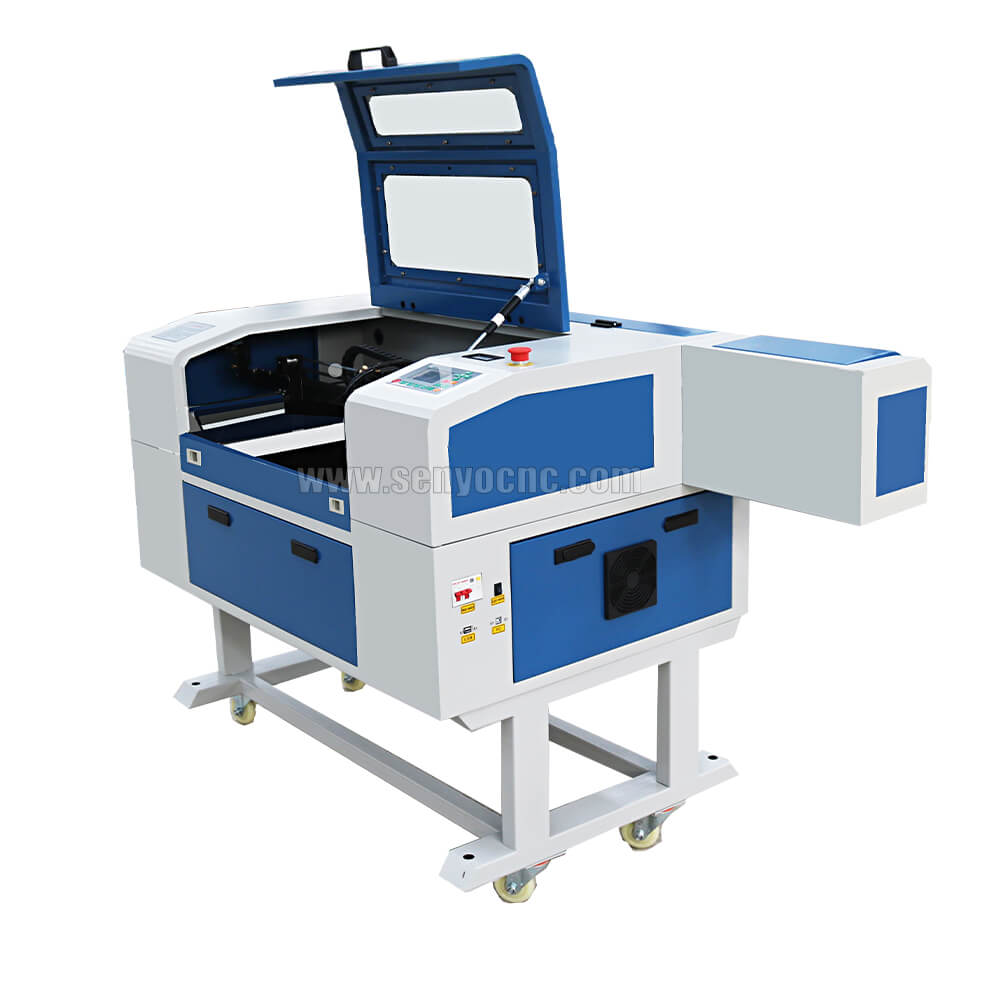

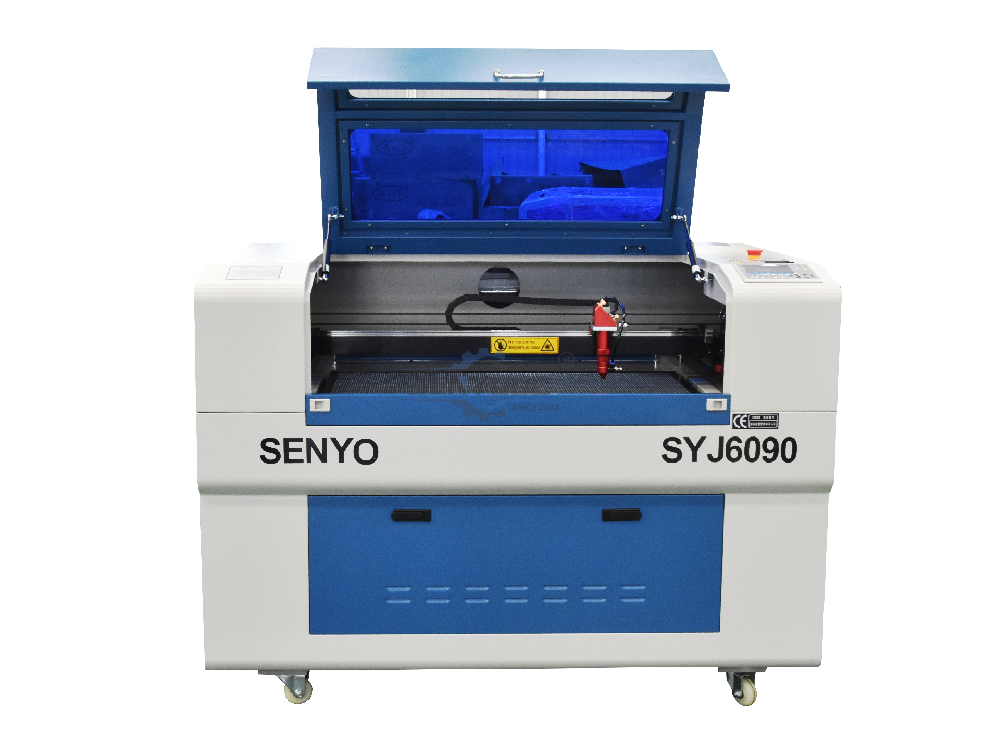

How To Install & Setup CO2 Laser Engraving Cutting Machine?

From: 本站 Date: 31st August 2021 Author: shengangtong Views: 3261

