+86 1525 3141 880

+86 1525 3141 880

HOME >> Support and Service >> CNC FAQs

Mini Desktop CNC Router for Gifts Making Small Business

Best Granite marble manual polishing machine For Sale

Stone Processing CNC Equipment Automatic Tool Changer CNC Quartz Stone Machining

3020 40W Mini CO2 Laser Engraving Cutting Machine

New Design Mini Stone CNC Machine for Marble, Granite and Quartz

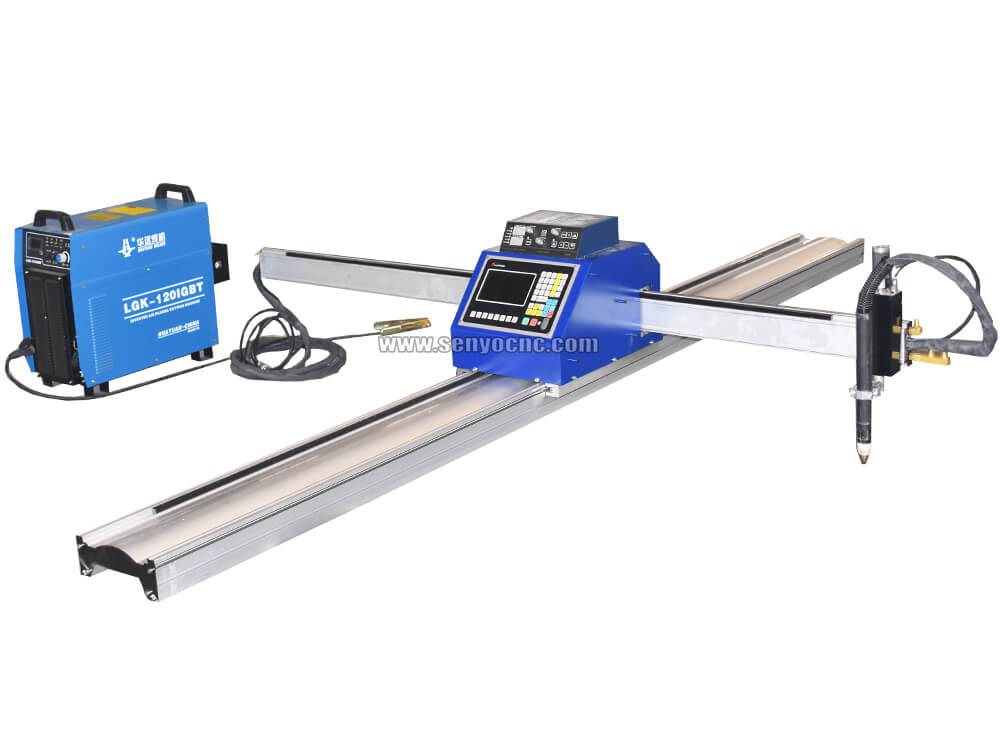

Portable CNC Flame Cutting Machine with Plasma Torch for Sale

High-Precision Mini Hobby CNC Plasma Cutting Machine for Metal

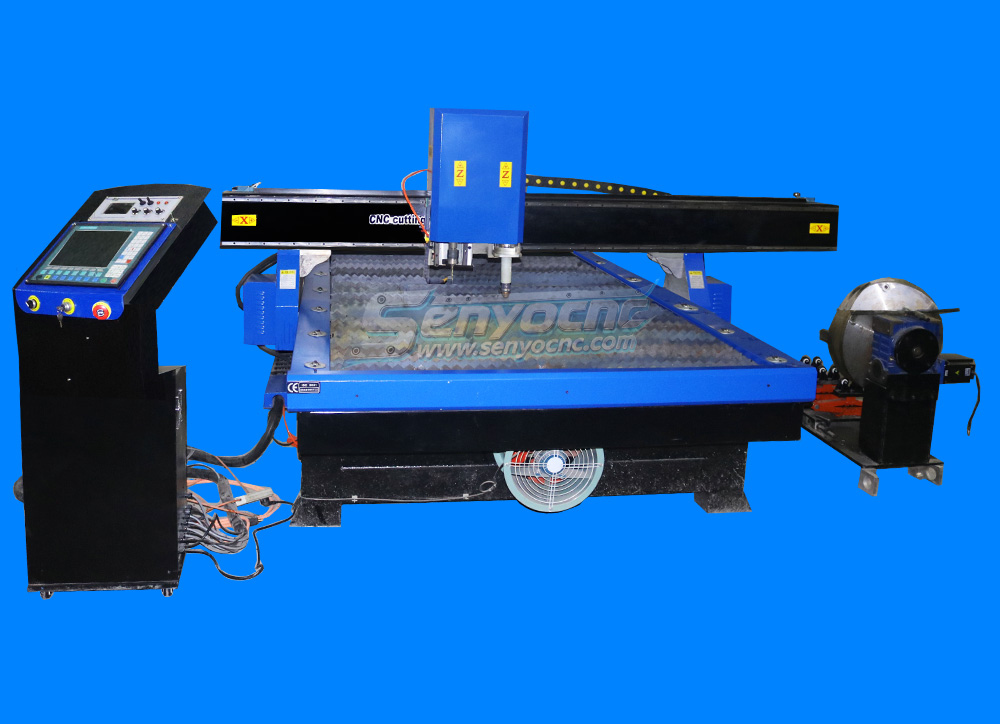

