The X,Y,Z axis adopts double sealing design, with external high-quality stainless steel brushed shell and high-quality dust-proof folding cloth, which can provide effective hard protection and full sealing for the equipment, and is the most effective sealing form of waterjet cutter at present

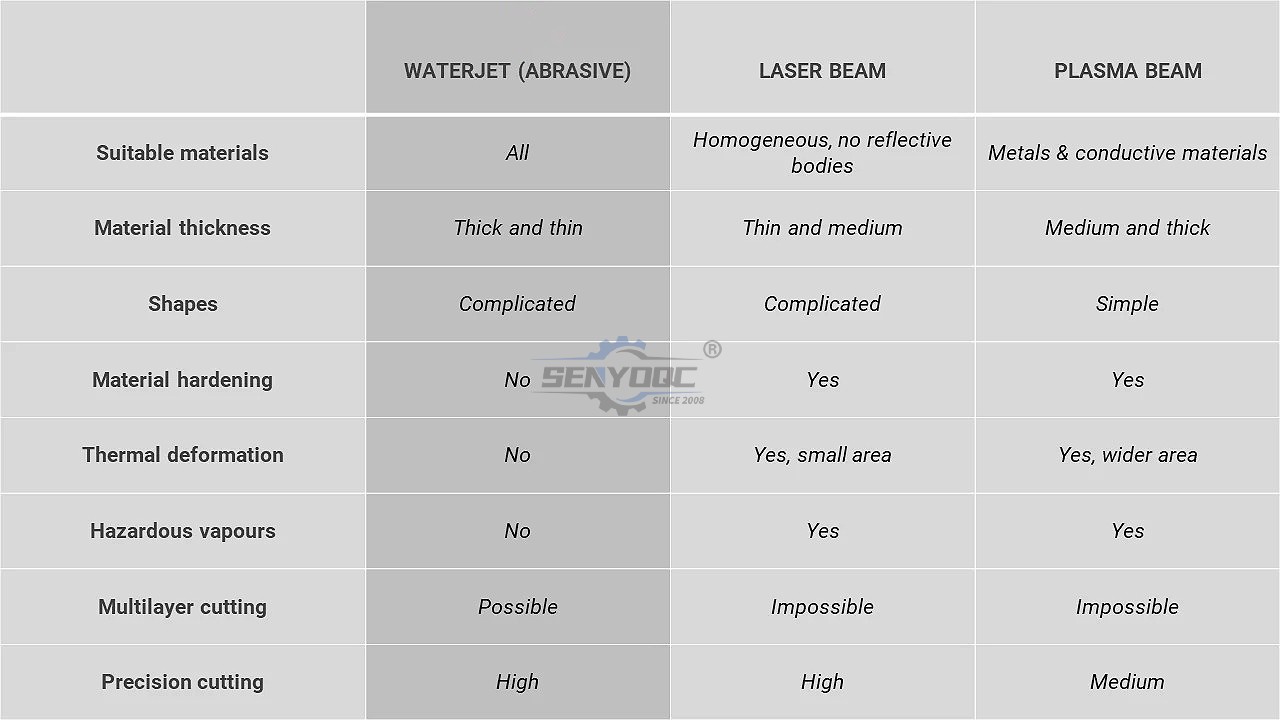

Water cutting cutting without thermal deformation, avoid physical and chemical changes of materials; Widely suitable for cutting all kinds of materials, the incision is smooth and smooth without burr, generally without reprocessing; The equipment is controlled by numerical control system with high cutting precision. The cutting joint is less than 1.2mm, which is convenient for nesting cutting and material saving. The process does not produce environmentally polluting waste; Numerical control water knife for those other methods are difficult to cut materials such as aramid, titanium alloy and a variety of composite materials is very ideal processing means.

