+86 1525 3141 880

+86 1525 3141 880

HOME >> Support and Service >> CNC FAQs

Mini Desktop CNC Router for Gifts Making Small Business

Best Granite marble manual polishing machine For Sale

Stone Processing CNC Equipment Automatic Tool Changer CNC Quartz Stone Machining

3020 40W Mini CO2 Laser Engraving Cutting Machine

New Design Mini Stone CNC Machine for Marble, Granite and Quartz

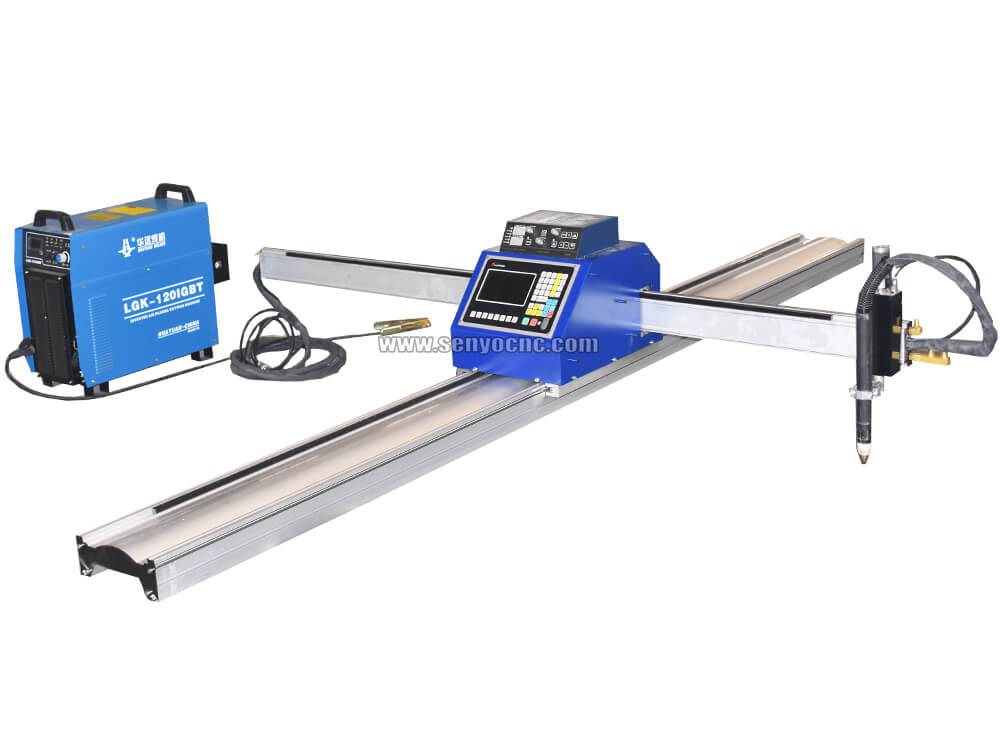

Portable CNC Flame Cutting Machine with Plasma Torch for Sale

