Handheld laser welding machine is a type of portable fiber laser beam welding machine which couples the high energy fiber laser beams into the optical fiber, after long-distance transmission, then transformed into parallel lights through collimating mirror to be focused on the work piece to implement the welding. The fiber laser welder is more flexible to implement flexible transmission of non-contact welding for those difficult to weld site. The manual laser beam welding can realize the spectrum separation on time and energy, it can do multi-beam welding at the same time, it provides the conditions for high precise welding compared with the traditional MIG & TIG welding, electric welding, and arc welding.

Advantages of Handheld Laser Welding Machine with Fiber Laser Beam

1.Handheld welding head is equipped with 1000 watt fiber laser power, flexible, enabling outdoor welding.

2. Fast welding speed, 2-10 times faster than traditional welding.

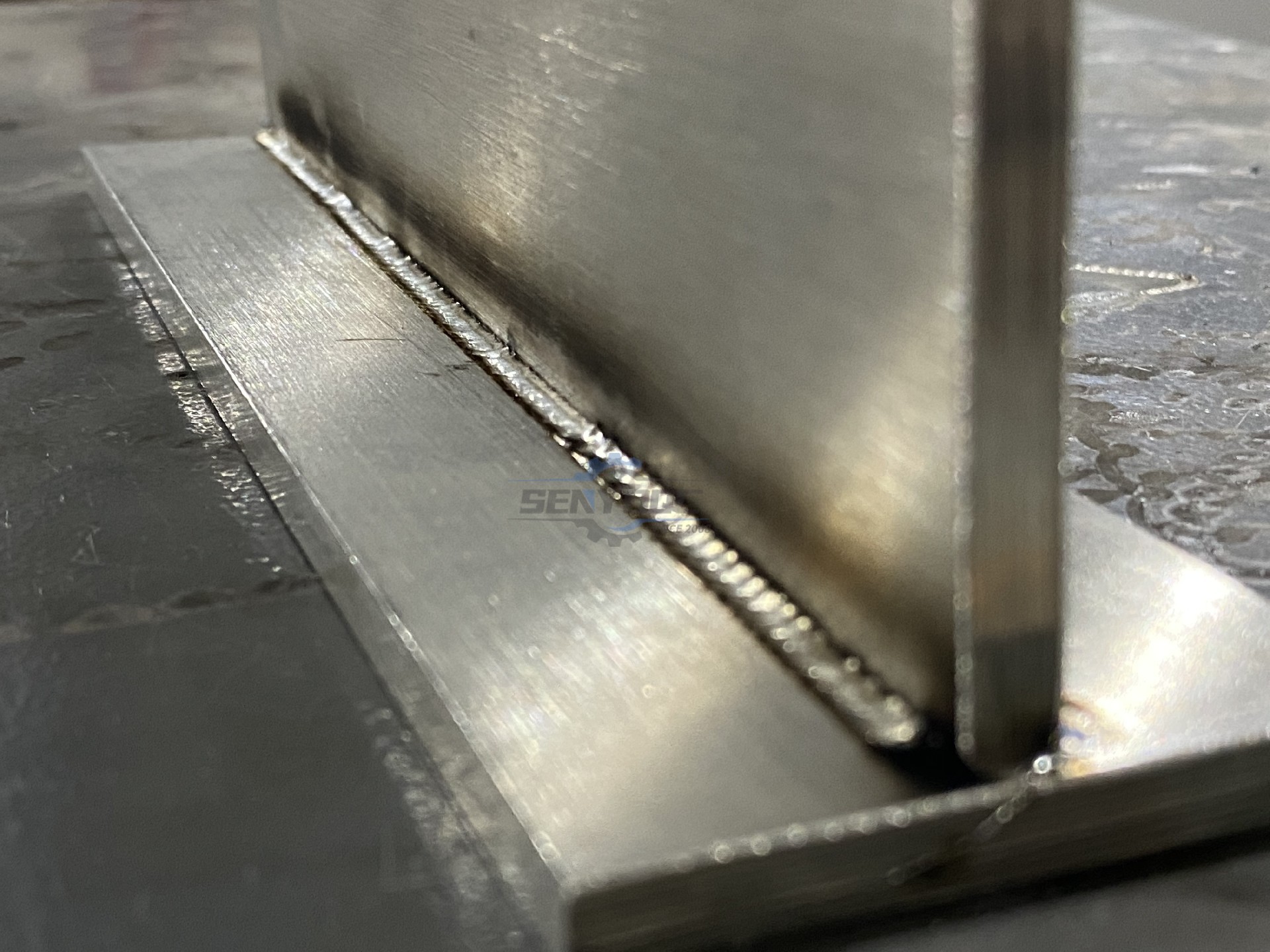

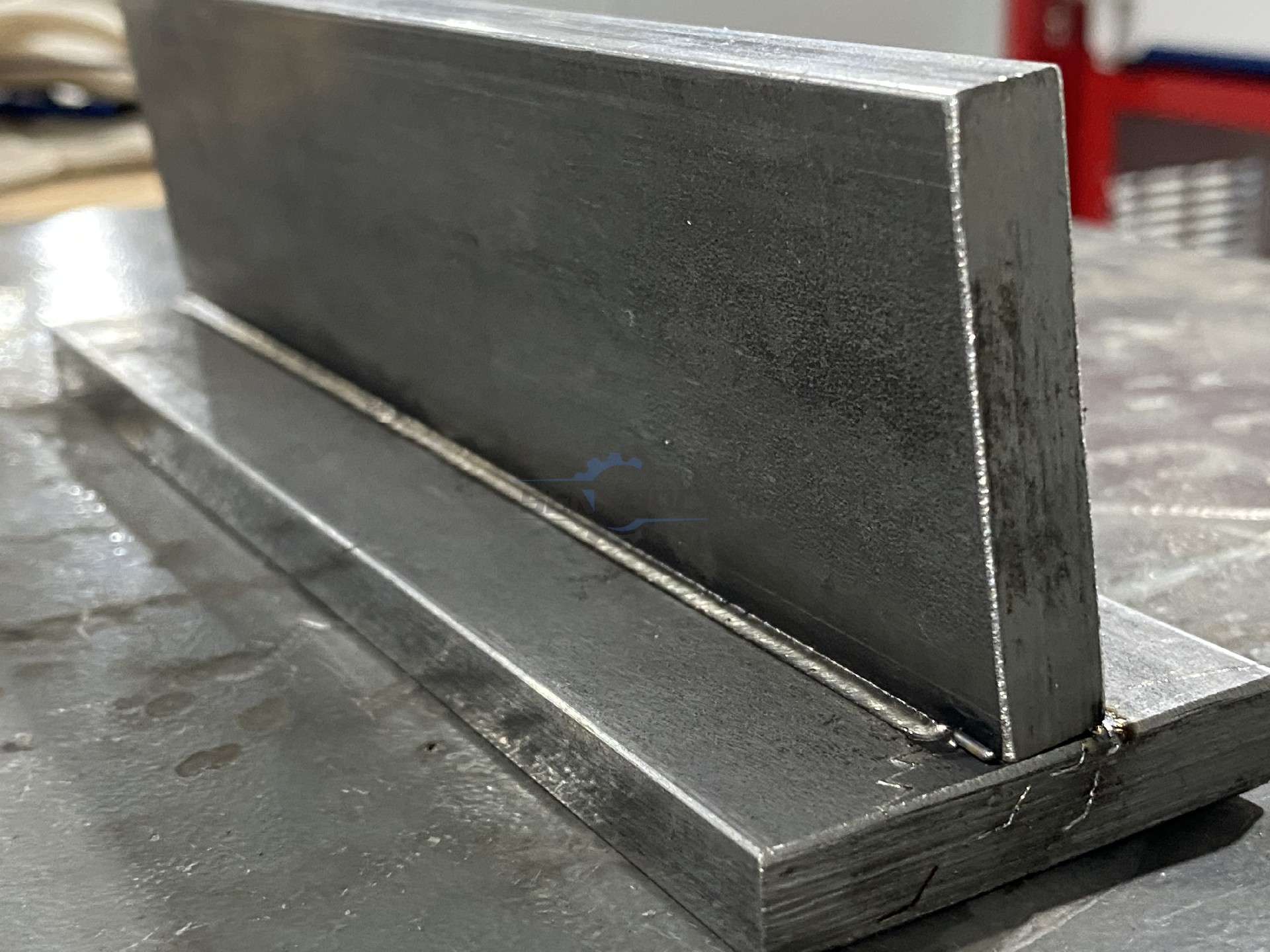

3. The welding seam smooth and beautiful, large depth, small taper, don’t need polish, save time.

4. No deformation or welding scar, firm welding of the workpiece.