Mini CNC Plasma Cutter With Rotary

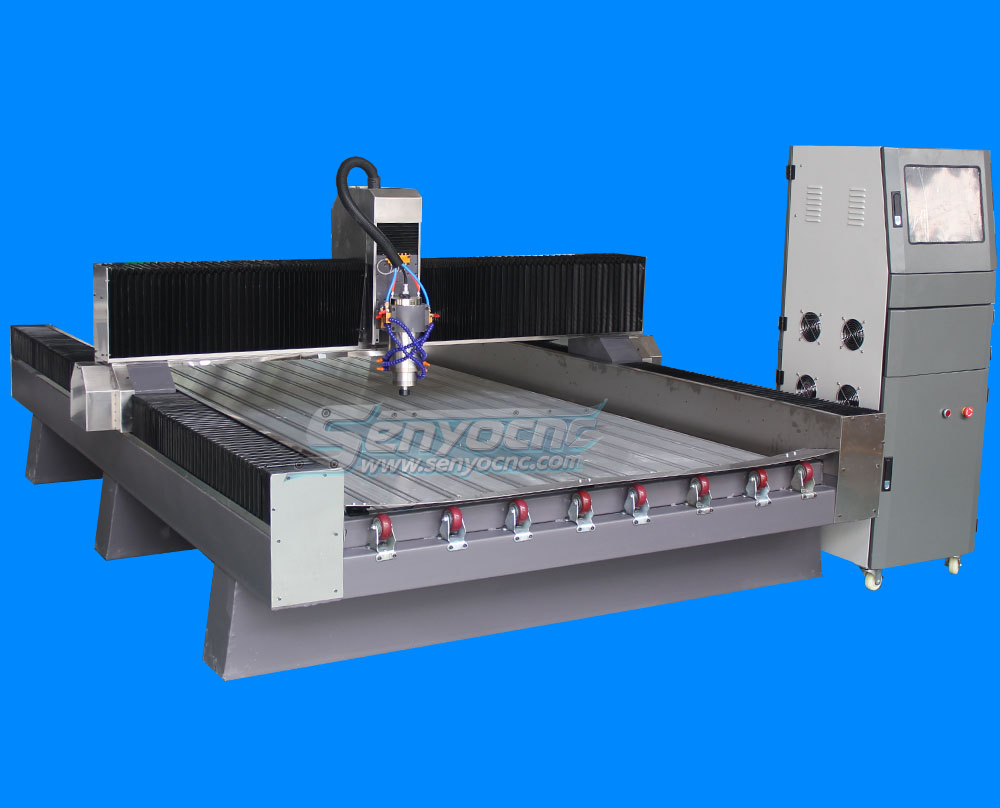

4 Axis 1325 Sculpture Machine Cnc Carving Marble Granite Stone Cnc Router

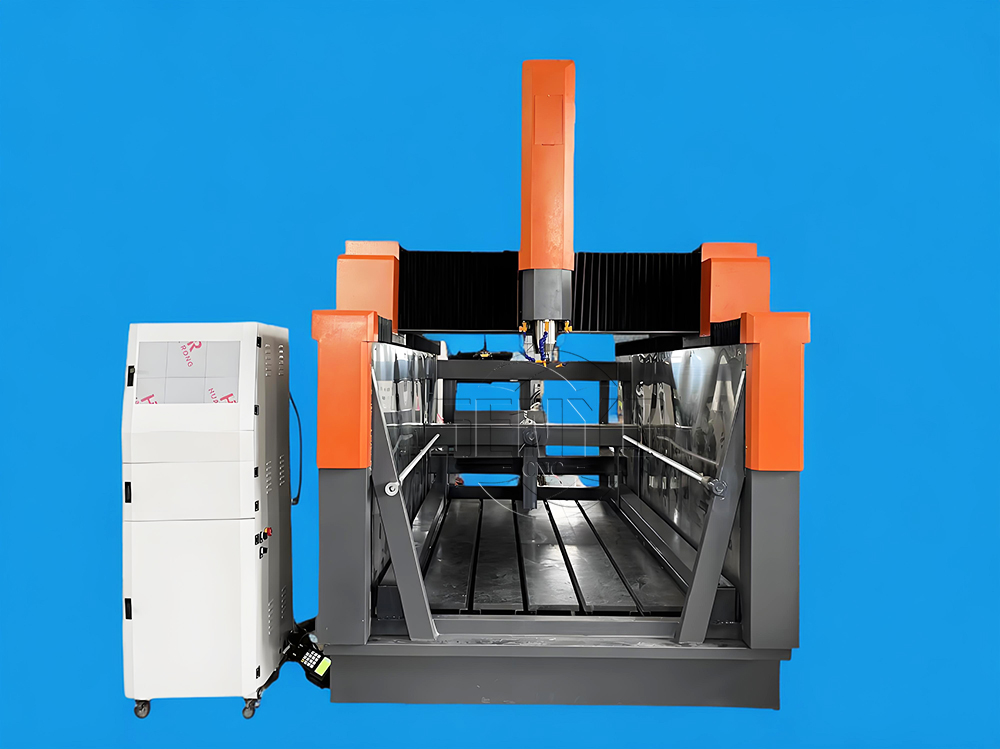

Z Height 1000MM 4-AXIS Stone Engraving CNC Machine Heavy-duty Stone CNC Machine Stone Relief Carving CNC For Sale

4030 portable mini co2 laser carving and desktop rubber stamp laser engraving machine

Stone CNC Router For Kitchen sink tile carving and cutting Marble, Granite and Quartz

Robust CNC Plasma Cutting Machines with Flame Cut Head for Heavy-Duty Industrial Use

