+86 1525 3141 880

+86 1525 3141 880

The size, accuracy, and adaptability of a 4x8 CNC router make it perfect for woodworking applications.

This kind of router is quite useful for

working with larger wood panels, which is why both professional and

amateur woodworkers use it.

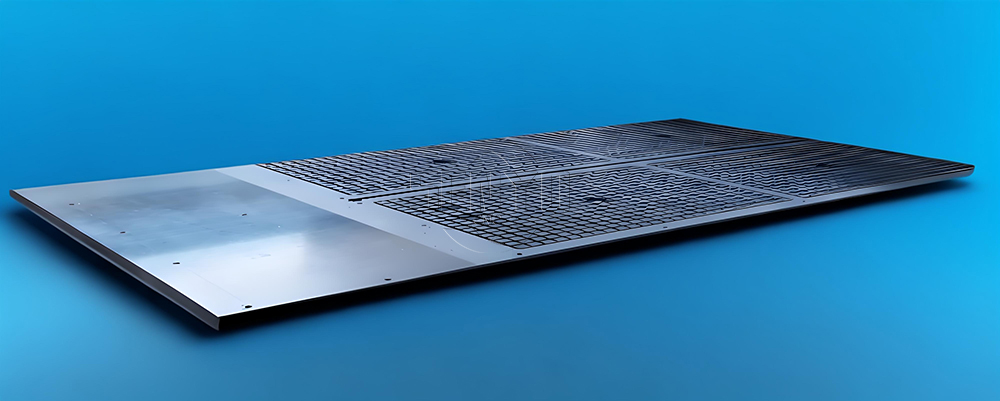

The CNC vacuum table is a workbench composed of bakelite boards with 6, 8, or 24 sections,

which uses a vacuum pump to ensure the suction strength and the stability of the workpiece on the table to ensure

that the workpiece will not vibrate and shake during the work of the CNC router machine.

The vacuum table is connected to the bottom of the CNC router machine by a vacuum pump through a pipeline.

There are many suction holes on the vacuum table. When we put the workpiece on it,

the workpiece will be firmly adsorbed by the negative pressure generated by the vacuum pump.

The machine starts to work at this time on the table, and the entire loading and unloading process does not exceed ten seconds with high efficiency and speed.

It is very suitable for making wood doors and cabinet furniture.

The suction holes on the CNC vacuum table will automatically close when there is a large amount of air intake,

thereby avoiding increasing the load of the vacuum system in order to ensure the vacuum suction effect,

and avoiding strong airflow between the vacuum table and the workpiece.

Why a 4x8 CNC router is unique?

1. Large Work Area: The 4x8 size allows you to work on large projects and full-size plywood sheets without having to chop them down first. Time is saved, and waste is reduced.

