How to Install and Use NcStudio Controller & Software for CNC Router Machine?

From: 本站 Date: 12th March 2021 Author: admin Views: 5674

For safe operation and operation, please ground CNC router safely.

1. Grounding of CNC router machine body.

2. Grounding of control box of frequency converter.

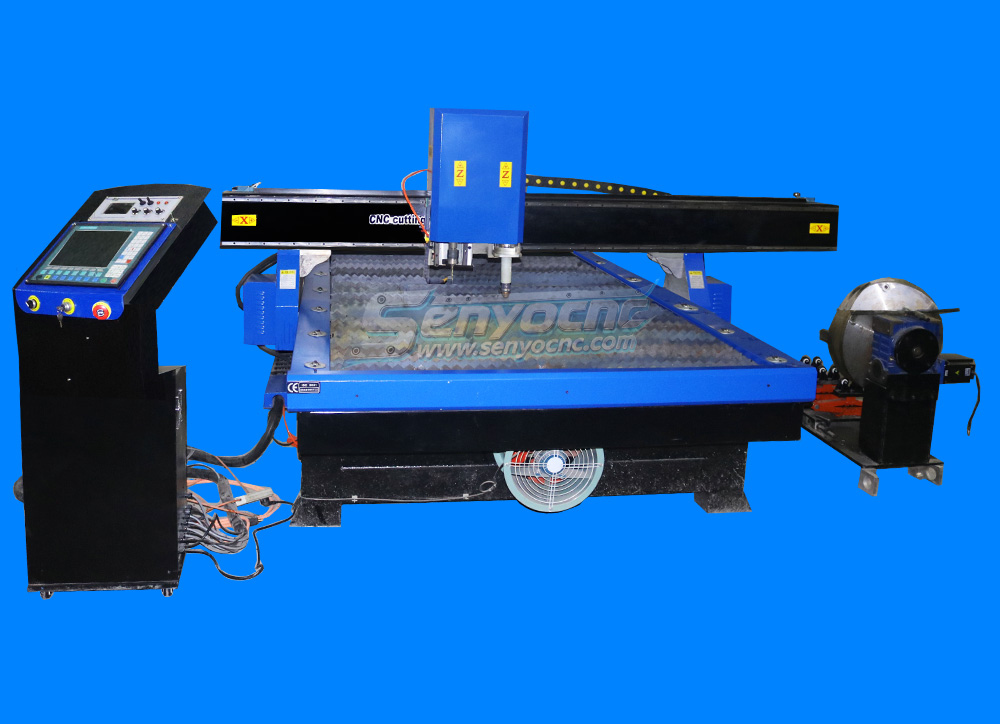

Introduction of wiring of CNC router machine:

Rear ends of control box of CNC router machine connect with X and Y (two pieces), Z, frequency converter, limit

switch and external power source (AC 220V) separately. Front panel connects signal wire, another end of signal

wire connects control panel interface on the computer.

After finishing wiring of engraver, we start to install control software of engraver. (ARTCUT software, graphic and

text design software for engraver, has detailed description on its software, so no further introduction is made here).

After finishing software installation, insert PCI control card into PCI slot of the computer.

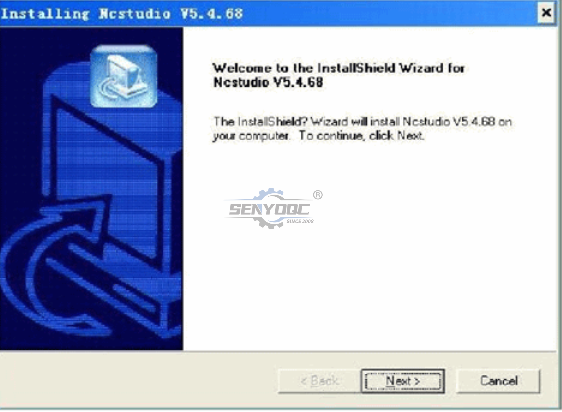

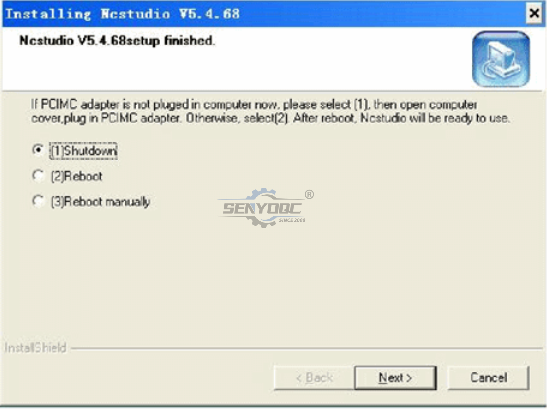

After placing control software into CD-ROM, operate SETUP. EXE file for installation, shown as following diagram:

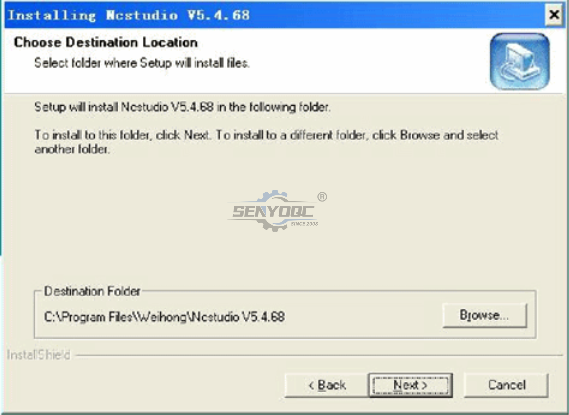

Press NEXT to select installation catalogue.

