What is a Fiber Laser?- A brief overview

From: 本站 Date: 16th March 2023 Author: SENYOQC Views: 2509

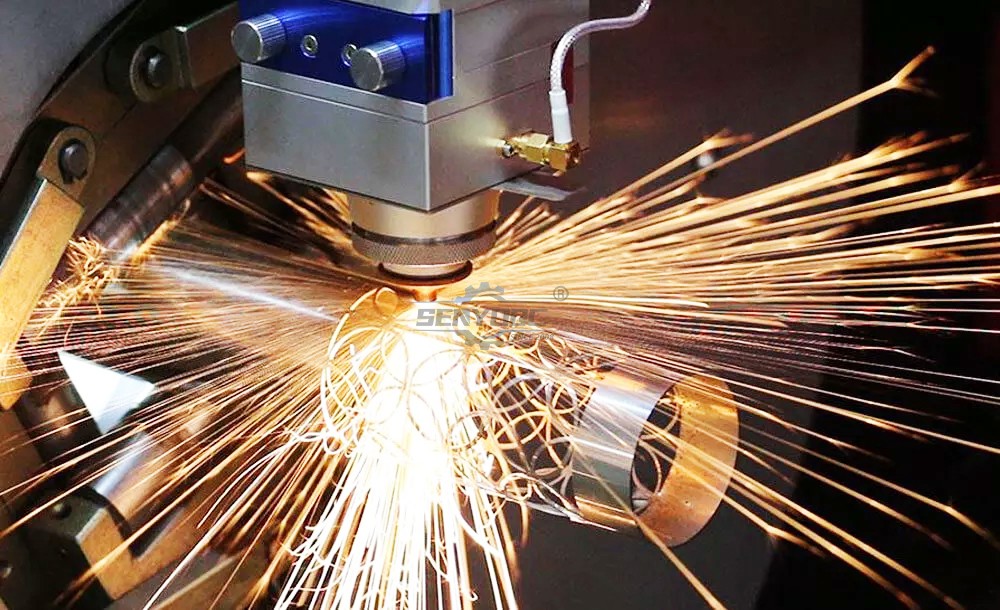

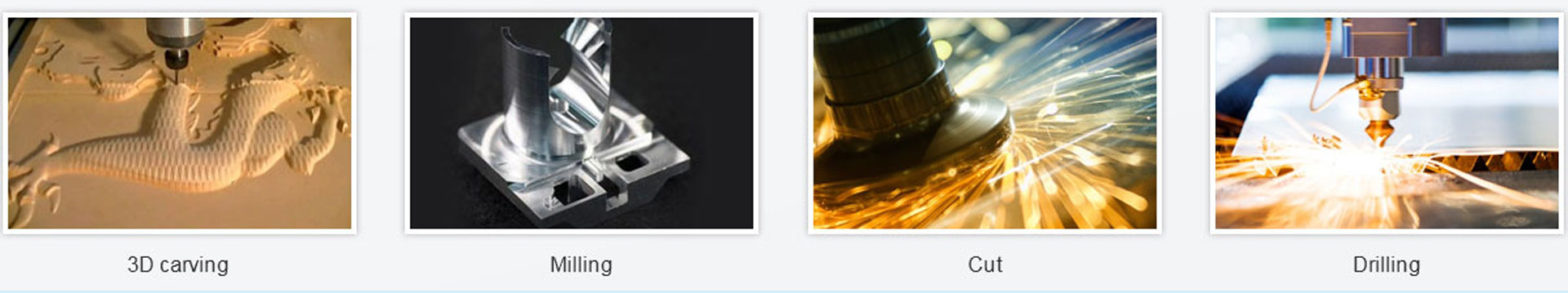

Fiber lasers is that they can perform various functions that are key to industrial manufacturing with high precision and accuracy. The most important one Laser Cutting ,one of the fundamentals.

The continuous wave (CW) Yb3+ doped fiber lasers are the most common in Laser Cutting machines as they are extremely powerful. A 01 µm fiber laser cutting

machine can cut through high-strength steel easily. Not to mention most

of the other metals and alloys.

Unlike traditional cutting

machines with some mechanical cutter bound to wear off, these lasers

don’t have such consumables. Hence, low maintenance saves energy, cost,

and time in cutting processes. This can increase the profit margin for

any industry.

