+86 1525 3141 880

+86 1525 3141 880

HOME >> Support and Service >> CNC FAQs

Mini Desktop CNC Router for Gifts Making Small Business

Best Granite marble manual polishing machine For Sale

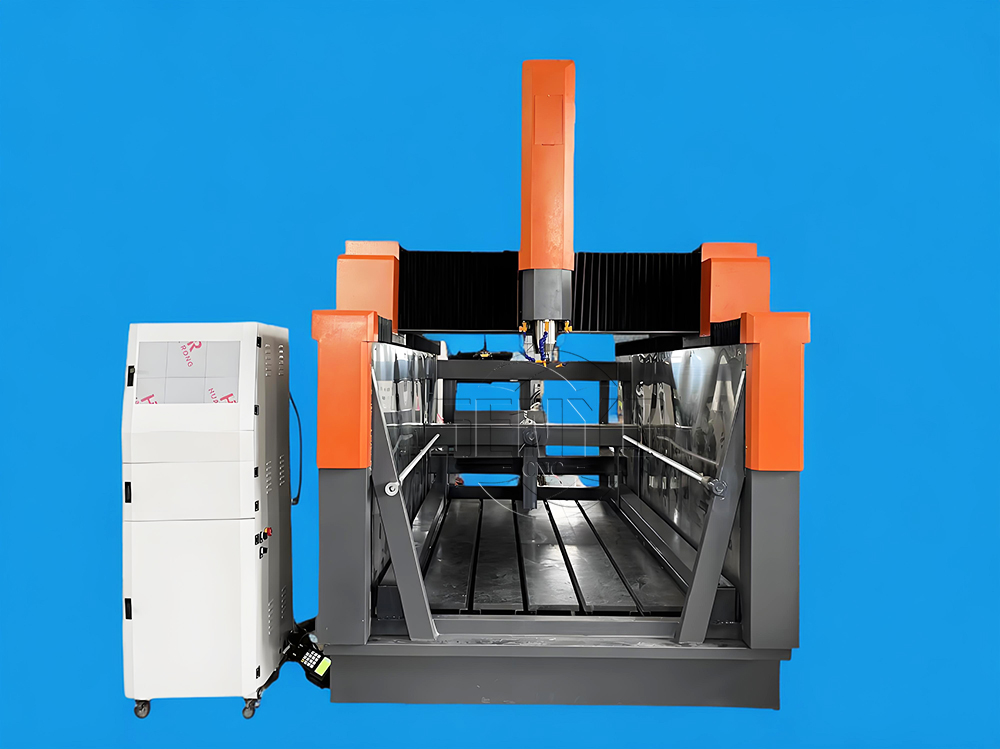

Stone Processing CNC Equipment Automatic Tool Changer CNC Quartz Stone Machining