After selecting installation catalogue, press NEXT.

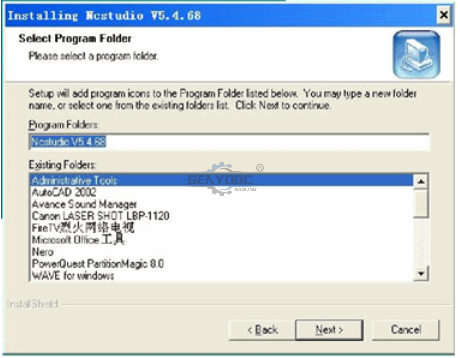

Press NEXT.

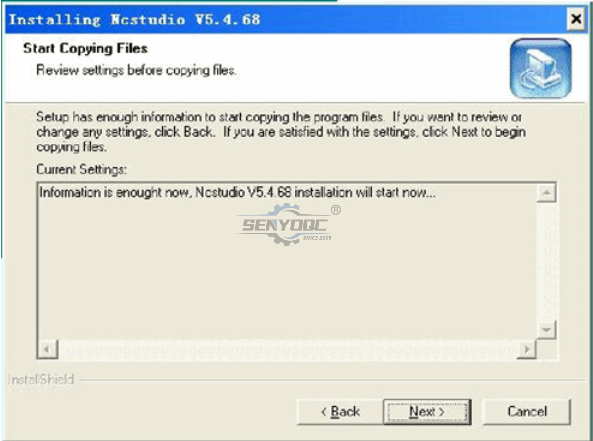

Press NEXT.

Press NEXT until finishing installation. Then turn off the computer and insert PCI control card into PCI slot of the

computer. Start the computer again, the computer will automatically install driver program.

Introduction of Software

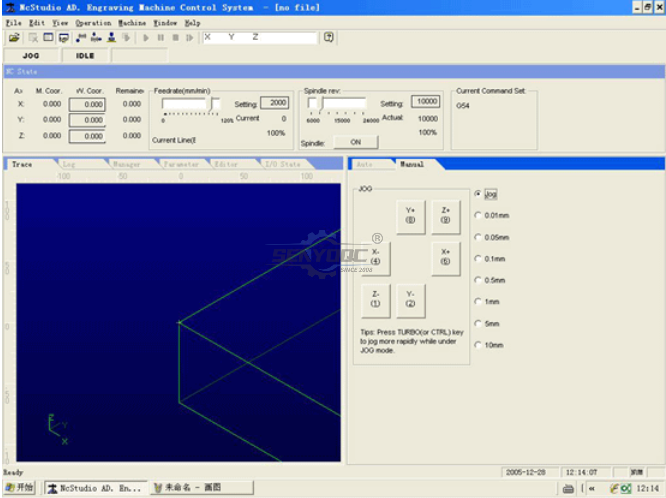

After the computer starts, start NC STUDIO from desktop of the computer, following interface will display.

How to Use NcStudio Controller?

Ncstudio TM interface consists of title bar, menu bar, tool bar, status bar and some function windows.

Operation modes and status

Operation mode

At any moment during user's operation on the machine, it is in one of following operation modes.

Automatic mode

Under automatic operation mode, machine movement functions by prior prepared processing program. Therefore,

the system shall be loaded processing program under automatic mode.

Jog mode

It is one of manual operation mode. Under jog mode, the user controls the machine by manual operation device, for

example, computer keyboard. When the user gives out movement signal by these devices, for example, press down

manual button, the machine continues movement until the signal disappears .

Increment mode

It is one of manual operation mode. Use computer keyboard to control the machine. The difference between jog

control mode and increment mode is the machine only moves defined distance by one pressing operation of the

user, i.e. from pressing to releasing. That is to say, the user can accurately control displacement of the machine by

increment mode.

Operation status

Each operation mode can be divided into several operation status, both operation modes and operation status

completely define the status of the machine.

ldle state

It is the most common state. Under this state, the machine hasn't any action output at present and is ready for

receiving new start and for starting new action.

L ocking state

Locking state is a kind of intemnal state and normally generates at state switchover, so the user can't contact it under

normal situations.

Operation state

When the machine is implementing any action, the system enters operation state.

Pause state

When the machine moves, if the user implements“operation | pause" command or the system receives MO1 (ready

command), then the system enters pause state and waits for further enter by the user, the user can continue to

implement by implementing“operation | start".

Function window is divided into three areas, including:

The first area: Digital control state window.