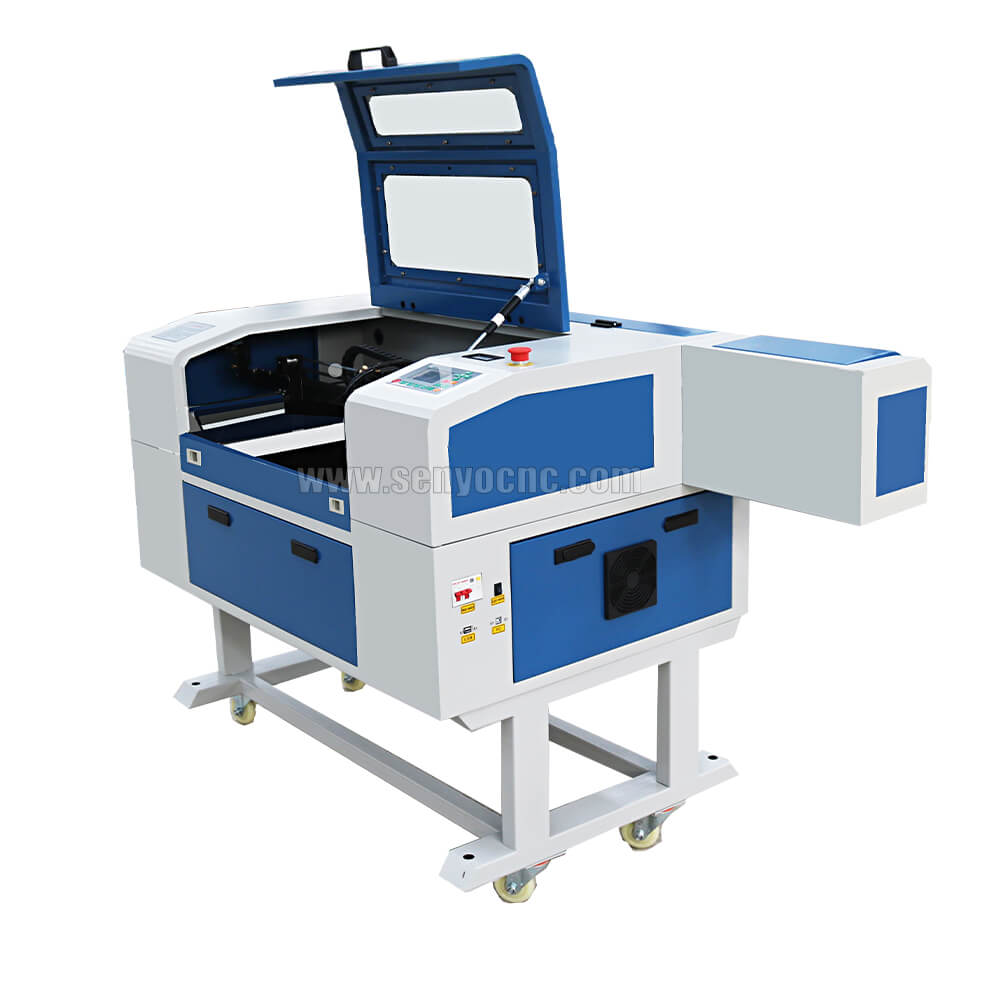

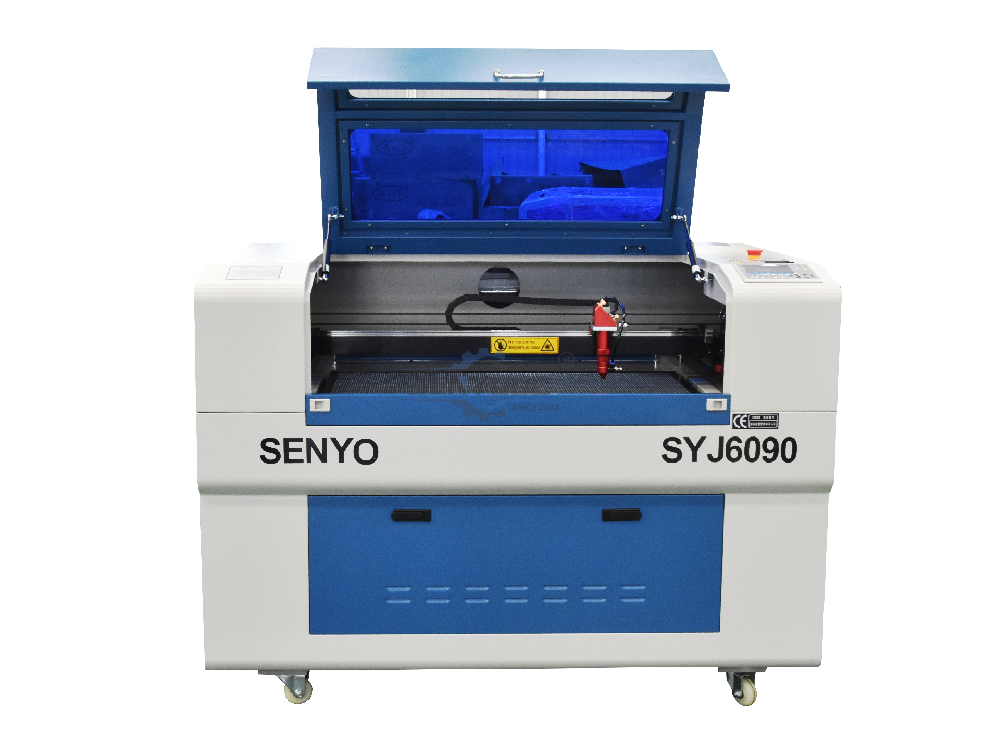

Small Portable CO₂ Laser Cutter Engraving for DIY & Business – Ideal for Wood, Acrylic, Leather

