+86 1525 3141 880

+86 1525 3141 880

Fiber laser cutting machine, with laser wavelength of 1070-1080nm, can cut different kind metals, like stainless steel, carbon steel, aluminum sheet, brass, copper, galvanized plate, etc.

Different thickness CS need different laser watt. Below the Max cutting thickness of different watt, for CS Cutting:

| Material | Cutting machine watt | Max cutting thickness |

| Carbon steel | 500w | 6mm |

| Carbon steel | 750w | 8mm |

| Carbon steel | 1000w | 10mm |

| Carbon steel | 1200w | 12mm |

| Carbon steel | 1500w | 16mm |

| Carbon steel | 2000w | 20mm |

| Carbon steel | 3000w | 22mm |

The laser power is one of the most important factors, in the laser treatment of different materials, as well as CS Cutting.

Also, a lower power laser beam is utilize when we want a greater cutting precision. On the other hand, thicker and more durable materials require a higher powered laser beam. For example, an 8mm metal sheet requires at least 1000 watts to cut effectively.

The pulse frequency is somewhat proportionally link to the laser beam power.

Modern lasers offer sophisticated control features for the laser cutting process

that allow for automatic increase or decrease of the pulse frequency according to the material at hand.

Each material requires a specific type of gas to use the laser

in order for the machining to effective and safe. The wood which is flammable excludes the use of oxygen for example because there would be a fire hazard. Oxygen on the other hand, is use when cutting metal surfaces which are free of oxides.

The gas type is not the only factor that comes into play. The quality of the gas is equally important. Different purity versions of the same type of gas, affect differently the cutting process both time- & quality-wise.

The pressure of the laser gas is another important factor to keep in mind. The gas pressure is influence he thickness of the material to cut. The thinner the material, the lower the gas pressure or there is a risk of damaging the material and the laser device itself.

The cutting nozzles significantly influence the laser cutting process. For example, when we have to deal with low-pressure laser cutting, smaller nozzles are require. Conversely, when the material machining calls for a higher-pressure cut, then we need to use larger nozzles.

The distance of the nozzles from the cutting surface plays an important role in the quality of the final laser cut result. As a rule of thumb, the shorter the distance between the tip and the surface, the more precise and higher-quality cut we have.

That being said, in several occasions it is advised to increase the distance in order to prevent damage to the equipment.

The focus lens needs to be clean and in perfect condition at all times. If there are pollution traces on the lens, then the laser cutting process is hindered and the results are of lower quality. Furthermore, a dirty focus lens is the main culprit for increased temperatures that may harm the laser device.

Hope the above can help you in your metal sheets cutting process, especially in CS Cutting.

Any question about fiber laser cutting, welcome to contact us.

• Previous: Stainless steel Fiber Laser Cutting

Jacob from United States

I am a beginner at CNC, I’ve never used a CNC machine before and with in a day I was carving. An awesome machine for a beginner to learn as hobbyists. I used the manual and the help video. One hour to assemble and test, very friendly and easy to use. It’s a good buy for the money. I would definitely recommend this machine to someone getting into CNCs.

Weinstein from France

I've been using CNC plasma SYP2060-300A and I am very impressed with this unit.

This unit is of higher quality, made in China. Five stars all the way!

2040 from INDIAN

Best 2040 CNC Router Good Price and Quality ! Thank SENYOQC

10w uv laser from American

Best supplier ! I bought 3 machines for laser and router , thank you Aillen ! --Alec

12KW Fiber Cutting - 2000X6000mm -- 이병헌 from Korea

Good machine for metal cut ! Thanks Senyo , Its prefect , I like your business patient kind!

I am a furniture manufacturer, and this machine is very good and fast. thanks Senyoqc Team ! from Bangladesh

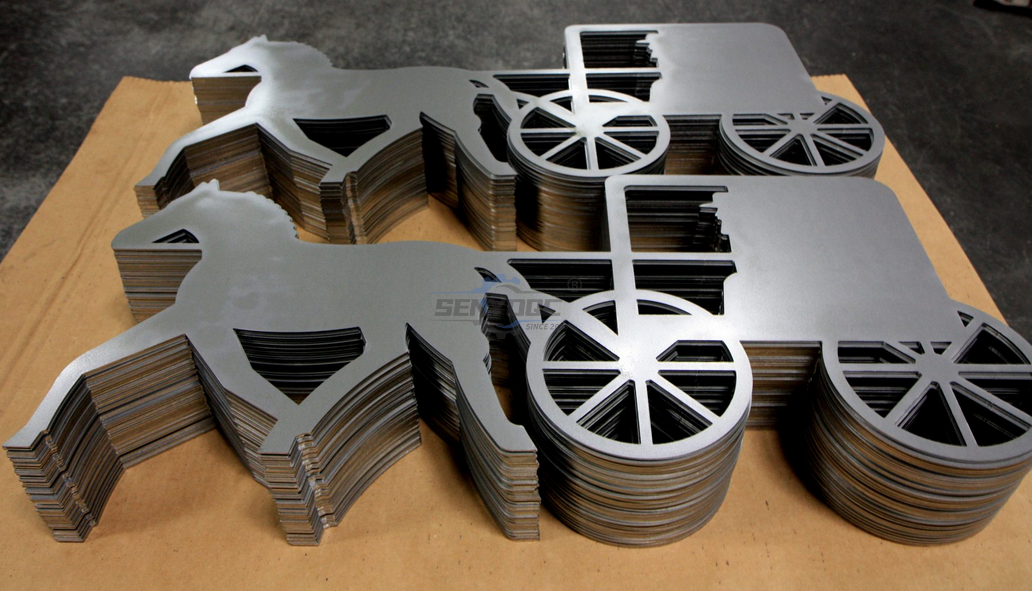

Metal ArtWork from Denmark

The plasma cutting machine makes my artistic creation more convenient and precise!! Created more artistic ideas and value! Thank you Aillen team!

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen. from

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen.

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo from

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo

Thank you Senyo for SYJ1290-150W! from

Retired, ex mainframe systems programmer. Now full-time recreational woodworker majoring in puzzles, pens, boxes, Toys and occasional small furniture. Thank you Senyo for SYJ1290-150W!