The second area: Processing locus, system log, program management, system parameter, programming and l/O

state window.

The third area: Automatic operation window and manual operation window.

Title bar

Title bar is on the topmost end of NcstudioTM software interface and is used for displaying software name and

loading processing program name, colors of title bar are used for indicating whether corresponding windows are

enabled.

Note:

In default setting of Windows, color of title bar of active window is blue; color of title bar of non-active window is

gray.

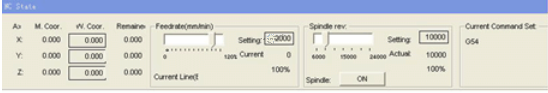

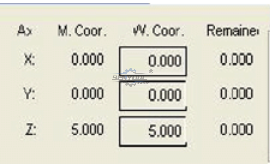

Digital control state window

Coordinate display window is at upper part of the screen and displays current position, feed speed and feed rate

adjustment of principal axis (cutting tool).

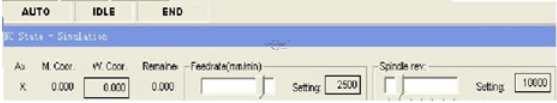

Processing status and time information

Title bar of digital control window also displays some state information. As shown in above diagram, for example,

during the system emulates, title bar displays“emulation mode" text, estimated implementation time (calculating by

100% feed rate) also displays at right side of title bar. During actual processing, actual processing time displays at

the right side.

Current position

For the convenience of describing various positions, Ncstudio TM displays two sets of coordinate systems of

mechanic coordinate system and work piece coordinate system at the same time.

The system supplies the method for convenient setting and revising base point of work piece. Set current point as

base point of work piece, that is to say, zero relative position of single axis. Move the cursor to coordinate display

area of this axis and click left key of mouse, then coordinate of this axis can become 0. If needing set all current

positions of three axes into 0, only need click in various coordinate areas.

Prompt:.

Another method for zeroing all work piece coordinates is to select the manual“operation (O) | setting current point

as work piece base point ()..." or to select equivalent tool bar button.

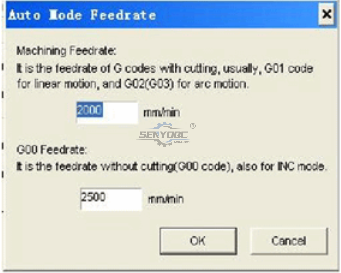

Feed speed

Various information such as setting speed, transient speed, speed scale factor and current line (paragraph) number

displays in feed speed area. Speed setting value and feed rate can be also revised.

| Feed rate slide bar: Dragging slide bar can adjust current movement speed within the range of 0~120%. Feed rate

displays in the form of percentage.

I Setting value. Setting value of feed speed is also the value given by parameter F in command G.

1 Actual value: Transient value of feed speed. It changes with setting value, current acceleration or deceleration

state and feed rate .

I Current line (paragraph) number: It displays paragraph number or line number of current implementation code.

When the system is at idle state, click setting value, and then speed setting dialog box pops up. When the system is

at automatic state, popup dialog box is used for setting default speed of automatic operation.

When the system is at manual state, popup dialog box is used for setting speed of manual operation, shown as

following diagram:

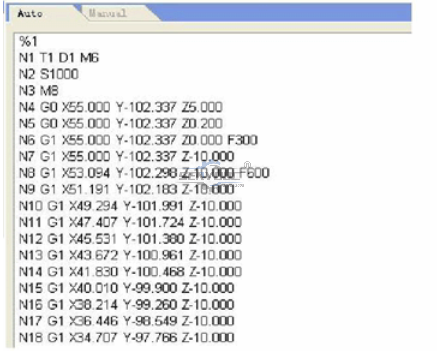

Automatic operation window

Automatic operation window displays current opening processing file. Ncstudio TM supports two processing program

formats of command G format and HP PLT fomat at present. The user can view current processing program by this

window.

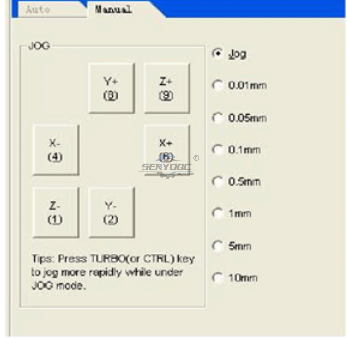

Manual operation window

Manual window supplies an interactive operation environment for controlling machine by manual way to the user.

Since manual window is at function window area of main window, the method for the user to switchover several

windows and to activate manual window is:

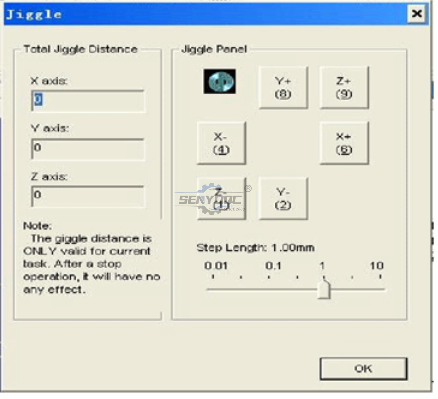

Manual button area in this window includes six manual buttons that correspond to positive and negative directions

of axes X, Y and Z respectively.