Laser cutting is everywhere, from small-scale

businesses to the giant automotive and aerospace industry. Fiber lasers

are also inherently suitable for micromachining, done on a micro-scale.

Thus, truly making it the face of modern manufacturing processes.

How Does the Fiber Laser Cutting Machine Work?

Fiber laser cutters use thermal cutting to cut through various metals and non-metals. It involves the following steps.

First, a high-intensity laser beam is shot from the laser generator to the workpiece. The laser beam usually reaches a high temperature close to 10000-11000 ℃ (19500 ℉), enough to melt or vaporize any material.

The details of the location and shape of the cut are fed through a numeric control system that guides the laser.

As the laser comes in contact with the material, it quickly melts or gasifies it, and pressurized auxiliary gas is blasted to the point of contact, which removes the debris.

The process continues until the desired shape is achieved.

Laser

cutting machines come in many shapes and sizes, but the phenomenon

behind their principal working is the same. Here are some of the crucial

components of a laser cutting machine.

1. Machine Laser Source

The laser source is the heart of any laser-cutting machine. A separate unit usually creates a laser fed to the cutting head. Research shows that ytterbium Yb3+ doped fiber laser produces high-intensity lasers ranging from 900 nm to 1200 nm. Having a wide range of wavelengths means various materials can absorb the laser.

This source is excellent for

cutting High Strength, Carbon, Alloy, etc. It can = produce more than 10

KW of power that is intense enough to cut through thin plates (<5

mm) as well as 5 mm-40mm

However, thulium Tm3+ and holmium Ho3+ doped fiber laser sources can cut non-metal and transparent materials. The source unit is attached to the main unit through heavy-duty connectors, amplifier plugs, encoder plugs, etc.

2. Electrical components and Numeric Control System

The

numeric control and the electronics are what you may call the “brains”

of laser cutting machines. The main components are electrical servo

motors, switches, operating systems, etc.

All the data about the characteristics of the laser beam and details of the soon-to-be machined part are entered here.

A led control panel outside the machine

gets data from the operator through computer-aided manufacturing (CAM)

files.

This control system feeds all the data regarding output power, cutting speed, cutting angles, depth of cut, etc.

After that, it

guides the control head and rails during the cutting process. With the

advent of computer numeric control (CNC),

the precision of laser cutting

is increased manifolds, so much so that the only limiting factor of

laser cutting is the driving system.

