What's Water Jet Cutting Machine ?

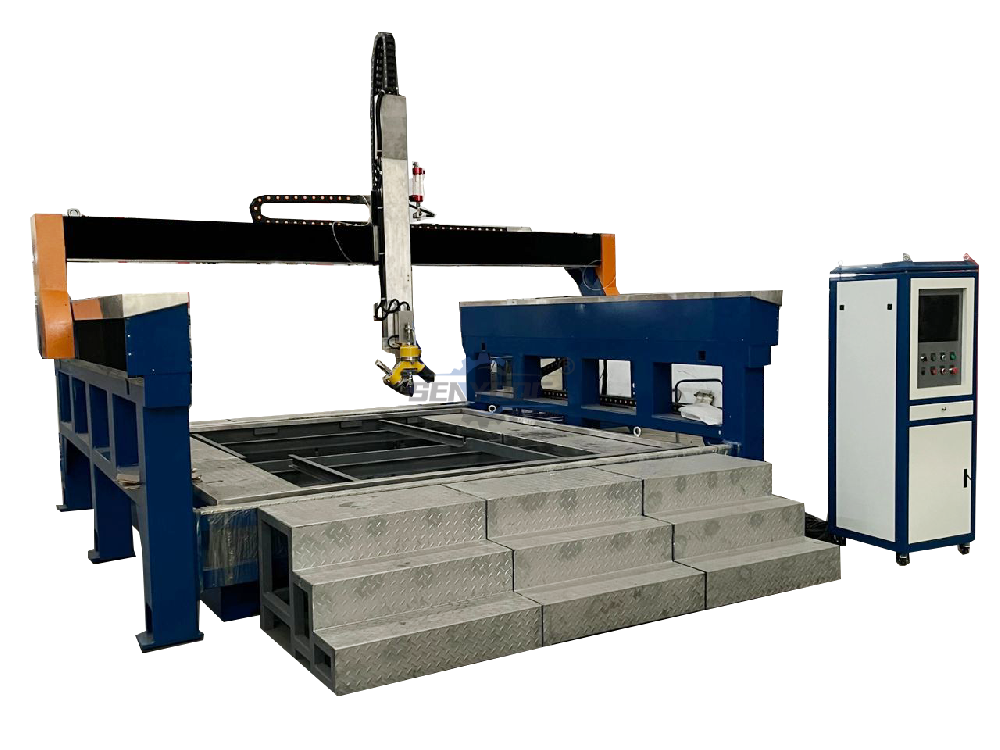

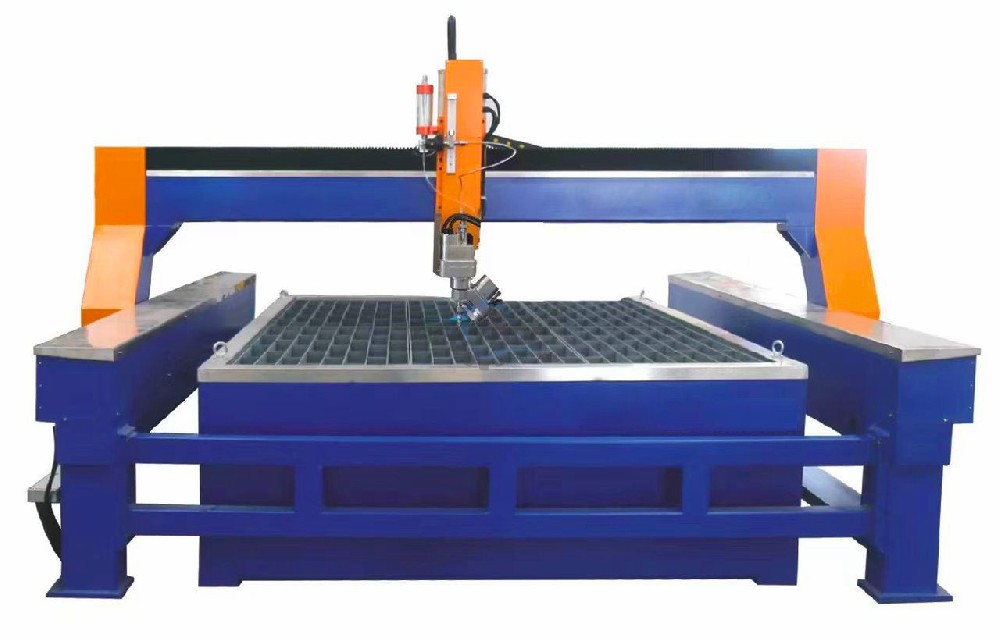

The CNC waterjet cutting machine is composed of a CNC cutting platform, an ultra-high pressure generator,

a waterjet cutting software system and a cutting head, a high-pressure water switch valve, a sand control system,

an automatic abrasive supply system, etc. According to customer needs, you can also choose soft water treatment system,

oil cooling system, automatic sand discharge system and other optional items.