Manual operation of the machine has two ways. Continuous jog way and increment stepping way that are

respectively introduced as following:

Continuous jog way.

Under continuous jog way, when manual window is current active window, press corresponding numerical key on

the keypad. When the key is at pressing state, the machine acts; when the key is released, the machine stops

action.

When implementing jog action, track window displays track locus by color of command G0O.

Increment stepping way.

It is similar to manual way. The difference between continuous jog way and increment stepping way is increment

stepping way can accurately control feed speed of machine kinematical axis.

The user can implement increment stepping operation by mouse and keyboard through interactive interface and

can also implement this operation by manual operation panel or operation box. Touching manual button every time

can correspond to given step length of axis movement.

Keyboard way.

When jog window is current active window, increasing or decreasing jog step length by direction key can see

change of jog step length button.

Mouse way.

Directly use mouse to click suitable step length button.

Note:

Avoid setting too large jog step length so as not to damage the machine by misoperation.

Mouse way.

Use left key of mouse to click the button, then the button is triggered once.

Note:

Since implementing jog command by the system each time needs certain time, so too frequent clicking may cause

the system to prompt error information that‘equipment is busy and current operation is invalid".

Increase/decrease depth.

Using +/-keys on the keypad and digital keys can quickly increase and decrease depth.

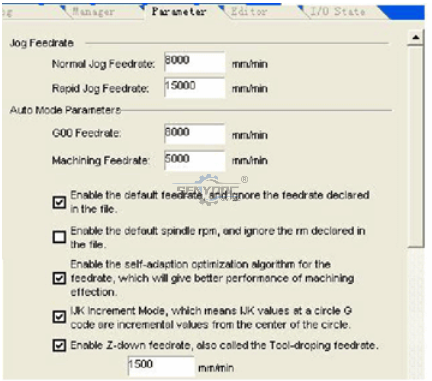

System parameter window

System parameters include two types: Processing parameters and producer parameters.

Their various parameters are explained in detail as following.

1. Processing parameters

Ncstudio TM processing parameters are set as following:

Manual speed: It includes manual high speed and manual low speed. These two values are used for movement

speed under "jog" mode.

I Manual low speed refers to movement speed when only pressing manual direction key;

| Manual high speed refers to movement speed when pressing "high speed" key at the same time.

These two values can be also set directly under digital control state window. Automatic parameters:

I ldle running speed: Movement speed of command G00;

I Processing speed: Interpolation speed of processing commands G01, G02, G03 and so on.

These two values control movement speed under automatic mode. If processing program or command MDI doesn't

define the speed, then the machine moves by here setting speed.

Note:

Movement speed by increment way is idle running speed.

I Using default speed: Whether to abandon the speed specified in processing program and to use above setting

system default speed.

I Speed self adoption and optimization: Whether to allow the system to optimize processing speed according to

connection feature of processing work piece.

. | lJK increment mode: Whether circle center programming (IJK) is increment mode and IJK value used by arc

programming for some post processing programs is increment value. Refer to descriptions on corresponding post

processing programs for this point.

I Using tool-owering speed in direction Z: Whether to use specific tool-owering speed during vertical downward

movement in direction Z.

I Optimizing tool-raising speed in direction Z: Whether to use G00 speed to raise tool during vertical upward

movement in direction Z.

. | Idle running (G00) command uses fixed feed rate 100%: This parameter is an option. It shall direct the system

whether to neglect influence of feed rate when implementing idle running command. Ildle running speed will not be

influenced when changing the rate by this way.

. | During pausing or ending, automatically stop principal axis (need restart): Setting whether to automatically stop

rotation of main axis when one processing program pauses or after ending processing.

I Mirror axis X: Setting making mirror image for axis X.

I Mirror axis Y: Setting making mirror image for axis Y.

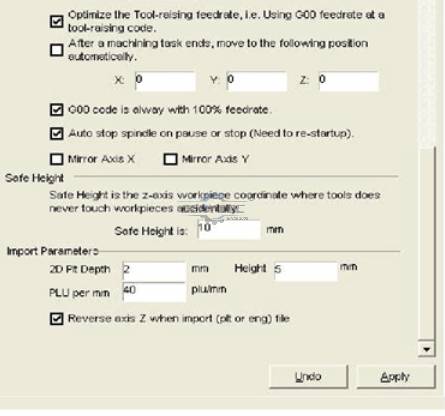

Tool change position parameters:

I Using tool change position: Please select this option if automatic return to certain position is required after ending

processing.

Other tool change position parameters can function only when using tool change position is enabled.

I Mechanic coordinates X, Y and Z of tool change position: Setting mechanic coordinates of tool change position

(note. not coordinates of work piece!).

Tool return point parameters:

Tool return point: Tool raising height (in relation to base point of work piece) when retumning base point and break

point of work piece for continuous operation.

File input parameters:

I 2D PLT processing depth: Setting tool depth when loading PLT file processing.