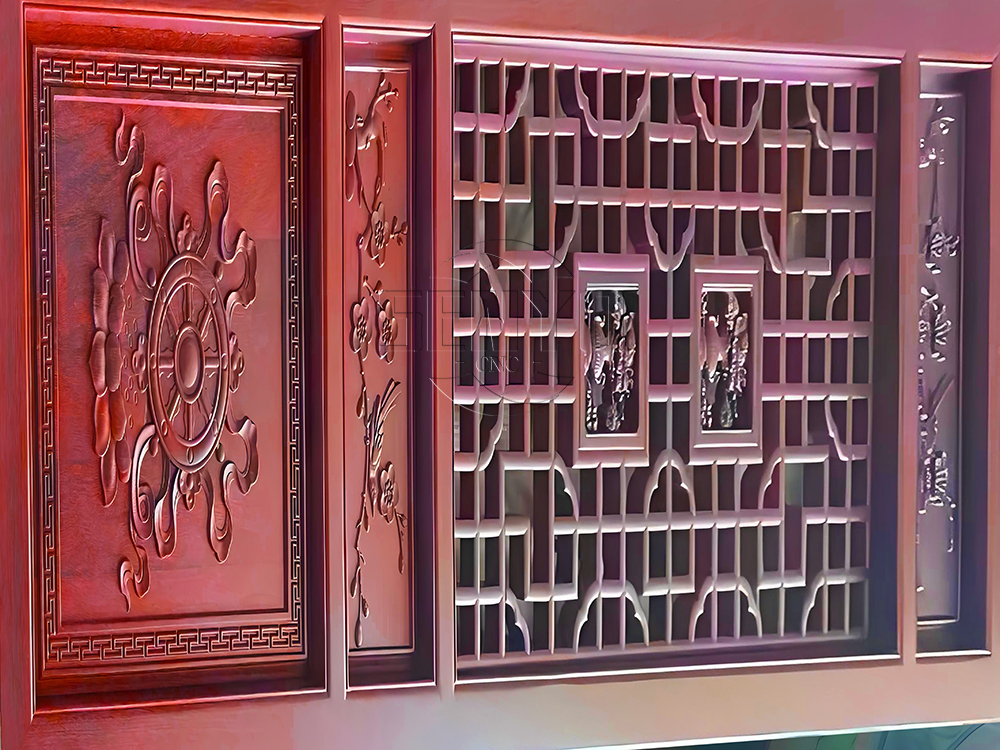

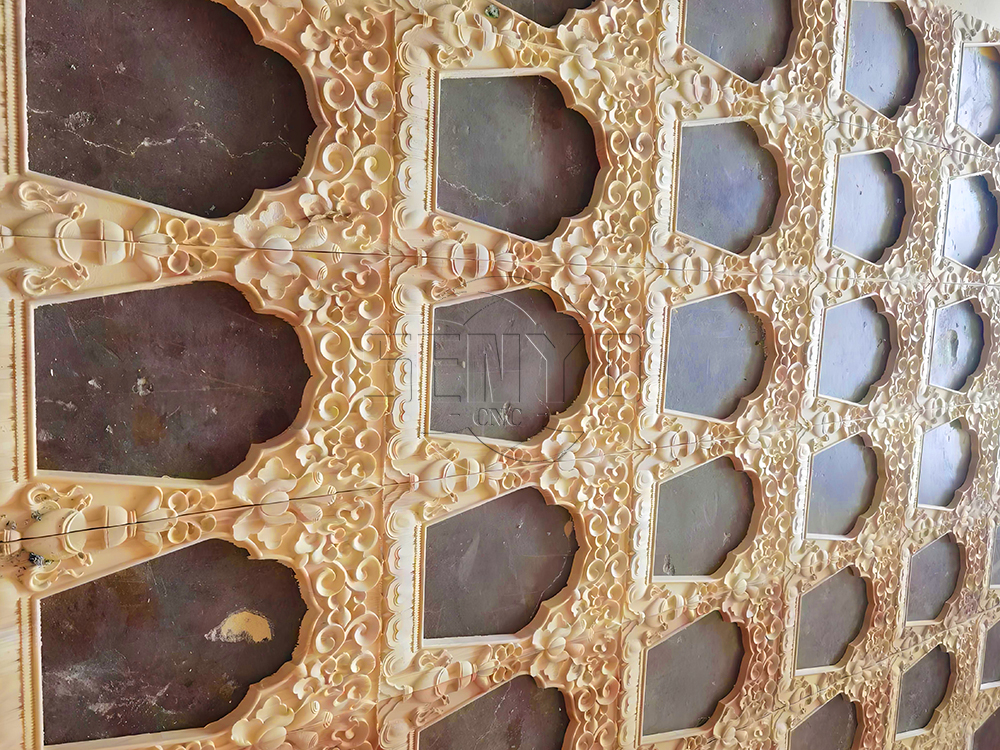

2. Extreme Precision and Consistency: CNC routers ensure consistency in every item by producing carvings and cuts with extreme precision.

For intricate patterns or finely detailed carpentry, such as that found in furniture and cabinets, this is crucial.

3. Versatility: From simple cuts to complex three-dimensional carvings, it may be used for a wide range of woodworking tasks.

Because of its versatility, you may create a wide range of projects with just one machine.

4. Efficiency and Speed: By automating the cutting process, CNC routers save labor expenses and increase productivity.

This is quite helpful for businesses looking to increase output.

5. Simple to Use: Even starters can easily begin creating with the help of the user-friendly software that comes with modern CNC routers.

