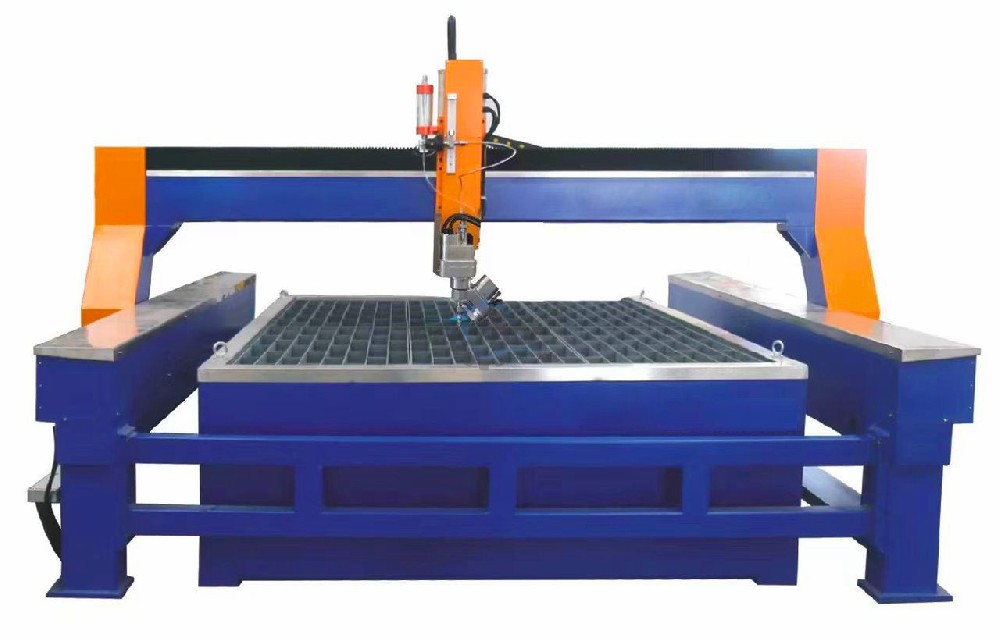

The AC five axis water jet is a traditional three axis water jet (x y z) ,Two additional servers have been added to achieve dynamic and directional linkage cutting. This enables the one-time forming and cutting of irregular parts. The AC five axis water jet breaks through the limitations of traditional water jet cutting that can only cut vertically or at small angles in rock plate processing, and also breaks through the limitations of traditional manual adjustment cutting.

With the five axis CNC system ,Our water jet equipment coordinates the rotation axes of x, y, and AC simultaneously, allowing the water knife cutting head to swing in any direction without stopping during turns and without turning circles, resulting in faster cutting speed.When cutting rock slabs, the computer calculates in real-time based on the density and thickness of the cut rock slab workpiece, and controls the cutting tool head to run along the cutting trajectory, achieving three-dimensional cutting of complex shapes of the workpiece

Such as cutting slopes, chamfers, high-precision conical surfaces, arc surfaces, and other complex spatial surfaces, eliminating the phenomenon of small surfaces and large bottoms. The front splicing gap required for stone mosaic is smaller, and it can be directly spliced without polishing, effectively reducing production costs. To achieve higher performance and bring better benefits to users for water knives.

