+86 1525 3141 880

+86 1525 3141 880

Supplies

Tools:

CNC 6090/ Any size your laser engraver , we use power 80w

orbital sander

Software:

Materials:

wood block (mine was a 2" pine cube)

clearcoat

Start by sanding all six sides of the cube to your desired smoothness.

Keep in mind that you’ll only be able to do minor sanding after the engraving is complete.

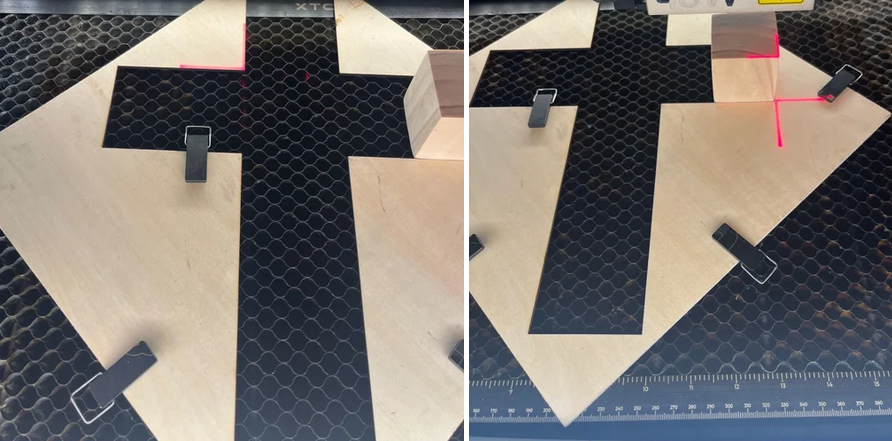

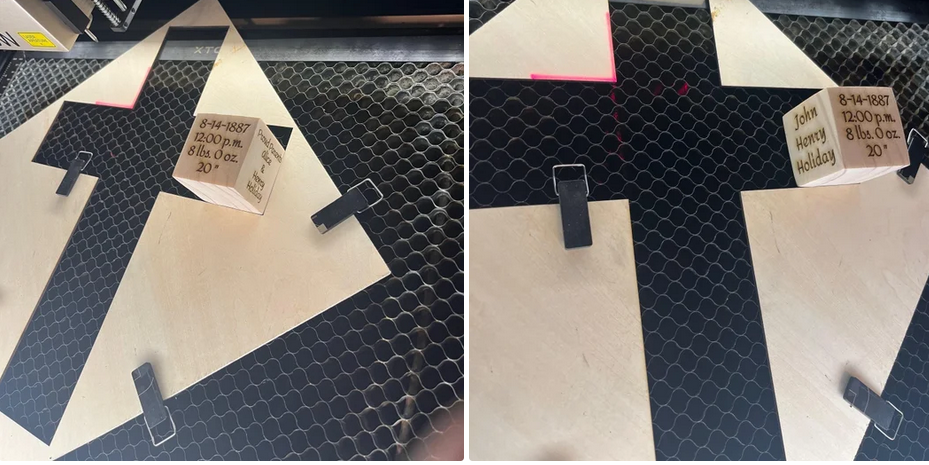

You’ll need to run the laser five separate times, so it’s crucial to place the block in the same position each time.

The best way to ensure consistent placement is by using a simple jig.

I used a piece of scrap plywood with a 90-degree cutout to secure the cube.

Place the cube in the jig with the end grain facing up, and establish your working area for each side.

For this cube, I had a working area of 1.88”.