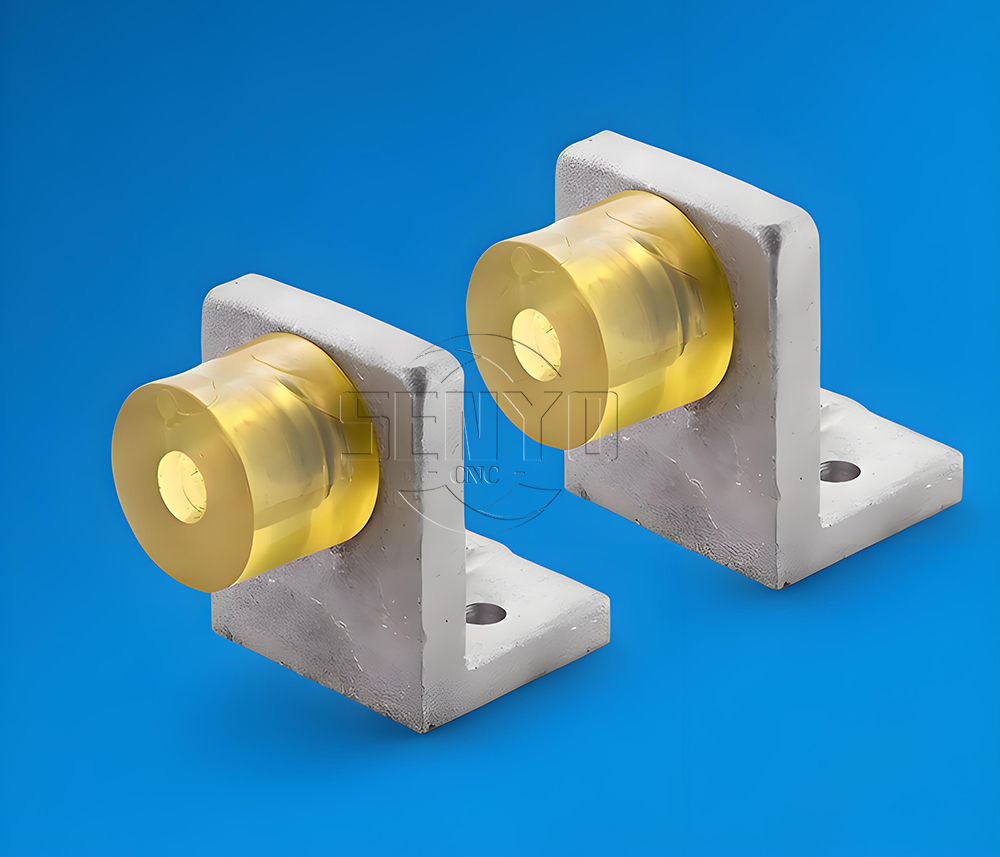

Detials Parts and Features

Control System, DSP/ NC Studio /mach3 optional, easy to operate

Taiwan guide rail,Famous brand guide rail from Taiwan, less friction, more durable.

Oil Lubrication which easy operation .