Equipped with a variable oil pump and an intelligent variable high pressure system composed of four imported valve bodies, which can intelligently adjust the amount of oil according to the pressure requirements and has high cutting efficiency, better oil temperature control and more energy-saving, so that each pressurization is just right

Split structure

The X,Y,Z axis adopts double sealing design, with external high-quality stainless steel brushed shell and high-quality dust-proof folding cloth, which can provide effective hard protection and full sealing for the equipment, and is the most effective sealing form of waterjet cutter at present

Equipped with a variable oil pump and an intelligent variable high pressure system composed of four imported valve bodies

which can intelligently adjust the amount of oil according to the pressure requirements and has high cutting efficiency, better oil temperature control and more energy-saving, so that each pressurization is just right

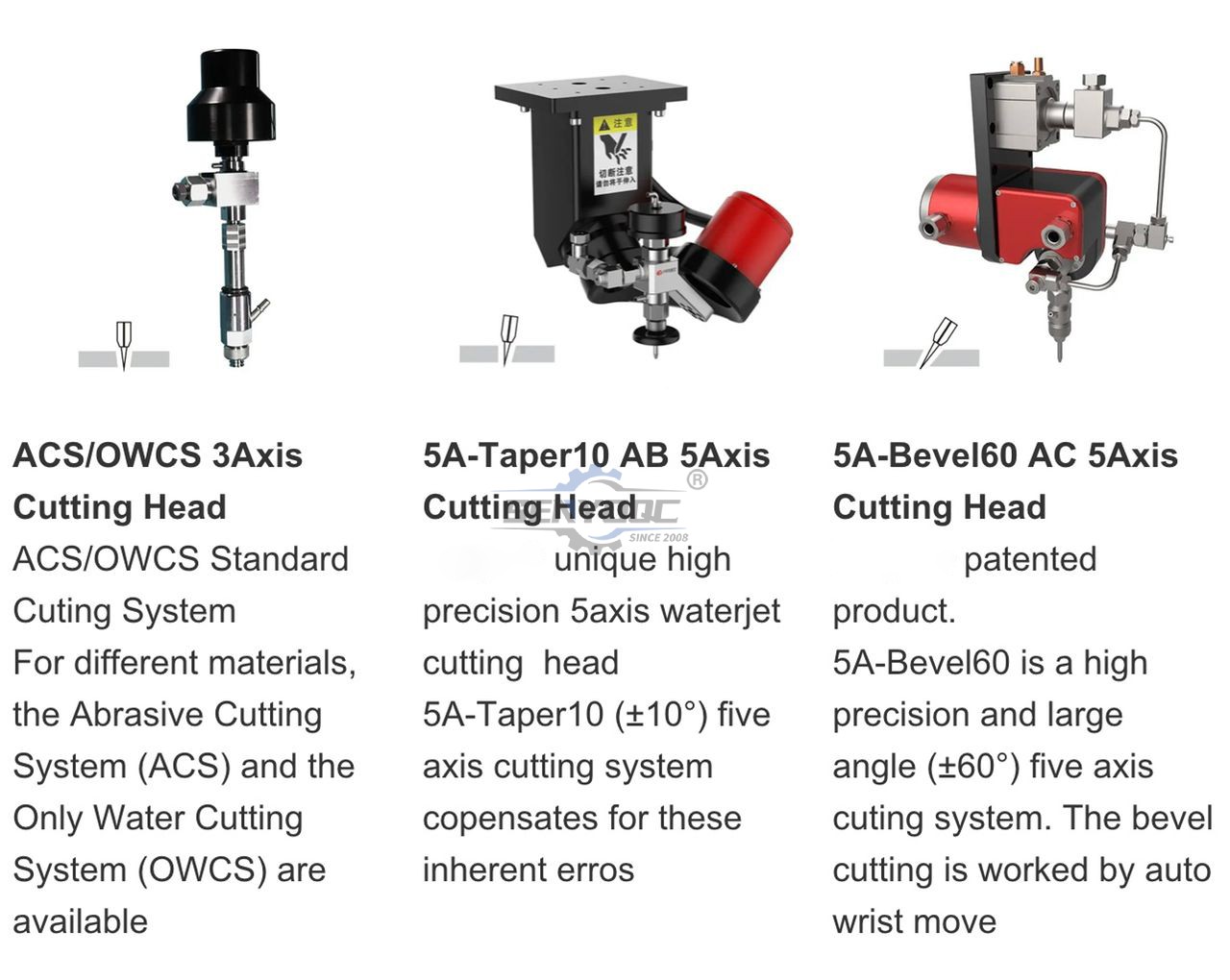

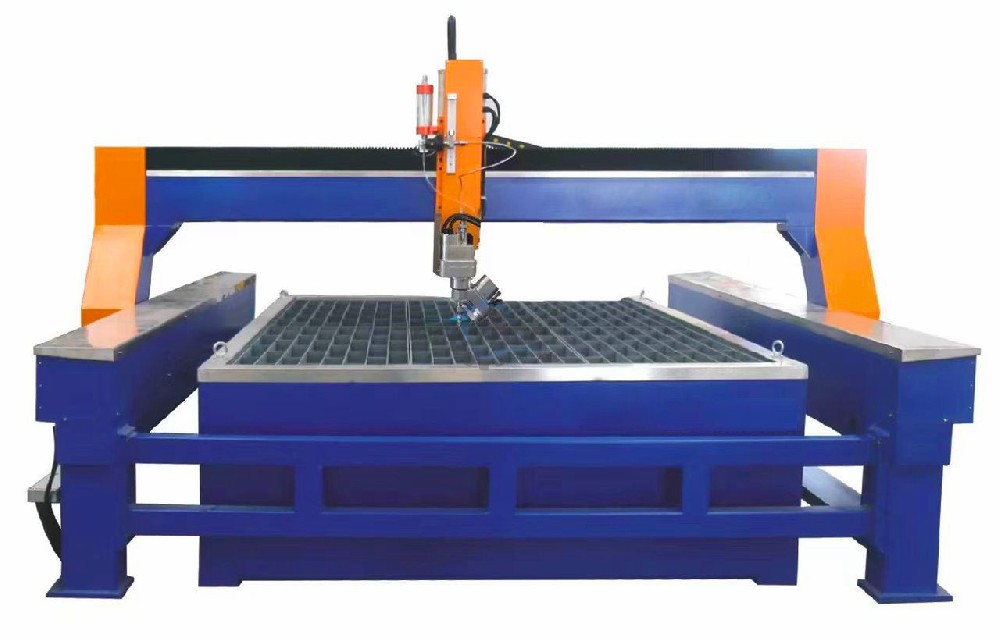

3 axis waterjet machine

A high pressure water jet cutting machine is a tool which slices into metal and other materials, using a jet of water at high velocity and pressure.

Because of its advantages of low noise, no pollution, high precision and good reliability, it has been widely used in mining, automobile, paper-making,

food, art, construction and other industries.Waterjet can cut almost every thing, including metal,glass,plexiglass,ceramic,marble, granite,

rubber and compound material etc.