High-Precision Mini Hobby CNC Plasma Cutting Machine for Metal

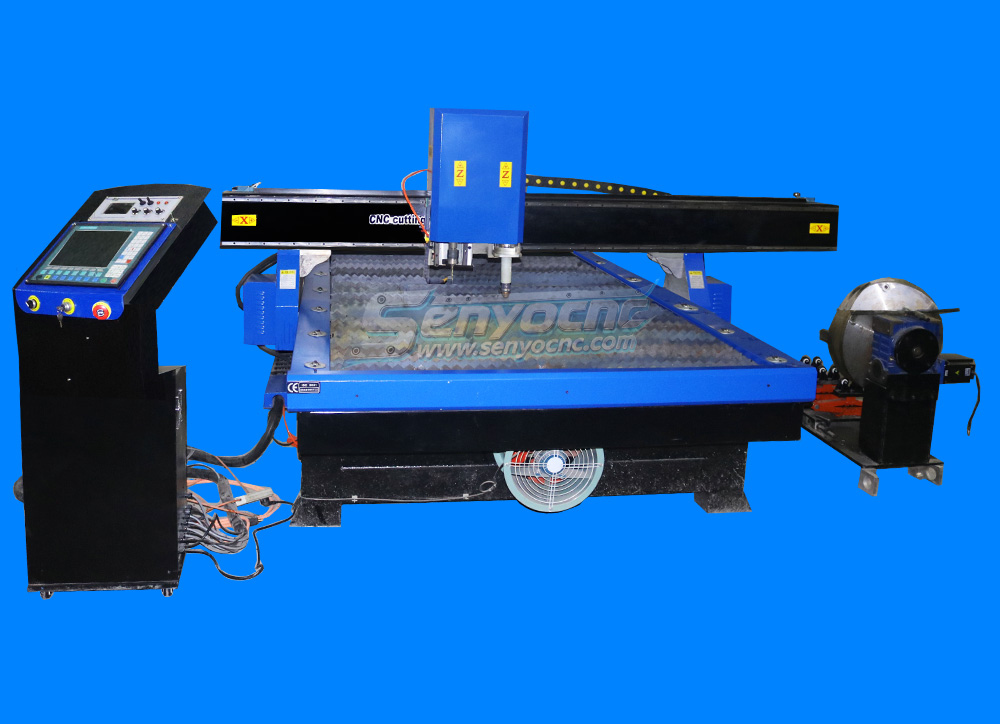

Mini CNC Plasma Cutter With Rotary

4 Axis 1325 Sculpture Machine Cnc Carving Marble Granite Stone Cnc Router

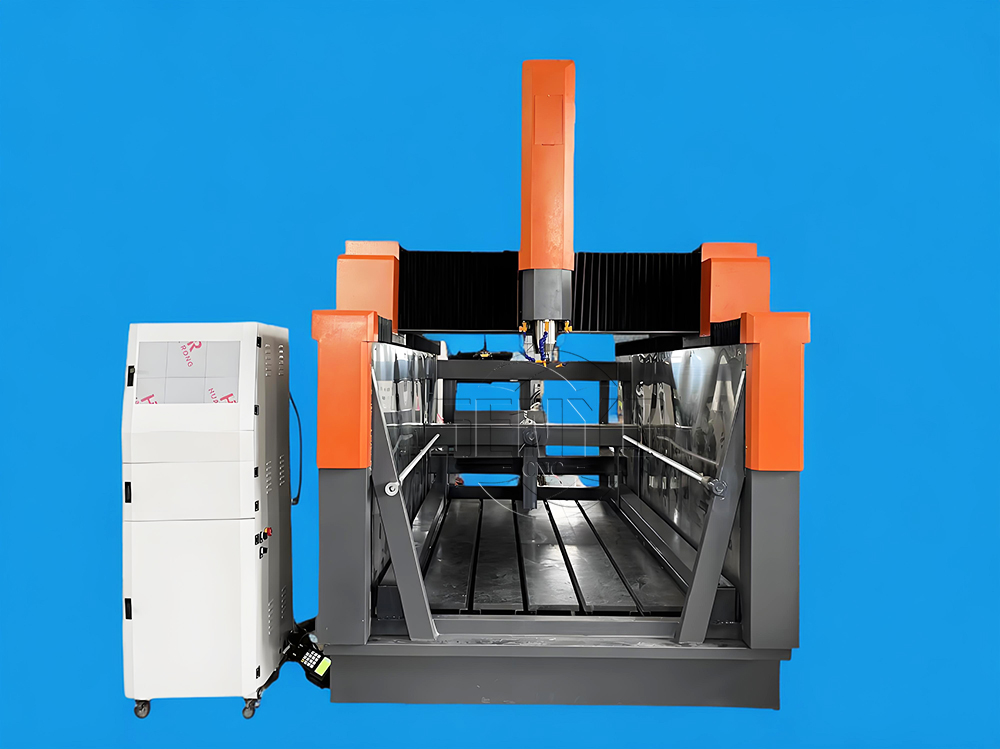

Z Height 1000MM 4-AXIS Stone Engraving CNC Machine Heavy-duty Stone CNC Machine Stone Relief Carving CNC For Sale

4030 portable mini co2 laser carving and desktop rubber stamp laser engraving machine

Stone CNC Router For Kitchen sink tile carving and cutting Marble, Granite and Quartz