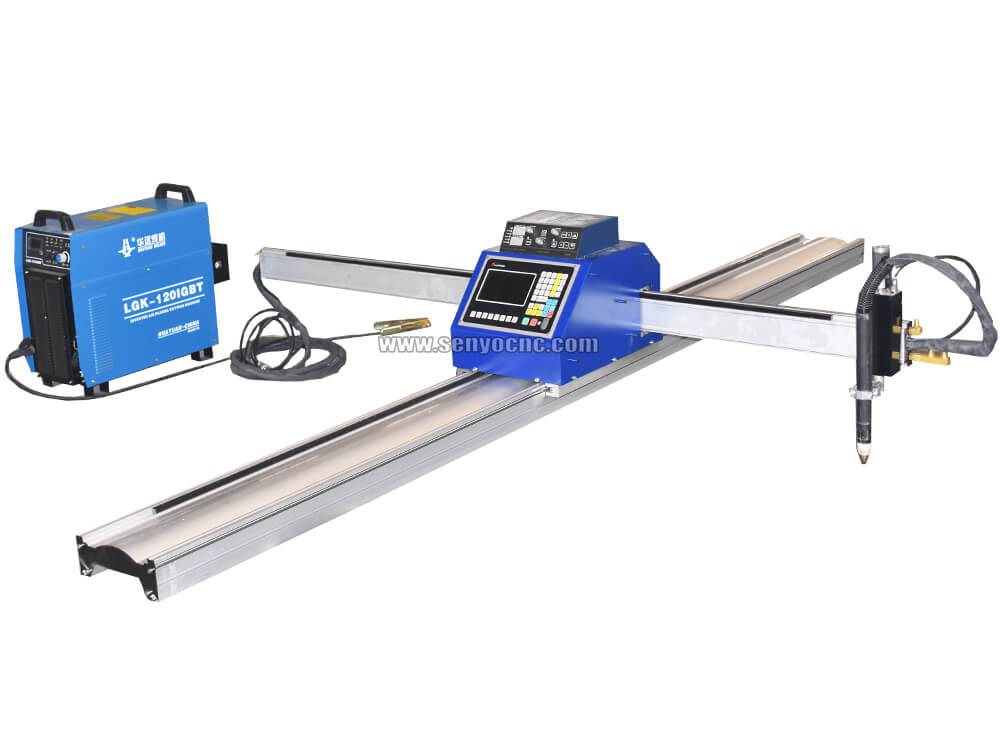

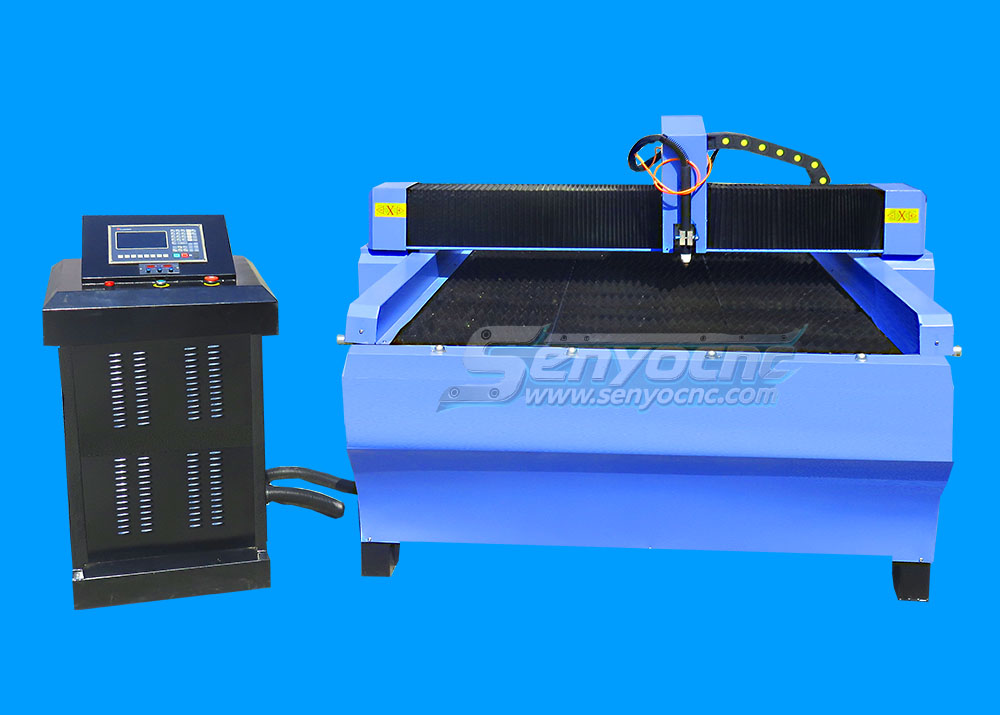

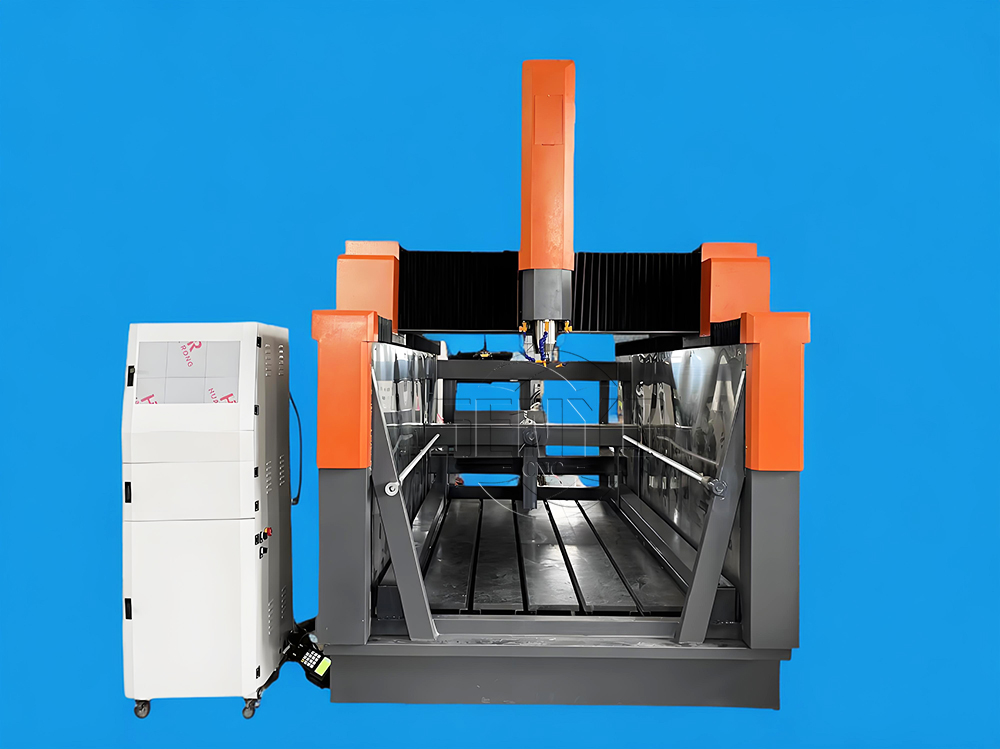

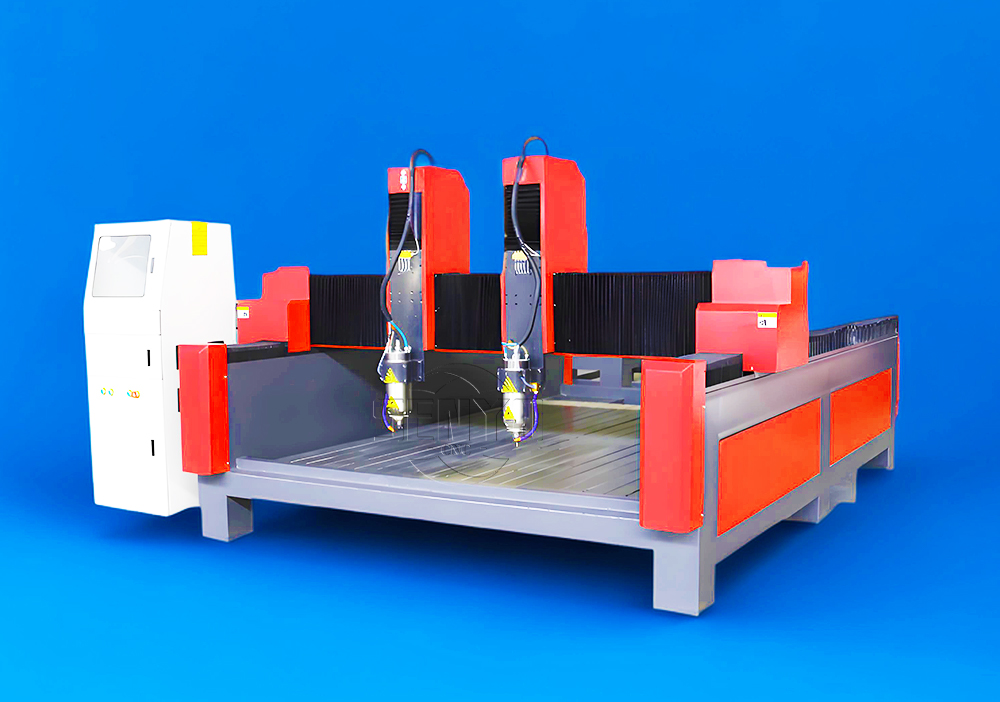

3. Gantry System and Auxiliary Parts

Every

industrial-sized fiber laser machine has a gantry system, a mechanized

driveway that helps move the laser head in three-dimensional space.

The gantry system comprises rails, chains, and motors that help guide the laser head.

Constant research has been going on to improve the

gantry system for fiber laser to reduce the machine time and improve

efficiency.

Other parts include the working table(work tables)

that holds the workpiece together.

Some fiber laser cutting machines

have large tables that could compensate 12 meters long metal sheets and

carry up to 9 tons of weight.