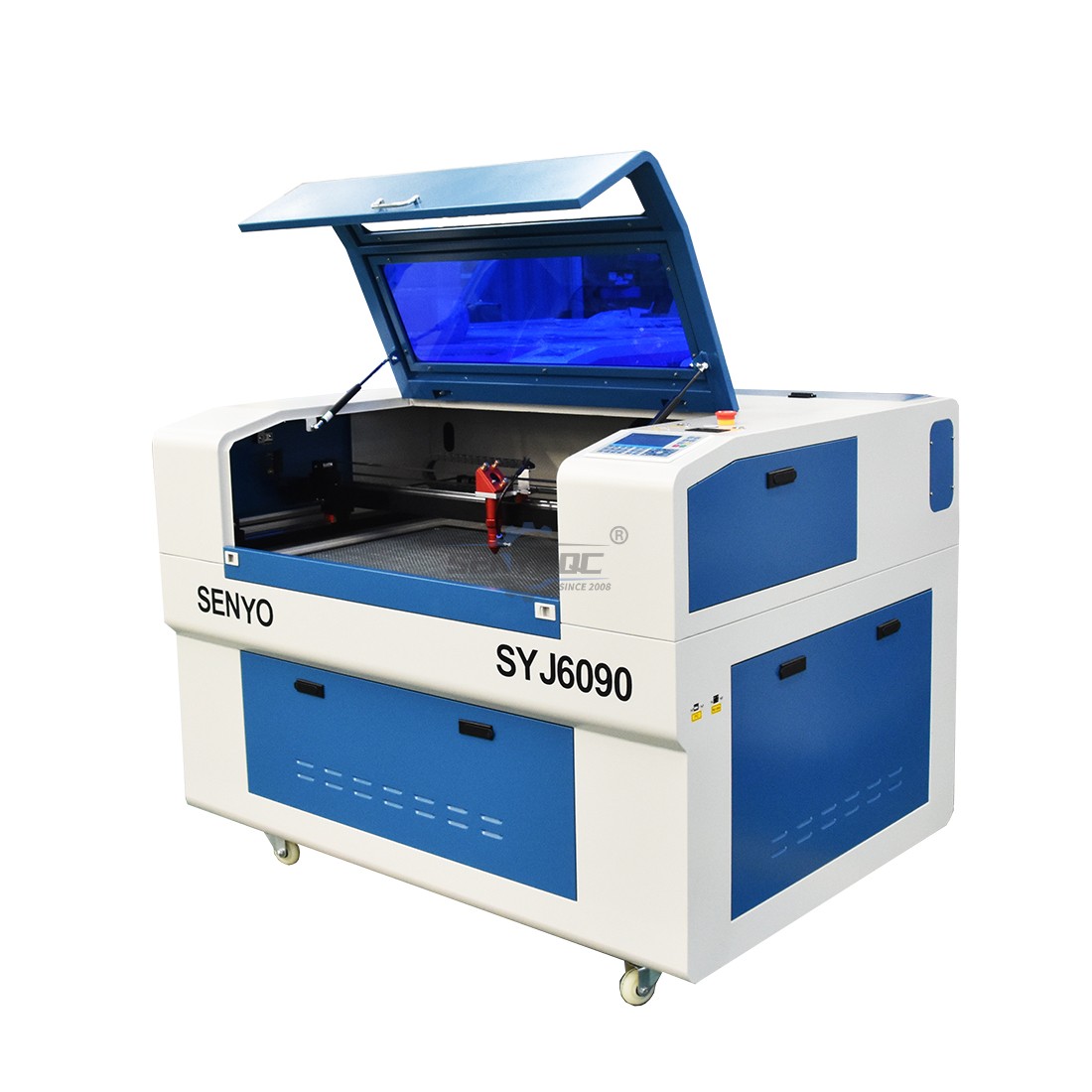

How to install CO2 laser engraving and cutting machine correctly? This is a key point, CO2 laser machine will go