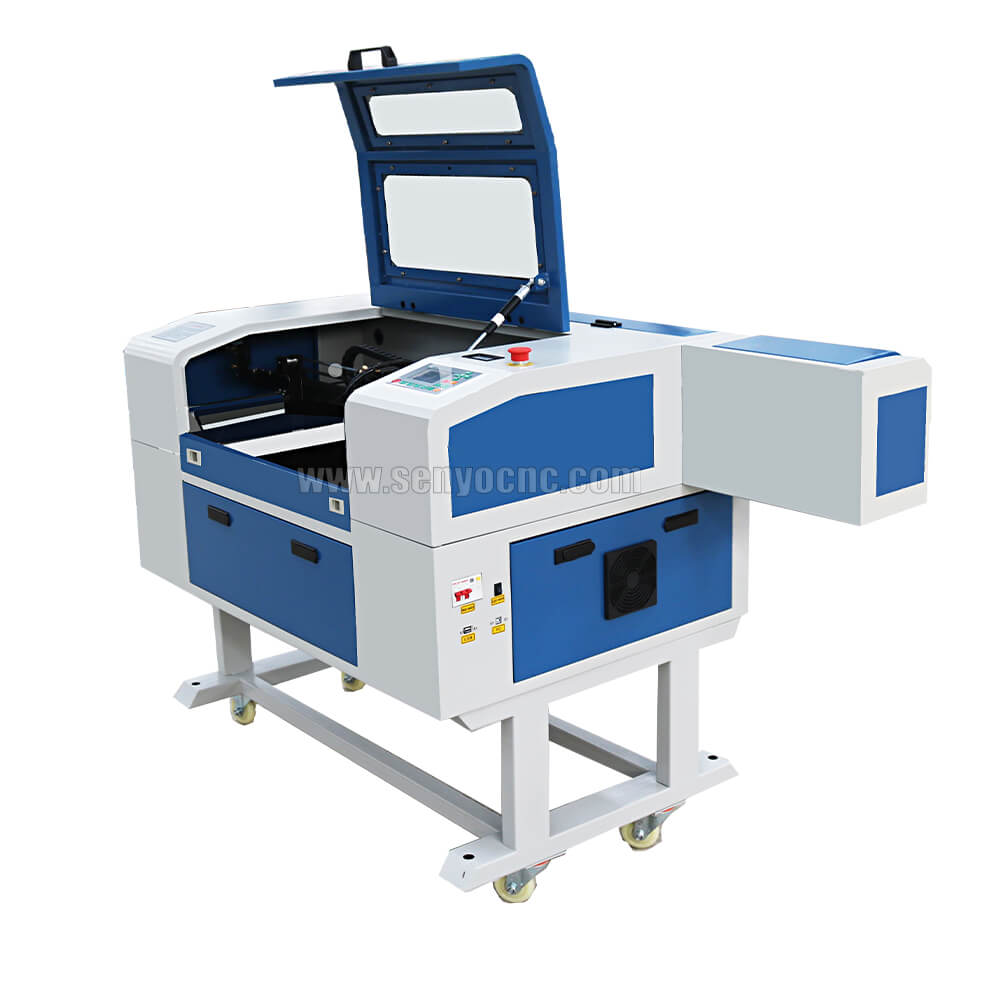

3020 40W Mini CO2 Laser Engraving Cutting Machine

New Design Mini Stone CNC Machine for Marble, Granite and Quartz

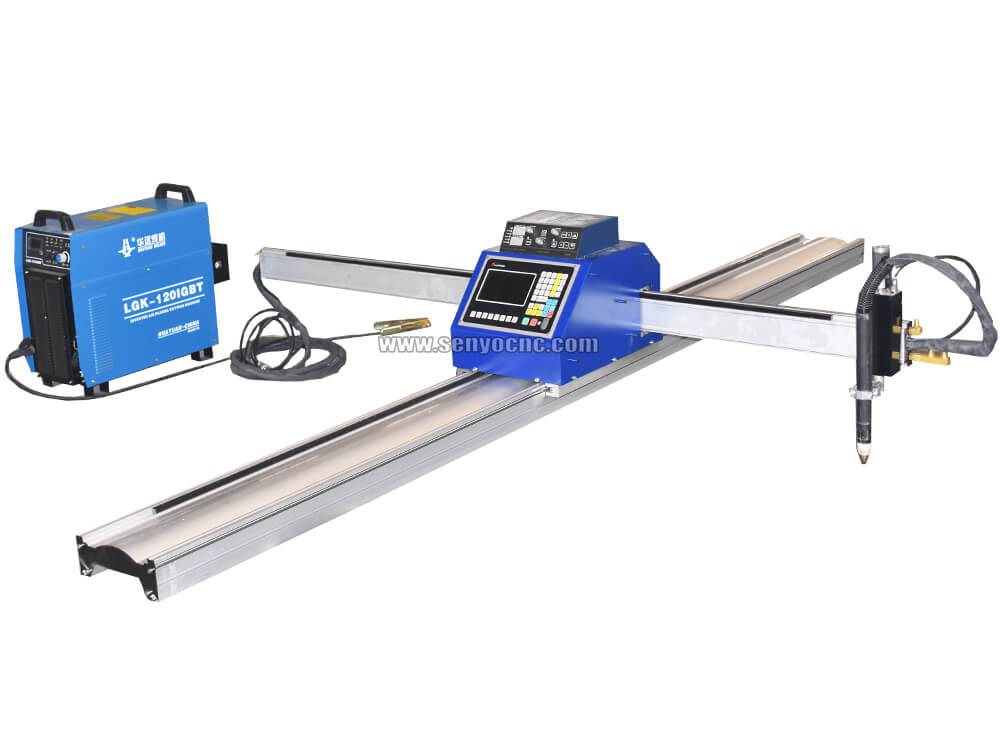

Portable CNC Flame Cutting Machine with Plasma Torch for Sale