Many laser cutting machines also have an exhaust system that removes toxic gasses from the enclosure.

4. Fiber Laser Cutting Head

The fiber laser cutting head is a device that shoots a laser onto the workpiece. It has a complex system of mirrors (traditional laser machines) or optical fibers that guide the laser beam through the nozzle.

Nozzles are an important component of the laser head controlling the light beam. Not only does it directs the laser, but it also gives direction to discharge gas that blows off the molten material.

Nozzles can be

adjusted manually and have a lot of influence on the cutting quality.

It’s carefully calibrated before to prevent lack of penetration which

can result in material melting.

Different diameter nozzles are used to

cut various thicknesses.

The laser head is a moving part guided

by a gantry system. Typical, the laser head can move in

three-dimensional space.

But in special cases, laser heads are designed to move at a 45-degree angle, which helps create bevel shape cuts. These metal plates are meant to be welded later on. It saves much money, labor, and time otherwise spent on creating bevels.

Other characteristics regulated by the laser head are beam intensity, beam focus position, cutting speed, cutting feed, gas pressure, etc.

The

right cutting power, speed, and feed can make or break your

manufacturing processes. Just like a traditional mechanical machine, a

laser cutting machine comes with a detailed chart that defines the

characteristics of a laser suitable to a particular material.

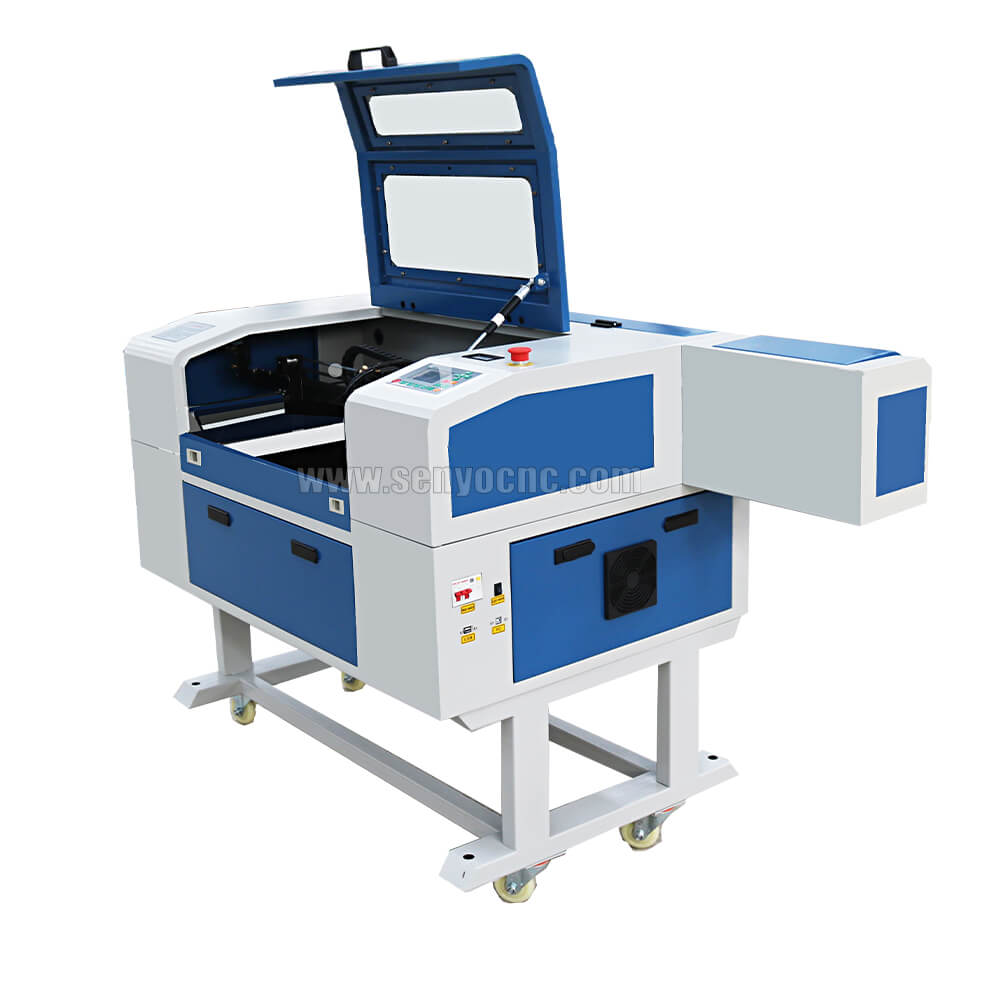

The whole working station is shielded by a metallic cover that gives the laser cutting machine an enclosed environment. This protects the laser beam and workpiece from external factors like air and dust. It also protects the human eyes as the invisible rays are hazardous.

