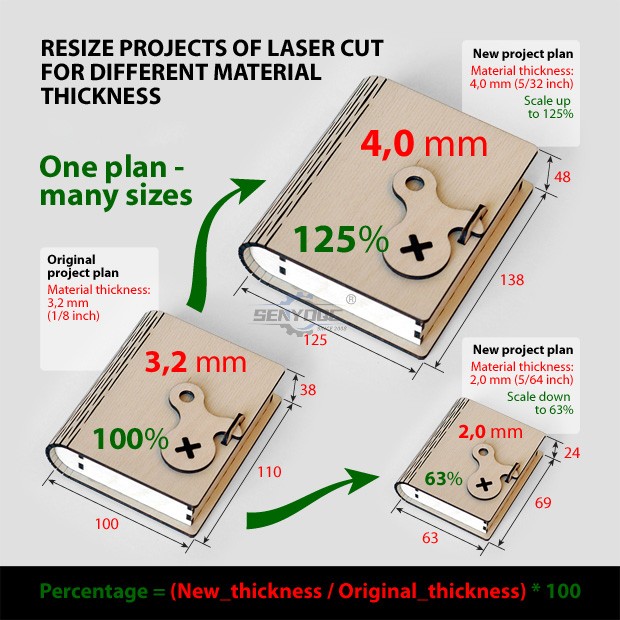

Resize projects of laser cut for different material thickness

From: 本站 Date: 12th August 2021 Author: shengangtong Views: 1667

Resize projects of laser cut for different material thickness

How to resize project plan of laser cut for different material thickness

We make projects mainly for 3,2 mm (1/8 inch) material thickness.

But you have material other thickness?

There is fast and simple method to resize project for your thickness.

Percentage = (New_thickness / Original_thickness) * 100

1) Open project file 3,2 mm

2) Select All elements

3) Scale to X% proporcionally

4) Done!

For material thickness 3,0 mm:

X = (3 / 3,2) * 100 = 94%

For material thickness 4,0 mm:

X = (4 / 3,2) * 100 = 125%

Of cource, dimensions of final product will be decreaced for thiner and increaced for thicker materials.

Advise

If you have plan for 3.2 mm.

But you have slightly thicker material i.e. 3.3 mm.

Connecting details will be very tightly.

Use this metod.

Scale up to 103% and details will fit perfect.

At the same time, dimensions of product practically will not changed.

• Previous: How-to: White engraving

- Fiber metal Laser Sensor And Its Application

- Laser Cutting Machine Inspection Process For Manufacture

- How Control Costs Use of UV Printers ?

- Why UV flat printing machine is popular in market ?

- How does UV ink jet printer save UV ink?

- Waterjet Machine delivery and Shipping

- Waterjet Machine finish manufacture 5axis

- Waterjet Machine delivery and Shipping

- How to Create Connected Text – Inkscape for Laser Cutting

- How to get started with laser cutting in 4 steps

- How does a laser cutter work?

- Wine butler

Jacob from United States

I am a beginner at CNC, I’ve never used a CNC machine before and with in a day I was carving. An awesome machine for a beginner to learn as hobbyists. I used the manual and the help video. One hour to assemble and test, very friendly and easy to use. It’s a good buy for the money. I would definitely recommend this machine to someone getting into CNCs.