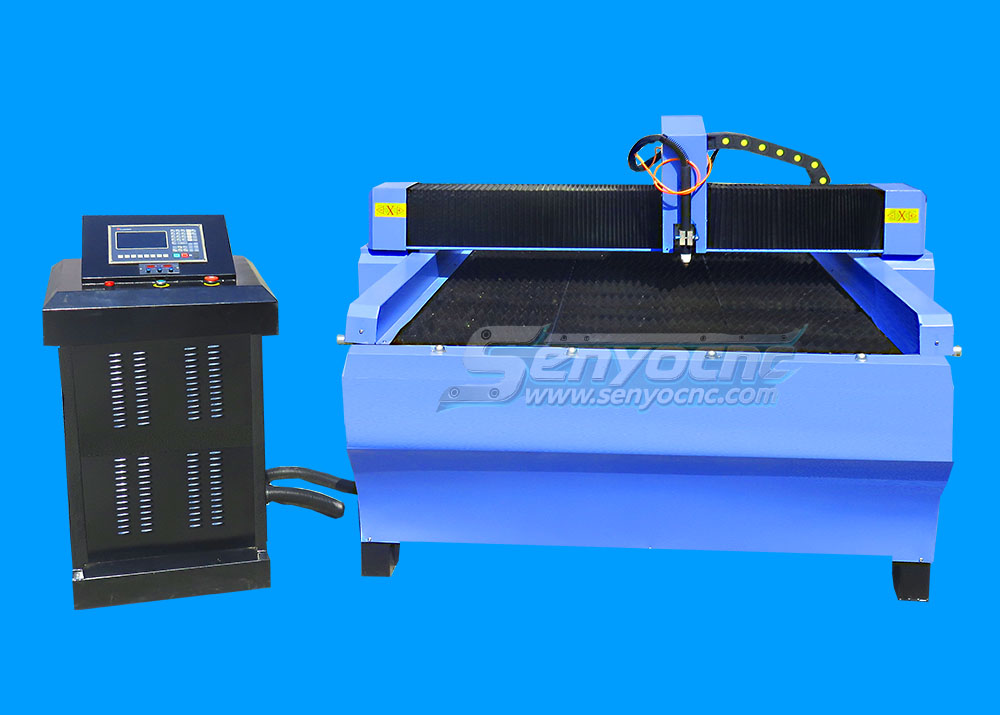

Robust CNC Plasma Cutting Machines with Flame Cut Head for Heavy-Duty Industrial Use