1325 3 Axis 4x8 CNC Stone Router for Sale

Mini CO2 Laser 5030 Cutting Engraving Machine For Sale

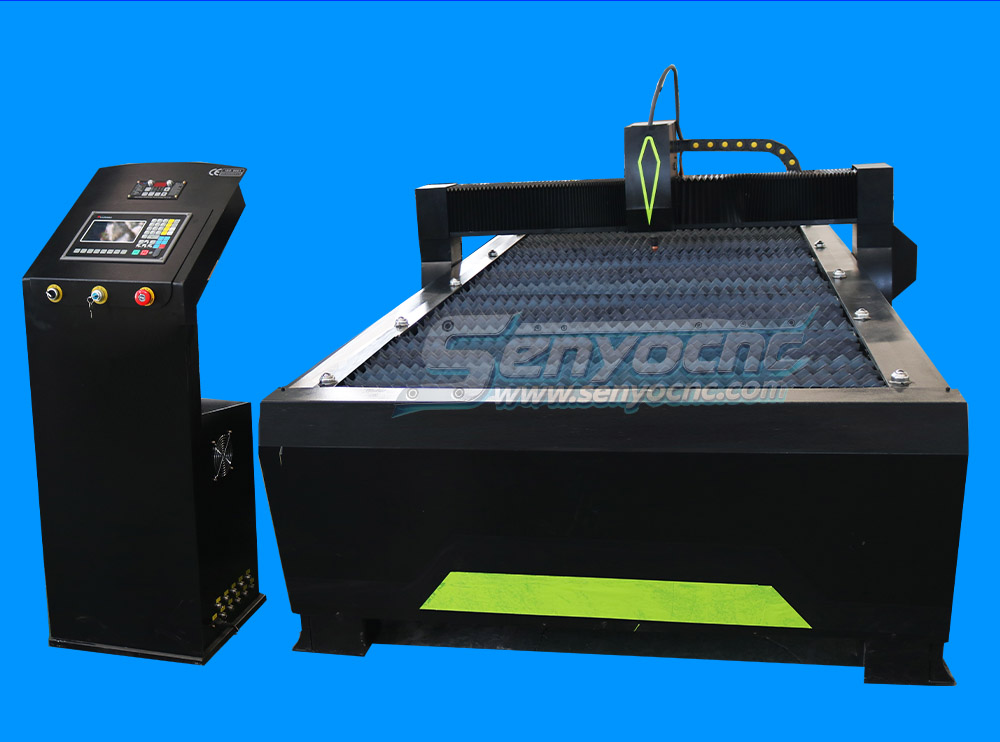

Portable CNC Plasma Flame Cutting Machine for Sale at Cost Price

Portable Cnc Plasma Oxyfuel Sheet Metal Cutting Machine for sale

CNC Plasma Cutters for Customized Metalwork –Rotary&Drilling Head

Small Table design 6040 Easy Move CO2 Hobby Laser Cutter Machine for Beginners

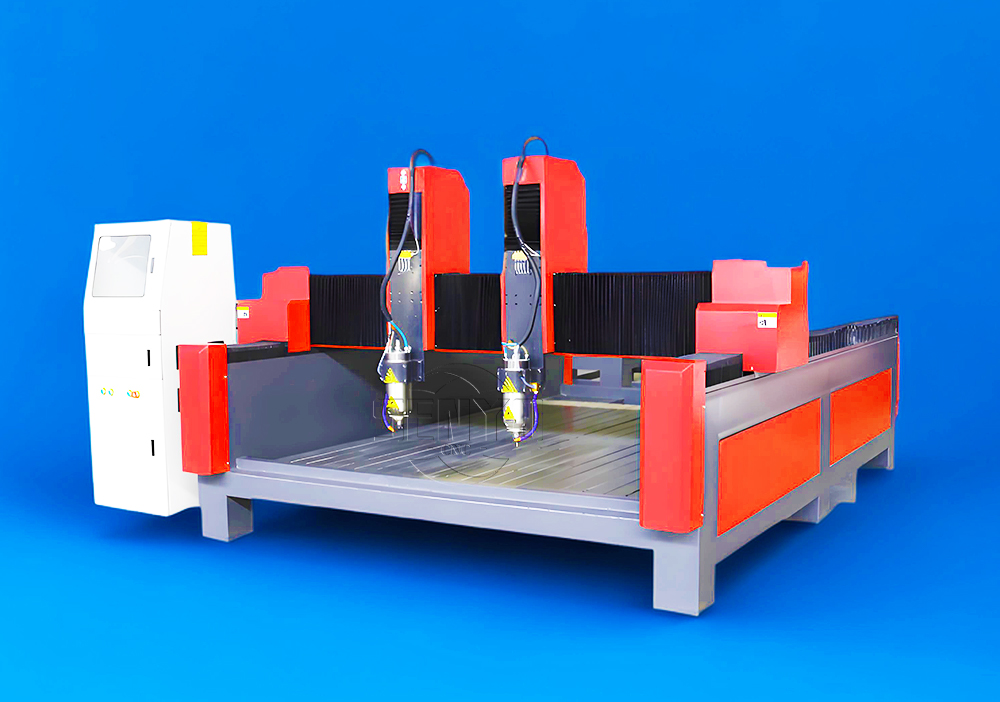

High-Efficiency 2 Heads CNC Machine for Aluminum Stone Marble Engraving & Cutting

Best CNC 2 Spindle 4-AXIS Stone Carving Machine High-precision Stone Carving Stone Countertop Fabrication

Top Rated 2x3 CO2 Hobby Laser Cutting Machine for Sale at Affordable Price

