+86 1525 3141 880

+86 1525 3141 880

HOME >> Support and Service >> CNC FAQs

Mini Desktop CNC Router for Gifts Making Small Business

Best Granite marble manual polishing machine For Sale

Stone Processing CNC Equipment Automatic Tool Changer CNC Quartz Stone Machining

3020 40W Mini CO2 Laser Engraving Cutting Machine

New Design Mini Stone CNC Machine for Marble, Granite and Quartz

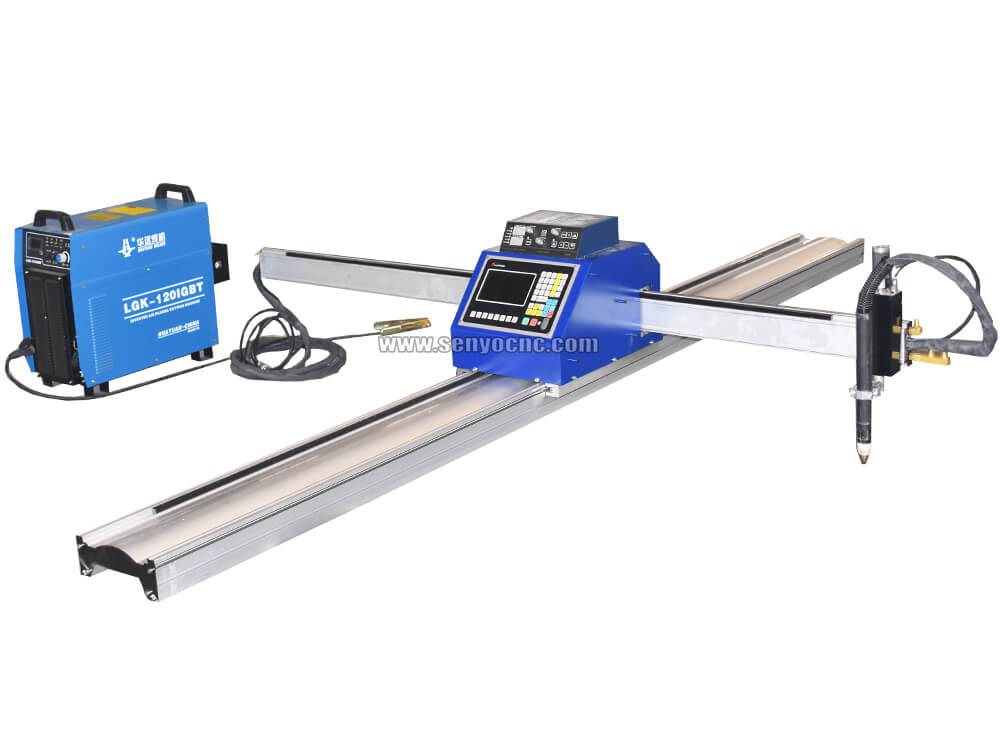

Portable CNC Flame Cutting Machine with Plasma Torch for Sale

High-Precision Mini Hobby CNC Plasma Cutting Machine for Metal