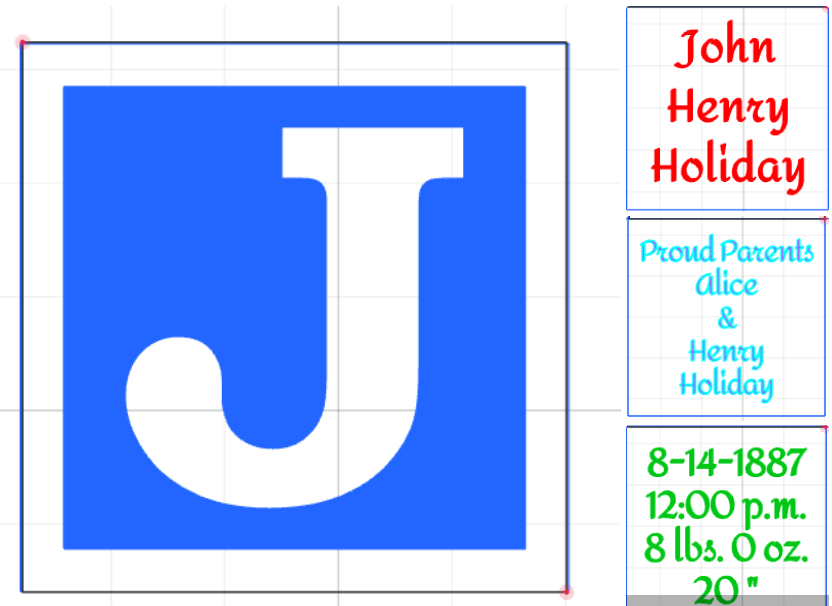

Choose a font for the letter on the top of the block.

I recommend experimenting with different fonts to find the best one for the specific letter you’re working with.

Create a square the size of your working area, then create an inset approximately 0.125” inside the square.

Combine the letter with the inset rectangle to form a single object,

allowing you to engrave the negative space and leave the letter with a border.

Next, select a font for the remaining text. I used the “Amita” font with sizes ranging from 20 pt. to 30 pt.

Optional: After creating your engraving designs, make a copy of each and set it for score lines to outline the engraving.

This adds a neat detail to your finished block.

Engraving settings: 30% power, 150 mm/sec speed

Scoring settings: 30% power, 50 mm/sec speed

Engrave each side of the cube individually, following the design.

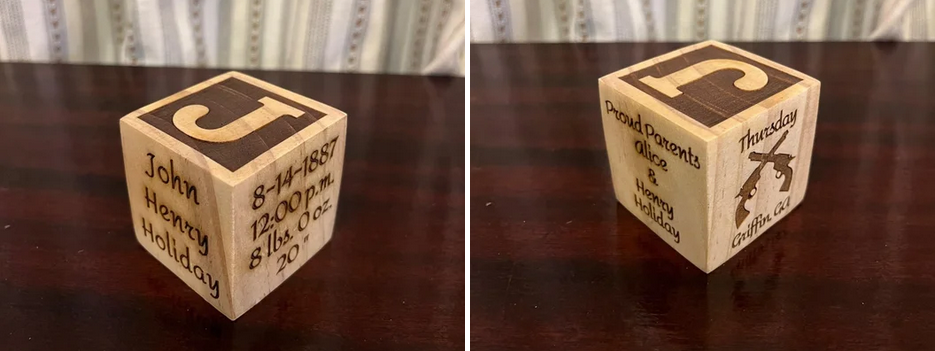

Lightly sand the block to remove any scorch marks, and use an air compressor to blow off the dust from the engravings.

After reviewing the pictures, I noticed my block could have used a bit more sanding.

Apply a clear coat and allow it to dry completely. Finally, lightly sand the finished block to achieve a smooth surface.

• Previous: Co2 laser wood cut Illuminated Pattern Box

• Next: Laser Cut Adjustable Table Lamp

Jacob from United States

I am a beginner at CNC, I’ve never used a CNC machine before and with in a day I was carving. An awesome machine for a beginner to learn as hobbyists. I used the manual and the help video. One hour to assemble and test, very friendly and easy to use. It’s a good buy for the money. I would definitely recommend this machine to someone getting into CNCs.

Weinstein from France

I've been using CNC plasma SYP2060-300A and I am very impressed with this unit.

This unit is of higher quality, made in China. Five stars all the way!

2040 from INDIAN

Best 2040 CNC Router Good Price and Quality ! Thank SENYOQC

10w uv laser from American

Best supplier ! I bought 3 machines for laser and router , thank you Aillen ! --Alec

12KW Fiber Cutting - 2000X6000mm -- 이병헌 from Korea

Good machine for metal cut ! Thanks Senyo , Its prefect , I like your business patient kind!

I am a furniture manufacturer, and this machine is very good and fast. thanks Senyoqc Team ! from Bangladesh

Metal ArtWork from Denmark

The plasma cutting machine makes my artistic creation more convenient and precise!! Created more artistic ideas and value! Thank you Aillen team!

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen. from

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen.

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo from

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo

Thank you Senyo for SYJ1290-150W! from

Retired, ex mainframe systems programmer. Now full-time recreational woodworker majoring in puzzles, pens, boxes, Toys and occasional small furniture. Thank you Senyo for SYJ1290-150W!