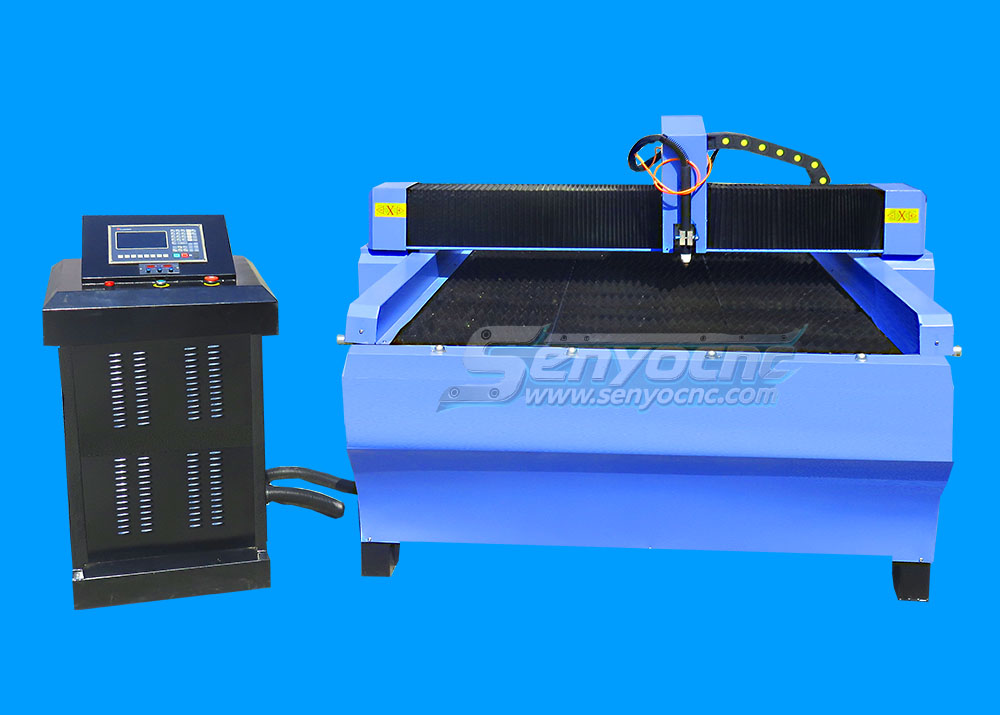

Best 4x8 CNC Plasma Cutter Table for Sale at Affordable Price

Entry Level CO2 Hobby Laser Cutter Machine for Beginners

Top CNC Plasma Cutters for Automotive, Aerospace, and Manufacturing Industries

Precision Stone Engraving Machines for Memorials & Signs

Portable Co2 9060 Laser Nonmetal Cutting Engraving Machine

1090 CO2 Laser Machine with Ruida Controller for Non-metal Glass Acrylic Engraving Cutting

Entry Level 9060 CO2 Hobby Laser Cutter Machine for Beginners

1.Roughness

Laser cutting cross section will form a vertical lines, the depth of the texture of the cut surface of the roughness of the cut surface,