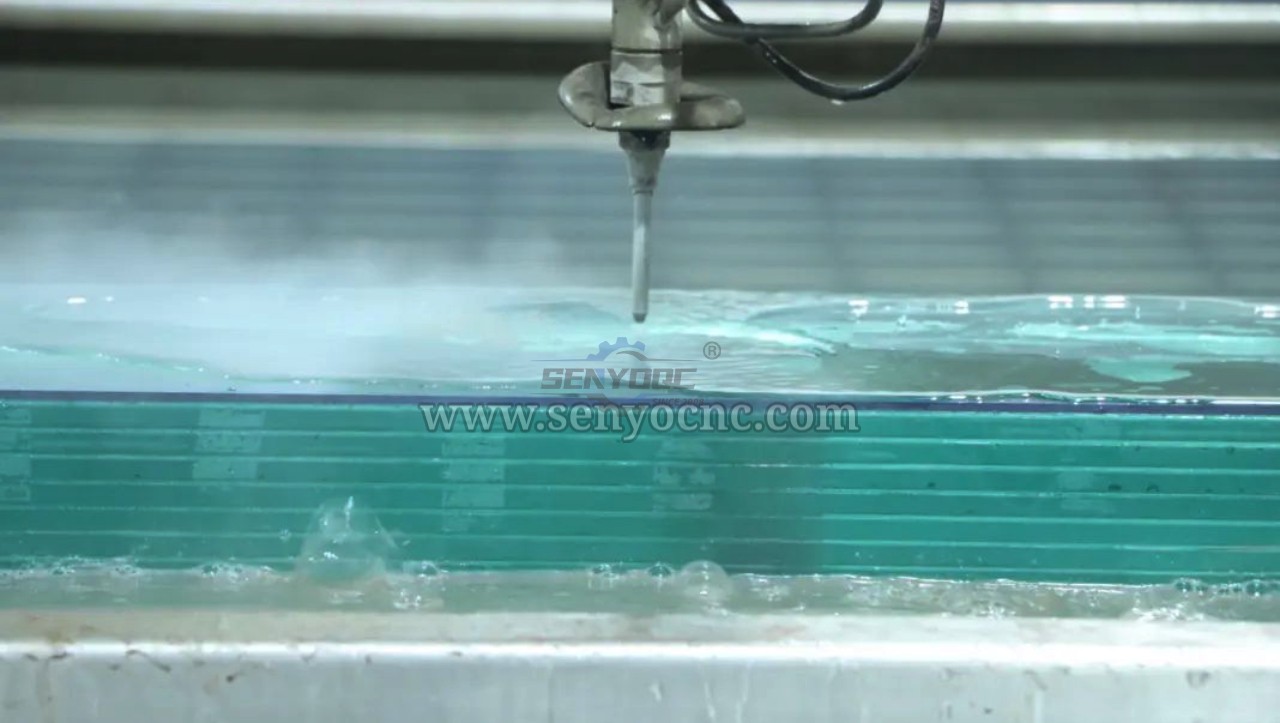

Water jet cutting machine is a high-pressure water jet cutting machine that utilizes straight pure water cutting or abrasive

waterjet cutting to cut several types of material.

We using the water jet high-pressure cutting process to cut material thicknesses from gauge up to 200mm(8").

Perfect small water jet cutting machine

Water jet cutting machine is achieved by forcing a large volume of pure water under high pressure through a small orifice

in the cutting nozzle. The accelerated steam of water leaving the nozzle impacts the material and starts the cutting process. Kerf

from the accelerated stream of water is extremely narrow.

This pressure is then concentrated in a small area on the material which

starts to erode the material. Softer materials can be cut with water pressure. Harder materials require the use of an abrasive

feed system, such as metal cutting.

Machine Features

1. The reciprocating supercharger assembly and variable oil pump based on technology have strong cutting ability and stable performance, and are suitable for long-term, large-scale batch production.

2. It has two different operating modes of high and low pressure, which are based on the characteristics of various materials and the requirements of processing technology. It can realize automatic conversion between high and low pressure, especially suitable for cutting brittle materials and conforming

materials.

3. The high-pressure pump has an external touch screen. The customer operation interface allows customers to observe various data on the operation of the equipment. The engineer maintenance interface sets key parts and alarm points to facilitate quick and accurate judgments on faults.