Mini CNC Plasma Cutter With Rotary

4 Axis 1325 Sculpture Machine Cnc Carving Marble Granite Stone Cnc Router

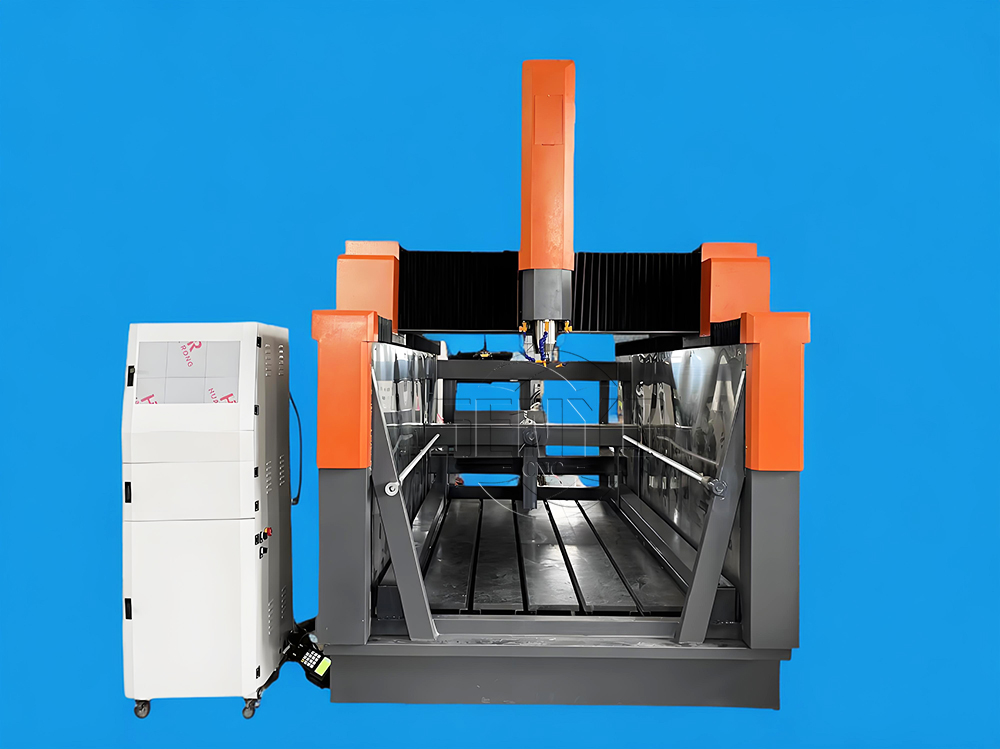

Z Height 1000MM 4-AXIS Stone Engraving CNC Machine Heavy-duty Stone CNC Machine Stone Relief Carving CNC For Sale

4030 portable mini co2 laser carving and desktop rubber stamp laser engraving machine

Stone CNC Router For Kitchen sink tile carving and cutting Marble, Granite and Quartz

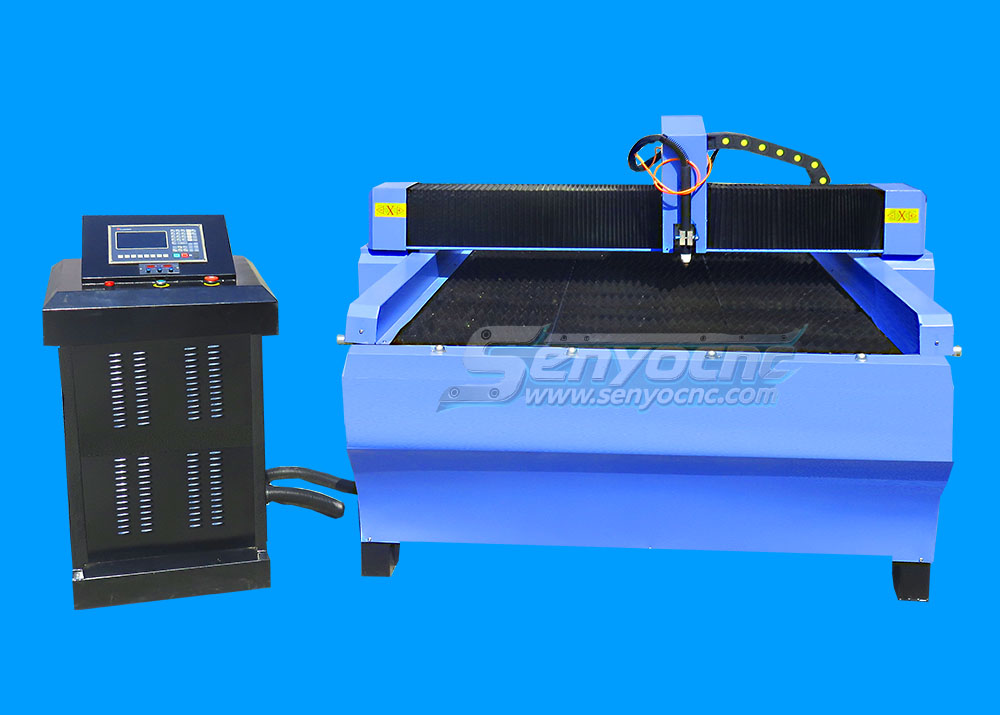

Robust CNC Plasma Cutting Machines with Flame Cut Head for Heavy-Duty Industrial Use