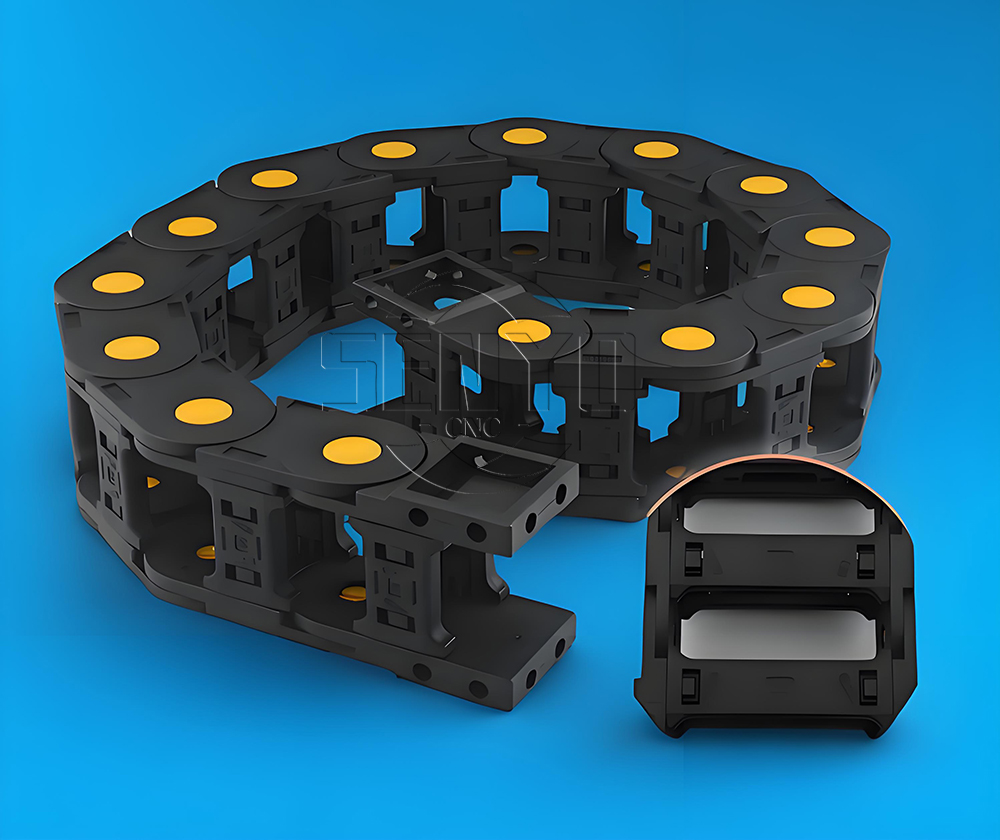

Fully closed drag chain

Nylon material, fully closed, dustproof, oilproof, prolong the service life of the machine.

Vavvum and T-slot table Thickened aluminum profile table.It is easy to fix various materials.