High-Precision Mini Hobby CNC Plasma Cutting Machine for Metal

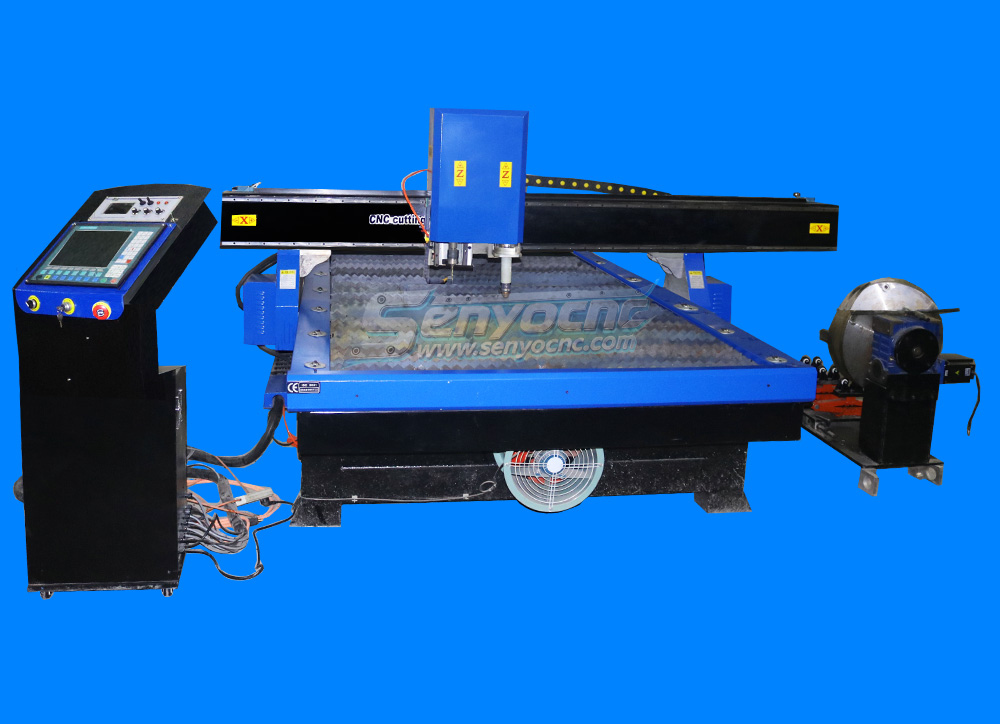

Mini CNC Plasma Cutter With Rotary

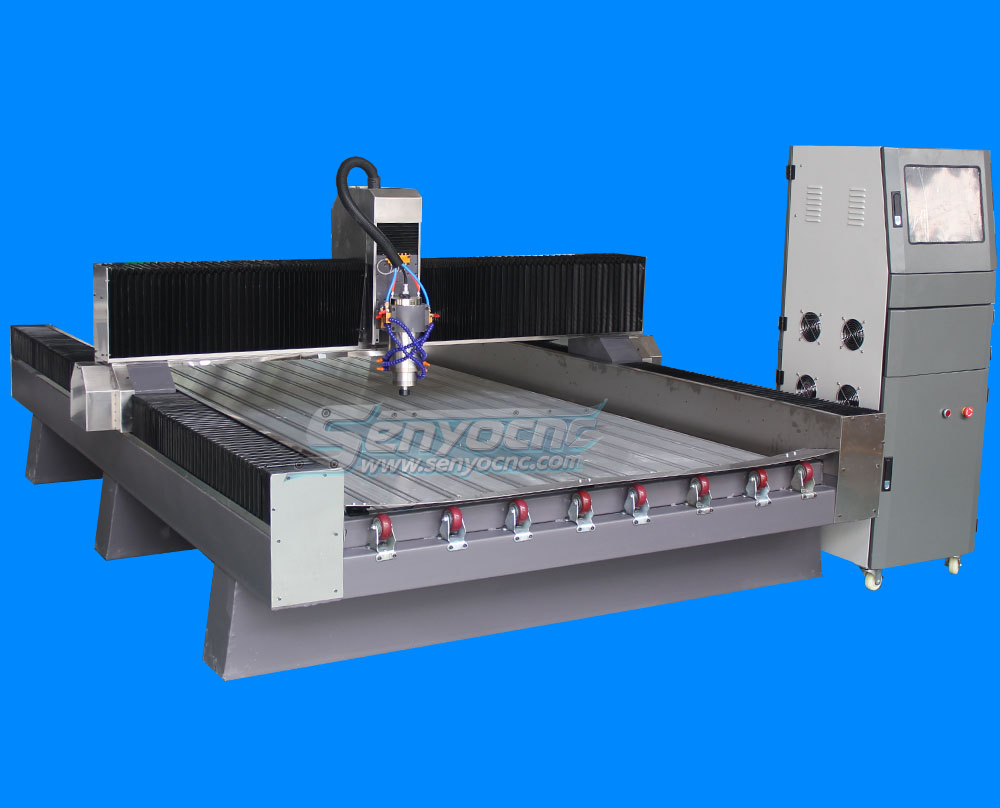

4 Axis 1325 Sculpture Machine Cnc Carving Marble Granite Stone Cnc Router

Z Height 1000MM 4-AXIS Stone Engraving CNC Machine Heavy-duty Stone CNC Machine Stone Relief Carving CNC For Sale

4030 portable mini co2 laser carving and desktop rubber stamp laser engraving machine

Stone CNC Router For Kitchen sink tile carving and cutting Marble, Granite and Quartz