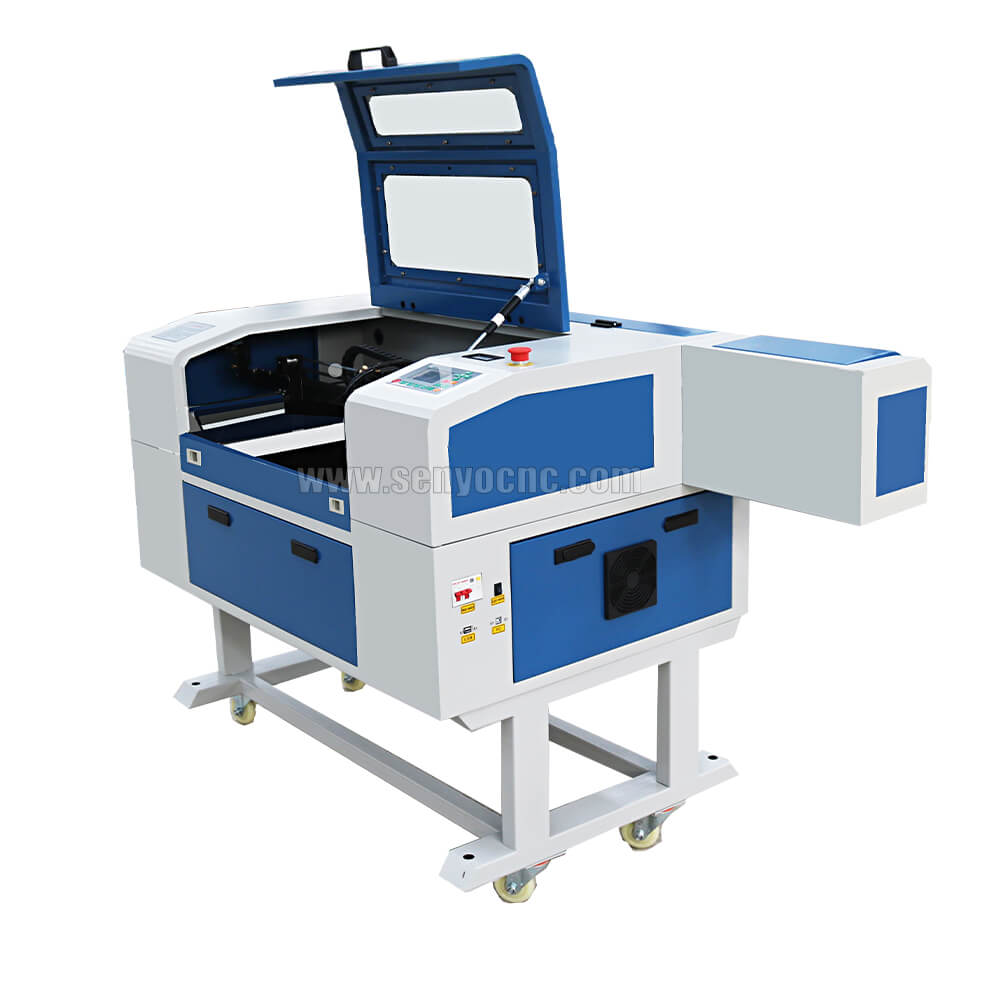

Small Portable CO₂ Laser Cutter Engraving for DIY & Business – Ideal for Wood, Acrylic, Leather

