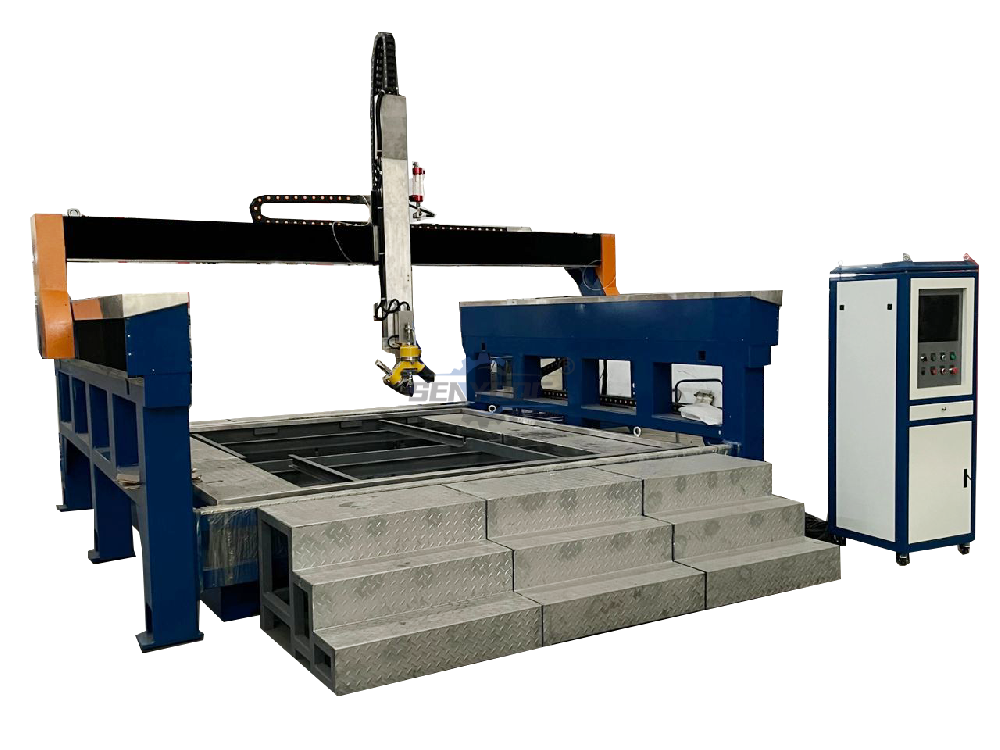

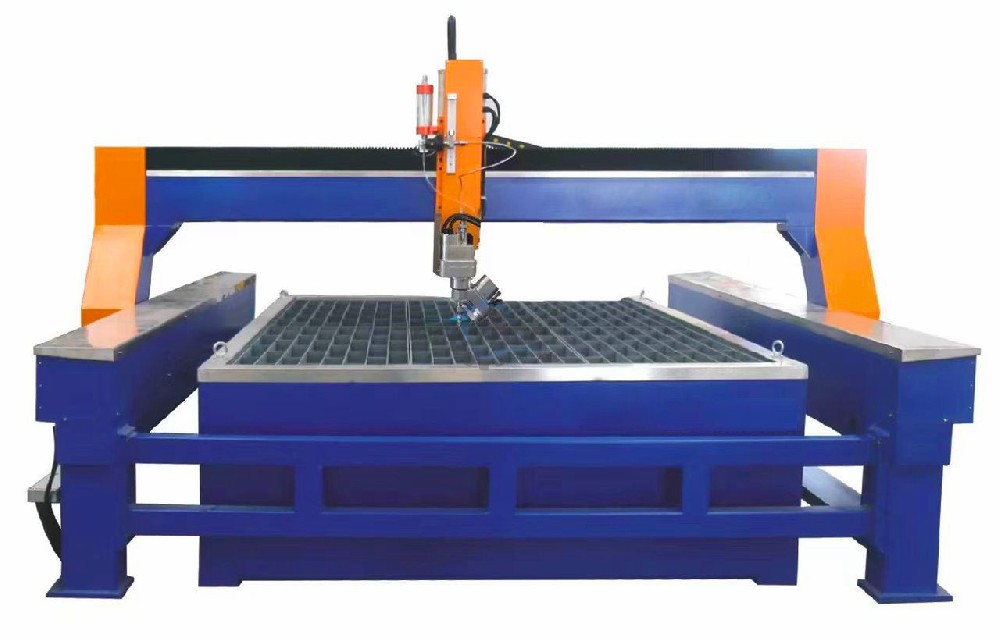

A Set of standard waterjet cutting machine includes 4 parts.