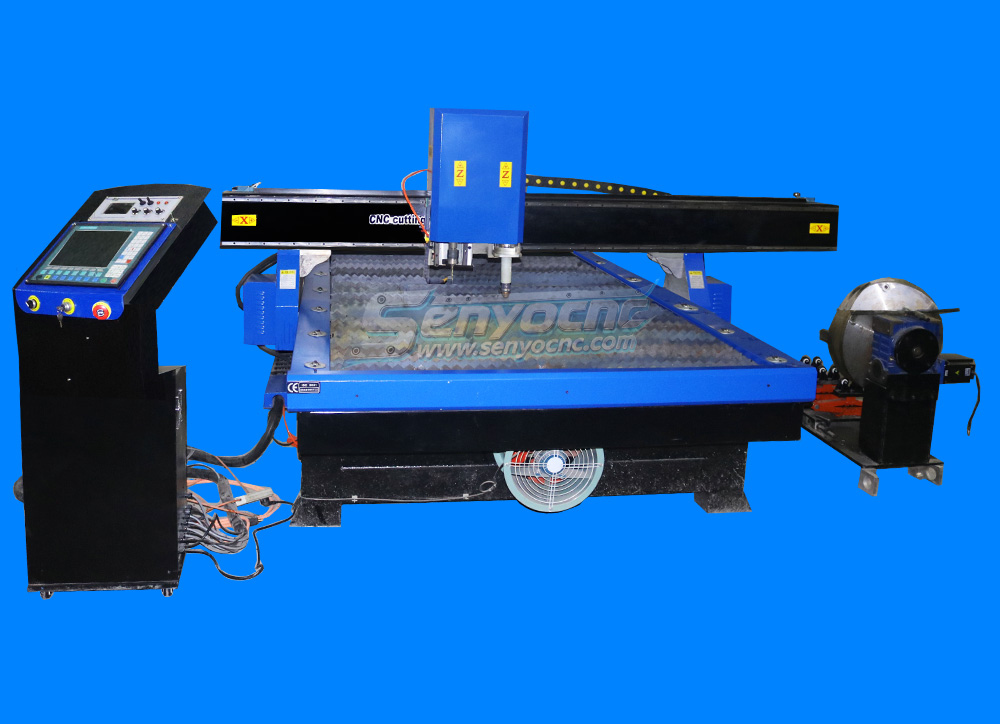

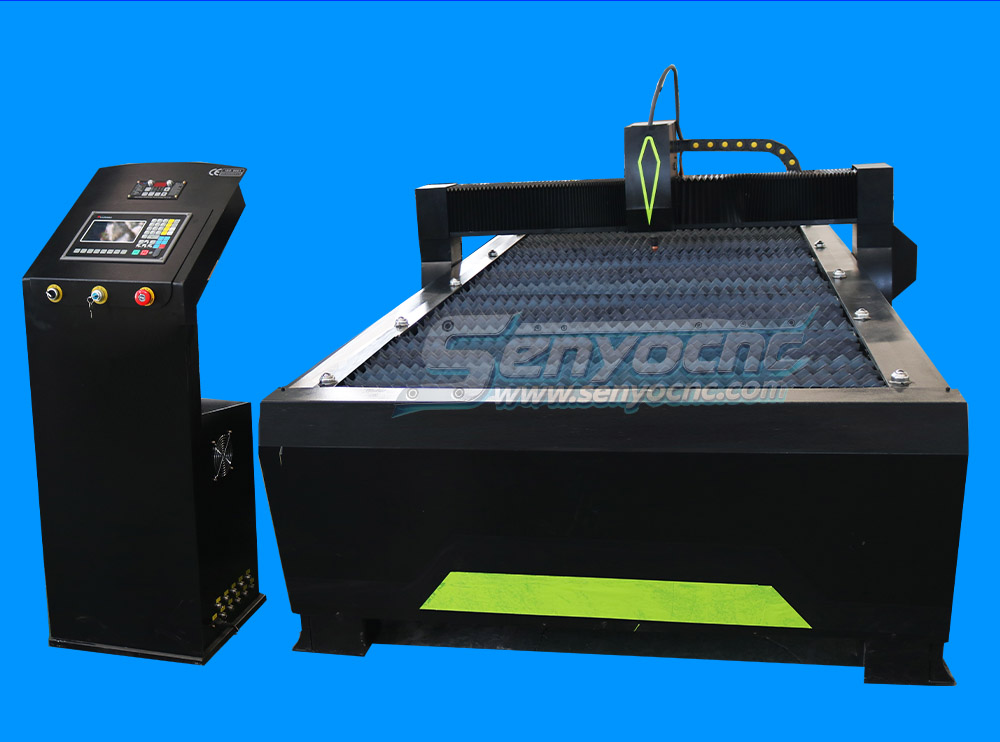

Weinstein from France

I've been using CNC plasma SYP2060-300A and I am very impressed with this unit.

This unit is of higher quality, made in China. Five stars all the way!