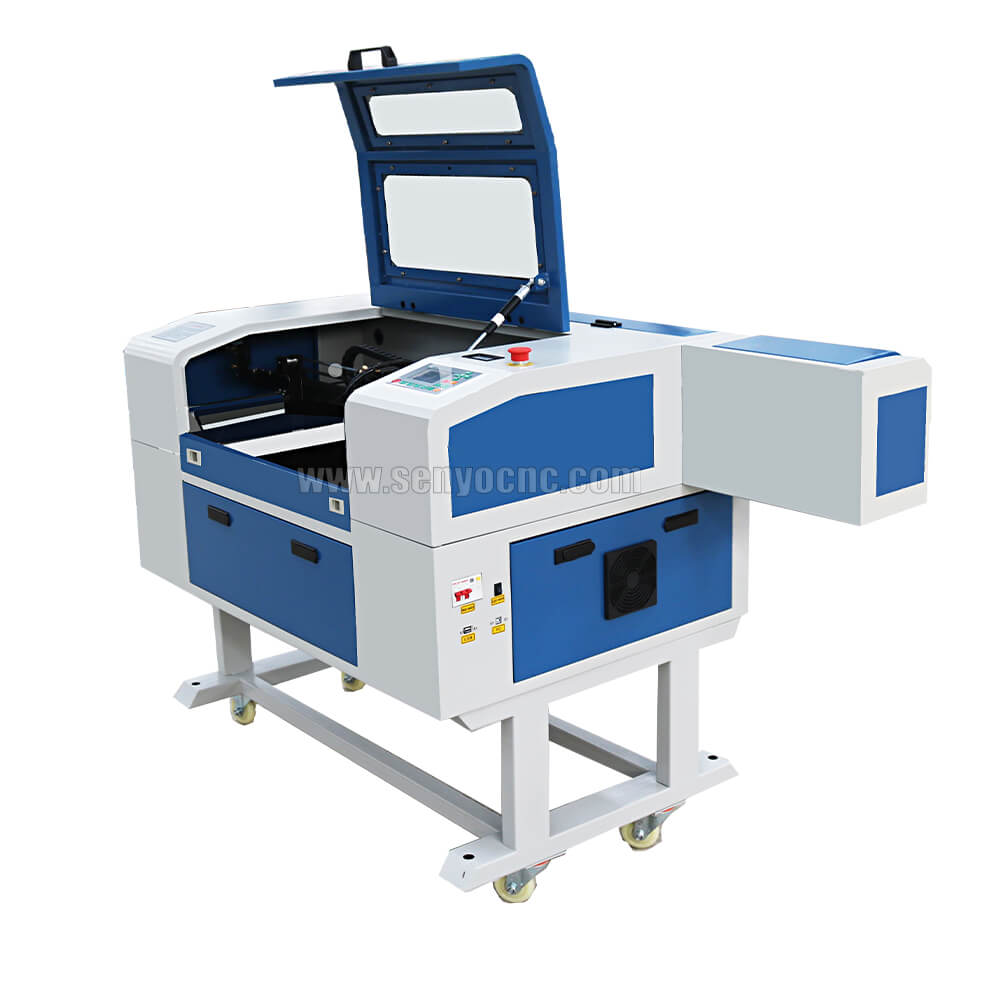

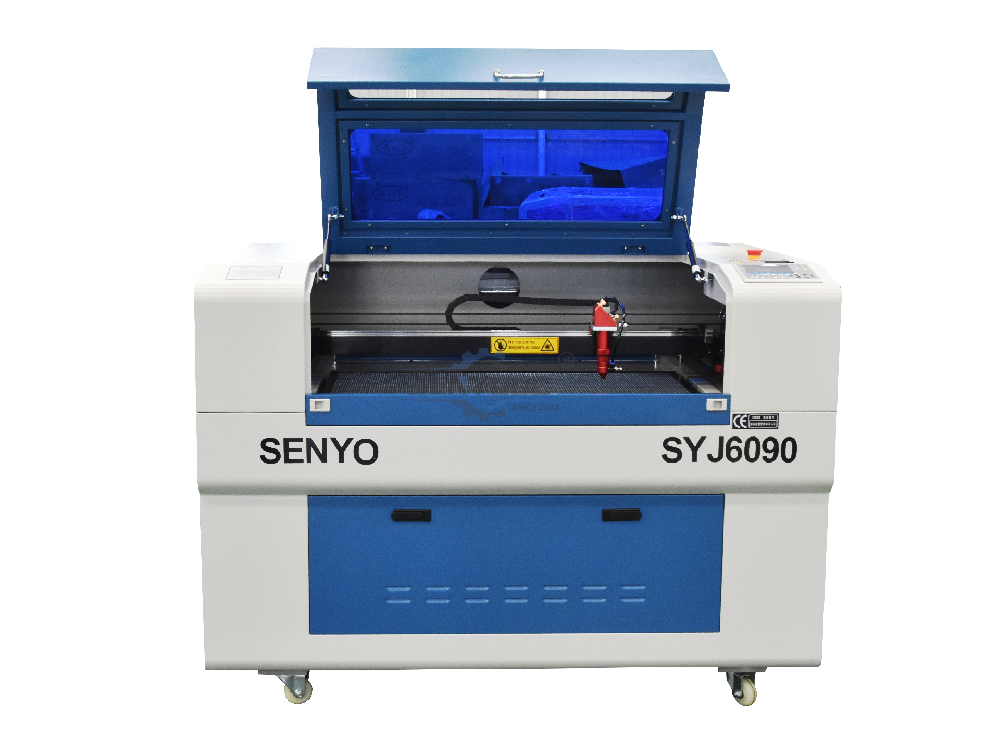

Small Portable CO₂ Laser Cutter Engraving for DIY & Business – Ideal for Wood, Acrylic, Leather