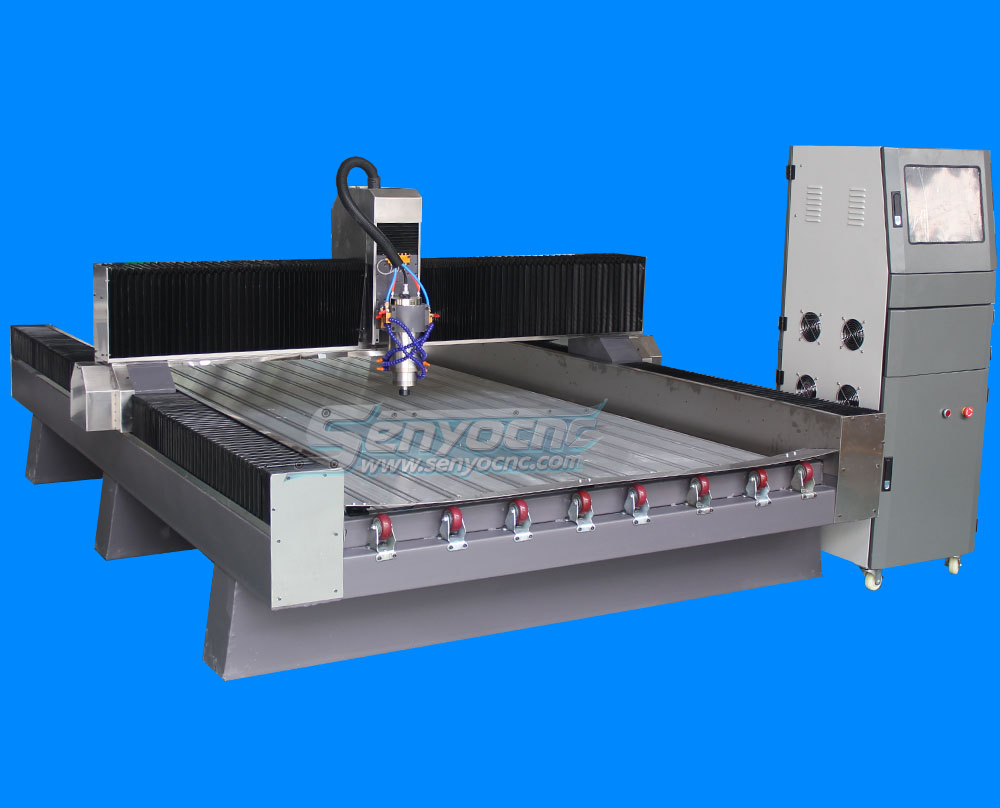

1325 3 Axis 4x8 CNC Stone Router for Sale

Mini CO2 Laser 5030 Cutting Engraving Machine For Sale

Portable CNC Plasma Flame Cutting Machine for Sale at Cost Price

Portable Cnc Plasma Oxyfuel Sheet Metal Cutting Machine for sale

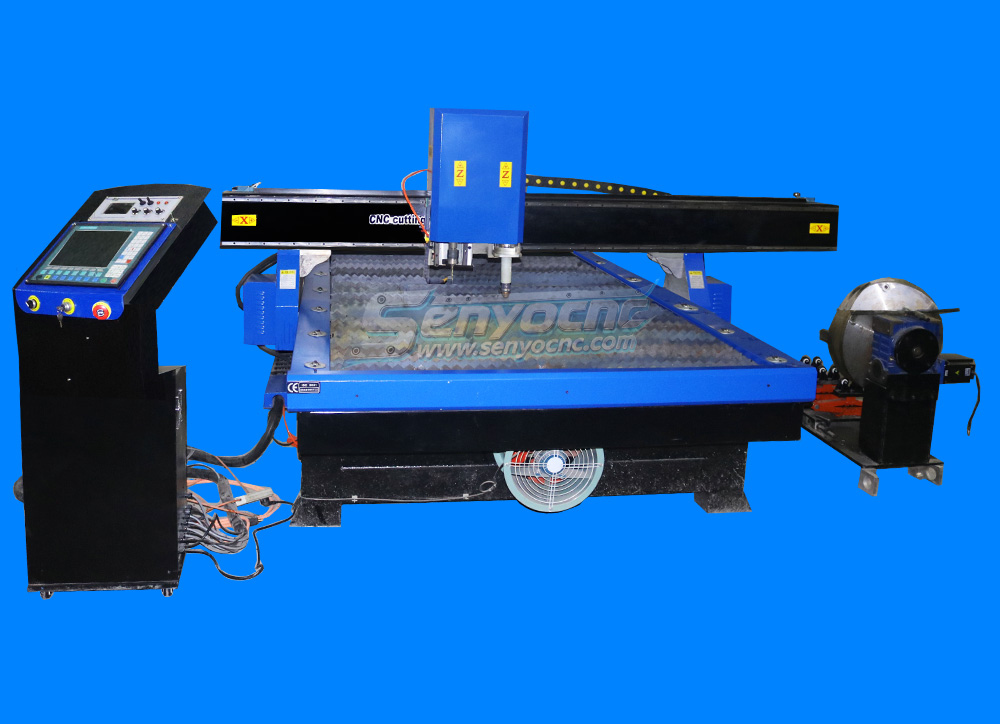