• Previous: How To Install & Setup CO2 Laser Engraving Cutting Machine?

• Next: What Is Custom Laser Engraving?

- What's the MOPA Fiber Laser Machine?

- What is the difference between Laser 2D 2.5D 3D machines?

- What Can Laser Marking Machines Do for You?

- What's the differences between Raycus, JPT, Max, and IPG fiber source?

- What Is Custom Laser Engraving?

- What is a Fiber Laser?- A brief overview

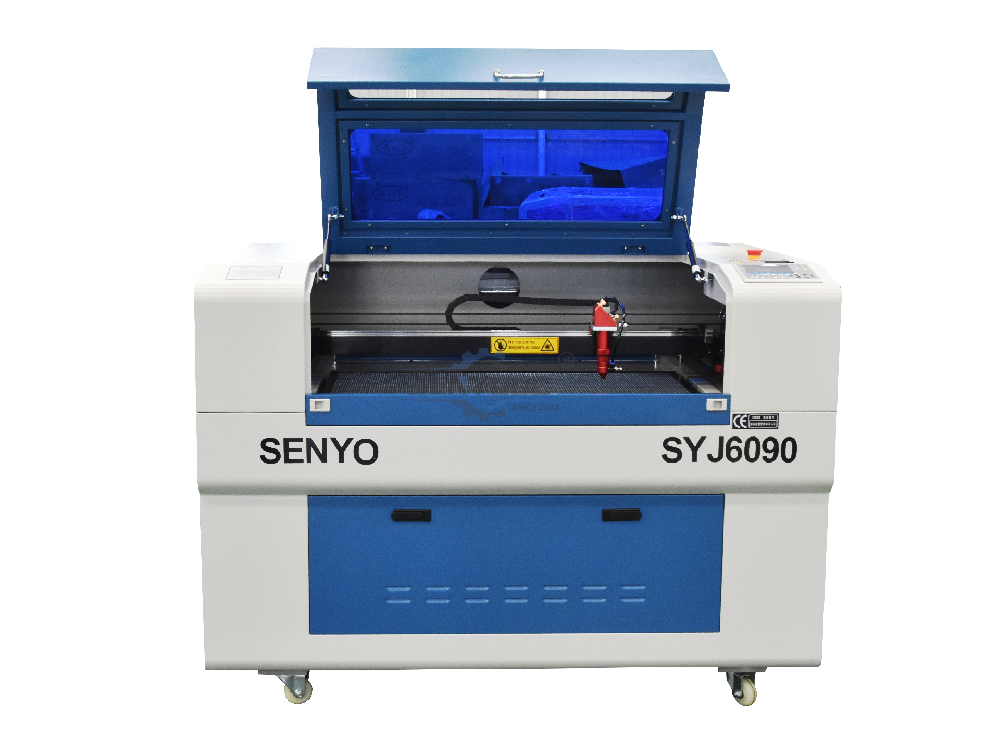

- How To Install & Setup CO2 Laser Engraving Cutting Machine?