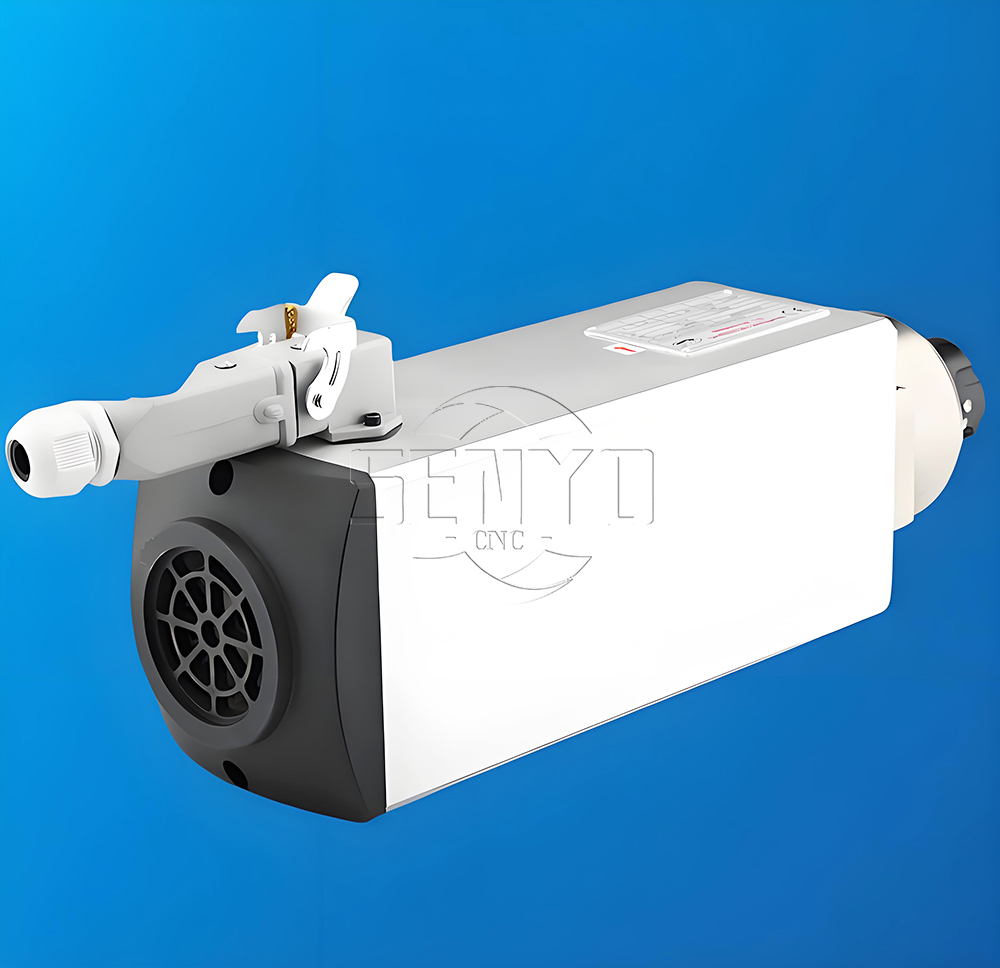

Water-cooled/ HQD air-cooled spindle is optional, high speed, 3.5KW high power

Dust hood

Dust brush

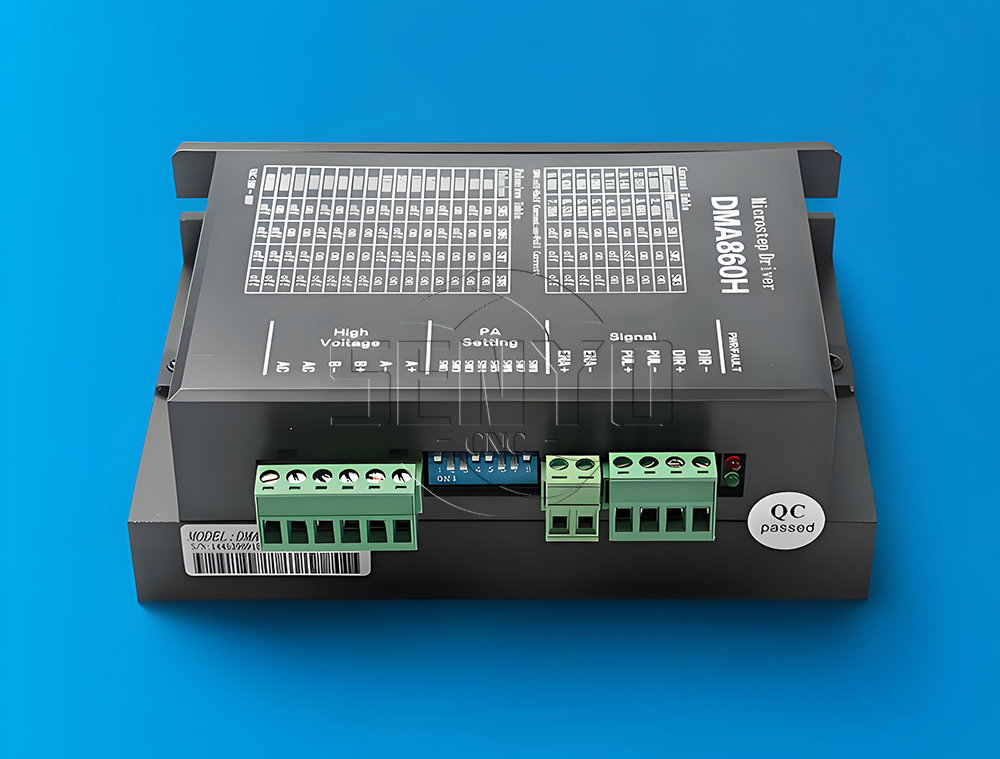

China famous leadshine driver

Hard limit switch

china famous electric parts

Application

Wood Furniture Industry: Wave Plate, fine pattern, antique furniture, wooden door, screen, craft sash, composite gates,cup board doors,

interior doors, sofa, headboards ,game cabinets, computer tables,

sewing machines table, instruments.

Advertising Industry: advertising identification, sigh making,

Acrylic engraving and cutting, crystal word making,blaster molding,and other advertising materials derivatives making.

Crafts: engraving characters of any language and patterns on gifts and souvenirs, primitive processing and shaping of artistic crafts,

stilett Moulding: engraving delicate letter and flower pattern, primitive and fine processing of the small mould.