5. Laser welding has less consumables, low energy consumption and long service life.

6. Safety, easy operation and more environmentally friendly

Technical Parameters of Handheld Laser Welding Machine

Model | SYJW1000 /SYJW1500 / SYJW2000 |

Laser Power | 1000W / 1500W / 2000W |

Laser WaveLength | 1080nm |

Fiber Length Standard | 10M/Maximum15M |

Operate Mode | Continuation |

Welding Speed Range | 0-120mm/s |

Cooling Chiller | Industrial Water ChillerInside |

Working Environment Temperature Range | 15-35 ℃ |

Humidity Range of Working Environment | < 70% No Condensation |

Welding Thickness Recommendations | 0.5 - 3mm |

Welding Gap Requirements | ≤0.5mm |

Working Voltage | 220V/2P for 1000W and 1500W 380V/3P for 2000W |

RAYCUS 1000w Laser source | 1. 100,000 hours of lifetime, free maintenance. 2. High electronic optical conversion efficiency (up to 25-30%), excellent beam quality. 3. High energy density, and reliability, a wide modulation frequency |

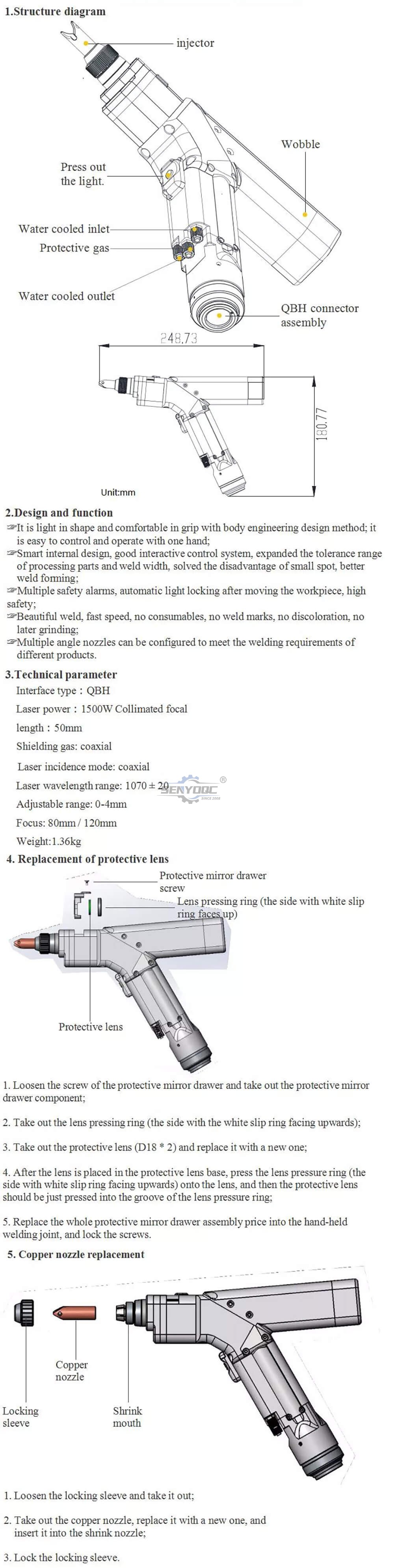

| 2.Welding head | 1.Galvanometer width adjustable, bead width 0.5-6mm. 2.Dedicated welding tip for welding at any position and angle 3.Infrared positioning, more accurate welding position |