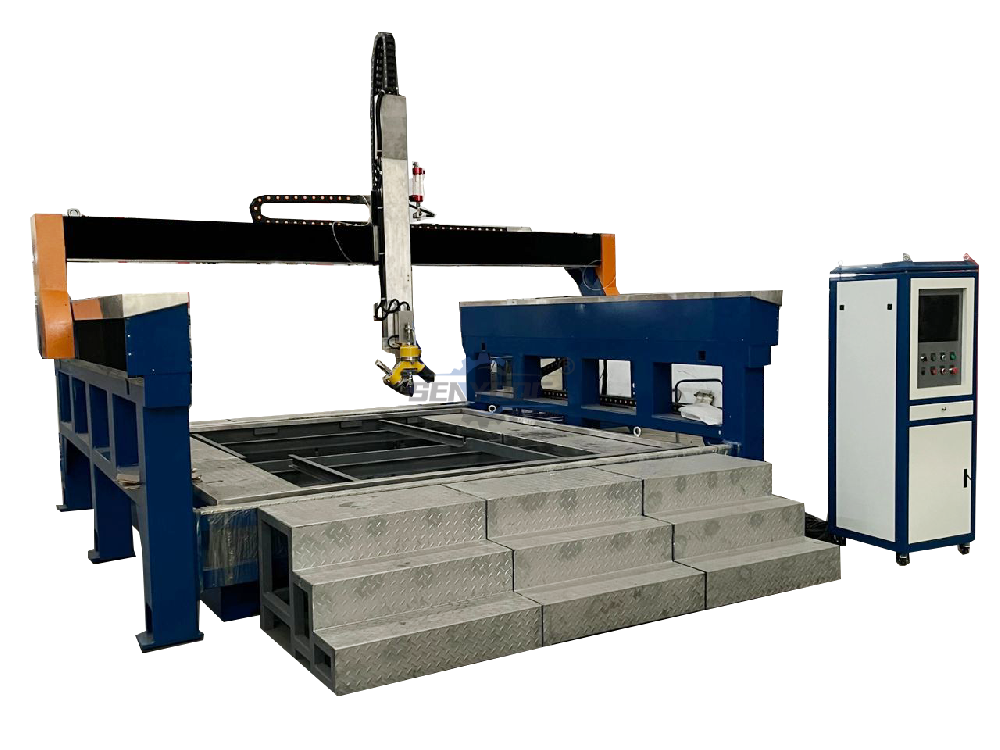

We can provide customized solutions for different customers and applications. The X,Y and Z axis of our water jet cutting machine all can be customized ,

We've done a lot of cases, such as 2000mm*6000mm, 4000mm*8000mm, 3000mm*12000mm, the largest waterjet cutting machine we have built that can be transported is 4000mm*12000mm, the maximum of Z axis can be 1000mm.

Lathe bed and water tank are detachable, which are designed to reduce the pressure from water with sands and machined parts to moving parts.

The base of Y-axis is overall manufacturing, It’s convenient for disassembly, transportation and assembly.

X-axis and Y-axis adopt high-precision ball screw and guide linear rail.

The size of cutting table can be customized, such as 3000mm*8000mm, 3500mm*7000mm, 2000mm*12000mm as below, the max size can be 4000mm*12000mm.