well only when you install the CO2 laser machine correctly. Don't worry, this article will help you to know the process

of how to correctly install CO2 laser engraving and cutting machine.

Let's go with the following 12 steps to install a CO2 laser machine:

Step 1:

Remove all the package recover the machine like the wood, plastic flm and so on. (be careful of the nails)

Step 2:

Open the front door, side- door and get all the extra parts of the machine out, like. water chiller/water-pump, dust

collector, air pump, laser tube, softdog, rotary device, etc.

After you open the front door, please cut the tie on the belt of the X-axis and Y-axi, get the CD, then move the laser

head to the center of the working area by your hand.

Step 3:

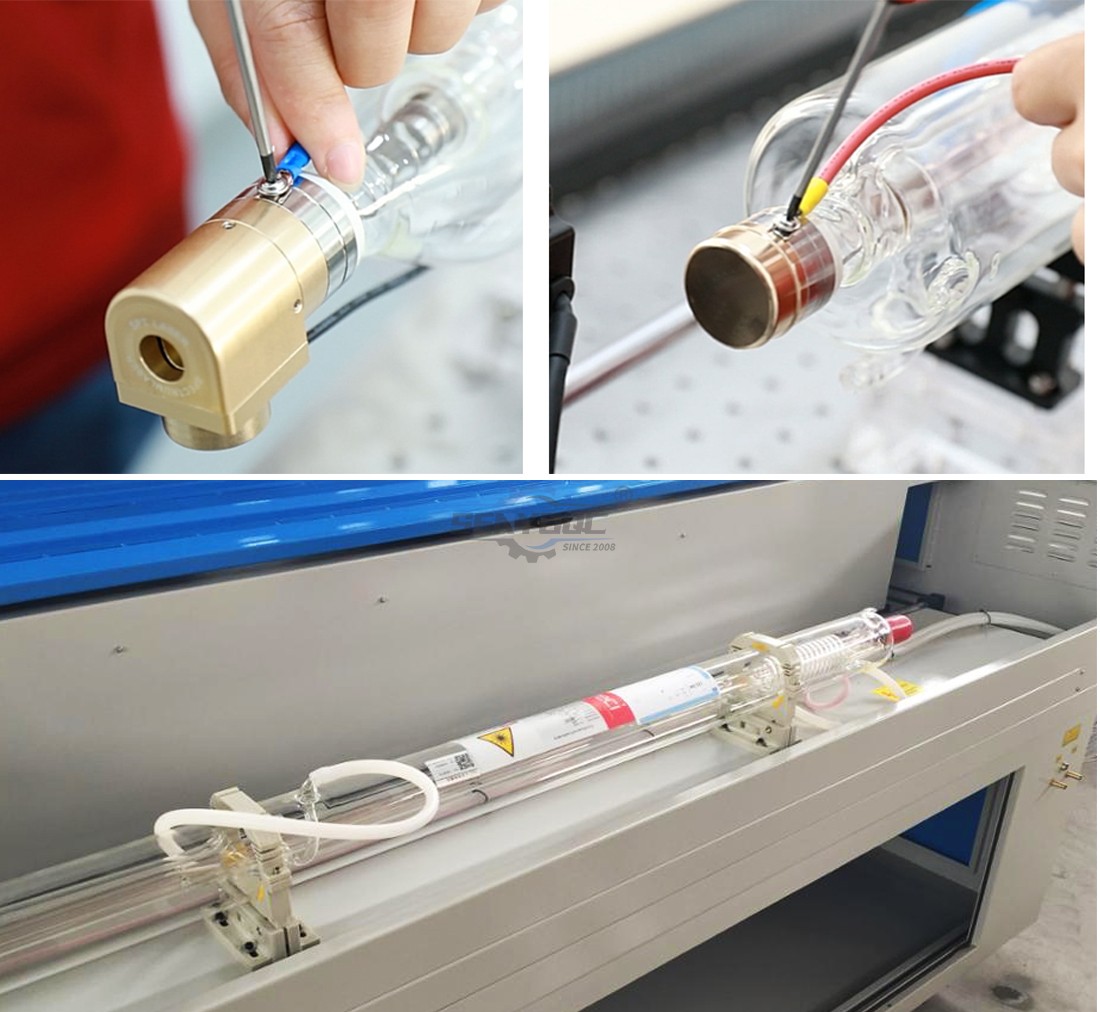

The most important step to correctly install a CO2 laser engraving and cutting machine is to install the CO2 laser

tube. So, pay special attention here.