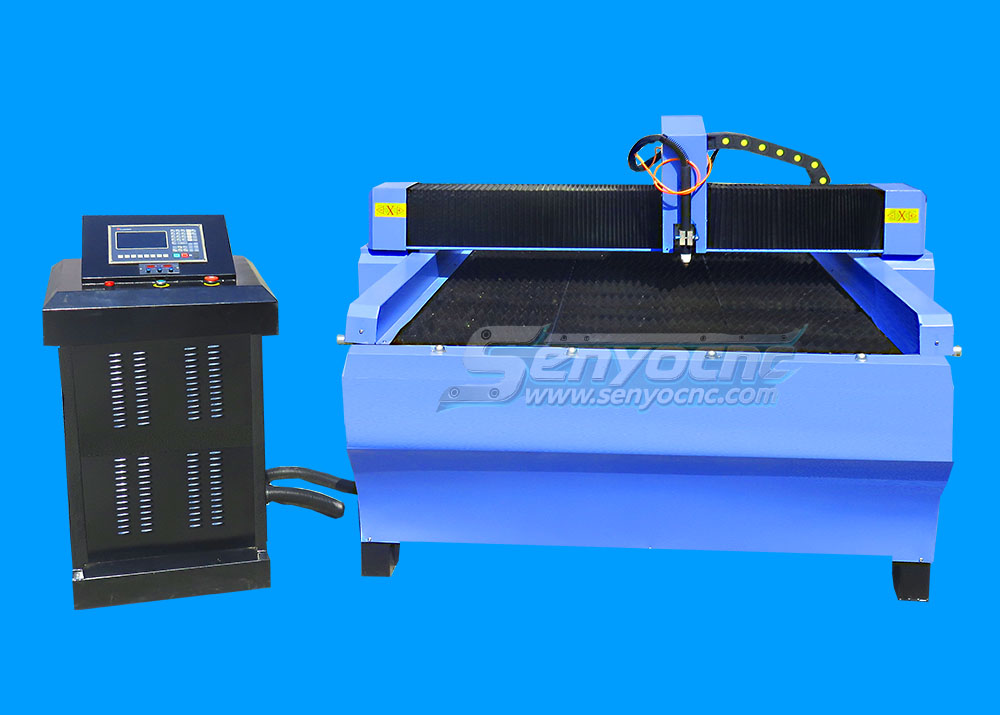

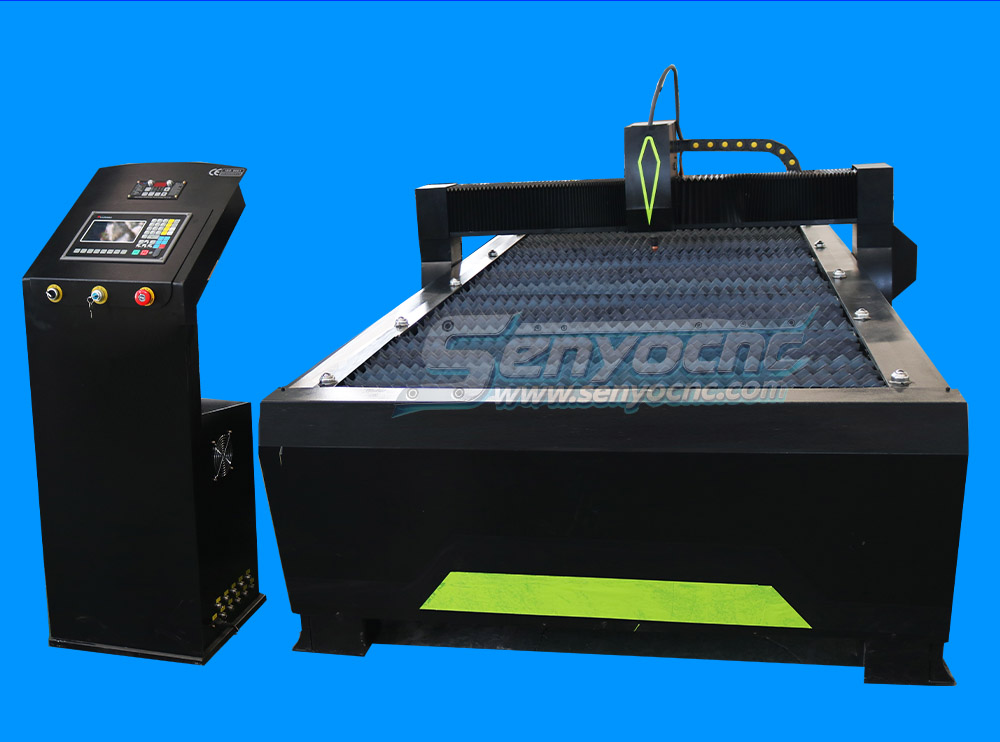

Robust CNC Plasma Cutting Machines with Flame Cut Head for Heavy-Duty Industrial Use

Small Portable CO₂ Laser Cutter Engraving for DIY & Business – Ideal for Wood, Acrylic, Leather

