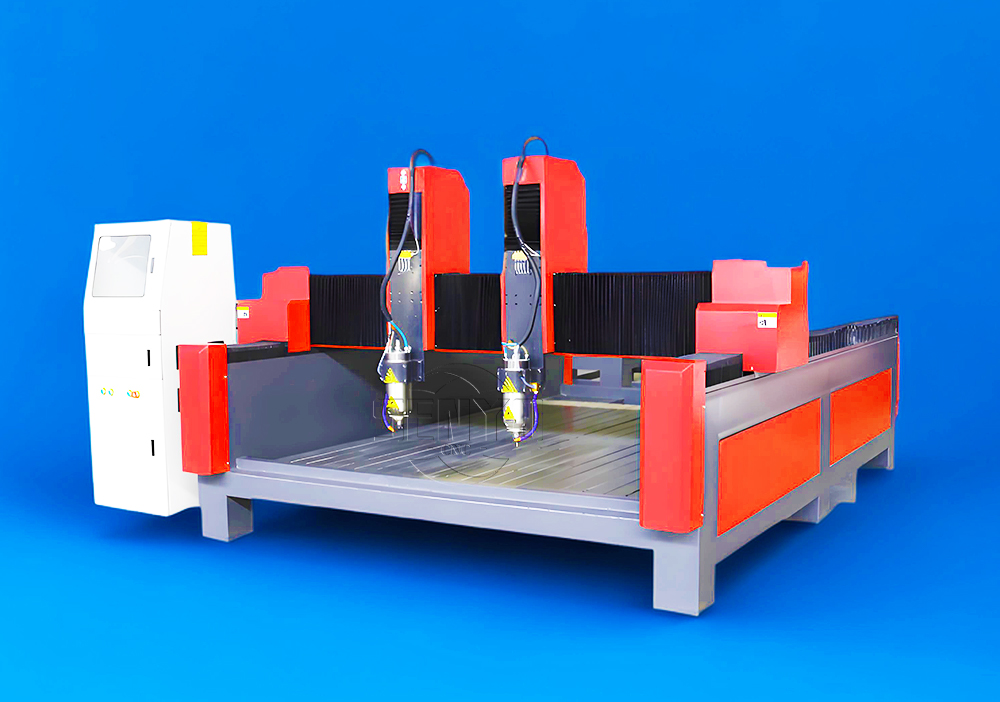

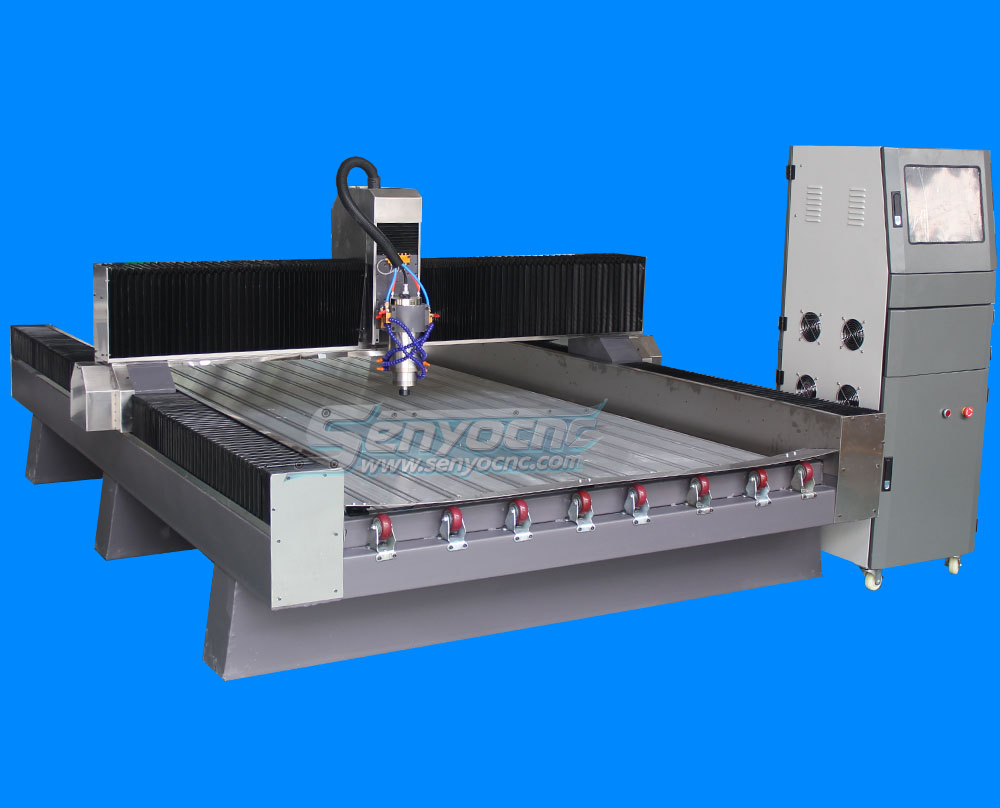

2040 from INDIAN

Best 2040 CNC Router Good Price and Quality ! Thank SENYOQC

10w uv laser from American

Best supplier ! I bought 3 machines for laser and router , thank you Aillen ! --Alec

12KW Fiber Cutting - 2000X6000mm -- 이병헌 from Korea

Good machine for metal cut ! Thanks Senyo , Its prefect , I like your business patient kind!

I am a furniture manufacturer, and this machine is very good and fast. thanks Senyoqc Team ! from Bangladesh

Metal ArtWork from Denmark

The plasma cutting machine makes my artistic creation more convenient and precise!! Created more artistic ideas and value! Thank you Aillen team!