I Tool-raising height: Setting tool-raising height during PLT file processing.

IPLT unit per mm: Setting PLT unit value.

| Reverse axis Z: Setting whether to use reverse function of axis Z. Default of the system is the part above axis is

positive.

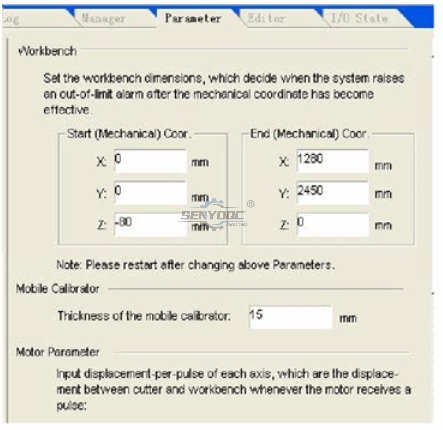

2. Producer parameters

The user doesn't contact' "producer parameters" that needs input password (ncstudio) when contacting. This is only

for avoiding any system failure caused by changing these important parameters accidentally by the user.

Workbench dimensions:

Please make setting according to above parameters so as to avoid any possible damage caused by impacting limit

switch or hard limit.

Note:

This value has been set before out of factory; don't revise it! !

Mobile calibrator parameters: (a block for cutting tool)

I Thickness of mobile calibrator: Please accurately measure thickness of mobile calibrator and fill it here.

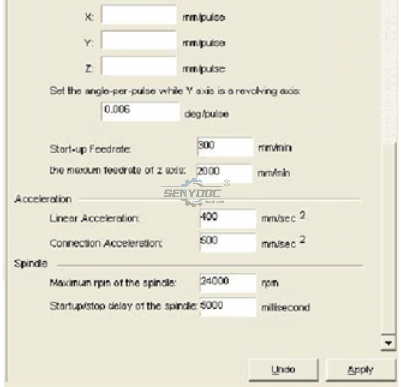

Motor parameters:

I Pulse value. It refers to minimum displacement that can be processed by movement control card. In stepping

system, it normally corresponds one stepping pulse and changes angle displacement of stepping pulse into linear

displacement according to transmission relation.

I Start-up speed: This parameter corresponds start-up frequency of stepping motor.

Acceleration: The system uses tow acceleration parameters to define acceleration capacity of movement:

I Single axis acceleration: It is used for describing acceleration and deceleration capacity of single feed axis.

I Curve bend acceleration: It is used for describing acceleration and deceleration capacities of multiple feed axes

during linkage .

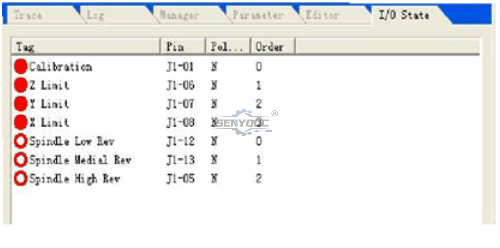

Input/output state (I/O state) window

It is very helpful for system monitor and failure diagnosis. Press and hold three keys of SHIFT, CTRL and ALT, use

right key of mouse to click the direction or limit to be revised, select and change polarity, then turn on or off relevant

functions.

Description of Software Menus

“File” menu includes command options for controlling file.

Former two options of this pulldown menu are used for "Iloading”and“unloading”of program file. Medium seven

options are used for editing program file. The file opened by editing function displays in edit window. Please note

the differences between“Iloading”" function and“unloading”function.

Edit menu

Edit menu has menu options for editing window. This menu option will change with current active window in the

second window area, since these windows may have some specific editing functions.

Operation menu

Various operations can be realized in operation”menu, but the menu doesn't include control for

direction output (M function) feed rate and principal axis, these functions are in“machine”menu.

Limit release

This function is a means for masking limit function when the system meets hard limit and for restoring normal

position of machine when using manual operation. Since limit function is masked at this moment, so the operator

shall pay special attention to use this function.

This menu operation enables and disables single step processing mode. Once“single section implementation" is

enabled, processing program enters pause mode when implementing each section.

Setting current point as base point of work piece

Select menu option“setting current point as base point of work piece", this can set work piece coordinates at

current point as zero, this actually doesn't cause actual position movement.

Setting work piece coordinates at current point...

This function allows the user to set work piece coordinates at current point conveniently. Selecting this menu option

can change coordinates of current tool position. After selecting this menu option, the system will pop up dialog box

“setting work piece coordinates at current point".

Input suitable values into corresponding edit boxes of axes X, Y and Z, then coordinates of current position are

changed.

Returning base point of work piece...

Base point of work piece is base point of work piece coordinate.

After selecting the option‘returning base point of work pie..." tool tip will automatically return base point of work

piece from current position in the sequence ofZ, X and Y.

Since Z coordinate of final point is always on processing surface of work piece, in order to avoid damaging work

piece surface or tool tip caused by tool tip returning to zero point of work piece, in fact, axis Z doesn't return to zero

point, but it returns to deflection value above zero point. This value is set by“tool return point" in processing

parameter of "system parameter window".