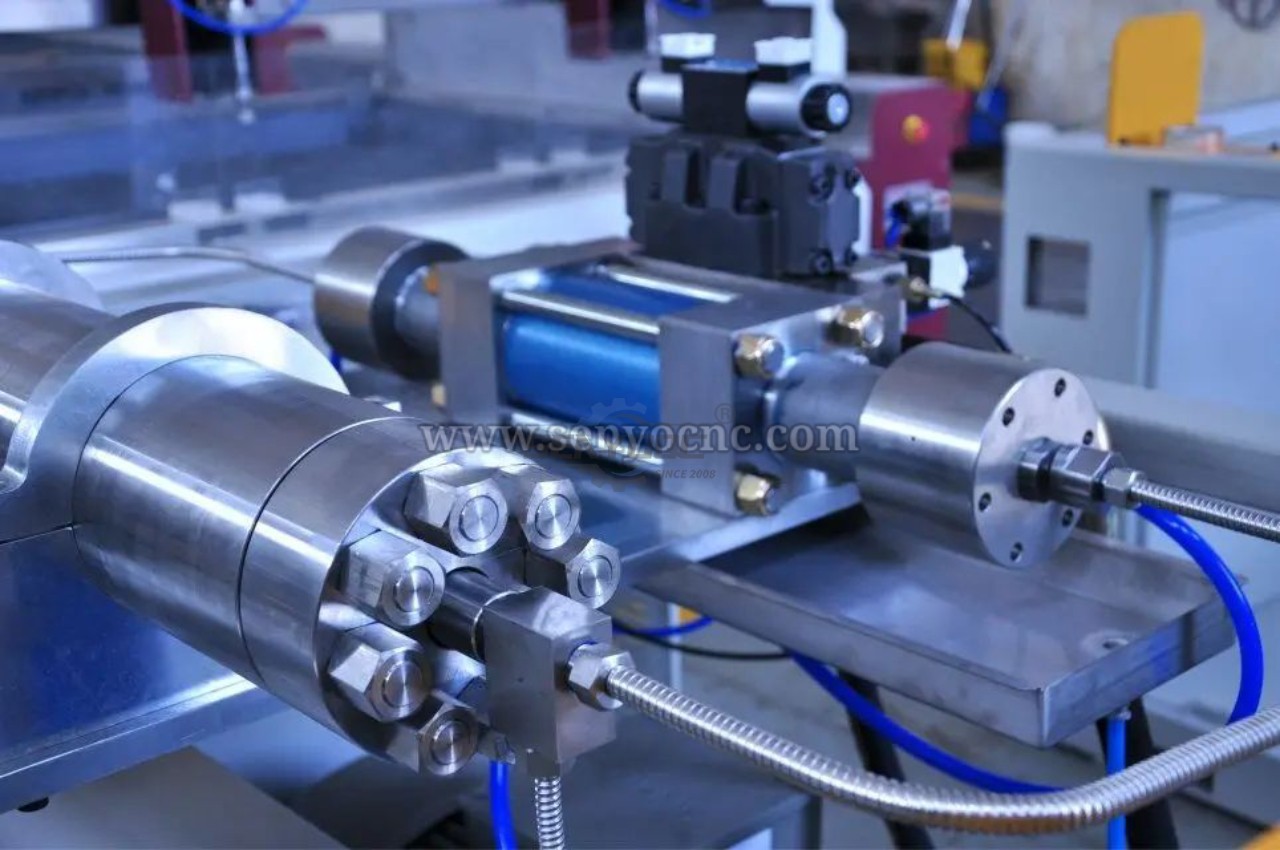

ultra high pressure system enables our company to independently develop an ultra-high pressure generation system based on the advantages of similar foreign products, which has the characteristics of compact structure, reasonable layout,high energy and low consumption.long service life without reducing high pressure, and high comprehensive cost-effectiveness combined with cost-effectiveness; The key high-pressure components of the turbocharger are imported products ensuring long-term continuous operation.