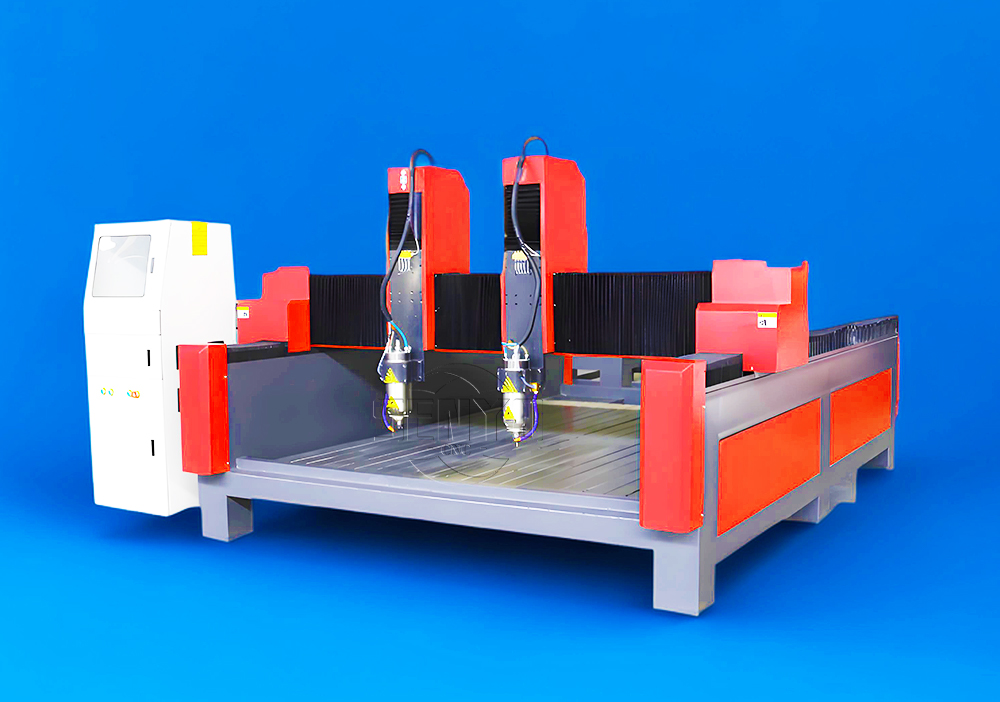

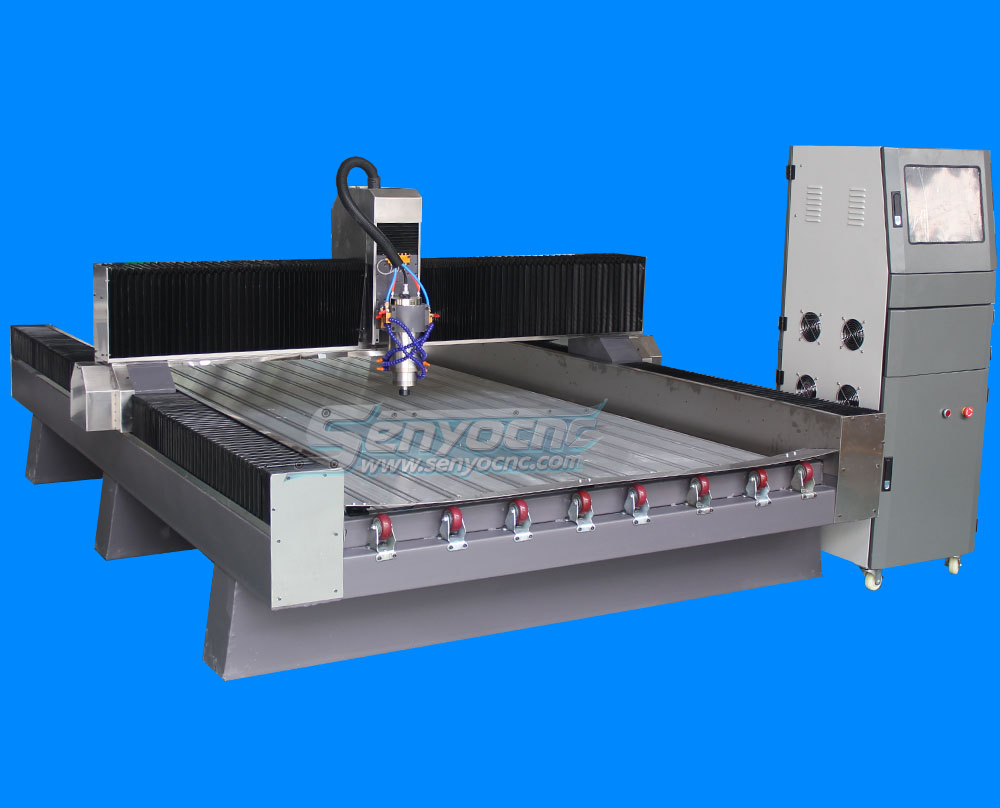

2040 from INDIAN

Best 2040 CNC Router Good Price and Quality ! Thank SENYOQC

10w uv laser from American

Best supplier ! I bought 3 machines for laser and router , thank you Aillen ! --Alec

12KW Fiber Cutting - 2000X6000mm -- 이병헌 from Korea

Good machine for metal cut ! Thanks Senyo , Its prefect , I like your business patient kind!