CNC Plasma Cutters for Customized Metalwork –Rotary&Drilling Head

Small Table design 6040 Easy Move CO2 Hobby Laser Cutter Machine for Beginners

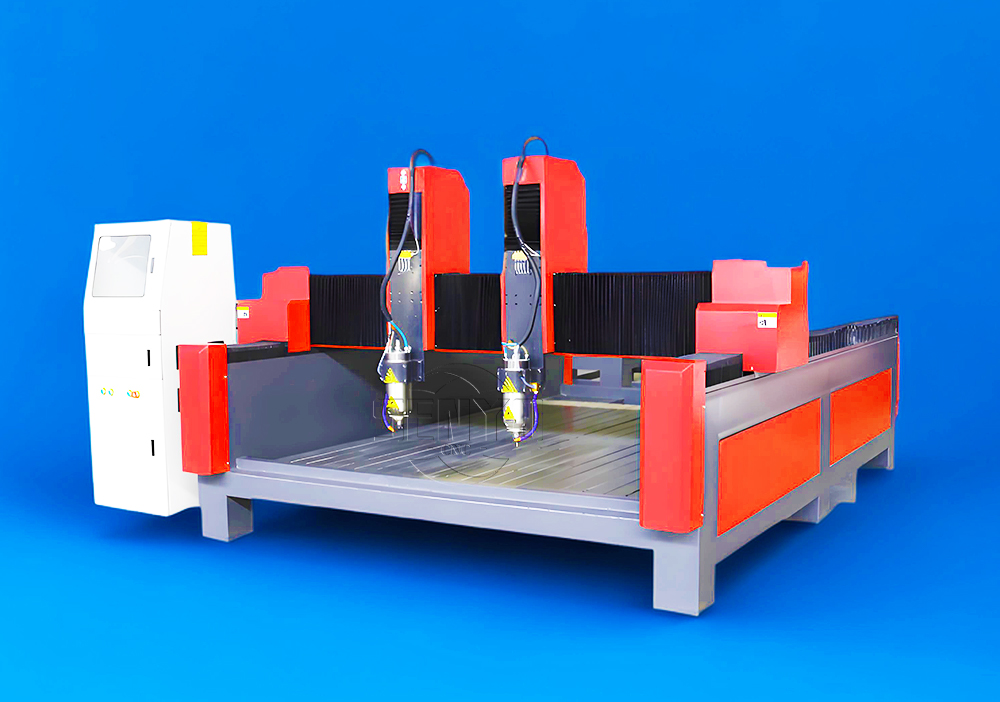

High-Efficiency 2 Heads CNC Machine for Aluminum Stone Marble Engraving & Cutting

Best CNC 2 Spindle 4-AXIS Stone Carving Machine High-precision Stone Carving Stone Countertop Fabrication