1. Intensifier Pump (It is the power source of a whole waterjet system, it determines the machine working stability and working service life)

2. Cutting table

We can OEM for you according to your work piece size and we can also provide 3 axis, 5 axis cutting head

which one to choose depends on your detailed cutting requirement。

3. CNC Controller (It is the brain of a waterjet system, it control the machine to cut)

4. Auto Abrasive delivery system. (Water Jet needs to mix the abrasives to cut the hard materials, abrasives let the water more powerful)

Competitive Price CNC Water Jet Mirror Cutting Machine New Design for Glass Processing Machinery

Waterjet cutting is best described as a controlled, accelerated erosion process.

For this reason, a waterjet stream can cut through virtually any known material, making waterjet one of the most versatile machines available.

Paramaters For Waterjet Cutting Machine

| A water jet mirror cutting machine is made up of 4 key components, that is Intensifier pump; Cutting table; CNC controller; Auto abrasive feeder. | |||

| Intensifier Pump | Max. water pressure | 410Mpa | |

| Continuous working pressure | 360-380Mpa | ||

| Max. oil pressure | 20Mpa | ||

| Motor power | 37KW/50HP | ||

| Cutting water inlet pressure | 0.3Mpa | ||

| Cooling water inlet pressure | 0.3Mpa | ||

| Power supply | 380V/50HZ/3PH | ||

| Max. flow rate | 3.7L/Min | ||

| Oil tank volum | 30Gal.(114L) | ||

| Cutting Table | Structural style | Cantilever style | |

| Cutting area | 3000x2000x150mm | ||

| Max. moving speed for X/Y-axis | 6000mm/min | ||

| Max. moving speed for Z-axis | 1000mm/min | ||

| Load bearing | 500kg/ Squre meter | ||

| Control accuracy | 0.01mm | ||

| Cutting accuracy | 0.1mm | ||

| Power supply | 220V | ||

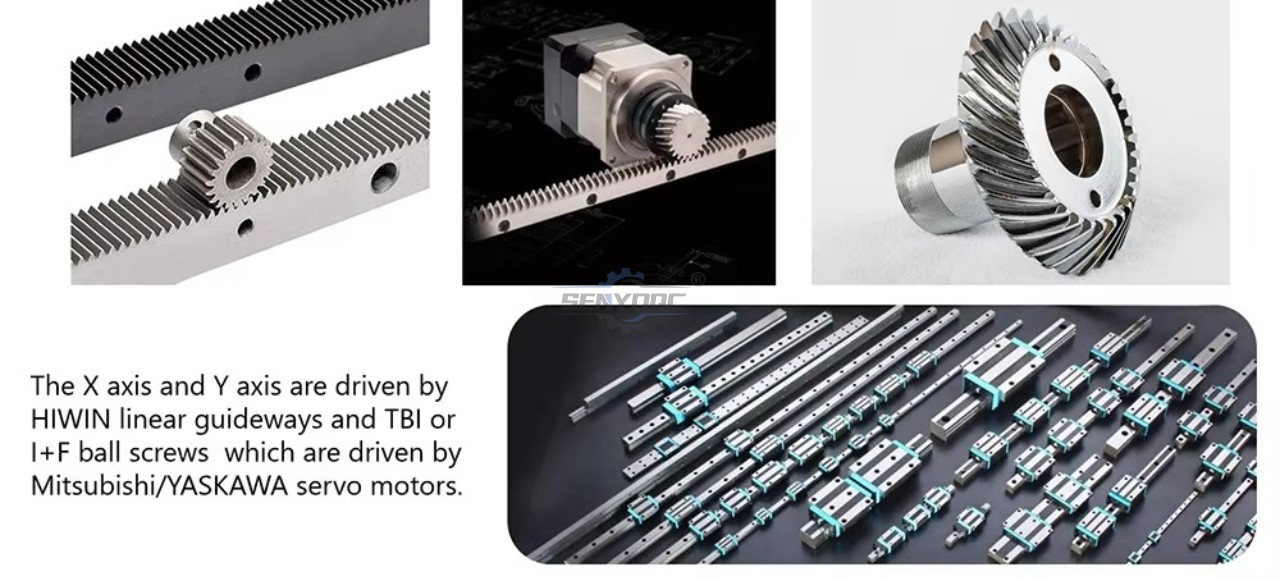

| Way of drive | AC Servo | ||

| X/Y-axis structure | Aluminum structure | ||

| Cutting Head | Mode | 3-axis | |

| Max. orifice diameter | 0.33mm | ||

| Max. nozzle diameter | 1.02mm | ||

| Z-axis step motor | 0.9N.M | ||

| CNC Controller | 15 inch LCD monitor | ||

| Support DXF and NC code file | |||

| Software: Windows XP | |||

| Resistance of the shoch and electro-magnetic | |||

| The key function | |||

| Forward & backward processing function | Even pace control function | ||

| Small arcs speed auto processing function | Circle processing function | ||

| Partial and smooth processing modes | |||

| Abrasive Feeder | Max. inlet air pressure | 0.6Mpa | |

| Min. inlet air flow | 0.028m3/min | ||

| Abrasive capacity | 225KG | ||

| Features | |||

| Air valve to prevent jams and breakages | Self sealing | ||

| Auto control with CNC auxiliary function | Slightly adjust the flow | ||

Parts Detials