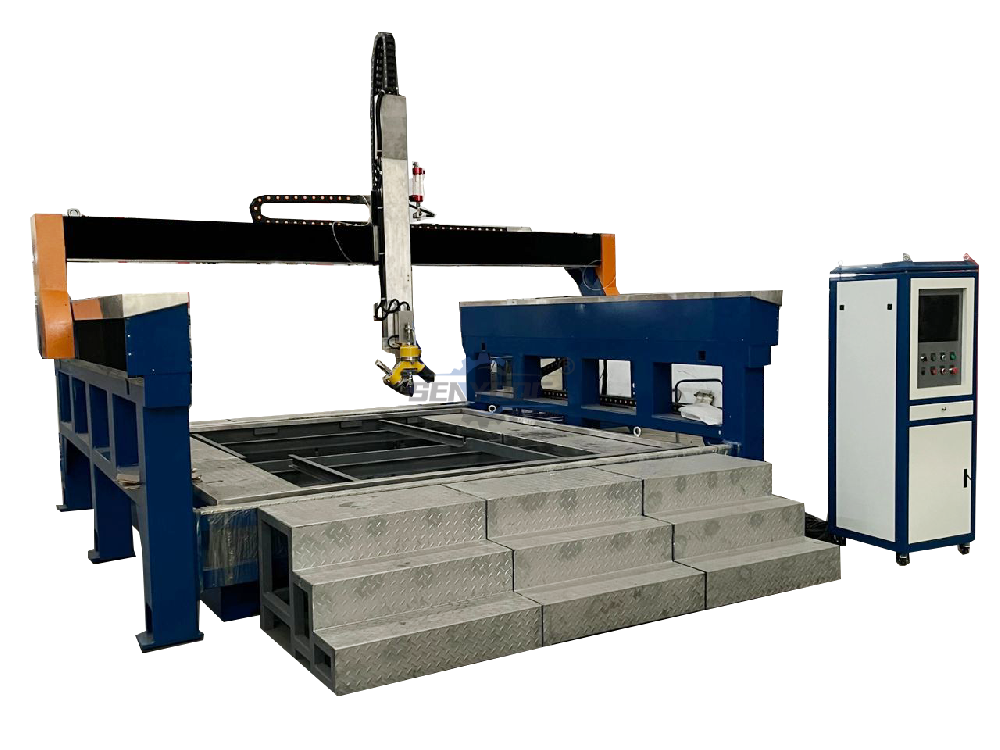

Dynamic 5axis water jet cutting machine

Dynamic 5 axis waterjet cutting machine is specially used to cut marble and granite,

because it can compensate 10° cutting angle and make the stone patchwork more perfect. It is a kind of bevel cutting machines.

Due to the water jet cutting is a way of flexible cutting, therefore the product cross section will have a certain degree of inclination

after cutting by the traditional 3 axis water jet cutting machine. In order to ensure the accuracy of vertical cutting section,

it must reduce the cutting speed.

However, our 5 axis water jet cutting machine can not only ensure the accuracy of vertical cutting section by compensating the cutting angle,

but also not reduce the cutting speed.Therefore, it is the best choice to use it to cut mosaic stone,

which saves the time and manpower for the second polishing of mosaic stone.

Max5 axis waterjet cutting machine

MAX5 series 5 axis water jet cutting machine unlike a conventional 3-axis waterjet cutting machine,

this product is added with A-axis (in a vertical direction) and C-axis (which rotates around the Z axis).

By using state-of-the-art technology and the Italian ECS control system,

it can produce 0-±45° inclined cuts with a maximum rotation angle of up to ±540°.

Currently, this state-of-the-art cutting equipment has been applied by a wide variety of advanced processing industries.

It can cut the product cross section without inclination, and cut bevel at any angle, as well as cut the workpiece vertically,

especially cut cone, curved impeller, gear, etc.

Parts Detials

All of them adopt Siemens electronic components. The wiring is simple and practical.