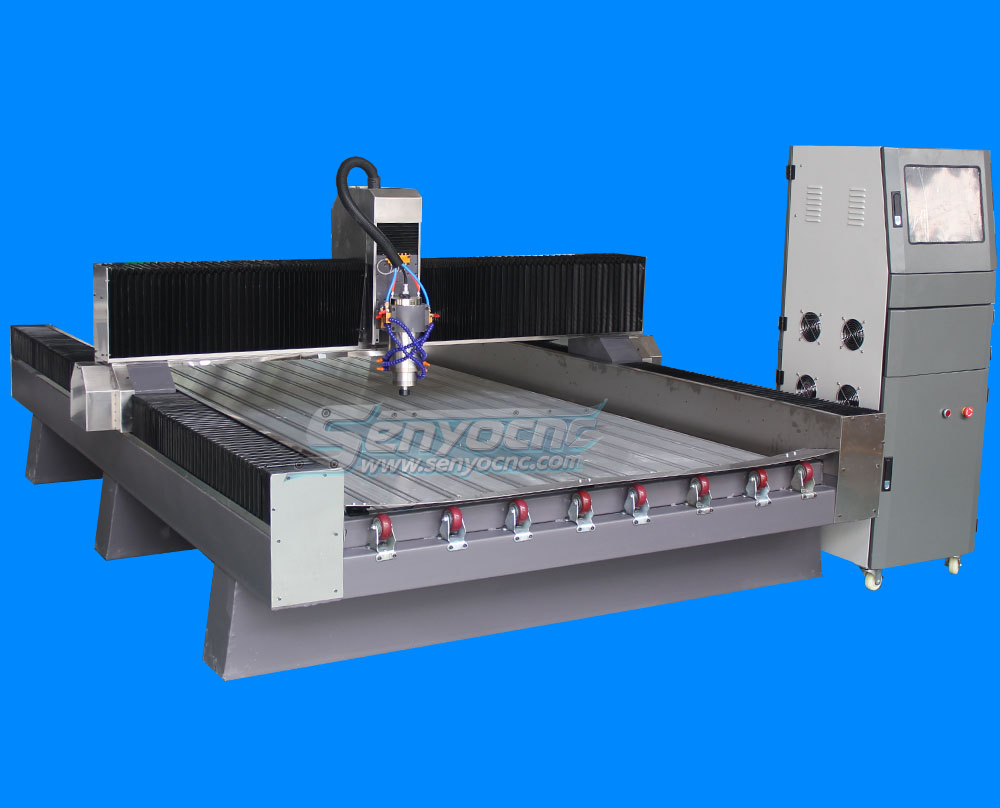

- How to Install and Use NcStudio Controller & Software for CNC Router Machine?

- A guide to CNC Router Tools and CNC Router Bits

- How to buy a CNC machine?

Jacob from United States

I am a beginner at CNC, I’ve never used a CNC machine before and with in a day I was carving. An awesome machine for a beginner to learn as hobbyists. I used the manual and the help video. One hour to assemble and test, very friendly and easy to use. It’s a good buy for the money. I would definitely recommend this machine to someone getting into CNCs.