| 3.Qilin Controller | 1.Preset multiple process modes to meet different process needs. 2.Preset multiple security alarms, more secure and reliable 3.Support multi country languages |

| 4.Water Chiller | 1.Intelligent temperature control and compressor refrigeration 2.20μm fiber core warp, higher electro-optical conversion efficiency |

| 5.Optical fiber cable | Standard length is 10 m |

| Handheld laser welder | Depth of penetration | Depth of fusion | sample |

| 1000W | Stainless steel: 3mm | 4mm |  |

| Galvanized sheet:2mm | 3mm | ||

| lron:3mm | 4mm | ||

| Mild steel : 3mm | 4mm | ||

| Aluminum: 1mm | 2mm | ||

| 1500W | Stainless steel: 4mm | 5mm | |

| Galvanized sheet: 3mm | 4mm | ||

| lron:4mm | 5mm | ||

| Mild steel: 4mm | 5mm |  | |

| Aluminum: 2mm | 3mm | ||

| 2000W | Stainless steel : 5mm | 6mm | |

| Galvanized sheet: 4mm | 5mm | ||

| lron:5mm | 6mm | ||

| Mild steel: 5mm | 6mm | ||

| Aluminum: 3mm | 4mm |

Handheld Fiber Laser Welding Machine Project

How Much Does A Handheld Laser Welding Machine Cost?

The average cost of a handheld laser welding machine is around $7,980 depending on the fiber laser powers based on the data from Google, Amazon, and SENYOQC.