Saving base point of work piece

The user can save frequent using base point of work piece as presetting value, 10 sets of coordinate data can be

saved in total.

Reading base point of work piece

Read presetting coordinate value of base point of work piece, quickly return to read presetting base point of work

piece. After reading base point of work piece, use the command "base point of work piece”to return to presetting

base point of work piece.

Starting

This menu option has two functions:

The first function: If certain processing program is loaded and current system state is "idle", after selecting this menu

option, the machine will automatically start to implement automatic processing procedure from the first sentence of

processing program. Once processing starts, the system enters“automatic | operation" static; if the system is at

emulation state, it implements processing procedure by emulation state.

The second function: If the system is at“automatic | pause”state, after selecting this menu option, the system will

continue automatic processing procedure from pause position and enters“automatic | operation" static. If the

system is at emulation state, it implements processing procedure by emulation state.

Prompt:

The system has two routes for entering“pause" state: The first one is the system is at“singe step processing" mode

at present, the second one is the user selects "pause”function during processing procedure.

Pause

During automatic processing procedure,“pause”function is enabled. Then enter “automatic| pause" state. Select

“start”menu option if needing continue processing procedure.

If the system is at emulation state, after selecting“pause" menu option, the system will pause emulation and enter

“automatic | pause”state. Select "start”" menu option if needing continue emulation.

Stop

During automatic processing procedure, i.e., the system is at' automatic| pause” state, "pause”function is enabled.

Select this menu option at this moment, the machine will stop processing and raise tool, whole processing task

ends, then the system enters“automatic | idle”" state, this is the method for making the system normally stop

processing procedure during processing procedure.

Following contents describe "reset" function that is the method for abnormally stopping processing procedure used

under abnormal situation.

If the system is at emulation state, after selecting“stop" menu option, the system will pause emulation and enter

“automatic | idle”state, but it will not exit emulation state, its function is to allow the user to analyze emulation

results. If the user also needs repeat policy, he can implement various menu options such as“start", “advanced

start" and "break point continue" to continue emulation.

Entering emulation and starting emulation

It is similar to“start" menu. If certain processing program is loaded and current system state is "idle", after selecting

this menu option, the machine will automatically high speed emulation from the first sentence of processing

program. Emulation function is similar to demonstration function, but is better than demonstration function.

Emulation supplies a quick and vivid simulation processing environment to the user.

When operating processing program under emulation way, the system will not drive the machine to make

corresponding mechanic and electric actions, but it will only display tool processing route in high speed on track

display window. The user can understand movement form of the machine in advance by emulation, avoid damaging

the machine caused by fault when preparing processing program and know other additional information.

Once emulation process starts, this menu option becomes "stopping emulation and exiting emulation mode", after

implementing this function, emulation will stop immediately.

Advanced start

This function realizes skipping implementation function of program.

Break point continue

Function of this menu option actually is a simplified edition of“advanced start". The system continues from last

processing break point by implementing this function.

This function can be also used for implementing emulation.

Implementing processing command..

When implementing this menu option, the system will pop up dialog box "implementing processing command" as

following diagram:

Fine adjustment

This function is enabled only in pause state during automatic processing procedure. It is used for realizing fine

adjustment of depth without stopping processing procedure. Its operation interface is similar to manual window:

Tool calibration

The user can conveniently define suitable coordinate in direction Z of base point of work piece and calibrate the

coordinate again after changing tool by using tool calibration function. When implementing this function, select tool

calibration function from the menu.

When making tool calibration, firstly define processing surface manually, set processing surface as base point of

work piece in direction Z, then make tool calibration for the first time. After changing tool each time, make tool

calibration for the second time.

Operating Procedures

1. Starting-up

Before starting-up, firstly ensure all connections between the machine and the computer are normal, and then tum

on power supply of the machine and the computer. After the system finishes starting-up, it enters Ncstudio TM digital

control system.

2. Mechanic resetting (option)

The contents are involved only for the machine with the function of returning mechanic base point; please refer to

the manual of the machine.

If the machine supports the operation of returning mechanic base point, select“returning mechanic base point"

menu. The machine will automatically returs mechanic base point and calibrate coordinate system of calibration

system.

Under certain situations, for example, after last normal stop, turn on the machine again and continue last operation,

the user doesn't need implement mechanic resetting operation, since Ncstudio TM system saves current coordinate

information during normal exit.

Furthermore, the user doesn't need implement this operation if the user ensures current position is correct.

3. Loading processing program

Before starting processing, the user shall normally load required processing program, otherwise some functions

relevant with automatic processing are disabled.

After selecting the menu“open (F) | open (0)..”" dialog box of Windows standard file operation will pop up, select

the driver, route and file name of the file to be opened from this dialog box.

After clicking“open" button, processing program is loaded into the system. At this moment, the user can press F2

key to switch over "processing program" window and to view current processing program.

4. Manual operation

Displaying manual operation interface

After selecting menu option“view (V)| display manual interface (M)", parameter display window will display manual

operation interface. You can make manual operation on the machine by this interface by referring to Section 5.2.