the more shallow lines, the more smooth cut section. Roughness not only affects the appearance of the edges, but also affect the

friction characteristics, in most cases, it is necessary to minimize the roughness, so the more shallow texture, the higher the quality

of the cut.

2. Verticality

If the sheet thickness exceeds 10mm, the verticality of cutting edge is very important. Away from the focus, the laser beam

becomes divergent, according to the location of the focus, cutting to the top or bottom of the variable width. Cutting edge off the

vertical line of a few millimeters, the edge of the more vertical, the higher the quality of cutting.

3. Cutting width

Kerf width generally does not affect the cutting qualit, only in the internal components formed special precision contour, cutting

width is important. This is because the cutting width determines the contour of the minimum, when the plate thickness increases,

the cutting width also increases. So want to guarantee the same high precision, no matter how much the width of the cut, the

workpiece in the laser cutting machine processing area should be constant.

4. Lines

High speed cutting thick plate, the molten metal will not appear in the vertical laser beam below the incision, but will be sprayed out

at the laser beam side. As a result, the curved lines are formed on the cutting edge, and the lines are closely followed by the laser

beam. In order to correct the problem, the feed rate can be reduced at the end of the cutting process.

5. Burr

Burr formation is a very important factor to determine the quality of laser cutting, because the removal of burr need extra work, so

the amount of burr is serious and how much is able to directly determine the quality of cutting.

6. Material Deposition

Laser atinr mactine oeore he ognin ot mlino and peraonoro he wrpece sutce wh。ayer olonon he stacora

special iqud Gsiaion and al kndns omlaease,s the mateial does not neto use the wind o blow he cut, but the upwardor

downward discharge also can form the depsition on the surface.

7. Sag and Corrosion

Sag and corrosion have adverse effects on the surface of the cutting edge, affecting the appearance. They appear in the error of the

cut which is generally supposed to be avoided.

8. Heat Affected Zone

In the laser cutting,the area in the near the notch is heated, At same time, the structure of the metal changes ,For example ,some of the

metal can be hardened , the heat affected zone refer to the depth of the area that is changed by the internal structure.

9.Deformation

If the cutting makes the component heat , it will deform . This is particularly important in fine processing ,

because the profile and connection pieces are usually only a few millmeters wide . Control of laser power

and use of short laser pulses can reduce the parts become hot to avoid deormation.

Concept

NC (Numerical Control)

NCilthnologo hat uses dgtal sgnals 1o aumaial comrol oipetes ouch as he motion of he machine lo and ts woring

process), rferred to as numerical control.

NC Technology

NC refers the organic cntol ehnoloy hat uses numbers, lees and symbols 10 pogom a cetain working process.

NC System

NC system refers to the organic integrated system of software and hadware moules the function of NC techology

is the carrier of NC technology

CnC System (Computer Numerical Control Sytem)

CNC (Computer Numeical Contol) system rfe to the numerical control system with computer as the core.

CNC Machine Tools

CNC machine efes to a machine to hat uses CNC tehnoloy 1o conrol the mahining pcs. or a machine to equipped with

a CNC system.

NC Definition

Numeical Contol is the full fom of NC for machine tool, (Numirca Cotol 0NC) enables an operator to communicate with machine

tools through numbers and symbols.

CNC Definition

CNC is the abbreviation of Computer Numberiacal Control. CNC has brought tremendous changes to the manufacturing business.

New machine tools with CNC have enabled industry to consistently produce parts to accuracies undreamed of only a few years ago.

The same part can be reproduced to the same degree of accuracy any number of times if the CNC program has been properly

prepared and the computer properly programmed. The operating commands which control the machine tool are executed

automatically with amazing speed, accuracy, eficiency, and repeatability.

CNC machining is a computerized manufacturing process, the machine is connected to a computer, the computer will tell it where to

move. First, the CNC operator should do the toolpath creation, the operator uses a software program to draw the shapes and create

the tool path that the machine will fllow.

The ever-increasing use of CNC in industry has created a need for personnel who are knowledgeable about and capable of preparing

the programs which guide the machine tools to produce parts to the required shape and accuracy. With this in mind, the authors

have prepared this textbook to take the mystery out of CNC - to put it into a logical sequence and express it in simple language that

everyone can understand. The preparation of a program is explained in a logical step-by-step procedure, with practical examples to

guide the user.

Component

CNC technology consists of three parts: machine tool body, CNC system and peripheral technology.