1325 3 Axis 4x8 CNC Stone Router for Sale

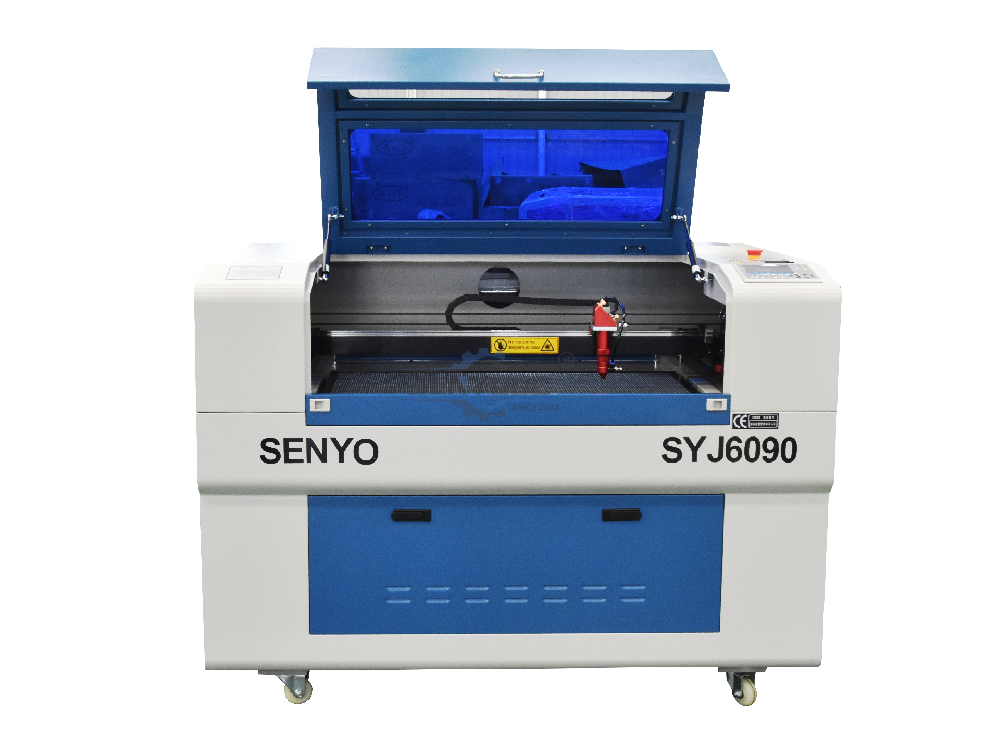

Mini CO2 Laser 5030 Cutting Engraving Machine For Sale

Portable CNC Plasma Flame Cutting Machine for Sale at Cost Price

Portable Cnc Plasma Oxyfuel Sheet Metal Cutting Machine for sale

CNC Plasma Cutters for Customized Metalwork –Rotary&Drilling Head

Small Table design 6040 Easy Move CO2 Hobby Laser Cutter Machine for Beginners

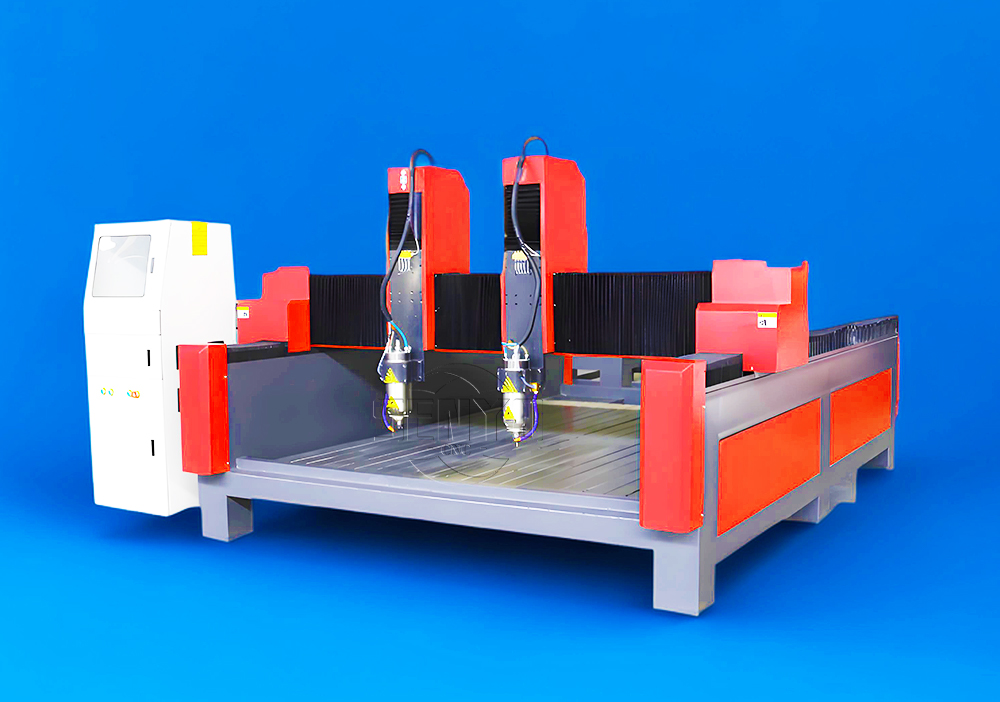

High-Efficiency 2 Heads CNC Machine for Aluminum Stone Marble Engraving & Cutting