Manual movement

Make manual movement on the machine by using corresponding keys on digital keypad of the computer.

NUMLOCK light on the keypad will turm on at this moment.

Corresponding keys are:

6 - Positive direction of axis X

4 - -Negative direction of axis X

8 - Positive direction of axis Y

2 - -Negative direction of axis Y

9 - Positive direction of axis Z

1一-Negative direction of axis Z

Manual high speed movement of the machine can be realized by combining these keys and CTRL key.

Increase/decrease depth

Using +/- keys on the keypad and digital keys can quickly increase and decrease depth.

5. Defining base point of work piece

Base point of three coordinates X, Y and Z in processing program is base point of work piece. Before making

processing, we need connect this position with actual position. The procedures are:

Manually make axes X and Y of the machine move base point position of work piece, select the menu“setting

current point as base point of work piece" or zero coordinate values of current position in coordinate window, then

make processing by using current position as starting point when implementing processing program.

Above procedure finishes base point of work piece on axes X and Y, but setting base point of work piece on axis Z

needs more accurate operation means. The system and machine hardware together supply the function of tool

calibration on axis Z.

Select the function "operation (O) | automatic tool calibration (E)...”and finish automatic tool calibration.

After finishing above two procedures, base point of work piece for processing is defined.

6. Implementing automatic processing

Automatic processing refers to the machine automatically makes processing according to selected processing

program.

Starting automatic processing

After selecting menu option“operation (O)| start or continue (S)", the machine will automatically start automatic

processing procedure from the first sentence of processing program

Machine stop

During automatic processing procedure, if processing program is required for stopping, select menu option

"operation (O) | stop (O)", the machine will stop processing after finishing processing of current sentence and enter

"idle” state. This method is the method for allowing the system to stop accurately and orderly and is also

recommending method.

Note:

When connection feature of high and smooth speed is enabled, the system will stop when link speed is zero.

Machine emergency stop

During automatic processing procedure, select menu option "operation (O) | emergency stop (B)" if any emergency

situation happens, the machine will stop processing immediately. If needing processing again, firstly select the

menu“operation (O) | emergency restore (R)" and select the menu "operation (O) | start or continue (S)", the

machine will implement automatic processing procedure from the first sentence of processing program, otherwise

the machine can't operate .

Machine pause

During automatic processing procedure, if needing processing pause, select menu option "operation (O) | pause

(P)", the machine will stop processing after finishing current processing sentence, only select menu option

"operation (O) | start or continue (S)" if needing continue processing program.

Program skipping implementation

After selecting menu option“advanced start (A)", a dialog box will pop up to inquire starting from which sentence of

program and ending at which sentence of program. If you fll in sentence paragraph number and click“start”key, the

machine will only implement certain sentence of program according to your requirement, but paragraph number

shall be before sentence of proaram when imnlementina this fi Inction

7. Direction positioning function

If you want to position certain point quickly, try“direct positioning function" .

Shortcut key of“direct positioning function" is F5; Shortcut key of exiting“direct positioning function” is Esc.

Inputting signal + before X in“direct positioning function" window can realize increment input.

Inputting signal * before X in“direct positioning function”window can realize mechanic coordinate positioning.

Inputting signal + @ before X in“direct positioning function" window can realize the function of revising base point of

work piece (including increase/decrease depth).

Shortcuts for NcStudio Software

1. Overall shortcuts

ESC Switchover between various windows

TAB Switchover between various controls

Ctrl+ TAB Switchover between various folding windows

Ctr+1 Display automatic window

Ctrl+2 Display manual window

Alt+ 1/F4 Display processing locus window

Alt+2 Display system lag window

Alt+3 Display program management window

Alt+4 Display system parameter window

Alt+5 Display program edit window

Alt+6 Display I/O state window

Ctrl+Enter Full screen

Ctrl+Del Clear processing locus window

Ctrl+O Open and load

CtrI+N New processing program

Ctrl+E Open and edit

CtrI+P Edit current processing program

Ctrl+S Save

Ctrl+| Processing program information

F5 Direct positioning

F6 Set coordinate of work piece at current point

Shft+F6 Set current point as base point of work piece

F7 Return base point of work piece

CtrI+F7 Floating tool calibration

Shift+F7 Fixed tool calibration

F8 Enter (exit) emulation

F9 Start

CtrI+F9 Advanced start

Shift+F9 Break point continue

Ctrl+Shift+F9 Implement processing command

F 10/Pause Break Pause

F11 Stop

F12 Reset

2. Manual window shortcuts

ScrollL _ock Activate manual window

4 (keypad) X-direction manual (including jog and increment)

6 (keypad) X+ direction manual (including jog and increment)

2 (keypad) Y- direction manual (including jog and increment)

8 (keypad) Y+ direction manual (including jog and increment)

1 (keypad) Z- direction manual (including jog and increment)

9 (keypad) Z+ direction manual (including jog and increment)

+ (keypad) Increase depth (input number)

- (keypad) Decrease depth (input number)

3. Processing locus window shortcuts

Home Center

End Display current processing point

or > Zoom up

or < Zoom down

(keypad) Switchover step lengths

Alt+-→or Alt+e - Rotate around axis Z

Alt+↑or Alt+↓Rotate around axis X

Alt+PgUp or Alt+PgDn Rotate around axis Y

• Previous: A guide to CNC Router Tools and CNC Router Bits

• Next: How To Install & Setup CO2 Laser Engraving Cutting Machine?