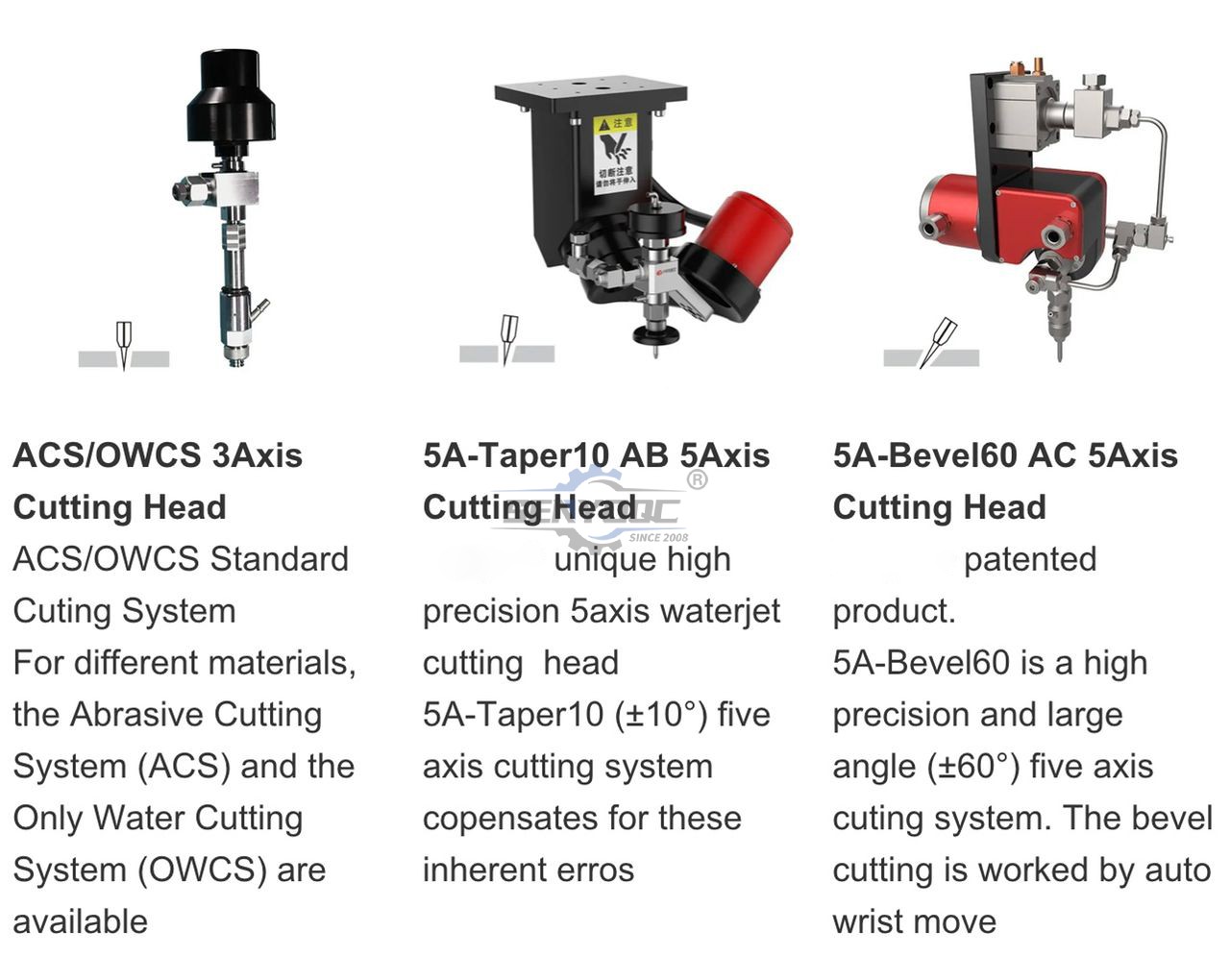

1. Adopting an AC axis design, achieving CNC five axis (X, Y, Z, A, C) linkage.

2. The structure is simple and practical, with tighter waterproofing and sand prevention, and more ingenious electrical wiring.

3. All parts are processed using high-precision machining centers imported from Japan to ensure machining accuracy.

4. Adopting high-end imported brand servo motors and servo drives for higher control accuracy.

5. Reasonable design, uniform force distribution, effectively improving the operating life and reliability of the five axis water jet

Water supply system

Cutting water: The intensifier must be supplied with water of 20-1000psi (1.4-6.9bar). The input water should not less than the output water by 1.5 times.

Cooling water (for the heat exchanger): The heat exchanger is used to adjust the accumulated heat in the hydraulic oil.

High pressure pipeline: Imported high pressure pipeline using right angle joints to reduce impact and increase service life. More than 10 times the lifespan of other bend pipe manufacturers.

Hydraulic system

37kw drives the hydraulic pump, then the pump will pressurize the hydraulic oil up to 20Mpa max.

Electrical control system

Waterjet Intensifer system

The intensification system mainly refers to the intensifier, but it also includes other components in the water circuit that make the lower pressure water into high pressure water. Specifically, it includes intensifier, accumulator, high pressure tube,connector etc. Intensifier is main part of the intensification system. A section for the intensifier 's principle, structure, and maintenance is contained in this manual.