I am a furniture manufacturer, and this machine is very good and fast. thanks Senyoqc Team ! from Bangladesh

Metal ArtWork from Denmark

The plasma cutting machine makes my artistic creation more convenient and precise!! Created more artistic ideas and value! Thank you Aillen team!

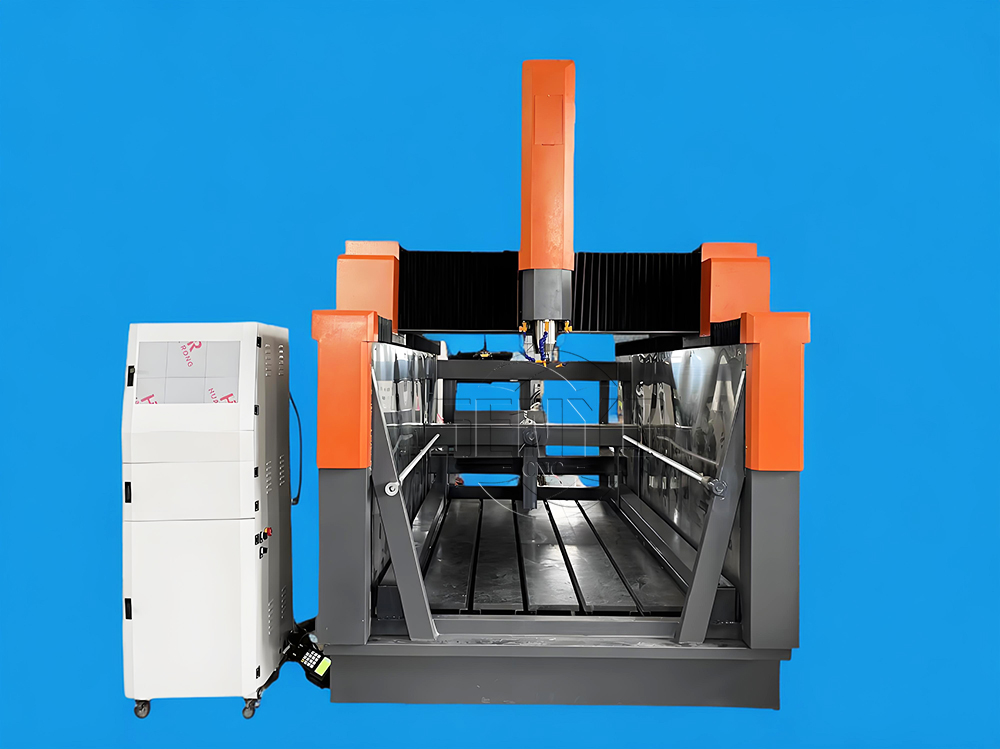

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen. from

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen.