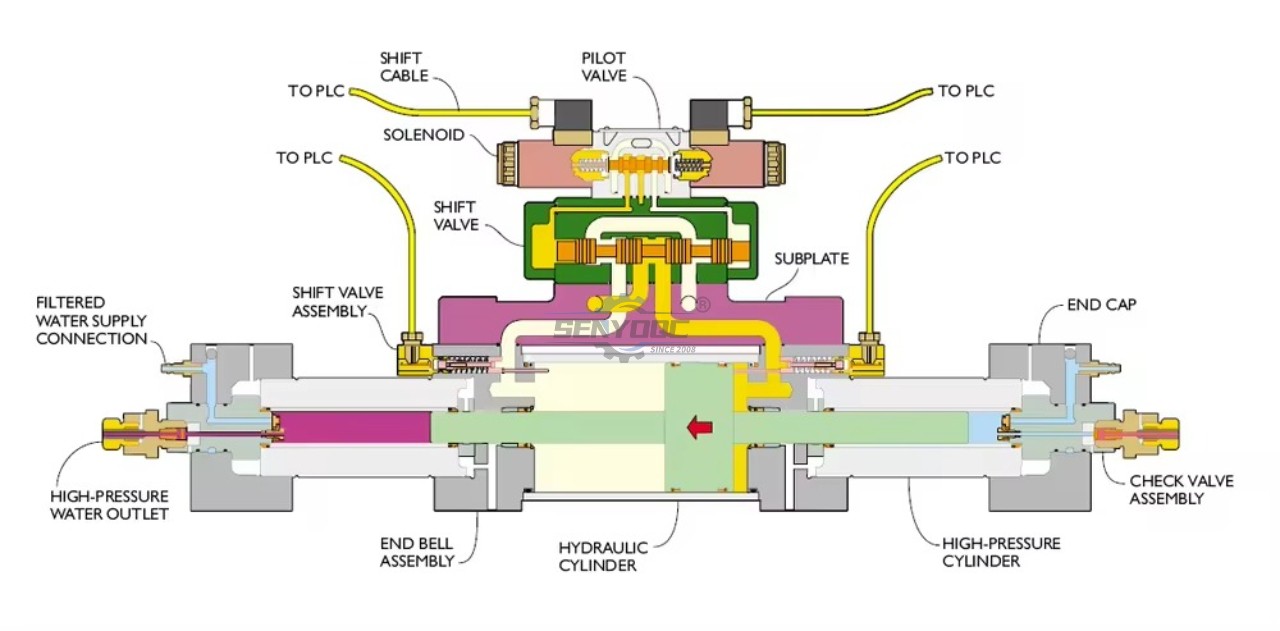

What's Intensifier Pump for Water Jet Cutting Machine ?

The linear intensifier pump is the original, and most common, technology used in waterjet cutting. Intensifier pumps use the “intensification principle” to pressurize water.

The “intensification principle”, or ratio, uses the difference in biscuit/plunger area to intensify, or increase the pressure.

Hydraulic oil is pressurized and the low pressure oil pushes against a biscuit, which has a face area 20 times greater than the face of the high pressure plunger that pushes against the water. Therefore, the pressure is “intensified” twenty times.

E.g., 3,000 psi of oil pressure will generate 60,000 psi of water pressure due to the 20:1 ratio of biscuit area to plunger area.

More Design Option

Machine Application

1. Metal cutting

2. Cutting of glass and stone

Water cutting glass is commonly used in home appliances, architectural glass, automotive glass, etc. In addition, water jet cutting can also be used to cut stone and ceramics to create beautiful ceramic mosaics.

3. Composite materials

Machine will cut material such as Aluminum, Armor Plate, Brass, Carpet, Copper, Glass,Granite, Leather, Marble, Mild Steel,Plastic,

Stainless Steel, Stone, Tile, Titanium,Ceramic tile,Acrylic,Fiber glass ,Rubber,Foam,Composite materials etc.

Working Project

Different Design for Option

Excellent manufacturing capability.

Workshop area of 50,000 square meters, including more than 100 on-the-job workers.

We have manufacture department for quality control.

Machine Test And Shipping

SENYOQC has the most sophisticated testing capabilities, with a total of 28 testing processes from parts processing to equipment delivery.

These include three-dimensional coordinate measuring machines, ball bar instruments, laser interferometers, metallographic microscopes, hardness testers, and other testing equipment.