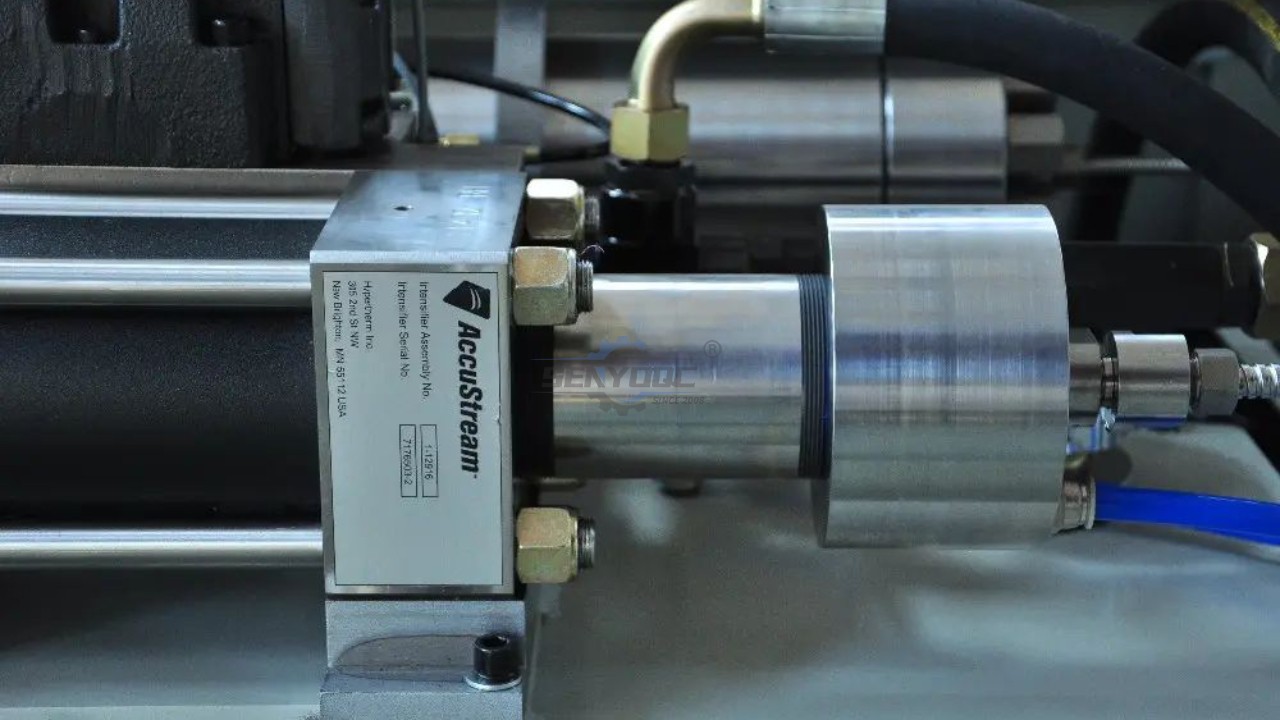

Increase pressure machine; Adopting the imported American ACC brand, ensuring continuous 24-hour operation,increasing customer production capacity, and reducing maintenance rates

| Glass. Waterjets are used for a number of glass projects, including kitchen and bathroom splashbacks, stained glass for mosaics or lamp shades, frameless shower screens, laminated and bullet-proof glass, and inlays of floor, walls, and table tops. | Metals.One of the most common uses for waterjet cutting is cutting metals like steel, aluminum, titanium, brass, and nickel. |

| Stone.Waterjets are used for cutting floor and wall inlays, custom stepping stones, custom border tiles, and bench tops for kitchens and vanities. | Soft Materials. Waterjets are often used for cutting soft materials like dense foams, components for car interiors and bodies, rubber, plastics, and cork. |

| Automotive. Waterjets are used in the automotive industry for truck bed liners, bumpers, fiberglass body components, interior trim, and foam | Electronics. Waterjets are used in the electronics industry for cable stripping and circuit boards. |

| Aerospace. Waterjets are used in the aerospace industry for cutting engine parts, interior cabin panels, aluminum body parts | Food. Waterjets are often used in the food industry for jobs such as slicing mass quantities of vegetables and processing meat like chicken nuggets and frozen fish. |

| Fiberglass. Waterjets are used to cut fiberglass for home insulation, boat bodies, panel insulation, and personal watercraft bodies. | Textiles. Because of their ability to cut multiple layers at once, waterjets are popular for cutting textiles like sports lettering, fabrics, healthcare products, feminine hygiene products, and diaper |

| Munitions Demilitarization. Waterjets are used in the arms industry for chemical weapons and high explosives. | Titanium bodies for military aircrafts. |

Work Project

Package and Shipping

Enginner Test Machine Process Detail

International Shipping

Around the World All the CNC Machines can be shipped worldwide by sea, by air or by international express logistics via DHL. FEDEX. UPS. You are welcome to get a free guotation by fling up the form with name, email, detailed address.Product and recuirements. We will shortly contact you with the full information includina the most suitable delivery method fast secure discreet and freight.

waterjet , cnc water jet machine, waterjet cutter, marble cutting machine, glass cutting waterjet,metal cutting machine water jet ,cnc water jet

• Previous: Cantilever Gantry Integrated Waterjet Cutting Machine Lowest Price

• Next: None

Fiber metal Laser Sensor And Its Application

Category: SENYO NEWS 11th Mar, 2021A CNC wood router will use 3D machining in relief carving, the effect is more artistic beauty, but also has a strong sense of three-dimensional 3D, realization of this function is to ...