The machine frame kit is mainly composed of basic parts such as bed, column, guide rail, working table and other supporting parts

such as tool holder and tool magazine.

The numerical control system is composed of input/output equipment, computer numerical control (CNC) device, Programmable

Logic Control (PLC), spindle servo drive device, feed servo drive device and measuring device. Among them, the CNC device is the

core of the numerical control system.

Peripheral technology mainly incldes tool technology (tool system), programming technology, and management technology.

Component

CNC technology consists of three parts: machine tool body, CNC system and peripheral technology.

The machine frame kit is mainly composed of basic parts such as bed, column, guide rail, working table and other supporting parts

such as tool holder and tool magazine.

The numerical control system is composed of input/output equipment, computer numerical control (CNC) device, Programmable

Logic Control (PLC), spindle servo drive device, feed servo drive device and measuring device. Among them, the CNC device is the

core of the numerical control system.

Peripheral technology mainly includes too technology (tool system), programming technology, and management technology.

Glossary

CNC: Computer Numenical Control.

G Code: A nherel nmeical coro 0NC) machine to lgugoe ha seie axis poits o wmich h mache wi none.

CAD: Computer Aided Design.

CAM: Computer Aided Manufacturing.

PLT HPGL: Standard Language for printing vector based drawing. suppprted by CAD drawing

Step Down: Dstace in Zaxis that the cuting tl plungs into the matrial.

Step Over. Maximum dstance inXor Y axis that cuting tol wil engave with in to the material.

Spindle Speed: Rotational speed of cuting tool (RPM).

Home Position (Machine Zero): Machine designated zero point determined by physical limit switches.

(It does not identify actualwork origin when processing a workpiece.)

Climb Cut: Cutter rotates with direction of feed. Climb cutting prevents tearout, but can lead to chatter marks with a straigh-futed

bit; a spiral-futed bit will reduce chatter.

Work Origin (Work Zero): The user-designated zero point for the workpiece, from which the head will perform all it's cutting. X, Y

and Z axes are set to zero.

LCD: Liquid Crystal Display (used on the contoller).

U Disk: External data storage device that is inserted into a USB interface.

Features

High Accuracy

CNC machines are highly integrated mechatronic products, which are composed of precision machinery and automatic control

systems. They have high positioning accuracy and repeat positioning accuracy. The transmission system and the structure have

high rigidity and stability to reduce errors. Therefore, CNC machine has higher machining accuracy, especially the consistency of

parts manufacturing in the same batch, and the product quality is stable, the pass rate is high, which is incomparable with ordinary

machine tools.

High Efficiency

CNC machines can use a larger amount of cutting, which effectively saves processing time. CNC machines also have automatic

speed change, automatic tool change and other automatic operation functions, which greatly shorten the auxiliary time, and once a

stable processing process is formed, there is no need to perform inter-process inspection and measurement. Therefore, the

productivity of CNC machining is 3-4 times higher than that of ordinary machine tools, or even more.

High Adaptability

CNC machine performs automatic processing according to the CNC program of the processed parts. When the machining object

changes, as long as the CNC program is changed, there is no need to use special process equipment such as masters and

templates. This is helpful to shorten the production preparation cycle and promote product replacement.

High Machinability

Some mechanical parts formed by complex curves and curved surfaces are dificult to process or even impossible to complete with

conventional techniques and manual operations, and can be easily realized by CNC machines using multi-coordinate axes linkage.

High Economic Value

CNC machining centers mostly use process concentration, and one machine is multi-purpose. In the case of one clamping, most

parts of the parts can be processed. CNC machining center can replace several ordinary machine tools. This can not only reduce

clamping errors, save auxiliary time between transportation, measurement, and clamping between processes, but also reduce the

types of machine tools, save machine tool area, and bring higher economic benefits.

Applications

From the perspective of CNC technology and equipment applications in the world, its main application areas are as follows:

Manufacturing Industry

The machinery manufacturing industry is the earliest industry to apply CNC technology, and it is responsible for providing advanced

equipment for various industries of the national economy. The main applications are the development and manufacturing of five-axis

vertical machining centers for modern military equipment, five-axis machining centers, large-scale fve axis gantry milling, CNC

machine tools for flexible manufacturing lines for engines, gearboxes, and crankshafts in the automotive industry, and high-speed

machining centers, as well as welding, assembly, painting robots, plate laser welding machines and laser cutting machines, high-

speed five-coordinate machining centers for machining propellers, engines, generators and turbine blade parts in the aviation, marine

and power generation industries, heavy duty turning and milling complex machining center, etc.

Information Industry

In the information industry, from computer to network, mobile communication, telemetry, remote control and other equipment, it is

necessary to adopt manufacturing equipment based on super-precision technology and nanotechnology, such as wire bonding

machines for chip manufacturing, wafer lithography machines, etc. The control of these equipment needs to use CNC technology.

Medical Equipment Industry

In the medical industry, many modern medical diagnosis and treatment equipment have adopted numerical control technology, such

as CT diagnostic instruments, whole body treatment machines and minimally invasive surgical robots based on visual guidance,

orthodontics and dental restoration in stomatology are required. Using high-precision CNC machines to produce teeth.