1325 3 Axis 4x8 CNC Stone Router for Sale

Mini CO2 Laser 5030 Cutting Engraving Machine For Sale

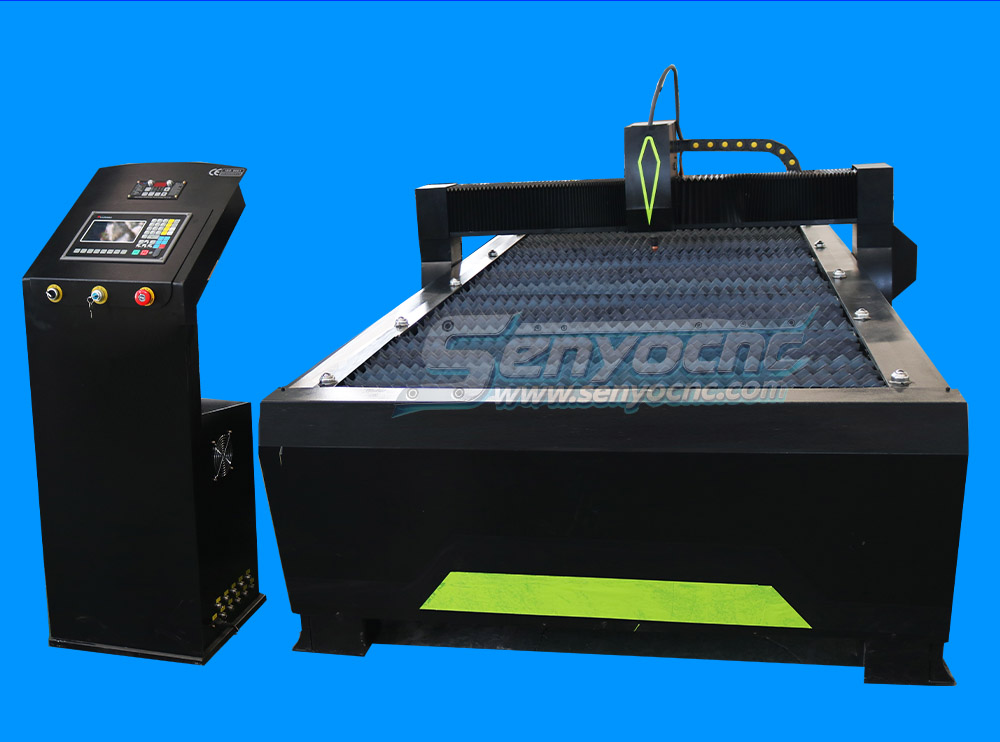

Portable CNC Plasma Flame Cutting Machine for Sale at Cost Price

Portable Cnc Plasma Oxyfuel Sheet Metal Cutting Machine for sale

CNC Plasma Cutters for Customized Metalwork –Rotary&Drilling Head

Small Table design 6040 Easy Move CO2 Hobby Laser Cutter Machine for Beginners

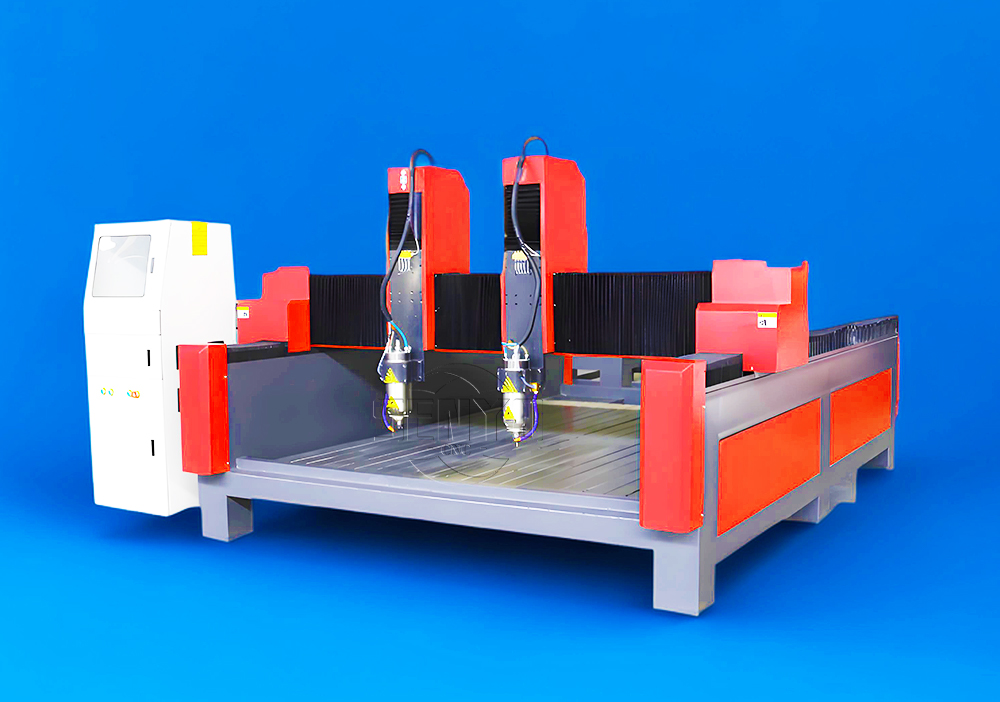

High-Efficiency 2 Heads CNC Machine for Aluminum Stone Marble Engraving & Cutting