Precision Cutting Stents with Fiber Lasers

A CNC wood router will use 3D machining in relief carving, the effect is more artistic beauty, but also has a strong sense of three-dimensional 3D, realization of this function is to ...

How to Laser Cut Copper and Other Reflective Metals

Laser cutting of mild steel and stainless steel has a long history and has been one of the primary applications for CO2lasers. However CO2lasers have not traditionally offered a good solution for cutting highly reflective materials.Fiber lasers have an emission wavelength of around

Laser Cutting Machine Inspection Process For Manufacture

SENYOCNC Have Strict quality monitoring will be carried out when the parts are in the factory.

How Control Costs Use of UV Printers ?

UV flatbed printers are rapidly being used by more and more manufacturers, thanks to its efficient production efficiency, and the control of production costs also needs to arouse our attention.

Why UV flat printing machine is popular in market ?

For the majority of designers, give full play to the creative ability, the design sample can be arbitrarily modified on the computer, the effect on the computer, is the effect after the finished product, customer satisfaction can be directly produced. UV flat printing pattern fine, rich and clear layers, high artistry, strong three-dimensional sense, many high precision equipment can also print photography and painting style patterns.

How does UV ink jet printer save UV ink?

UV inkjet printer use process is an important consumable UV ink, reasonable use of equipment, can save UV ink , it can be said to be the best choice to directly save the cost. In the process of using some skills you need to be familiar with, the following small make up to share with you:1. Try to us

Waterjet Machine delivery and Shipping

Please tell us your max working size and what materials will cutting , also what max cutting thickeness.If you have Working photo sample please also send us , it will be helpful to choose machine with suitable models .

Waterjet Machine finish manufacture 5axis

Waterjet cutting technology is one of the fastest growing major machine tool processes in the world due to its versatility and ease of operation.

Waterjet Machine delivery and Shipping

Waterjet cutting technology is one of the fastest growing major machine tool processes in the world due to its versatility and ease of operation.There are multiple advantages to adding waterjet cutting capabilities to your shop.We are company leading ultrahigh-pressure waterjet system so

How to Create Connected Text – Inkscape for Laser Cutting

Step 1: Create Some TextFirst, we need some text to work with. To create the text, select the Text Tool (keyboard shortcut: T), click somewhere on the canvas, and type your text.You can use the drop-down list on the top left to select your desired font.Step 2: Convert Text to PathNext, we need to tu

Jacob from United States

I am a beginner at CNC, I’ve never used a CNC machine before and with in a day I was carving. An awesome machine for a beginner to learn as hobbyists. I used the manual and the help video. One hour to assemble and test, very friendly and easy to use. It’s a good buy for the money. I would definitely recommend this machine to someone getting into CNCs.

Weinstein from France

I've been using CNC plasma SYP2060-300A and I am very impressed with this unit.

This unit is of higher quality, made in China. Five stars all the way!

2040 from INDIAN

Best 2040 CNC Router Good Price and Quality ! Thank SENYOQC

10w uv laser from American

Best supplier ! I bought 3 machines for laser and router , thank you Aillen ! --Alec

12KW Fiber Cutting - 2000X6000mm -- 이병헌 from Korea

Good machine for metal cut ! Thanks Senyo , Its prefect , I like your business patient kind!

I am a furniture manufacturer, and this machine is very good and fast. thanks Senyoqc Team ! from Bangladesh

Metal ArtWork from Denmark

The plasma cutting machine makes my artistic creation more convenient and precise!! Created more artistic ideas and value! Thank you Aillen team!

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen. from

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen.

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo from

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo

Thank you Senyo for SYJ1290-150W! from

Retired, ex mainframe systems programmer. Now full-time recreational woodworker majoring in puzzles, pens, boxes, Toys and occasional small furniture. Thank you Senyo for SYJ1290-150W!

/5 based on 100votes/5 based on votes

/5 based on 100votes/5 based on votes

manager@senyocnc.com

manager@senyocnc.com

SENYOCNC

SENYOCNC

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

2061579344

2061579344