1. Take the laser tube out of the package slowly, then put it on the laser tube socket at the back of the machine.

2. There are two ends of the laser tube. One is laser light out and the other is high pressure end.

3. If the laser tube has the plastic protective sleeve, please cover the protective tape. If not, please cover sufficient

waterproof tape. On the laser light out is the water out, behind the high pressure end is the water in. The theory is

“low in high out”.

Step 4:

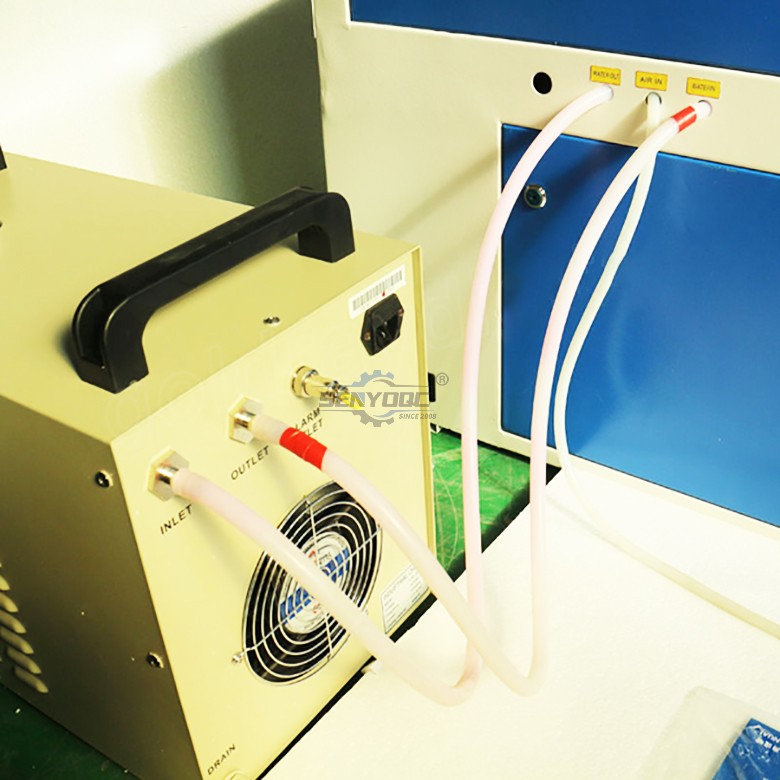

The installation of the water chiller/water pump:

1. Water chiller: connect the water inlet and water outlet of water chiller with the water outlet and water inlet of the

machine by the Silicone tube, then connect the air plugs AL ARM OUTLET (water protective)

2. Water pump: connect the silicone tube with the water outlet of the water pump with the water inlet of the laser

machine. Then use the other silicone tube connect the water outlet of the machine with the bucke.

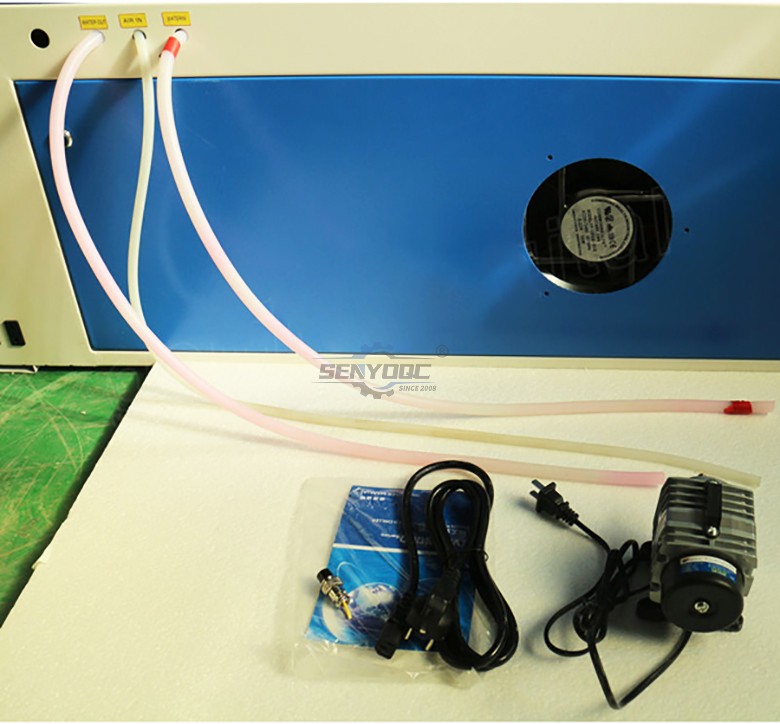

Step 5:

The installation of the air pump:

Connect the air outlet of the air pump with the air inlet of the laser machine. (Air inlet)

Step 6:

The installation method of the dust collector.

Connect the exhaust port of the dust collector with the telescopic pipe of the laser machine.

Step 7:

The installation of the Ground:

Connect the ground security, find a wire (above one square metre), and should connect the machine to the ground.

the other end connect the steel bar, it must be buried under the ground 1.5 metre. If in the wet place, the bury depth

can be shallow.

You should check wether all parts of the laser machine are installed correctly and wether the electrical accessories

and line are dropped or damaged.

This is aslo significant to correctly install a CO2 laser engraving cutting machine.

Step 8:

Our CO2 laser machine should use the power with the 220v. If you local power is 220v, you can connect it directly. If

not, you need an extra power transformer for the machine to the change the power.

Step 9:

First, supply the power to the water chiller. Then check the silicone tube to see whether it can make water, special

whether the water flow is normal.

Step 10:

Connect the power. connect the 220v power to the laser power and open the urgent stop, thenthe power locks in

order to see whether the power is normal. Press ESC twice,then press the up-down-right-left on the Leetro control

panel to see whether the laser head can move normally.

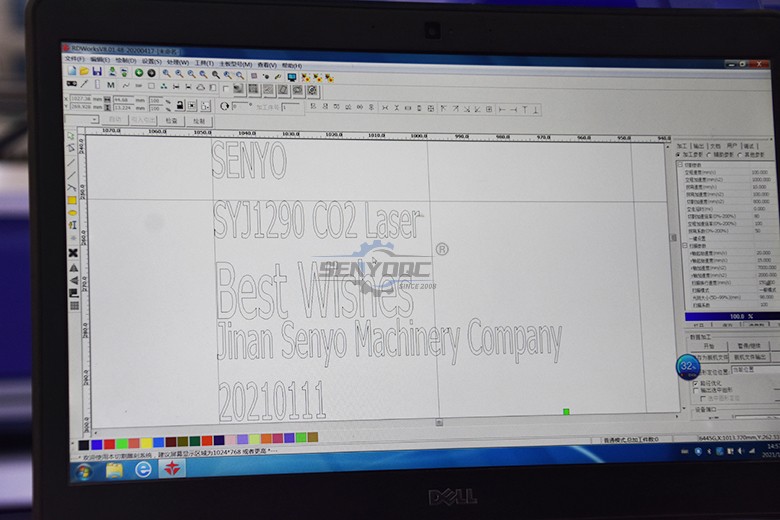

Step 11:

Plug the softdog in the computer, copy the data of the CD to the computer, use the blue data cable to connect the

computer with the leetro card, then install the software correctly.

Step 12:

Open the Lasercut icon on the computer desktop, and design a circle about 40*40 mm, the processing method is

(cutting), speed is (100),power is (1), then download to the machine. Move the laser head to the proper place then

press "test" to see whether the laser head can go around the border. If it is normal, press "start" and begin work.

Hope the 12 steps can help to remove your confusion about the installation of CO2 laser engraving and cutting

machine. If you sill have any questions, please feel free to contact with us. We will try our best to help you.

• Previous: How to Install and Use NcStudio Controller & Software for CNC Router Machine?

- What's the MOPA Fiber Laser Machine?

- What is the difference between Laser 2D 2.5D 3D machines?

- What Can Laser Marking Machines Do for You?

- What's the differences between Raycus, JPT, Max, and IPG fiber source?

- What Is Custom Laser Engraving?

- What is a Fiber Laser?- A brief overview

- How To Install & Setup CO2 Laser Engraving Cutting Machine?

- How to Install and Use NcStudio Controller & Software for CNC Router Machine?

- A guide to CNC Router Tools and CNC Router Bits

- How to buy a CNC machine?