- What's the MOPA Fiber Laser Machine?

- What is the difference between Laser 2D 2.5D 3D machines?

- What Can Laser Marking Machines Do for You?

- What's the differences between Raycus, JPT, Max, and IPG fiber source?

- What Is Custom Laser Engraving?

- What is a Fiber Laser?- A brief overview

- How To Install & Setup CO2 Laser Engraving Cutting Machine?

- How to Install and Use NcStudio Controller & Software for CNC Router Machine?

- A guide to CNC Router Tools and CNC Router Bits

- How to buy a CNC machine?

Jacob from United States

I am a beginner at CNC, I’ve never used a CNC machine before and with in a day I was carving. An awesome machine for a beginner to learn as hobbyists. I used the manual and the help video. One hour to assemble and test, very friendly and easy to use. It’s a good buy for the money. I would definitely recommend this machine to someone getting into CNCs.

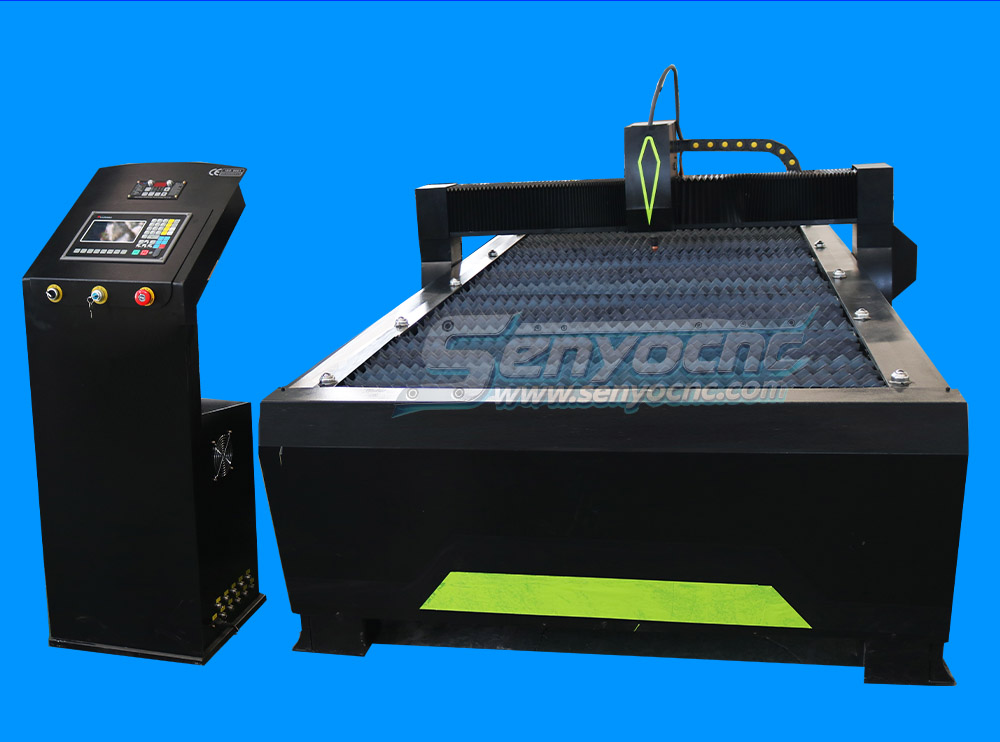

Weinstein from France

I've been using CNC plasma SYP2060-300A and I am very impressed with this unit.

This unit is of higher quality, made in China. Five stars all the way!

2040 from INDIAN

Best 2040 CNC Router Good Price and Quality ! Thank SENYOQC

10w uv laser from American

Best supplier ! I bought 3 machines for laser and router , thank you Aillen ! --Alec

12KW Fiber Cutting - 2000X6000mm -- 이병헌 from Korea

Good machine for metal cut ! Thanks Senyo , Its prefect , I like your business patient kind!

I am a furniture manufacturer, and this machine is very good and fast. thanks Senyoqc Team ! from Bangladesh

Metal ArtWork from Denmark

The plasma cutting machine makes my artistic creation more convenient and precise!! Created more artistic ideas and value! Thank you Aillen team!

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen. from

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen.

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo from

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo

Thank you Senyo for SYJ1290-150W! from

Retired, ex mainframe systems programmer. Now full-time recreational woodworker majoring in puzzles, pens, boxes, Toys and occasional small furniture. Thank you Senyo for SYJ1290-150W!

manager@senyocnc.com

manager@senyocnc.com

SENYOCNC

SENYOCNC

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

2061579344

2061579344