Best CNC 2 Spindle 4-AXIS Stone Carving Machine High-precision Stone Carving Stone Countertop Fabrication

Top Rated 2x3 CO2 Hobby Laser Cutting Machine for Sale at Affordable Price

Best 4x8 CNC Plasma Cutter Table for Sale at Affordable Price

Entry Level CO2 Hobby Laser Cutter Machine for Beginners

Top CNC Plasma Cutters for Automotive, Aerospace, and Manufacturing Industries

Precision Stone Engraving Machines for Memorials & Signs

Portable Co2 9060 Laser Nonmetal Cutting Engraving Machine

1090 CO2 Laser Machine with Ruida Controller for Non-metal Glass Acrylic Engraving Cutting

Entry Level 9060 CO2 Hobby Laser Cutter Machine for Beginners

The CNC plasma cutter consists of:

power source

plasma torch

ground cable

power line

compressed air supply (option)

cooling

CNC machine

CNC plasma cutter or plasma torch is a tool that is able to cut metals through a generated arc between an electrode and the workpiece. The intensity and stability is increased by the supply of compressed air which is added through a cutting nozzle during the procedure. The result is a high-energy heated gas in the plasma cutter. So energetic that this is immediately converted into heat. Very hard materials such as steel, stainless steel, cast iron, copper and aluminum can be cut without any problems with a plasma cutter. Hardly any other device can cut so precise cuts and shapes metal. The cuts are clean and to accomplish much faster. In addition, also round shapes can be cut out

Only a few years ago a skilled engraver still manually engraved workpieces in hours of detailed work. Today this highly challenging job is often done with mechanical precision by CNC photo engraving machines.

Hobbyists and beginners increasingly use a CNC-controlled photo-engraving machine. Last but not least, to save time and a lot of hard work, but also to achieve professional results.

Photo Engraving are applicable in:

Engraving of Medallions

Engraving of pictures on grave stones and grave plaques

Photo engravings or logos of any kind as on cups, machine parts, technical equipment, grave stonesNumbering of metal components (serial numbers)

Personalizing gift items with photo engraving

Manufacturing of individual and high quality jewelry

When purchasing a CNC engraving, it’s best to look for a technically competent manufacturer or seller. The most important rule when buying an Engraving machine or milling machines is:

The more accurate my machine is adapted to the needs of a workpiece, the more accurate the result is!

Some preliminary questions should be answered:

Size

What size should my engraving machine have? What are the maximum dimensions of the workpiece to be machined?

For a gravestone engraving, I need a different size than for series identification plates. Principle of “Bigger is better” – If I buy a smaller engraving machine I am limited in terms of future projects, if I buy a bigger one, I have more flexibility in the implementation of major projects.

Tools

What should I consider when buying the CNC tools? The accessories are an important criterion. Here it is essential to use the right tool, suitable to the material of my workpiece and the performance of my machine. Rotating tools (Engraving) are used but also fixed Slicing machines (mostly diamond tips) for various purposes. Again, advice should come by a well-trained salesperson.

Suction

Do I necessarily need a suction when engraving? As it comes to increased dust production, by removed material when engraving, you should draw a suction into consideration. The dust can change the engraving depth and hence also the precision of the result. It may also (especially with abrasive materials) come to buildup on the mechanical components of the engraving machine, which may affect the function of the CNC engraving machine.

The abbreviation CNC stands here again for Computerized Numerical Control. A machine, in this case, the engraving machine is, therefore, controlled numerically by a computer.

Previously entered data records are passed to the engraving system, so that they can be traversed appropriately and gradually until the desired result is achieved. This happens using a mounted on the engraving machine tool, this miles or scratches in highest precision, complex and multidimensional forms, even in stone materials.