We adopt the imported component of cnc water jet mirror cutting machine like Rexroth hydraulic pump;

USA intensifier; Siemens motor; Omron PLC; Yaskawa servo drive; Yuken direction control valves etc.

The whole parts of Intensifier are assembled in USA (not just some parts),

most of the smaller parts are also imported from USA to ensure its good stability during cutting, durability and long working service life.

Application And Working Samples

Glass. | Metals. One of the most common uses for waterjet cutting is cutting metals like steel, aluminum, titanium, brass, and nickel. |

Stone. | Soft Materials. Waterjets are often used for cutting soft materials like dense foams, components for car interiors and bodies, rubber, plastics |

Waterjets are used in the automotive industry for truck bed liners, bumpers, fiberglass body components, interior trim, and foam. | Aerospace. Waterjets are used in the aerospace industry for cutting engine parts, interior cabin panels, aluminum body parts, and titanium bodies for military aircrafts. |

| Food. Waterjets are often used in the food industry for jobs such as slicing mass quantities of vegetables and processing meat like chicken nuggets and frozen fish | Electronics. Waterjets are used in the electronics industry for cable stripping and circuit boards |

Fiberglass. Waterjets are used to cut fiberglass for home insulation, boat bodies, panel insulation, and personal watercraft bodies. | Textiles. Because of their ability to cut multiple layers at once, waterjets are popular for cutting textiles like sports lettering |

| fabrics, healthcare products, feminine hygiene products, and diapers. Munitions Demilitarization. | Waterjets are used in the arms industry for chemical weapons and high explosives. |

Competitive Price CNC Water Jet Mirror Cutting Machine New Design for Glass Processing Machinery The technology for water jet mirror cutting machine is a great method for cutting glass because it allows for contours and shapes that cannot be achieved with other cutting machines at a reasonable cost. For glass, ceramics and other brittle materials, you must gradually increase and reduce the cutting pressure by means of proportional pressure control of the intensifier pump, otherwise the material would be destroyed. | From artistic tabletop inlays to detailed stained glass designs, mirrors, glass ornamentsreplacement windows for antique cars, and more, there’s almost no glass cutting application that a water jet mirror cutting machine fromWaterjet can’t tackle. Glass has a tendency to crack, so it is very important that the initial holes are produced with a reduced pressure. Subsequently, the pressure must be increased to a cutting speed that is cost-effective. |