Architectural models: engraving fine window, fencing and wall patterns, etc.

Techology Paramaters

Brand | SENYOCNC |

Model | SYM1325 |

Table Size | 4x8 feet (48x96 inches, 1300x2500mm) |

Working Area | 1300x2500x200mm |

Traveling Positioning Accuracy | ±0.03/300mm |

Repositioning Accuracy | ±0.03mm |

Table Surface | T-slot Table (Vacuum Working Table for Option) |

Frame | Welded Structure |

X/Y Structure | Helical rack, Taiwan HIWIN Rail Linear Bearings |

Z Structure | Taiwan HIWIN Rail Linear Bearings and Ball Screw |

Max Power Consumption | 3.2KW (Without Spindle) |

Max. Rapid Travel Rate | 20000mm/min |

Max. Working Speed | 15000mm/min |

Spindle Power | 3KW water cooling spindle (Italy HSD Spindle for Option) |

Spindle Speed | 0-24000RPM |

Drive Motors | Lead shine |

Working Voltage | AC380V/50/60Hz, 3PH (220V for Option) |

Command Language | G Code |

Operating System | DSP ,Ncstudio,Mach3 for Option) |

Computer Interface | USB |

Collet | ER20 |

X,Y Resolution | <0.01mm |

Software | Type3/Ucancam/Artcam |

Running Environment Temperature | 0 - 45 Centigrade |

Relative Humidity | 30% - 75% |

Price Range | US$2500.00 - US$5500.00 |

Whether you are a novice or a professional, you should do regular care and maintenance for 48"x96" CNC wood router kit and its accessories.

• The control cabinet should be placed in a well-ventilated place and cannot be placed in a high-temperature environment.

Prevent the electrical components in the control box from malfunctioning due to high temperature.

• The machine should be placed in a dry and well-ventilated place (to prevent parts and accessories from malfunctioning due to exposure to the fuselage).

• The machine must be equipped with a reliable voltage stabilizer to ensure the safe grounding of the ground wire.

At this point, the manufacturer has basically installed and debugged the customer in advance when configuring the control cabinet. It is best to consult before purchasing the machine.

• Try not to use the internet computer to transfer files to the machine.

Computers connected to the network are likely to cause abnormalities in the machine through file transfer.

• The machine needs to be maintained every other month (add a proper amount of special lubricating oil to the screw rod and the guide rail rack).

Now many manufacturers are equipped with manual or electric lubricators, which can realize faster feeding of the slider and the wire.

The bar is filled with oil and does not need to be disassembled, making maintenance easier and faster.

• Maintain a good lubrication state, regularly check and clean the lead screw, add or replace lubricating grease and oil,

so that the lead screw, nut and other moving parts always maintain a good lubrication condition to reduce the wear speed of mechanical parts.

• Do not allow the machine to work on the same part of the table for a long time (in case that the screw,

guide rail and other transmission devices are not in contact with the beam for a long time and cannot be reasonably lubricated).

• Check whether the wiring and screws of the machine are loose within a certain period of time. It is best to tighten the screws regularly.

This can also improve the accuracy of routing.

• Do not place debris (magnetic materials, corrosive items, overweight items, liquids) on the table or machine head.

If you're shopping for a new 4x8 CNC router in today's marketplace.

you'll have to research and understand its various features and costs, and get quotes from different merchants in conjunction with your plan.

budget, and needs, find and buy the best option for your business from a variety of popular brands, dealers, and manufacturers.

Here are eight

easy-to-follow steps that can save you thousands of dollars on your next

4x8 CNC.

Step 1. Plan Your Budget & Needs

Planning a budget that matches your needs starts you out on the right foot. Once you get an idea of how much you can afford,

you will be able to easily compare different features and costs.

Step 2. Research Features

Not

sure what machine you want yet? In fact, everything will be easy as

long as you determine what materials you need to cut and mill,

the maximum machining size, and the final project you want to get.

If you need rotary milling, the 4th axis is ideal, if you need 3D modeling, the 5-axis is professional.

All in all, every feature is optional based on your needs.

Step 3. Locate Your Machine

Once you understand the various features of the machine, it's time to figure out which brands and models of machines fit your budget and needs.