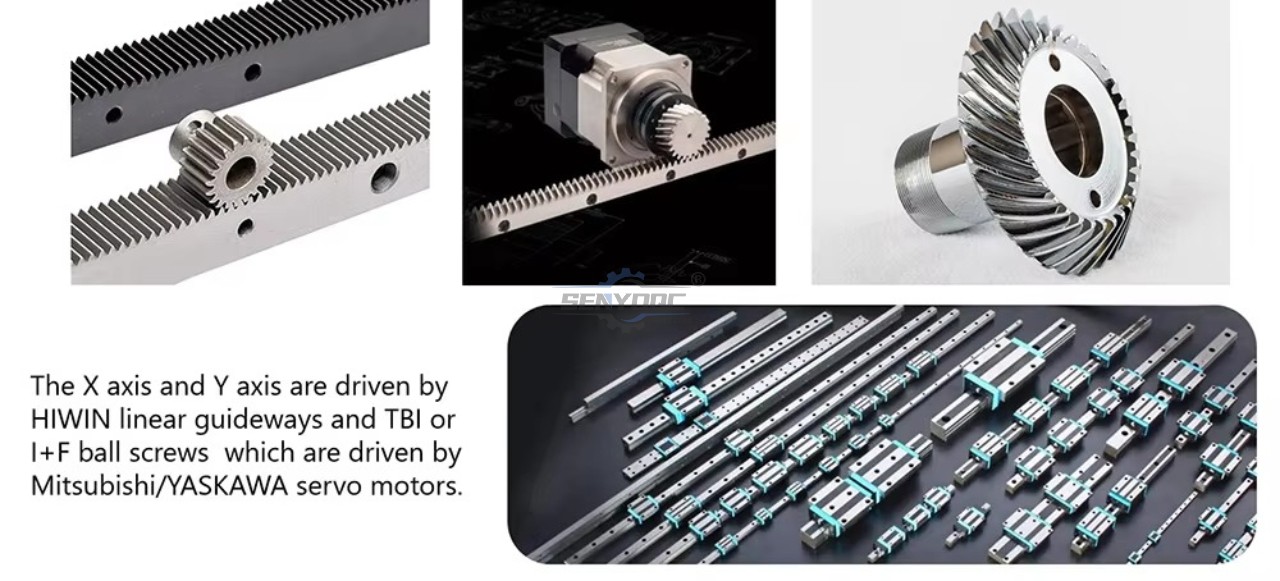

X axis, Y axis using Fully sealed oil bubble type:

The guide screw is completely immersed in the oil tank, which can fully lubricate and prevent the wear of the transmission system from the splashing of abrasive and water. And it has high cutting accuracy, but also greatly improves the service life of the equipment, and solves the serious accuracy attenuation problem of water jet cutter in the past, and the cutting is accurate at any time

Application and advantages

Waterjet Cutting Machine is an effective tool for any shape of artistic creation.

The traditional cutting method is saw cutting only in a row. When cutting the curves, the model should be made according to the size and then polished.

Waterjet Cutting Machine can cut any shape of models under the control of the CNC program.

1. Smooth cutting quality is perfect.

2.The cutting accuracy of waterjet cutter is up to 0.1mm. Edge joints are regular, and water jet cutting can also make very complex puzzles and murals.

3. Cutting speed is fast, and product consistency and interchangeability are very good.

4. Drilling, cutting and forming can be done at once.

5. Improve the working environment and reduce the impact of dust and noise on the operator.

6. Waterjet cutting is a cold cutting that does not damage the internal structure of the material.

7. It is the only machine for processing composite materials and fragile porcelain.

8. Waterjet Cutter can cut metal, rubber, foam, plastic, composite materials, stone, ceramic tile, marble, glass, etc.

After Services All Machine Life

1.For on site installition and training: the buyers take responsibility for technician’s air-ticket,hotel and food.

2.Free warranty for the machine is one year(except wearing parts and the replacement of wearing parts).

3. Training of personnel as requirement of customer.

4. To guarantee long term supply of spare parts.

5. lifetime service, maintenance.

6. the buyers have the special price when there are new products updating and ne technologies.

7.Quick response time: when the user’s machine any fails,response within 12 hours after receipt of written notice.

by phone,email or fax.the seller will help buyers solve problem ASAP.

International Shipping

Around the World All the CNC routers can be shipped worldwide by sea, by air or by international express logistics via DHL. FEDEX. UPS. You are welcome to get a free guotation by fling up the form with name, email, detailed address.Product and recuirements. We will shortly contact you with the full information includina the most suitable delivery method fast secure discreet and freight.

Waterjet, marble cnc waterjet cutting machine, cnc waterjet stone cutting machine

• Previous: Split design Waterjet Cutting Machine 5 Axis AB best price

• Next: Cantilever Gantry Integrated Waterjet Cutting Machine Lowest Price

Fiber metal Laser Sensor And Its Application

Category: SENYO NEWS 11th Mar, 2021A CNC wood router will use 3D machining in relief carving, the effect is more artistic beauty, but also has a strong sense of three-dimensional 3D, realization of this function is to ...

