+86 1525 3141 880

+86 1525 3141 880

In this Instructable you will:

Setup the CNC Router

Load a DXF file and generate the G-CODE the machine will use to cut out the stool

Cut out a bar stool using the CNC Router

You will need:

CNC Router and controlling computer with Cut 2D and Mach 3

Stool DXF file

0.25-inch End mill (2 flute)

4-foot by 3-foot piece of 0.703-inch thick plywood

"CNC Collet Nut" Wrench (or Adjustable Crescent Wrench)

21mm Wrench (or Adjustable Crescent Wrench)

Screwdriver and screws

Safety glasses

Hearing protection (optional, but recommended)

Tape measure (optional, but recommended)

Use DXF file

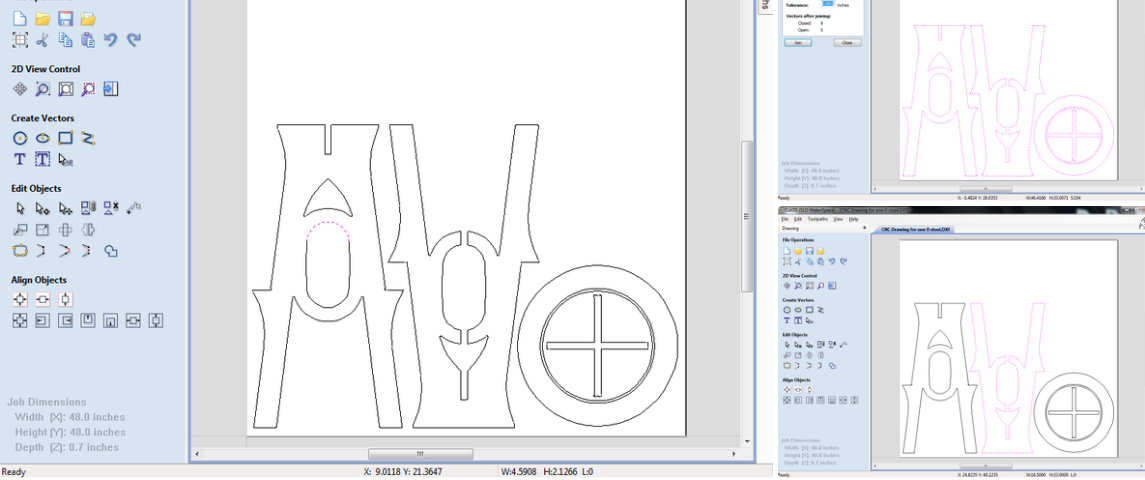

Open Cut 2D (Picture 1)

Click "Open an existing file" (Picture 2)

Select "CNC Drawing for one 0 stool.DXF" (Picture 3)

The "Job Setup" page will load (Picture 4)

Adjust size of wood (width = 48 inches, height = 36 inches)

Adjust thickness (0.7 inches)

Uncheck "Use origin offset"

Click "OK"

The imported DXF will be a series of unconnected lines and curves. (Picture 1) You will want to join the vectors to create closed objects.

To do this:

Type "j" on keyboard

The "Join Vectors" menu will appear on the left (Picture 2)

Select all of the objects on the sheet by clicking and dragging a box around them

Click "Join" in the "Join Vectors" menu on the left

There should now be 8 closed vectors which you can select by clicking on them. (Picture 3) We will use these vectors to create toolpaths in the next step.

Cut 2D Tip:

You can click and drag down and right to select only the objects within your selection window. You can click and drag up and left to select all objects touching or inside of your selection window.