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo from

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo

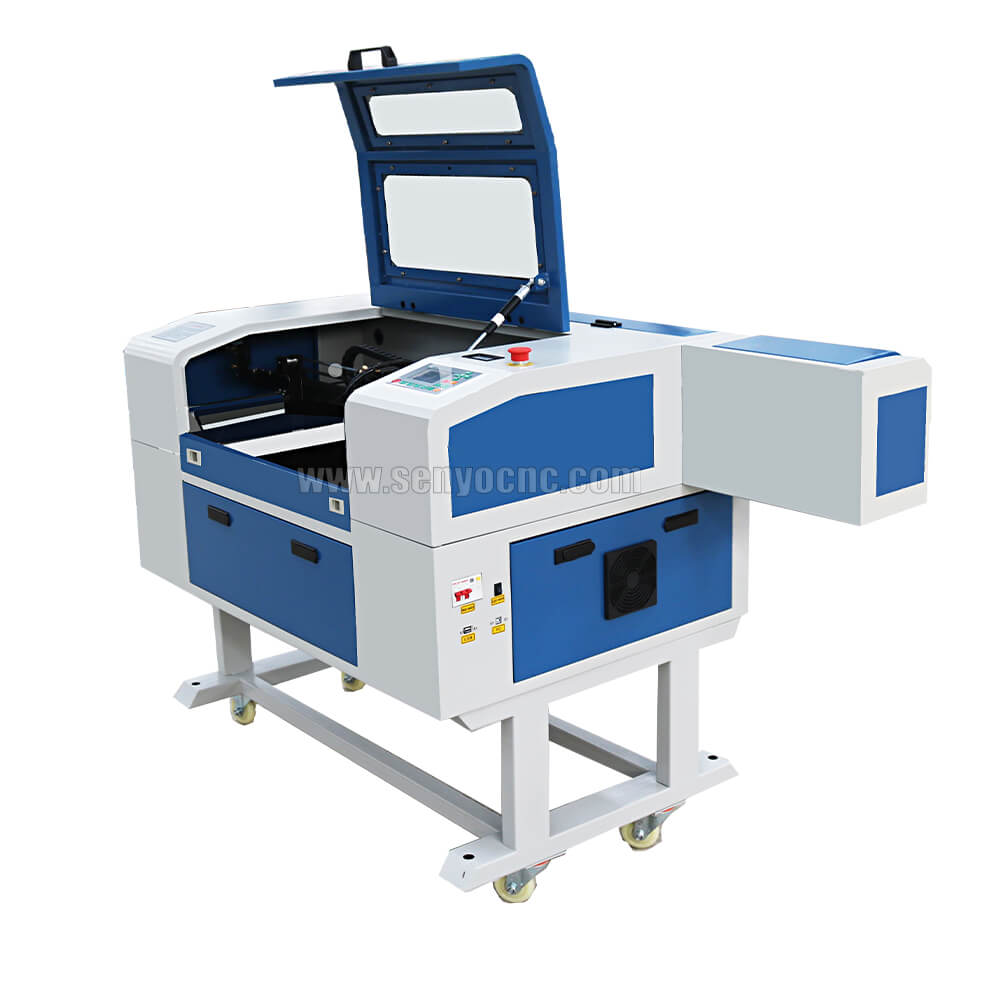

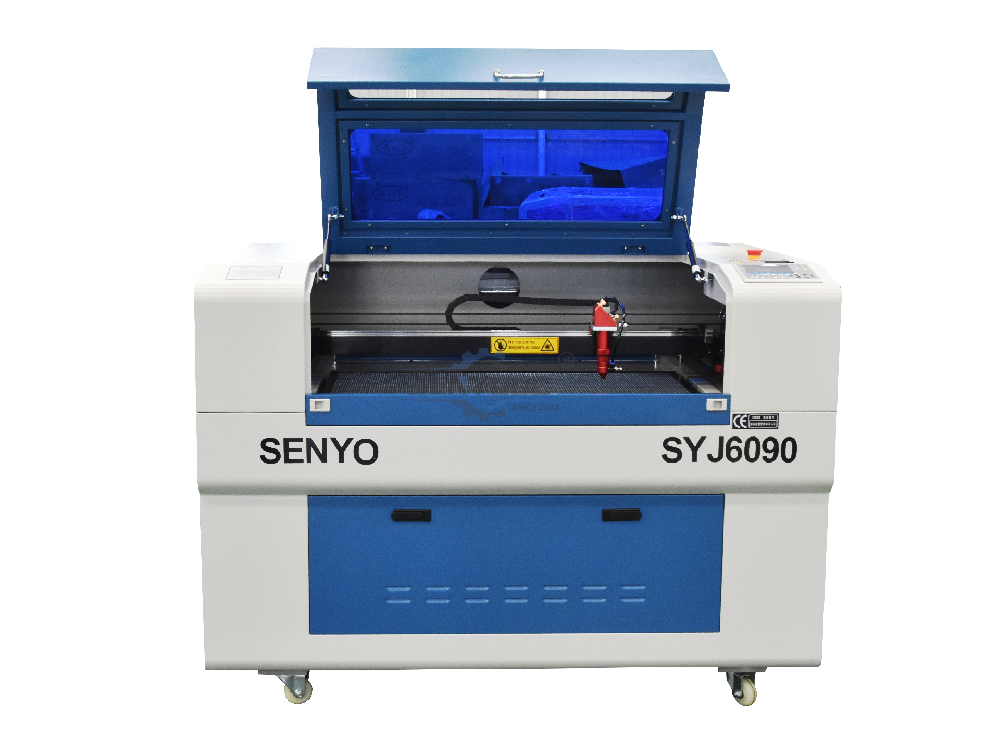

Thank you Senyo for SYJ1290-150W! from

Retired, ex mainframe systems programmer. Now full-time recreational woodworker majoring in puzzles, pens, boxes, Toys and occasional small furniture. Thank you Senyo for SYJ1290-150W!

manager@senyocnc.com

manager@senyocnc.com

SENYOCNC

SENYOCNC

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

2061579344

2061579344