Precision Cutting Stents with Fiber Lasers

A CNC wood router will use 3D machining in relief carving, the effect is more artistic beauty, but also has a strong sense of three-dimensional 3D, realization of this function is to ...

How to Laser Cut Copper and Other Reflective Metals

Laser cutting of mild steel and stainless steel has a long history and has been one of the primary applications for CO2lasers. However CO2lasers have not traditionally offered a good solution for cutting highly reflective materials.Fiber lasers have an emission wavelength of around

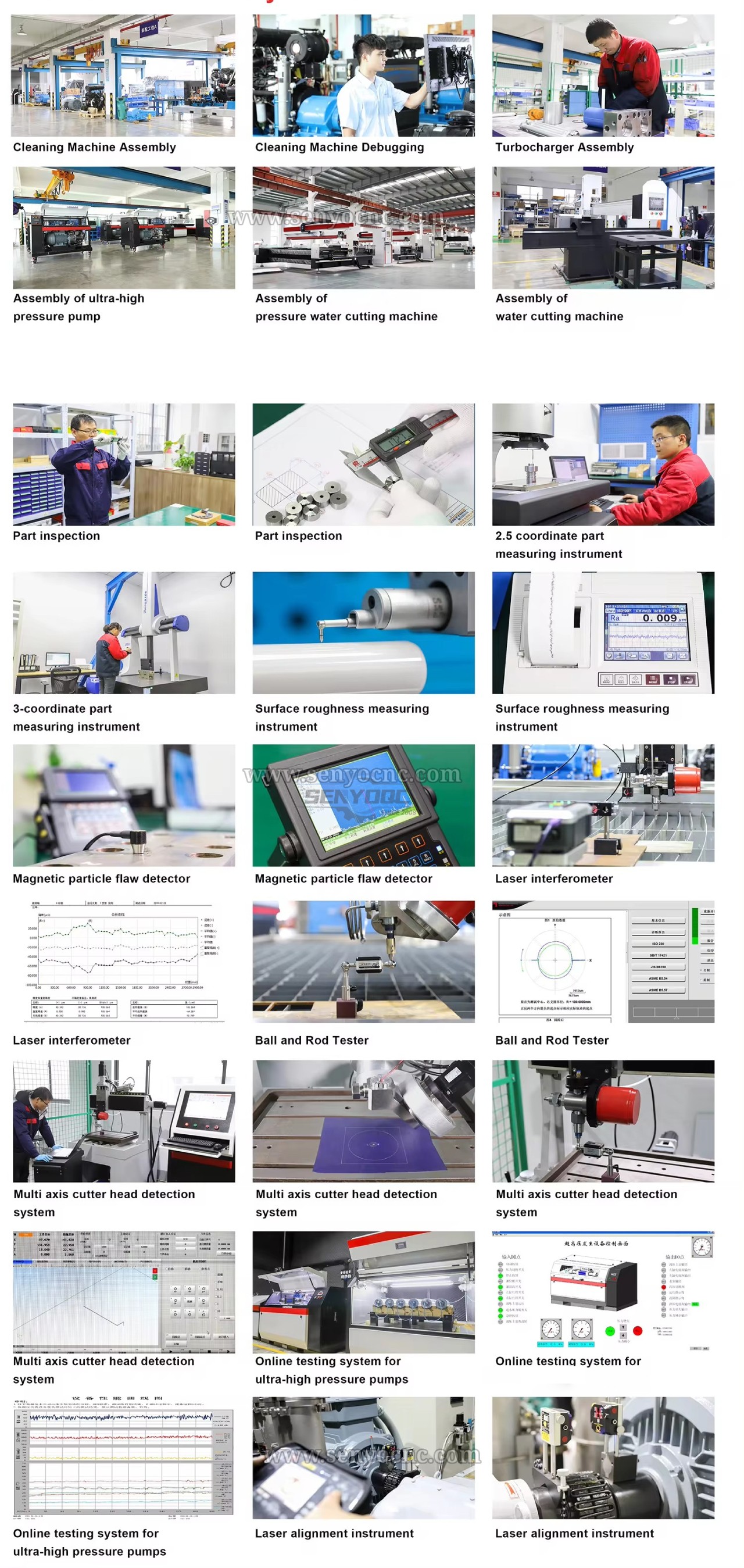

Laser Cutting Machine Inspection Process For Manufacture

SENYOCNC Have Strict quality monitoring will be carried out when the parts are in the factory.