Best CNC 2 Spindle 4-AXIS Stone Carving Machine High-precision Stone Carving Stone Countertop Fabrication

Top Rated 2x3 CO2 Hobby Laser Cutting Machine for Sale at Affordable Price

Best 4x8 CNC Plasma Cutter Table for Sale at Affordable Price

Entry Level CO2 Hobby Laser Cutter Machine for Beginners

Top CNC Plasma Cutters for Automotive, Aerospace, and Manufacturing Industries

Precision Stone Engraving Machines for Memorials & Signs

Portable Co2 9060 Laser Nonmetal Cutting Engraving Machine

1090 CO2 Laser Machine with Ruida Controller for Non-metal Glass Acrylic Engraving Cutting

Entry Level 9060 CO2 Hobby Laser Cutter Machine for Beginners

This type of multi-head engraving machine

is mainly applicable to the processing of three-dimensional wave board,

cabinet doors, solid wood doors, craft wooden doors, paint-free doors,

screens, craft window etc., and it is widely used in antique furniture,

European-style furniture and other furniture industries. And this type

of multi head CNC router is also suitable for processing cabinet doors,

art embossed screens, craft windows, embossed craft gifts, solid wood

art murals, woodwork calligraphy carving, art photo frames, electrical

countertops, sports equipment, violin arcs, non-ferrous metal carving

and cutting.

Multi-head engraving machine is a wood

CNC machine which mainly designed for users with small product size and

large processing volume. This kind of CNC wood router whose spindle can

be customized according to the user’s specific processing needs.

Multiple spindles can be processed simultaneously to meet the needs of

batch processing of products. Especially when processing the same

pattern on the board, multiple spindles process at the same time, which

greatly improves the processing speed of the board. One CNC

router complete the production of multiple machines at once, which

greatly improves the production efficiency, and the processed products

have better consistency. In the case of a small production volume, a

single spindle can be independently processed, and the production cost

can be controlled reasonably and effectively. Therefore, with the

advantages of fast product processing speed, good consistency, low cost,

high production efficiency, and diversified processing methods, such

multi-head engraving machines are welcomed by domestic and foreign

users. If you have similar batch production needs, this multi-head

engraving machine is definitely your ideal choice.

The use of automatic changers increases

the productive time and reduces the unproductive time to a large extent.

It provides the storage of the tools which are returned automatically

to the machine tool after carrying out the required operations,

increases the flexibility of the machine tool, makes it easier to change

heavy and large tools, and permits the automatic renewal of cutting

edges.

After receiving the tool change command, the tool to be changed will assume a fixed position known as the “tool change position”. The ATC arm comes to this position and picks up the tool. The arm swivels between machine turret and magazine. It will have one gripper on each of the two sides. Each gripper can rotate 90°, to deliver tools to the front face of the turret. One will pick up the old tool from turret and the other will pick up the new tool from the magazine. It then rotates to 180° and places the tools into their due position.

Now we are talking about the linear ATC CNC Machine. This type machine uses a straight-line tool change device, and the tool change device can be installed in different positions according to the specific needs of the user. Firstly, the in-line tool magazine can be placed behind the bed. This conventional in-line tool changer engraving machine is cost-effective and can meet a variety of processing requirements for complex work pieces without high procurement costs. Secondly, the in-line tool magazine can also be placed under the gantry.

This

type machine is also one of the most selected by users. The position of

the disc magazine can also be selected according to user needs. On the

one hand, the disc magazine can be placed next to the spindle. The

biggest advantage of this type machine is the fast tool change. However,

the number of tool bits should be guaranteed to be within 20 tools. If

the number of tool exceeds 20, the weight of the cutter head will

increase, which will affect the bearing capacity of the Z axis and the

gantry, especially the Z axis screw and the guide rail slider. And all

these will affect machining accuracy. On the other hand, the disc

magazine can be placed on the side of the gantry.

Depending on the shape of the magazine,

ATC can be of two types:

1) Drum Type changers(Disc/ carousel Types) are

used when the number of tools is lower than 30. The tools are stored on

the periphery of the drum.