A cheap portable laser welder with 1000W fiber laser source is priced from $5,500 for beginners with hobbyists in home use. An affordable 1500W handheld fiber laser welding machine cost start at $7,800 for small business with low cost. The top rated portable fiber laser welder machine with 2000W handheld laser welding gun will cost $10,500 for commercial use in industrial manufacturing. The best budget 3-in-1 laser welding, cleaning, cutting machine prices range from $5,400 up to $8,000.

Handheld Fiber Laser Welding Machine Features

1. High laser energy density, small thermal effect area, not easy deformation, less or no subsequent processing.

2. Top brand gold cavity, high temperature resistance, corrosion resistance, the service life is 8 to10 years, the xenon lamp service life is more than 800 million times.

3. Easy spot welding, stack welding, splicing and continuous welding.

4. Variety of detection and protection measures using, greatly avoid the faults caused by a variety of external factors or human misuse, to protect the equipment with long-term stable operation.

5. Non-contact processing, stress free, noiseless, no pollution to the environment, which belongs to the green processing.

6. Good welding quality, smooth and beautiful appearance.

7. The communication function monitors all data of the laser.

8. The small fiber laser welding machine adopts a specific fiber to achieve the welding of tiny solder bumps.

9. High quality fiber laser beam, high conversion efficiency and therefore high welding speed, high aspect ratio, high strength.

10. Excellent spectral system minimizes energy loss to ensure that the laser energy of each fiber is almost the same.

11. The portable laser welder adopts optical fiber transmission, can realize remote welding, conveniently to equip with automatic welding workbench, manipulator, assembly line and other equipment together to work. More uniform light spot and more beautiful solder joints after the light transmission.

12. A variety of input and output signals are very easy to achieve the machine's automated production and assembly line production.

13. Solder joints non-pollution, weld strength and toughness at least equivalent to or stronger than the base metal.

14. The manual fiber laser welder supports time spectroscopy and energy splitting or a combination of these two spectroscopic modes (customizable). Multi-channel fiber output, up to 4 fiber at the same time, significant cost savings, improve welding efficiency and reduce equipment space.

15. Touch screen input, friendly human-computer interaction makes setup and operation easier. The operating system is easy to learn and easy to operate.

What is Handheld Laser Welding Gun?

Laser Welding vs MMA Welding vs MIG Wedling vs TIG Welding

Shielded metal arc welding (SMAW), also known as manual metal arc welding (MMAW or MMA), shielded metal arc welding (SMAW): large spatter, low utilization rate of filler metal, frequent removal of welding slag, replacement of welding rods, extremely slow speed, low production efficiency, and a strong dependence on the welder's operating skills and experience.

Metal inert gas welding, also known as MIG welding: large welding wire consumption, large heat input, welding thin plates are easily deformed and burned through, welding of medium and thick plates needs to be grooved, and the welding seam is serious and requires subsequent polishing.

Manual tungsten inert gas welding, also known as manual TIG welding: The welding seam has shallow penetration and large melting width. It can only weld thin plates and has a large amount of deformation. Large currents will also cause the tungsten electrode to melt and evaporate. Manual wire filling is difficult and inefficient.

Hand-held laser welding: simple operation, deep penetration, fast speed, smooth and beautiful welding seam, small deformation, reduce the follow-up grinding process, and can weld beautiful products without a master.

Traditional manual arc welding requires experienced welders and a lot of training and research. The control device of GW air-cooled handheld laser welding machine is intuitive and concise. The machine is preset with commonly used welding parameters, and users can customize and save what they need Processing parameters, ordinary personnel can easily get started after a few hours of simple training, and they can work without a certificate.

The welding speed of traditional manual arc welding usually does not exceed 1cm/s, while the welding speed of hand-held laser welding can reach 2-10cm/s, and its efficiency is 2-10 times that of traditional manual arc welding, and at least 2 can be saved a year Labor cost.

In addition, manual arc welding usually requires polishing after welding, and there is almost no need for polishing and cleaning after laser welding, which can save part of the labor cost. Handheld laser welder can weld common steels (such as carbon steel, stainless steel, galvanized steel), aluminum alloys, and brass.

The weld seam is beautiful, no deformation, no deformation of the weldment, no need for subsequent processing. If the laser welding machine is used to weld steel, the penetration depth can reach 4mm, and if it is welding aluminum alloy or brass, the penetration depth can reach 3mm.