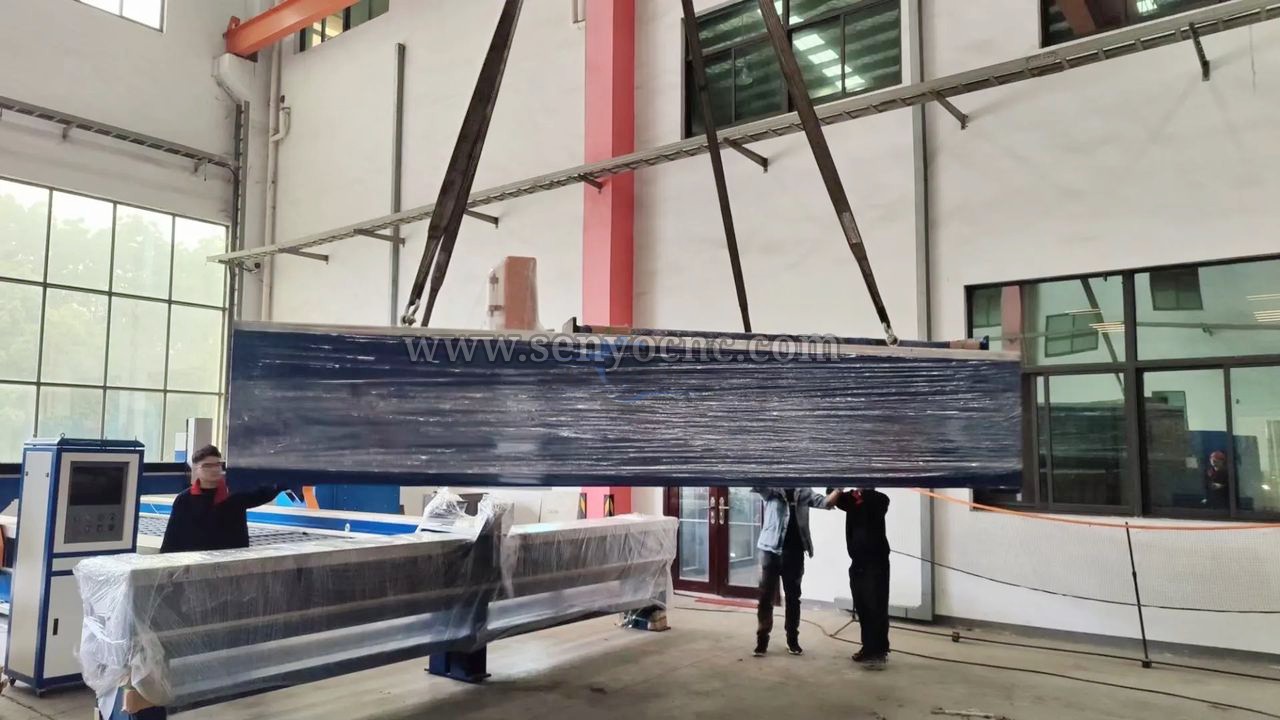

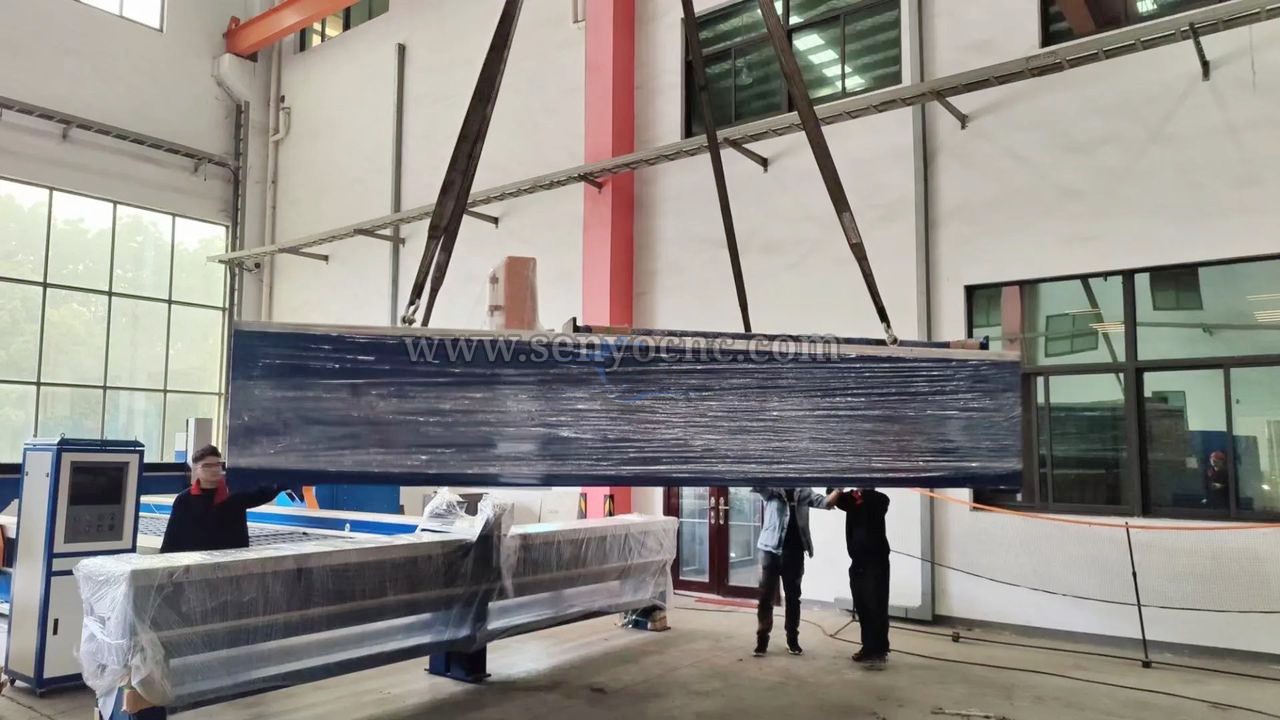

Shipping & Delivery

CNC water jet mirror cutting machine be packed in standard packing, suitable for long distance ocean transportation and well protected against damage, moisture, shock, rust and handling

Introduce For Our WaterJet Machine

1. Are there special considerations for making glass parts?

Dual pressure piercing allows for piercing of glass with minimal risk of cracking.

SENYO cnc water jet mirror cutting machine could work with low-pressure piercing to slowly raise the pump pressure during the pierce to avoid a sudden shock to the material by a rapid change in pressure. Using these techniques reduces the risk of cracking, making glass cutting into a very profitable venture.

2. What kind of glass does your cnc water jet mirror cutting machine can cut?

There are plenty glass our cnc water jet mirror cutting machine can cut, such as laminated glass,bullet-proof glass , stained glass, polished glass, wired glassect.

3. What your cnc water jet mirror cutting machine's Max. cutting thickness for glass?

In theory, the thickness is up to the Z-axis travel, for common style, it is 150mm,

but in practical it is better to cut 120mm glass with good quantity and speed.

4. What are the different between water-only water jet and abrasive water jet?

"Water jet" is commonly used to reference both water-only water jet and abrasive water jet cutting.

Water-only water jets cut with ultra-high pressure water alone.

Abrasive water jets cut with an abrasive material (usually garnet) that has been added to the water stream.

Water-only water jets can cut through softer materials such as rubber and foam.

Abrasive water jets are used to cut through harder materials such as plastic, composites, stone, glass and metal.

International Shipping

Around the World All the CNC routers can be shipped worldwide by sea, by air or by international express logistics via DHL. FEDEX. UPS. You are welcome to get a free guotation by fling up the form with name, email, detailed address.Product and recuirements. We will shortly contact you with the full information includina the most suitable delivery method fast secure discreet and freight.

waterjet , cnc water jet machine, waterjet cutter, marble cutting machine, glass cutting waterjet,metal cutting machine water jet ,cnc water jet

• Previous: Mini waterjet cutting machine for sale cheap factory price

• Next: Split design Waterjet Cutting Machine 5 Axis AB best price

Fiber metal Laser Sensor And Its Application

Category: SENYO NEWS 11th Mar, 2021A CNC wood router will use 3D machining in relief carving, the effect is more artistic beauty, but also has a strong sense of three-dimensional 3D, realization of this function is to ...