International Shipping

Around the World All the CNC routers can be shipped worldwide by sea, by air or by international express logistics via DHL. FEDEX. UPS. You are welcome to get a free guotation by fling up the form with name, email, detailed address.Product and recuirements. We will shortly contact you with the full information includina the most suitable delivery method fast secure discreet and freight.

waterjet , cnc water jet machine, waterjet cutter, marble cutting machine, glass cutting waterjet,metal cutting machine water jet ,cnc water jet

• Previous: None

• Next: Competitive Price New Design Waterjet Machine 3 axis Cutting Machine

Fiber metal Laser Sensor And Its Application

Category: SENYO NEWS 11th Mar, 2021A CNC wood router will use 3D machining in relief carving, the effect is more artistic beauty, but also has a strong sense of three-dimensional 3D, realization of this function is to ...

Precision Cutting Stents with Fiber Lasers

A CNC wood router will use 3D machining in relief carving, the effect is more artistic beauty, but also has a strong sense of three-dimensional 3D, realization of this function is to ...

How to Laser Cut Copper and Other Reflective Metals

Laser cutting of mild steel and stainless steel has a long history and has been one of the primary applications for CO2lasers. However CO2lasers have not traditionally offered a good solution for cutting highly reflective materials.Fiber lasers have an emission wavelength of around

Laser Cutting Machine Inspection Process For Manufacture

SENYOCNC Have Strict quality monitoring will be carried out when the parts are in the factory.

How Control Costs Use of UV Printers ?

UV flatbed printers are rapidly being used by more and more manufacturers, thanks to its efficient production efficiency, and the control of production costs also needs to arouse our attention.

Why UV flat printing machine is popular in market ?

For the majority of designers, give full play to the creative ability, the design sample can be arbitrarily modified on the computer, the effect on the computer, is the effect after the finished product, customer satisfaction can be directly produced. UV flat printing pattern fine, rich and clear layers, high artistry, strong three-dimensional sense, many high precision equipment can also print photography and painting style patterns.

How does UV ink jet printer save UV ink?

UV inkjet printer use process is an important consumable UV ink, reasonable use of equipment, can save UV ink , it can be said to be the best choice to directly save the cost. In the process of using some skills you need to be familiar with, the following small make up to share with you:1. Try to us

Waterjet Machine delivery and Shipping

Please tell us your max working size and what materials will cutting , also what max cutting thickeness.If you have Working photo sample please also send us , it will be helpful to choose machine with suitable models .

Waterjet Machine finish manufacture 5axis

Waterjet cutting technology is one of the fastest growing major machine tool processes in the world due to its versatility and ease of operation.

Waterjet Machine delivery and Shipping

Waterjet cutting technology is one of the fastest growing major machine tool processes in the world due to its versatility and ease of operation.There are multiple advantages to adding waterjet cutting capabilities to your shop.We are company leading ultrahigh-pressure waterjet system so

How to Create Connected Text – Inkscape for Laser Cutting

Step 1: Create Some TextFirst, we need some text to work with. To create the text, select the Text Tool (keyboard shortcut: T), click somewhere on the canvas, and type your text.You can use the drop-down list on the top left to select your desired font.Step 2: Convert Text to PathNext, we need to tu

Jacob from United States

I am a beginner at CNC, I’ve never used a CNC machine before and with in a day I was carving. An awesome machine for a beginner to learn as hobbyists. I used the manual and the help video. One hour to assemble and test, very friendly and easy to use. It’s a good buy for the money. I would definitely recommend this machine to someone getting into CNCs.

Weinstein from France

I've been using CNC plasma SYP2060-300A and I am very impressed with this unit.

This unit is of higher quality, made in China. Five stars all the way!

I am a furniture manufacturer, and this machine is very good and fast. thanks Senyoqc Team ! from Bangladesh

Metal ArtWork from Denmark

The plasma cutting machine makes my artistic creation more convenient and precise!! Created more artistic ideas and value! Thank you Aillen team!

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen. from

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen.

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo from

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo

Thank you Senyo for SYJ1290-150W! from

Retired, ex mainframe systems programmer. Now full-time recreational woodworker majoring in puzzles, pens, boxes, Toys and occasional small furniture. Thank you Senyo for SYJ1290-150W!

CNC Router I love woodworking and the Joy in the Journey! It's a Blessing! from Ricky

CNC Router I love woodworking and the Joy in the Journey! It's a Blessing!

CO2 1530H-300W Europe from

CO2 1530H-300W All really well done. these are something ive always wanted to do.

4040 Mini Desktop CNC Router for Small Business from France

Good Machine! Wonderful Service !

Thanks Senyoqc Team for whatsapp Group services , Excellent enginner ! Good work!

/5 based on 100votes/5 based on votes

/5 based on 100votes/5 based on votes

manager@senyocnc.com

manager@senyocnc.com

SENYOCNC

SENYOCNC

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

2061579344

2061579344