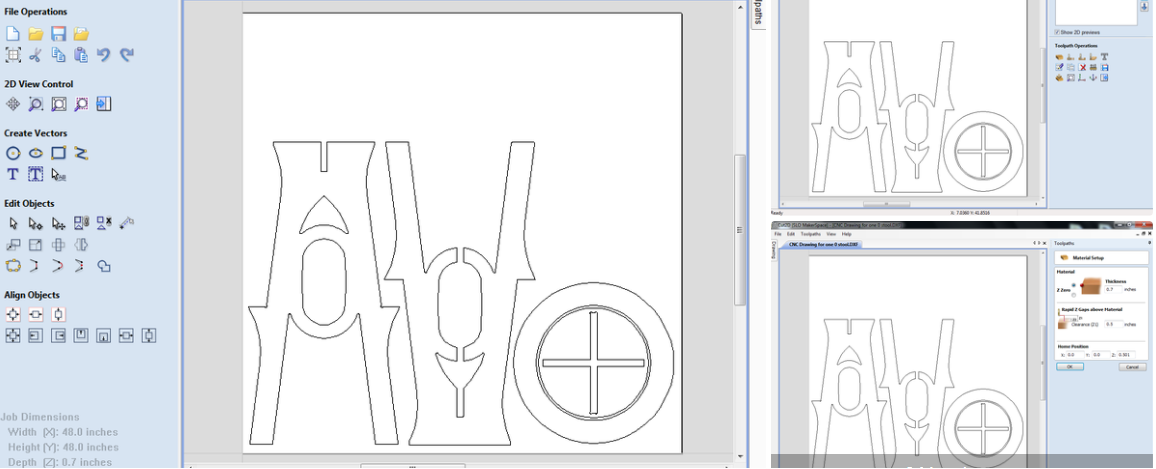

We will now create the code that the machine will use to cut out the stool.

Click the 5th button in the second row of the grid in the toolpaths menu: "Save toolpaths" (Picture 1)

Select all the toolpaths in the upper right list (Picture 2)

Make sure "Output all visible toolpaths to one file" is selected

Make sure Mach2/3 is selected as the post-processor

Click "Save toolpath(s) to file"

Pay attention the the place and name you are saving the file, and click "Save"

Move gantry out of the way

If stepper motors are powered up, use Mach 3 (details in Step 8: Load G-Code in Mach 3)

If stepper motors are not yet plugged in, you may gently push it by hand

Set plywood on top of spoils board. Be sure to line up the edges of the plywood with the edges of the spoils board.

Screw plywood into spoils board at edges.

Turn on sawdust collection vacuum (in the room behind the CNC Router) and make sure suction is generated at the inlet adjacent to the end mill.

Plug in water pump (the cord/plug attached to the white bucket between the CNC Router and the wall). This pump will circulate water and cool the spindle.

Plug in the spindle motor (the white 220V cord/plug labeled "Router")

Double-check all setup procedures and make sure you are wearing protective eyewear.

Press (and hold briefly) the green button on the spindle control box below the computer monitor to start the spindle. Wait for it to speed up. (

Click the green "Cycle Start" button in Mach 3. Watch the machine and the controls as it starts up to make sure everything is operating as expected. Verify that the zero Z coordinate is correct. Be ready to click the red "Cycle Stop" button if needed. Once clicked, it will stop the code from running and you can fix what you need to and press the green "Cycle Start" button again to continue. However, if it is stopped on a curve, you may need to restart the process.

Continue monitoring as the CNC Router cuts out the stool!

Once the cutting has been completed, press (and hold briefly) the red button on the spindle control box below the computer monitor to stop the spindle.

Unplug spindle motor, water pump, and stepper motor power

Turn off the sawdust collection vacuum

Remove the cut stool pieces

Remove remaining scrap from CNC Router table

Vacuum all surfaces

Remove end mill

Put all tools away

Close computer programs and delete your files from the desktop

Sand the edges of the stool pieces

Assemble the pieces

Screw in the footrest (and seat if necessary)

Enjoy your new stool!

Jacob from United States

I am a beginner at CNC, I’ve never used a CNC machine before and with in a day I was carving. An awesome machine for a beginner to learn as hobbyists. I used the manual and the help video. One hour to assemble and test, very friendly and easy to use. It’s a good buy for the money. I would definitely recommend this machine to someone getting into CNCs.

Weinstein from France

I've been using CNC plasma SYP2060-300A and I am very impressed with this unit.

This unit is of higher quality, made in China. Five stars all the way!

2040 from INDIAN

Best 2040 CNC Router Good Price and Quality ! Thank SENYOQC

10w uv laser from American

Best supplier ! I bought 3 machines for laser and router , thank you Aillen ! --Alec

12KW Fiber Cutting - 2000X6000mm -- 이병헌 from Korea

Good machine for metal cut ! Thanks Senyo , Its prefect , I like your business patient kind!

I am a furniture manufacturer, and this machine is very good and fast. thanks Senyoqc Team ! from Bangladesh

Metal ArtWork from Denmark

The plasma cutting machine makes my artistic creation more convenient and precise!! Created more artistic ideas and value! Thank you Aillen team!

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen. from

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen.

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo from

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo

Thank you Senyo for SYJ1290-150W! from

Retired, ex mainframe systems programmer. Now full-time recreational woodworker majoring in puzzles, pens, boxes, Toys and occasional small furniture. Thank you Senyo for SYJ1290-150W!