Military Equipment

Many modern military equipment use servo motion control technology, such as automatic aiming control of atillery, tracking control

Other Industries

In the ight industy there are pinting machinery, txtile machiery. packaging machiney and wowoking machinery that use,

mutiaxis senvo cntot, in the bulding marials idusty, there are CNC watejet cuting machies for stone pocessing. CNC glass

engaving machines for glass pocessing. CNC sewing machine used for smimons pocessing and CNC embroidery machine used

for clothing pocessing, in the art industry., more and more cats and at works wll be produced using high prformane 5 axis CNC.

AlI the CNC machines can be sipped wordwide by sea, by air or by iteational express lgistics viaDHL FEDEX.UPS.

You are welcome to get a free quotation by fling up the form with name, emal, detiled adress, produdt and rquirements,

we willshorty contact you with the ull ifomation induding the most sutable dlivev method (ast, secure, dscee) and feight.

A CNC machine firstly should be packaged well in a free fumigation wooden crate Usuall, we deiver the CNC machine by ship,

sometmes, as custmers rqurements, we can also delver by air or by tain. When the CNC machie arved at your sea port

or destiation, you can pick up with the bill oflading we ofre. We can also arange the cargo agento sendto your door.

Telegraphic Transfer

TT (Telegraphic Transfer) is the method of payment by electronic transfer of funds from one bank account to another.

Telegraphic transfers are also known as telex transfers, abbreviated TT. They can also refer to other types of transfers. The

payment abbreviation, as is often the case, is utilized to speed discussions in professional circumstances. Telegraphic transfer

is a fast nature of the transaction. Generally, the telegraphic transfer is complete within two to four business days, depending on

the origin and destination of the transfer, as well as any currency exchange requirements.

e-Checking

e-Checking is available to buyers with checking accounts from any bank in the United States.

Credit Card

Credit card payments with Visa or Mastercard are supported.

1. Usually, we will manufacture CNC machines as our common design.

2. Table sizes could be customized designs.

3. Logos could be customized as your requirements.

4. Colors could be customized as your requirements.

5. Special configurations could be customer-oriented designing.

1.Focus lens for contamination: Clean focusing miror.

2Fous reie laser egrain machie equpment wheher changes: Re adust me focus.

3. Light path is ofset Carefully adjustment ofthe optical path.

4.Rletive lens is cntaninatd or damaged: Clean or rplace the rece enses.

5.Laser power is ergzet Checking aser power spply cruit so htis normal.

6. Laser tube is damaged or aging Replace the laser tube.

7. Laser power suppy is damaged Replace the laser power.

8. Cooling water is crculaing flow: Clear cool water.

9.Tne coin water tmperature is normal or not Replace the de an cono water to ne tmperature to nomal.

Watteel rou aou ne lse weaker of aser egran mathine? we have to know how me above problem to be fixed and

welcome to our online support with laser engraving machine.

1. Consult: we will recommend the most suitable CNC machines to you after being informed by your requirements.

2. Quotation: We will supply you with our detail quotation according to our consulted machines with the best quality and price.

3. Process Evaluation: Both sides carefully evaluate and discuss all the details of the order to exclude any misunderstanding.

4. Placing Order: If you have no doubts, we will send you the PI (Proforma Invoice), and then we will sign a sales contract.

5. Production: We will arrange the production as soon as receiving your signed sales contract and deposit. The latest news

about production will be updated and informed to the buyer during the production.

6. Inspection: The whole production procedure will be under regular inspection and strict quality control. The complete machine

will be tested to make sure they can work very well before out of factory.

7. Delivery: We will arrange the delivery as the terms in the contract after the confirmation by the buyer.

8. Custom Clearance: We will supply and deliver all the necessary shipping documents to the buyer and ensure a smooth

customs clearance.

9. Suppot and Service: We will offer professional technical support and service by Phone, Email, Skype, WhatsApp around the clock.

Yes, we offer customer with CNC accessories including CNC router machine accessories (CNC router parts, CNC router bits,

CNC router tools), CNC laser machine accessories, CNC plasma cutter accessories and CNC wood turning lathe machine

accessories.

We have free online training. You can come to SENYO for training in factory. We can also assign technician for door-to-door

training with some charge.

1. For 3 axis CNC machine with standard specification, usually 7-15 days.

2. For 4 axis CNC machine with standard specification, usually 20-30 days.

3. For 5 axis CNC machine, OEM or Non-standard models, usually 60 days.

4. For laser engraving machine, laser cutting machine, laser marking machine, usually 5-10 days.

5. For high power laser cutting machine, usually 30-50 days.

6. For CNC wood turning lathe machine, usually 7-10 days.

7. For CNC plasma cutting machine, usually 7-10 days.

Mini Desktop CNC Router for Gifts Making Small Business

Best Granite marble manual polishing machine For Sale

Stone Processing CNC Equipment Automatic Tool Changer CNC Quartz Stone Machining