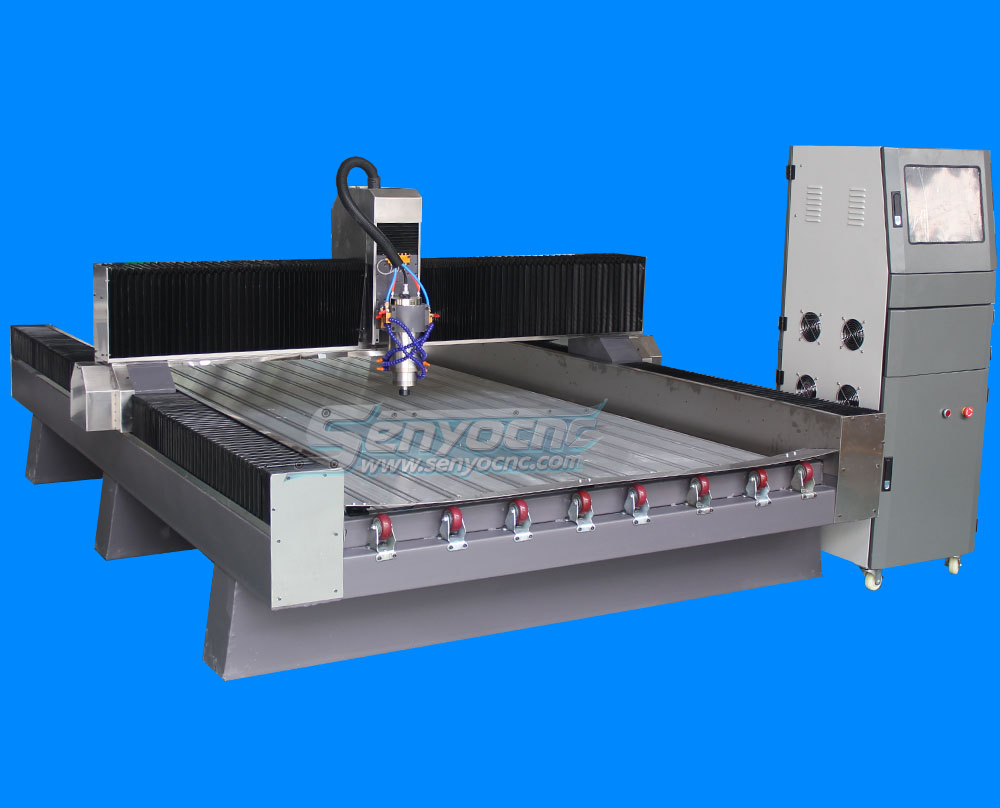

Jacob from United States

I am a beginner at CNC, I’ve never used a CNC machine before and with in a day I was carving. An awesome machine for a beginner to learn as hobbyists. I used the manual and the help video. One hour to assemble and test, very friendly and easy to use. It’s a good buy for the money. I would definitely recommend this machine to someone getting into CNCs.