2) Chain type changers(Liner Types) are

used when the number of tools is higher than 30(The number is different

depending on the design and manufacturer. It is important to note that

the number of tools for the drum type is fewer than the chain type). But

the tool search speed will be lower in this case

First, high productivity. Equipped with automatic tool changing device, which can meet the tool changing requirements during processing without manual participation. With simple and easy operation mode to learn, which can help users quickly grasp the use of methods and greatly improve production efficiency.

Second, imported spare parts.

Adopting the automatic tool changing spindle, it has the advantages of good starting performance, fast processing speed, large torque and high processing efficiency.

Adopting Italy HSD spindle motor, and spindle bearings with high-precision ceramic bearings, it has the advantages of low noise and long service life.

Equipped with the imported high torque servo motor, it has the advantages of low noise, fast speed and high positioning accuracy.

Equipped with a unique tool changing device and a dedicated tool setting table, it can realize automatic tool changing without intermittent with fast tool changing speed, and can accurately compensate for tool length errors.

Adopting Taiwan linear guide and ball screw, it has the advantages of high bearing capacity and accurate cutting.

Third, good software compatibility. Adopting open software interface, it can be compatible with the processing codes generated by various CAD / CAM design software, such as type3 / Artcam / JDpaint / Wentai, to ensure the realization of various design functions.

ATC CNC router is the first choice for

enterprises with large production volume. Compared with the traditional

manual tool change production method, this type of wood CNC machine has

an independent tool magazine with different tool bits. It can

automatically change the required tools by computer program control

without stopping work during processing. And this CNC wood router can

complete a series of cutting, hollowing, grooving, punching, milling

grooves, milling planes and other different processing needs. Therefore,

both the processing quality and processing efficiency have been greatly

improved.

Generally, an Automatic tool changer or ATC is used in computerized numerical control (CNC) machine tools to improve the production and tool carrying capacity of the machine. ATC changes the tool very quickly, reducing the non-productive time. Generally, it is used to improve the capacity of the machine to work with a number of tools. It is also used to change worn out or broken tools. It is one more step towards complete automation.

Simple CNC machines work with a single tool. Turrets can work with a large number of tools. But if even more tools are required, then ATC is provided. The tools are stored on a magazine. It allows the machine to work with a large number of tools without an operator. The main parts of an automatic tool changer are the base, the gripper arm, the tool holder, the support arm and tool magazines. Although the ATC increases the reliability, speed and accuracy, it creates more challenges compared to manual tool change, for example the tooling used must be easy to centre, be easy for the changer to grab and there should be a simple way to provide the tool’s self-disengagement. Tools used in ATC are secured in toolholders specially designed for this purpose.

an economical cutting process in the steel sector to 35 / 40mm thickness

the fastest thermal cutting process

High cutting quality

Less thermal influence than the autogenous flame cutting

Automation is given

Cuts all electrically conductive metals

Cutting speeds regardless of hardness of the material

less postprocessing

Smaller inner contours and holes possible

Cutting thicknesses up to 200 mm possible

Special cutting technologies used: drying sections and underwater sections

Complete CAD / CAM controlled production feasible

No special requirements on the working environment

Cuts even rusty steel or oily surfaces, painted surfaces up to a certain thickness

Fast grooving in thicknesses up to 50 mm (max. 80mm) possible.

Reduced investment and operating costs than with laser cutting

In the metalworking industry, the plasma cutting machine is an everyday occurrence.

There are three types:

Protable plasma cutter

Table plasma cutter

Gantry Plasma cutter

Electrically conductive materials up to 200 mm workpiece thicknesscan be cut , depending on the current intensity. Hand plasma systems have up to 120 amperes, machine-guided plasma cutters are often at ten times the value.

Mainly these materials can be plasma cut:

steel

stainless steel

Brass

copper

aluminum

Even the fire department use the advantages of plasma cutters. In some cases, the rescue operation no spreaders or cutters can be used for lack of space. Here they often use the plasma torch, the lower thermal expansion provides an important advantage: you can get closer to the person in an emergency . Even steering columns and suspension arms,due to the hardened steel are only cut with a Plasma Cutter. It reaches in small mobile devices a current strength of 20 to 60 A. Rescue teams it is thus possible to cut up to 60 mm thick construction steel.

Mini Desktop CNC Router for Gifts Making Small Business

Best Granite marble manual polishing machine For Sale

Stone Processing CNC Equipment Automatic Tool Changer CNC Quartz Stone Machining