Top Rated 2x3 CO2 Hobby Laser Cutting Machine for Sale at Affordable Price

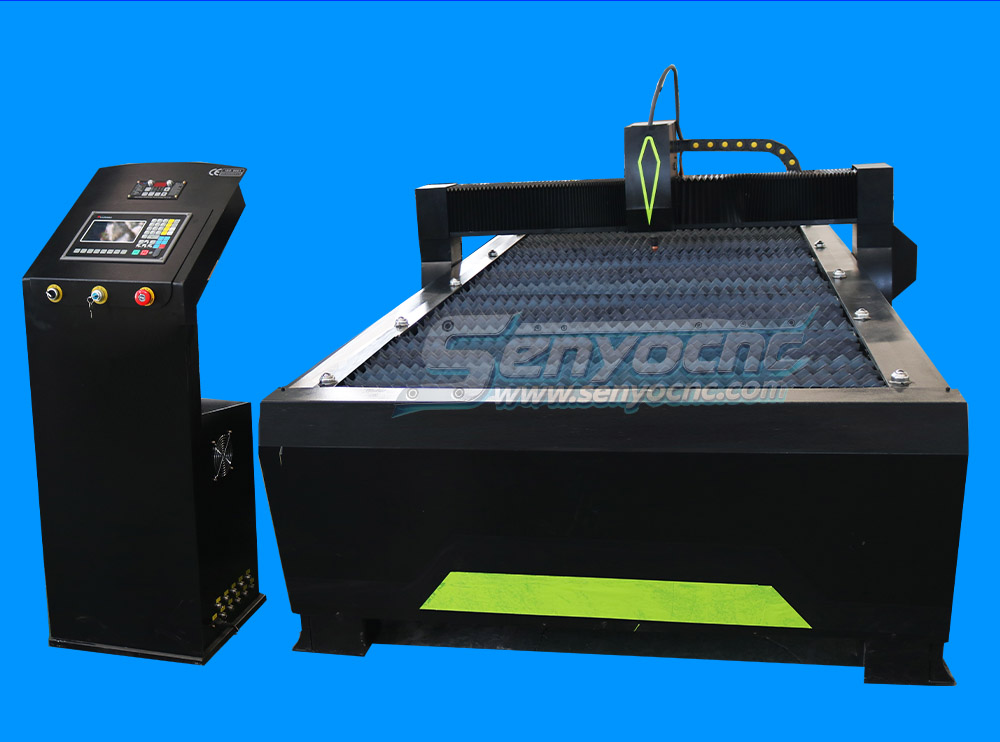

Best 4x8 CNC Plasma Cutter Table for Sale at Affordable Price

Entry Level CO2 Hobby Laser Cutter Machine for Beginners

Top CNC Plasma Cutters for Automotive, Aerospace, and Manufacturing Industries

Precision Stone Engraving Machines for Memorials & Signs

Portable Co2 9060 Laser Nonmetal Cutting Engraving Machine

1090 CO2 Laser Machine with Ruida Controller for Non-metal Glass Acrylic Engraving Cutting

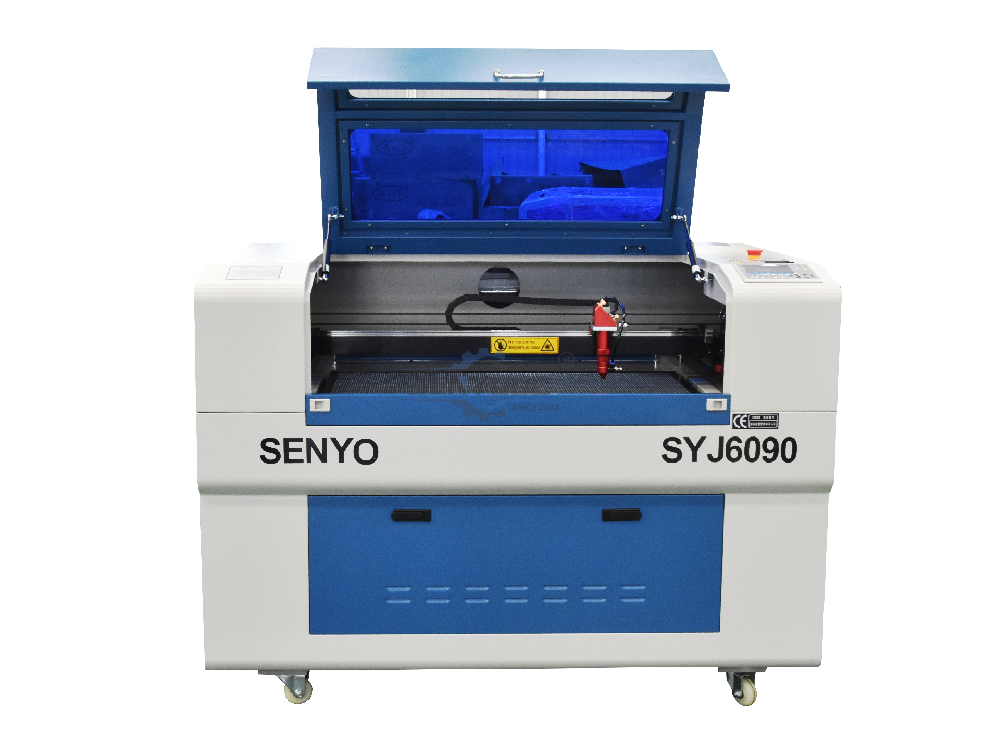

Entry Level 9060 CO2 Hobby Laser Cutter Machine for Beginners

You can also arrange the work surface can according to your wishes in terms of application and conditions. Either you work comfortably on the zone vacuum table with T-slot rails, with which the machine is equipped ex works, or you decide on the option with T-slot clamping possibility.