How Control Costs Use of UV Printers ?

UV flatbed printers are rapidly being used by more and more manufacturers, thanks to its efficient production efficiency, and the control of production costs also needs to arouse our attention.

Why UV flat printing machine is popular in market ?

For the majority of designers, give full play to the creative ability, the design sample can be arbitrarily modified on the computer, the effect on the computer, is the effect after the finished product, customer satisfaction can be directly produced. UV flat printing pattern fine, rich and clear layers, high artistry, strong three-dimensional sense, many high precision equipment can also print photography and painting style patterns.

How does UV ink jet printer save UV ink?

UV inkjet printer use process is an important consumable UV ink, reasonable use of equipment, can save UV ink , it can be said to be the best choice to directly save the cost. In the process of using some skills you need to be familiar with, the following small make up to share with you:1. Try to us

Waterjet Machine delivery and Shipping

Please tell us your max working size and what materials will cutting , also what max cutting thickeness.If you have Working photo sample please also send us , it will be helpful to choose machine with suitable models .

Waterjet Machine finish manufacture 5axis

Waterjet cutting technology is one of the fastest growing major machine tool processes in the world due to its versatility and ease of operation.

Waterjet Machine delivery and Shipping

Waterjet cutting technology is one of the fastest growing major machine tool processes in the world due to its versatility and ease of operation.There are multiple advantages to adding waterjet cutting capabilities to your shop.We are company leading ultrahigh-pressure waterjet system so

How to Create Connected Text – Inkscape for Laser Cutting

Step 1: Create Some TextFirst, we need some text to work with. To create the text, select the Text Tool (keyboard shortcut: T), click somewhere on the canvas, and type your text.You can use the drop-down list on the top left to select your desired font.Step 2: Convert Text to PathNext, we need to tu

Jacob from United States

I am a beginner at CNC, I’ve never used a CNC machine before and with in a day I was carving. An awesome machine for a beginner to learn as hobbyists. I used the manual and the help video. One hour to assemble and test, very friendly and easy to use. It’s a good buy for the money. I would definitely recommend this machine to someone getting into CNCs.

Weinstein from France

I've been using CNC plasma SYP2060-300A and I am very impressed with this unit.

This unit is of higher quality, made in China. Five stars all the way!

I am a furniture manufacturer, and this machine is very good and fast. thanks Senyoqc Team ! from Bangladesh

Metal ArtWork from Denmark

The plasma cutting machine makes my artistic creation more convenient and precise!! Created more artistic ideas and value! Thank you Aillen team!

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen. from

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen.

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo from

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo

Thank you Senyo for SYJ1290-150W! from

Retired, ex mainframe systems programmer. Now full-time recreational woodworker majoring in puzzles, pens, boxes, Toys and occasional small furniture. Thank you Senyo for SYJ1290-150W!

CNC Router I love woodworking and the Joy in the Journey! It's a Blessing! from Ricky

CNC Router I love woodworking and the Joy in the Journey! It's a Blessing!

CO2 1530H-300W Europe from

CO2 1530H-300W All really well done. these are something ive always wanted to do.

4040 Mini Desktop CNC Router for Small Business from France

Good Machine! Wonderful Service !

Thanks Senyoqc Team for whatsapp Group services , Excellent enginner ! Good work!

/5 based on 100votes/5 based on votes

/5 based on 100votes/5 based on votes

manager@senyocnc.com

manager@senyocnc.com

SENYOCNC

SENYOCNC

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

2061579344

2061579344