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen. from

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen.

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo from

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo

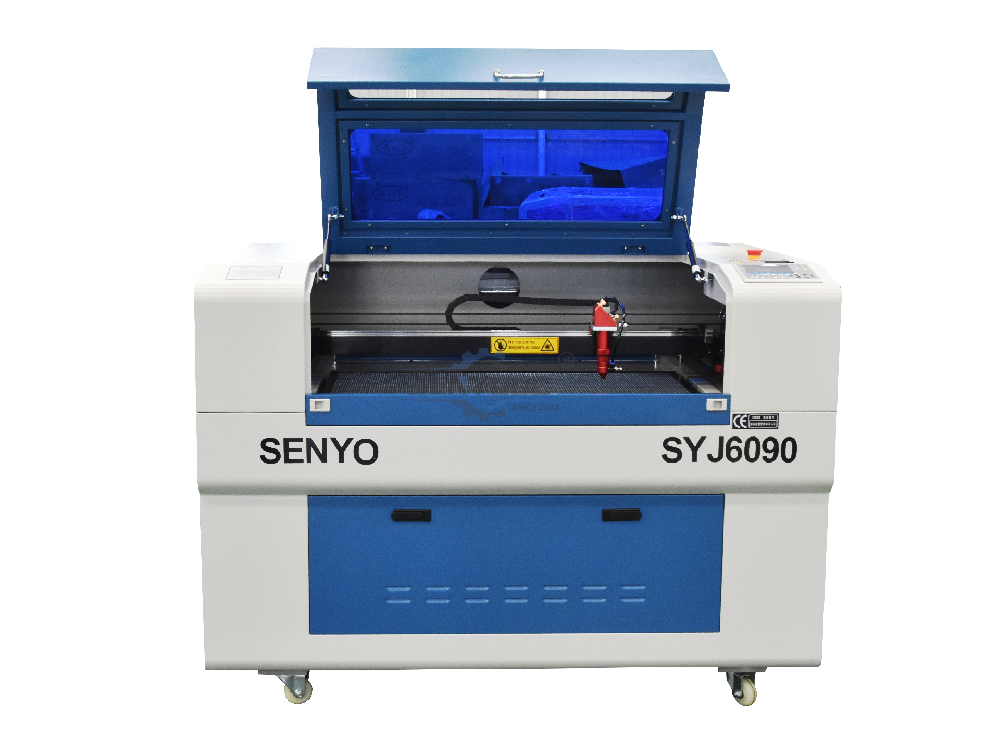

Thank you Senyo for SYJ1290-150W! from

Retired, ex mainframe systems programmer. Now full-time recreational woodworker majoring in puzzles, pens, boxes, Toys and occasional small furniture. Thank you Senyo for SYJ1290-150W!

manager@senyocnc.com

manager@senyocnc.com

SENYOCNC

SENYOCNC

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

2061579344

2061579344