Weinstein from France

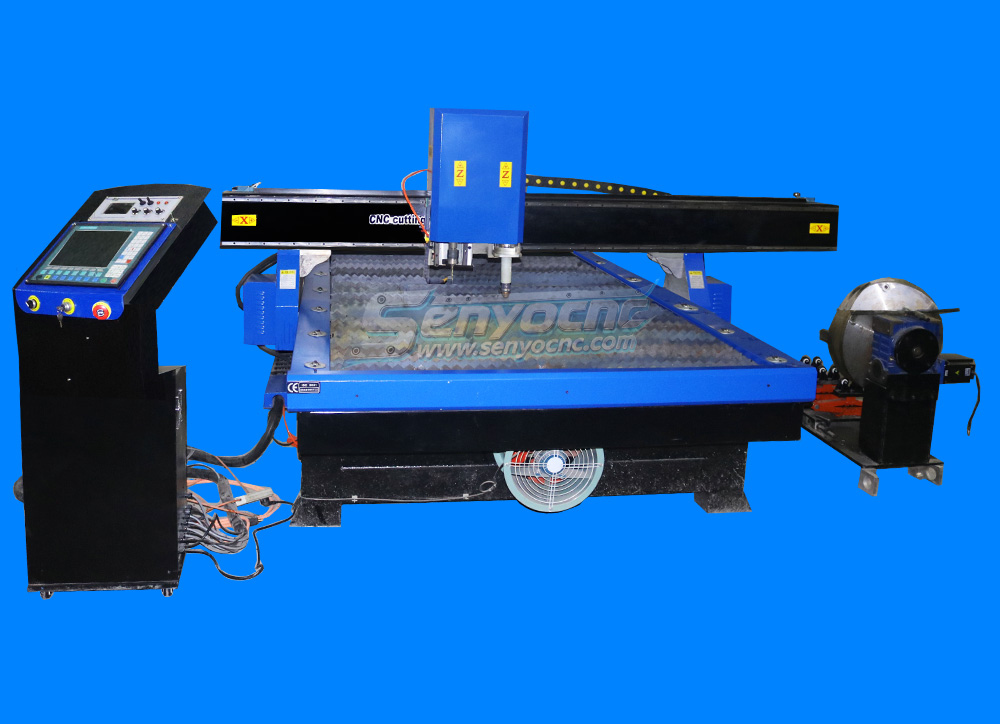

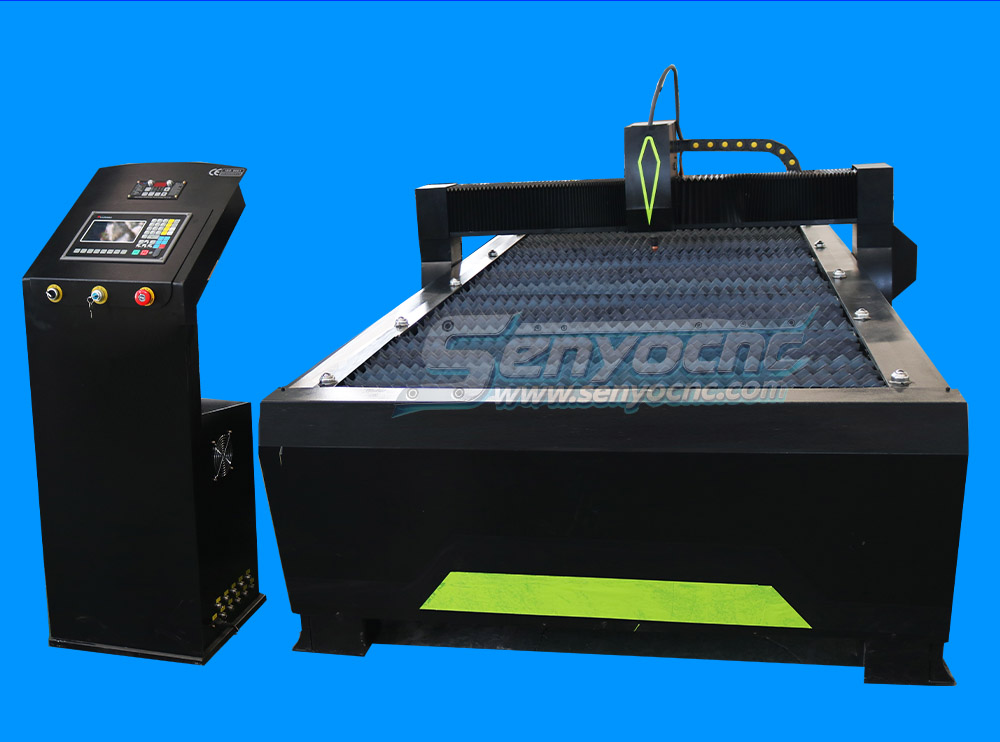

I've been using CNC plasma SYP2060-300A and I am very impressed with this unit.

This unit is of higher quality, made in China. Five stars all the way!

2040 from INDIAN

Best 2040 CNC Router Good Price and Quality ! Thank SENYOQC

10w uv laser from American

Best supplier ! I bought 3 machines for laser and router , thank you Aillen ! --Alec

12KW Fiber Cutting - 2000X6000mm -- 이병헌 from Korea

Good machine for metal cut ! Thanks Senyo , Its prefect , I like your business patient kind!

I am a furniture manufacturer, and this machine is very good and fast. thanks Senyoqc Team ! from Bangladesh

Metal ArtWork from Denmark

The plasma cutting machine makes my artistic creation more convenient and precise!! Created more artistic ideas and value! Thank you Aillen team!

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen. from

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen.

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo from

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo

Thank you Senyo for SYJ1290-150W! from

Retired, ex mainframe systems programmer. Now full-time recreational woodworker majoring in puzzles, pens, boxes, Toys and occasional small furniture. Thank you Senyo for SYJ1290-150W!

manager@senyocnc.com

manager@senyocnc.com

SENYOCNC

SENYOCNC

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

2061579344

2061579344