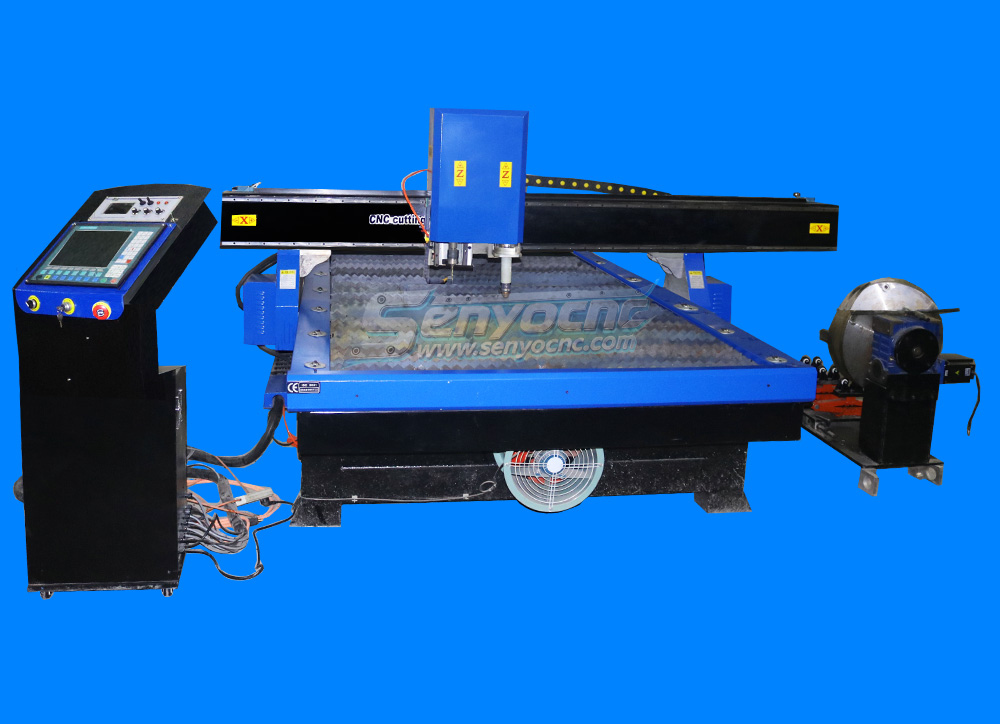

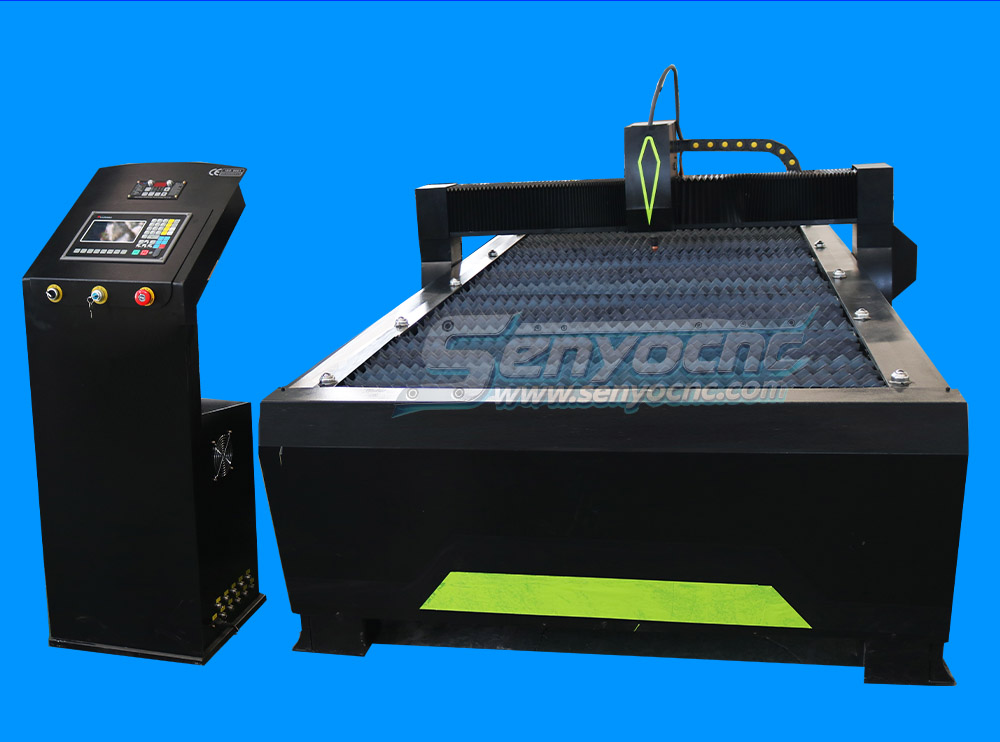

Weinstein from France

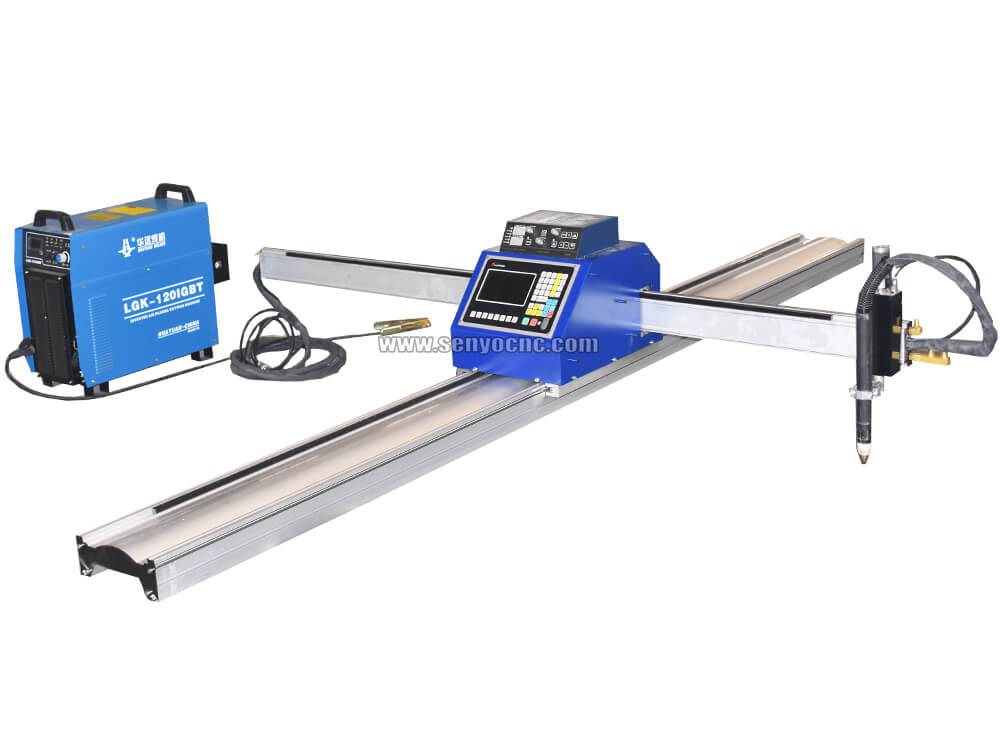

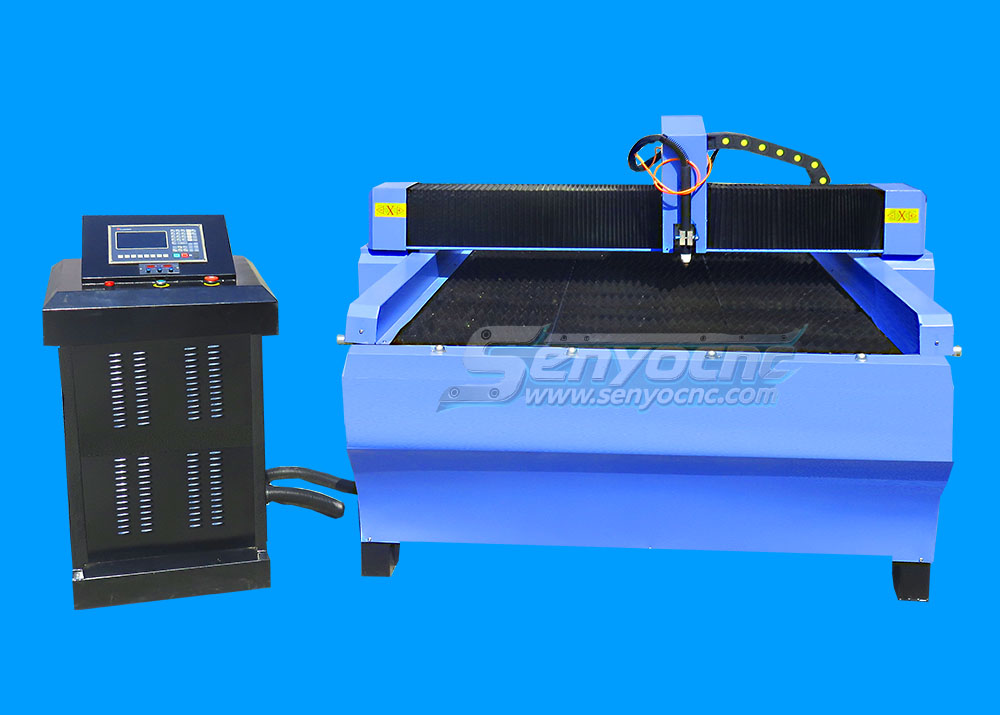

I've been using CNC plasma SYP2060-300A and I am very impressed with this unit.

This unit is of higher quality, made in China. Five stars all the way!

2040 from INDIAN

Best 2040 CNC Router Good Price and Quality ! Thank SENYOQC

10w uv laser from American

Best supplier ! I bought 3 machines for laser and router , thank you Aillen ! --Alec

12KW Fiber Cutting - 2000X6000mm -- 이병헌 from Korea

Good machine for metal cut ! Thanks Senyo , Its prefect , I like your business patient kind!

I am a furniture manufacturer, and this machine is very good and fast. thanks Senyoqc Team ! from Bangladesh

Metal ArtWork from Denmark

The plasma cutting machine makes my artistic creation more convenient and precise!! Created more artistic ideas and value! Thank you Aillen team!

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen. from

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen.

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo from

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo

Thank you Senyo for SYJ1290-150W! from

Retired, ex mainframe systems programmer. Now full-time recreational woodworker majoring in puzzles, pens, boxes, Toys and occasional small furniture. Thank you Senyo for SYJ1290-150W!

manager@senyocnc.com

manager@senyocnc.com

SENYOCNC

SENYOCNC

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

2061579344

2061579344