Here you decide for yourself how large the area you want to be to use it with T-slot plates. Of course, it is also possible to equip half of the working area with T-slot plates and leave the other half as it is. Depending on the planned application, the appropriate clamping method should be used.

As an optional accessory, we recommend the purchase of an oil-free vacuum pump or a side-channel compressor to make optimum use of the zone vacuum table. The individual zones of the vacuum table can be switched on and off independently of each other using levers on the long side of the milling machine. Depending on the size of the CNC portal milling machine, the vacuum table is divided into different numbers of zones.

As an option when choosing accessories, you can opt for automatic central lubrication. Here you can enter and save maintenance intervals in the software. That ensures economical and appropriate lubrication and maintenance of all ball screws and linear guides. As a result, production processes are optimised and ultimately more efficient, and at the same time, you will never miss maintenance again.

The manual central lubrication makes in the work process much more comfortable and is also equipped as a standard on Senyoqc machines. The use of the manual central lubrication system is effortless and convenient via a lever on the bridge of the CNC router.

As an option, you can choose the automatic central lubrication for an extra charge, thus not only saving on personnel expenses but also having a more efficient use of lubricants. Here you can program in intervals so that you do not have to check this always personally.

Depending on the application, different HF spindles can be optionally selected. You can choose between 1.5 kW ER20, 3.5 kW ER25, a high-frequency spindle with 6.0 KW or optionally also an HSD spindle with 7.5 kW and a SK30/ISO30 tool holder.

Our CNC mills are available in different sizes and with individual configuration. You, therefore, have the choice between machine systems with air-cooled or water-cooled high-frequency spindles, with or without a tool changing system, as required. We offer tool changing stations with up to 12 tool places, whereby the number of tools varies according to the size of the CNC router.

If you choose a CNC machine with tool changer, please note that the machine length increases by 300 mm in X-direction. That allows you to use the whole working area without any restrictions due to the mounted tool changing system.

If a decision is only made subsequently for a tool changing system, this is possible, but with a loss of the travel range by 300 mm.

Security should generally always be a priority. The risk of injury is very high with bench routers, as the rotating tool can always be accidentally touched by a finger etc. In contrast, the CNC milling machine can do its job without any manual intervention.

In the best case, the entire working area is even entirely inaccessible

for hands and other parts of the body through an appropriate safety enclosure.

The biggest difference between the two machines is probably the fact

that with the router table, the workpiece to be machined must be pushed

manually past the stationary, rotating cutter. In contrast, the CNC

milling machine moves the milling spindle around the workpiece

automatically with computer-controlled program support. The workpiece is always firmly clamped or fixed on the machine table of the CNC router.

Already anchored in the name of the tool, a router table is a floor-mounted table, which you use mainly to process wood. For example, for trimming/edge trimming with the help of straight or chamfered cutters. The design of these cutters is always the same or similar. For the worktop, there is usually a stable cast iron plate, sometimes also a screen-printing plate. The milling motor is permanently installed, generally under the table at the guide stop located on the side of the table.

Here the first differences to the CNC milling machine are visible. The milling motor of a CNC is installed above the table in up to 99% of all cases. It “points” with its tool (milling cutter) downwards. Besides, the milling motor is fixed but is moved by the moving axes of the machine.

The tool (usually referred to as a “milling cutter“)

rotates at very high speed around its vertical centre axis during the

machining process. The feed motion can be performed either vertically,

horizontally or diagonally to the rotation axis. Unlike some other turning machines, such as lathes, only the tool rotates, but not the workpiece. Again, there is no difference to the CNC milling machine.

A bench router is a helpful tool, which is mainly used

in woodworking. The material that is not needed is separated from the

raw material in the machining process to shape the final workpiece using chip removal. So far, there is no difference between the bench moulder and the CNC milling machine.

Mini Desktop CNC Router for Gifts Making Small Business

Best Granite marble manual polishing machine For Sale

Stone Processing CNC Equipment Automatic Tool Changer CNC Quartz Stone Machining