International Shipping Around the World All the CNC laser machines can be shipped worldwide by sea, by air or by international express logistics via DHL, FEDEX, UPS. You are welcome to get a free quotation by filling up the form with name, email, detailed address, product and requirements, we will shortly contact you with the full information including the most suitable delivery method (fast, secure, discreet) and freight.

laser welding machine , laser welder, cnc laser welder , laser welders, laser welder machine protable

• Previous: None

• Next: Handheld Laser Welder For Welding Steel Aluminium Brass

Fiber metal Laser Sensor And Its Application

Category: SENYO NEWS 11th Mar, 2021A CNC wood router will use 3D machining in relief carving, the effect is more artistic beauty, but also has a strong sense of three-dimensional 3D, realization of this function is to ...

Precision Cutting Stents with Fiber Lasers

A CNC wood router will use 3D machining in relief carving, the effect is more artistic beauty, but also has a strong sense of three-dimensional 3D, realization of this function is to ...

How to Laser Cut Copper and Other Reflective Metals

Laser cutting of mild steel and stainless steel has a long history and has been one of the primary applications for CO2lasers. However CO2lasers have not traditionally offered a good solution for cutting highly reflective materials.Fiber lasers have an emission wavelength of around

Laser Cutting Machine Inspection Process For Manufacture

SENYOCNC Have Strict quality monitoring will be carried out when the parts are in the factory.

How Control Costs Use of UV Printers ?

UV flatbed printers are rapidly being used by more and more manufacturers, thanks to its efficient production efficiency, and the control of production costs also needs to arouse our attention.

Why UV flat printing machine is popular in market ?

For the majority of designers, give full play to the creative ability, the design sample can be arbitrarily modified on the computer, the effect on the computer, is the effect after the finished product, customer satisfaction can be directly produced. UV flat printing pattern fine, rich and clear layers, high artistry, strong three-dimensional sense, many high precision equipment can also print photography and painting style patterns.

How does UV ink jet printer save UV ink?

UV inkjet printer use process is an important consumable UV ink, reasonable use of equipment, can save UV ink , it can be said to be the best choice to directly save the cost. In the process of using some skills you need to be familiar with, the following small make up to share with you:1. Try to us

Waterjet Machine delivery and Shipping

Please tell us your max working size and what materials will cutting , also what max cutting thickeness.If you have Working photo sample please also send us , it will be helpful to choose machine with suitable models .

Waterjet Machine finish manufacture 5axis

Waterjet cutting technology is one of the fastest growing major machine tool processes in the world due to its versatility and ease of operation.

Waterjet Machine delivery and Shipping

Waterjet cutting technology is one of the fastest growing major machine tool processes in the world due to its versatility and ease of operation.There are multiple advantages to adding waterjet cutting capabilities to your shop.We are company leading ultrahigh-pressure waterjet system so

How to Create Connected Text – Inkscape for Laser Cutting

Step 1: Create Some TextFirst, we need some text to work with. To create the text, select the Text Tool (keyboard shortcut: T), click somewhere on the canvas, and type your text.You can use the drop-down list on the top left to select your desired font.Step 2: Convert Text to PathNext, we need to tu

Jacob from United States

I am a beginner at CNC, I’ve never used a CNC machine before and with in a day I was carving. An awesome machine for a beginner to learn as hobbyists. I used the manual and the help video. One hour to assemble and test, very friendly and easy to use. It’s a good buy for the money. I would definitely recommend this machine to someone getting into CNCs.

Weinstein from France

I've been using CNC plasma SYP2060-300A and I am very impressed with this unit.

This unit is of higher quality, made in China. Five stars all the way!

12KW Fiber Cutting - 2000X6000mm -- 이병헌 from Korea

Good machine for metal cut ! Thanks Senyo , Its prefect , I like your business patient kind!

I am a furniture manufacturer, and this machine is very good and fast. thanks Senyoqc Team ! from Bangladesh

Metal ArtWork from Denmark

The plasma cutting machine makes my artistic creation more convenient and precise!! Created more artistic ideas and value! Thank you Aillen team!

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen. from

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen.

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo from

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo

Thank you Senyo for SYJ1290-150W! from

Retired, ex mainframe systems programmer. Now full-time recreational woodworker majoring in puzzles, pens, boxes, Toys and occasional small furniture. Thank you Senyo for SYJ1290-150W!

CNC Router I love woodworking and the Joy in the Journey! It's a Blessing! from Ricky

CNC Router I love woodworking and the Joy in the Journey! It's a Blessing!

CO2 1530H-300W Europe from

CO2 1530H-300W All really well done. these are something ive always wanted to do.

/5 based on 300votes/5 based on votes

/5 based on 300votes/5 based on votes

manager@senyocnc.com

manager@senyocnc.com

SENYOCNC

SENYOCNC

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

2061579344

2061579344