And in many cases, you can sort by style, size, cost and features.

Step 4. Sample Making

By now, you've settled on a few machine candidates. You should see what they can cut and mill in action before making a decision.

You can send your materials and designs to dealers or manufacturers, request sample making according to your needs,

and request that the results be shown to you in the form of video or live broadcast.

Step 5. Check Sale Price

Once you have a target machine, it's time to focus on getting a sale price, and folding the price into the purchase contract.

Step 6. Review Your Deal

Now that you have a price quote for the machine, your big question is probably whether it comes with additional costs and the contractual details of payment methods,

returns and refunds, warranty, shipping, customs clearance, machine assembly and operation,

software installation, setup and commissioning, repair and maintenance.

Step 7. Close Your Deal

If the price and fees look right, it's time to say yes to the deal. Once you've agreed on a price, you'll sign the contract with SENYO,

but be sure to review the contract carefully and make sure there are no other additional charges or fees.

Step 8. Take Delivery

Whether you take delivery by sea or by air, it should be well packed, free of any workmanship defects,

checking for any damage that might have occurred during transport.

For Our Work Steps:

1.Before-sale,we will try to know your requirement about our cnc router specification and what kind of work

you will do .then we will offer our best solution for your requirement.

2.During production: we will send photos of machines during making. so you can know more details about

the procession of making your machines.

3.Before shipping,we will take delivery photo and confirm the specification of order to avoid the mistake.

Machine will be adjusted before it is delivered.

4.After shipping: we will sent out the documents for your customs clearance ASAP . and check the

approximate date of arrival.

5.After arrival: we will confirm with you if machine is in good condition.and see if any spare parts missing .

6.About teaching: there are some manual and video about how to use machine , if you have question

about it. we will have professional technicist to help you install and teach how to use through skype ,

calling, video or mail.

1. Outside package: Standard plywood package.

2. Inner package:Stretchy film and plastic protective film for humidity.

3. We can package according to your requirements.

For

standard machines, 7-15 working days after payment.

For LCL Shipping (Less than Container Load),it is recommended to use export standard fumigation-free wooden boxes, which are stronger and suitable for long-distance transportation.

For FCL Shipping (Full Container Load),it can be loaded directly at the factory without wooden boxes, and the maximum number of machines can be loaded to reduce costs.

1. Our engineers available to service machinery overseas.

3. Technical support by calling, mail, whatsapp and skype. If you have any problems, we will help you to solve it within 12 hours.

4. You will be get free training advice towards our machine in our factory.

5. If you need any component of the machine, we will provide most affordable price for you.

6. Friendly English version manual and operation video CD disk.

• Previous: Best 4x8 Wood CNC Router Machine for Sale

• Next: Affordable 4x8 CNC Wood Router Machine for Beginners

Jacob from United States

I am a beginner at CNC, I’ve never used a CNC machine before and with in a day I was carving. An awesome machine for a beginner to learn as hobbyists. I used the manual and the help video. One hour to assemble and test, very friendly and easy to use. It’s a good buy for the money. I would definitely recommend this machine to someone getting into CNCs.

Weinstein from France

I've been using CNC plasma SYP2060-300A and I am very impressed with this unit.

This unit is of higher quality, made in China. Five stars all the way!

2040 from INDIAN

Best 2040 CNC Router Good Price and Quality ! Thank SENYOQC

10w uv laser from American

Best supplier ! I bought 3 machines for laser and router , thank you Aillen ! --Alec

12KW Fiber Cutting - 2000X6000mm -- 이병헌 from Korea

Good machine for metal cut ! Thanks Senyo , Its prefect , I like your business patient kind!

I am a furniture manufacturer, and this machine is very good and fast. thanks Senyoqc Team ! from Bangladesh

Metal ArtWork from Denmark

The plasma cutting machine makes my artistic creation more convenient and precise!! Created more artistic ideas and value! Thank you Aillen team!

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen. from

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen.

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo from

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo

Thank you Senyo for SYJ1290-150W! from

Retired, ex mainframe systems programmer. Now full-time recreational woodworker majoring in puzzles, pens, boxes, Toys and occasional small furniture. Thank you Senyo for SYJ1290-150W!