Precision Cutting Stents with Fiber Lasers

A CNC wood router will use 3D machining in relief carving, the effect is more artistic beauty, but also has a strong sense of three-dimensional 3D, realization of this function is to ...

How to Laser Cut Copper and Other Reflective Metals

Laser cutting of mild steel and stainless steel has a long history and has been one of the primary applications for CO2lasers. However CO2lasers have not traditionally offered a good solution for cutting highly reflective materials.Fiber lasers have an emission wavelength of around

Laser Cutting Machine Inspection Process For Manufacture

SENYOCNC Have Strict quality monitoring will be carried out when the parts are in the factory.

How Control Costs Use of UV Printers ?

UV flatbed printers are rapidly being used by more and more manufacturers, thanks to its efficient production efficiency, and the control of production costs also needs to arouse our attention.

Why UV flat printing machine is popular in market ?

For the majority of designers, give full play to the creative ability, the design sample can be arbitrarily modified on the computer, the effect on the computer, is the effect after the finished product, customer satisfaction can be directly produced. UV flat printing pattern fine, rich and clear layers, high artistry, strong three-dimensional sense, many high precision equipment can also print photography and painting style patterns.

How does UV ink jet printer save UV ink?

UV inkjet printer use process is an important consumable UV ink, reasonable use of equipment, can save UV ink , it can be said to be the best choice to directly save the cost. In the process of using some skills you need to be familiar with, the following small make up to share with you:1. Try to us

Waterjet Machine delivery and Shipping

Please tell us your max working size and what materials will cutting , also what max cutting thickeness.If you have Working photo sample please also send us , it will be helpful to choose machine with suitable models .

Waterjet Machine finish manufacture 5axis

Waterjet cutting technology is one of the fastest growing major machine tool processes in the world due to its versatility and ease of operation.

Waterjet Machine delivery and Shipping

Waterjet cutting technology is one of the fastest growing major machine tool processes in the world due to its versatility and ease of operation.There are multiple advantages to adding waterjet cutting capabilities to your shop.We are company leading ultrahigh-pressure waterjet system so

How to Create Connected Text – Inkscape for Laser Cutting

Step 1: Create Some TextFirst, we need some text to work with. To create the text, select the Text Tool (keyboard shortcut: T), click somewhere on the canvas, and type your text.You can use the drop-down list on the top left to select your desired font.Step 2: Convert Text to PathNext, we need to tu

Jacob from United States

I am a beginner at CNC, I’ve never used a CNC machine before and with in a day I was carving. An awesome machine for a beginner to learn as hobbyists. I used the manual and the help video. One hour to assemble and test, very friendly and easy to use. It’s a good buy for the money. I would definitely recommend this machine to someone getting into CNCs.

Weinstein from France

I've been using CNC plasma SYP2060-300A and I am very impressed with this unit.

This unit is of higher quality, made in China. Five stars all the way!

10w uv laser from American

Best supplier ! I bought 3 machines for laser and router , thank you Aillen ! --Alec

12KW Fiber Cutting - 2000X6000mm -- 이병헌 from Korea

Good machine for metal cut ! Thanks Senyo , Its prefect , I like your business patient kind!

I am a furniture manufacturer, and this machine is very good and fast. thanks Senyoqc Team ! from Bangladesh

Metal ArtWork from Denmark

The plasma cutting machine makes my artistic creation more convenient and precise!! Created more artistic ideas and value! Thank you Aillen team!

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen. from

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen.

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo from

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo

Thank you Senyo for SYJ1290-150W! from

Retired, ex mainframe systems programmer. Now full-time recreational woodworker majoring in puzzles, pens, boxes, Toys and occasional small furniture. Thank you Senyo for SYJ1290-150W!

CNC Router I love woodworking and the Joy in the Journey! It's a Blessing! from Ricky

CNC Router I love woodworking and the Joy in the Journey! It's a Blessing!

/5 based on 100votes/5 based on votes

/5 based on 100votes/5 based on votes

manager@senyocnc.com

manager@senyocnc.com

SENYOCNC

SENYOCNC

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

2061579344

2061579344