Engraving machines also exist in the form of laser engraving machines. Here the engraving is not performed by a mechanical milling body or graver but levitated by a high-energy laser that burns/engraves precise into the workpiece.

In the selection of materials to be processed you are almost unlimited:

steel

granite

Wood

plastic

Glass

ceramics

marble

MOP

stone

metals

What was once done manually with a lot of work by a professional engraver in long hours of arduous work, today is done by a CNC engraving machine.

But not only in the professional field, you can find more and more users, even hobbyists and beginners buy increasingly CNC engraving machines, to save time and effort and to obtain an accurate result.

CNC engraving machines are used for:

Sign engraving

Engraving of pictures on, e.g. stone, granite, marble or wood

Labelling of any kind as Trophies, machines, technical equipment, gravestones

The numbering of metal components (serial numbers)

Personalized gifts, e.g.Producing unique jewellery

photoengraving

Making of 3D lithophanes

3D or 2D point marking

The machine capacity

Consequently, before you send your inquiries to various manufacturers think about your project. For example, you should already have an idea of the approximate size of the materials which you will process. The traverse paths of the machine ultimately limit the size of the material that fits on the working area.

The pump and its performance

It is also extremely important to know which materials to machine, as this also determines the choice of the required pressure performance of the pump. Softer and thinner materials such as rubber, plastic or wood require less power than harder materials such as metals, for example, cast steel or steel. A knowledgeable machine manufacturer is happy to assist you in deciding.

Material to be machined

Furthermore, the torsional rigidity of the entire system is significant concerning the application. With water jet cutters, one can generally say that they should have high torsional stiffness. This is important since the recoil when the waterjet is switched on can sometimes cause a loss of accuracy on the material to be processed in an unstable system.

Accuracy – Set cutting values exactly

You should configure the cutting values of the water jet cutter as ideally as possible for the material you want to process. Because the more precisely the cutting system is adapted to the requirements of the material, the more accurate and clean the cutting results will be.

With these tips, you are well prepared accordingly. You should also consider a possible prior inspection of the machine. In this case, you can also ask the manufacturer or dealer of your choice for a test cut in the material you are using. In this way, you can personally convince yourself of the construction of the machine and the working results.

You can make the water jet even more effective by adjusting the water pressure, increasing the abrasive content and adjusting the nozzle diameter. This accelerates the flow rate of the water and the abrasive particles, which results in an increased impact of the jet on the material and thus increasing the cutting force. Of course, you should note that the dosage of garnet sand should be adjusted according to the thickness of the material to be cut.

With the technique of water jet cutting, for example, various materials can be ideally and precisely processed:

natural stone such as granite, marble, sandstone, slate, soapstone

ceramic tiles, flagstones, porcelain stoneware, clay

stainless steel, steel, brass, copper, tool steel

plastics like PTFE, Plexiglass, polycarbonate

woods like hardwood, beech, spruce, fir, multiplex

glass and many more

You will find the versatile application possibilities with our water jet cutters in this article.

On the other hand, you can add an abrasive in the form of garnet sand or corundum to the water. This produces a corresponding water-abrasive mixture, which is therefore ideal for cutting harder and stronger materials. Most people know corundum as a material for grinding wheels. In the grinding wheel, the corundum particles are firmly bonded by means of a binder and form a solid structure as a unit of thousands of particles bonded together. In waterjet cutting, however, each particle does this job on its own.

First, one must clarify what the term “CNC” means. This abbreviation stands for the English expression “computerized numerical control“. In short, it means that an electronic procedure is used to control the respective CNC machine. This enables the machine operator to quickly and precisely implement even complex contours and shapes in a wide variety of materials.

Like a CNC milling machine, this water jet cutter has at least three axis. The cutting head, which directs the abrasive water jet, is mounted on the Z-axis running horizontally to the work surface. The combination of the conveyor and the high-pressure pump produces a correspondingly strong jet depending on the material. The result is an almost burr-free workpiece.

Mini Desktop CNC Router for Gifts Making Small Business

Best Granite marble manual polishing machine For Sale

Stone Processing CNC Equipment Automatic Tool Changer CNC Quartz Stone Machining